National Electrical Code Article 410 Parts M and N provide special provisions for luminaires (lighting fixtures) installed within recessed cavities in walls or ceilings. Most of these code requirements focus on protecting combustible building materials from temperature greater than 90°C (194°F). To align with the Code, nationally recognized luminaire product standards have been developed that contain testing, construction and marking requirements necessary to list products for recessed applications. Products listed to these requirements are rated for specific required installation clearance between luminaire parts and combustible materials. An understanding of these ratings is essential to ensuring proper installation of recessed luminaires and compliance with the Code. Reviewing the tests performed to qualify products bearing the ratings provides deeper insight into the topic.

Recessed Luminaire Product Standard, Listing and Rating

Photo 1. During UL 598 luminary tests, temperatures are measured by means of thermocouples and suitable indicating devices.

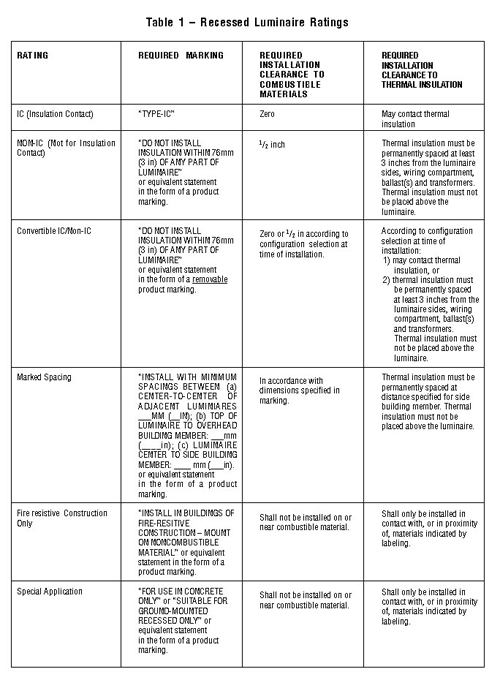

Underwriters Laboratories, Inc. Standard UL 1598 contains the product construction and performance requirements for recessed luminaires. This standard, which is harmonized with CSA C22.2 No.250.0-00, replaced UL 1570, UL 1571 and UL 1572, effective January 31, 2000. The basic UL 1598 ratings and required markings, along with required clearances to combustible materials and thermal insulation, are detailed in Table 1 (see page 28).

The UL 1598 ratings are based on compliance with normal and abnormal operation performance type tests. These ratings may apply to both ceiling and wall mounted luminaires. However, because of test differences, a recessed luminaire must only be ceiling mounted unless specifically labeled “Suitable for Wall Mounting.” [See photos 1 and 2]

Combustible Materials

Photo 2. UL 1598 requires recessed luminaire to be tested in wood boxes having dimensions based on installation clearances allowed by National Electrical Code

During UL1598 normal operation tests, careful consideration is given to measuring temperatures on combustible materials surrounding the luminaire. Such materials include the ceiling or wall materials that contact the luminaire and thermal insulation that may surround the luminaire. This aligns with two NEC requirements. One being Section 410-65(a), which states: “Fixtures shall be installed so that adjacent combustible materials will not be subject to temperatures in excess of 90°C (194°F)” 2. The second is Section 410-68, which states: “Fixtures shall be constructed so that adjacent combustible material will not be subject to temperatures in excess of 90°C (194°F)” 3. The 90°C (194°F) limit was developed from extensive research early in the twentieth century and has historically proven to provide an acceptable level of safety.

Thermal Protectors

To comply with the Code and test requirements, a recessed luminaire is provided with a thermal protector or is determined to be inherently protected. In either case, UL 1598 test requirements are used to determine compliance of the luminaire. During these type tests, the thermal protector must function properly when a luminaire is operated in an abnormal condition. Depending on the luminaire rating, these conditions may include contact with thermal insulation, incorrect lamp (bulb) or incorrect spacing to building members. Additionally, during normal operation tests, with the luminaire operating in accordance with the intended parameters, the thermal protector is not permitted to cycle (turn the lamp off), this requirement addresses nuisance operation which might tempt an end user to disable the protector. Inherently protected recessed luminaires are not provided with a thermal protector device but are still shown to comply with abnormal condition tests.

Type-IC Luminaires

The National Electrical Code Section 410-66 gives rules which allow Type-IC recessed luminaires to contact combustible materials and thermal insulation:

“A recessed fixture that is identified for contact with insulation, Type-IC, shall be permitted to be in contact with combustible materials at recessed parts, points of support, and portions passing through or finishing off the opening in the building structure” 1

“Thermal insulation shall not be installed above a recessed fixture or within 3 in. (76mm) of the recessed fixture enclosure, wiring compartment, or ballast, unless it is identified for contact with insulation, Type IC.” 1

Because of this code requirement, the normal UL 1598 temperature test performed on Type-IC recessed luminaires is conducted with the luminaire installed in an open top box constructed from 1/2 in thick plywood having walls spaced 8-1/2 inches from the luminaire. The luminaire is attached to the inside bottom of this box and the luminaire reflector trim passes through a hole in the plywood. The bottom surface of the luminaire and the portion of the luminaire that passes through and finishes off the hole are in contact with the plywood. The box is filled with cellulose thermal insulation to a depth 8-1/2 inches higher than the luminaire. The luminaire is operated in accordance with its ratings. Luminaire and test box temperatures are measured when thermal stability is attained. In order for test results to be considered acceptable, temperatures of combustible materials and thermal insulation surrounding and in contact with parts of the luminaire must remain at or below 90°C (194°F).

Photo 3. Temperatures of combustible building material may not exceed 90°C

Accordingly, combustible material (including wood, thermal insulation, ceiling tiles and vapor barriers) surrounding a Type-IC may contact exterior parts of the luminaire. Although permitted by the Code to touch exterior parts of the luminaire, some materials (including foam insulation and plastics) may be degraded by exposure to 90°C temperature. Such material degradation could be an annoyance to the building owner. Questions regarding the effect temperature has on building materials should be directed to the material manufacturer.

To determine compliance of the thermal protector, UL 1598 requires an abnormal test be conducted. This test involves operating the luminaire with incorrect lamps according to a schedule set by the standard. According to the luminaire lamp rating, the incorrect lamp may be one of excessive wattage. When the luminaire rating specifies a reflector type lamp, a non-reflector is also tried. In either case, the thermal protector must cycle within three hours or temperatures of combustible materials and thermal insulation surrounding and in contact with parts of the luminaire must remain at or below 90°C (194°F).

Non-Type-IC Luminaires

The 1999 National Electrical Code (NEC) Section 410-66 gives rules for non-Type-IC recessed luminaire clearance from combustible materials and thermal insulation:

“A recessed fixture that is not identified for contact with insulation shall have all recessed parts spaced at least 1/2 in. (12.7mm) from combustible materials. The points of support and the trim finishing off the opening in the ceiling or wall surface shall be permitted to be in contact with combustible materials.” 1

Table 1

“Thermal insulation shall not be installed above a recessed fixture or within 3 in. (76mm) of the recessed fixture enclosure, wiring compartment, or ballast, unless it is identified for contact with insulation, Type IC.” 1

Because of this code requirement, the normal UL 1598 temperature test performed on Non Type-IC recessed luminaires is conducted with the luminaire installed in a closed box constructed from 1/2 in thick plywood having walls and top spaced 1/2 in. from the luminaire. The luminaire is attached to the inside bottom of this box and the luminaire reflector trim passes through a hole in the plywood. The bottom surface of the luminaire and the portion of the luminaire that passes through and finishes off the hole are in contact with the plywood. The luminaire is operated in accordance with its lamp and input power ratings. Luminaire and test box temperatures are measured when thermal stability is attained. Temperatures of combustible materials surrounding and in contact with parts of the luminaire are limited to 90°C (194°F) or less.

Accordingly, combustible materials (including wood ceiling joists, plywood and particleboard) surrounding a non-Type-IC luminaire must be spaced at least 1/2 in from the luminaire. The bottom surface of the luminaire, the luminaire mounting hardware and the portion of the luminaire that passes through the ceiling may contact combustible ceiling materials (including ceiling tiles, wood plaster lathe and wood panels).

To determine compliance of the thermal protector, UL 1598 requires an abnormal test be conducted. This test is conducted with the luminaire installed in an open top box constructed from 1/2-inch thick plywood having walls spaced 8-1/2 inches from the luminaire. The luminaire is attached to the inside bottom of this box and the luminaire reflector trim passes through a hole in the plywood. The bottom surface of the luminaire and the portion of the luminaire that passes through and finishes off the hole are in contact with the plywood. The box is filled with cellulose thermal insulation to a depth of 4 inches or 2 inches from the top of the lamp whichever is deeper. Under this condition, the thermal protector must cycle within three hours. If the thermal protector does not cycle, subsequent test runs are conducted, each with an additional 2-inch depth of insulation added until the protector cycles. During iterations where the thermal protector does not cycle, temperatures of combustible materials and thermal insulation surrounding and in contact with parts of the luminaire must remain at or below 90°C (194°F).

Convertible IC/Non-IC

A convertible luminaire is basically a Type-IC luminaire provided with additional markings for use when it is installed in non-insulated cavities.

A convertible luminaire is subjected to both IC and non-IC test programs. During the IC test phase, the luminaire is buried under 8-1/2 inches of thermal insulation. In this condition, it must run within standard thermal limits when operated with the proper lamps. It is also subjected to abnormal tests to ensure that the thermal protector operates when improper lamps are installed while the luminaire is buried under insulation. During the second phase of testing, the type non-IC tests, the luminaire is installed in a closed wooden test box spaced 1/2 in from the luminaire sides and top. In this condition, the luminaire must run within thermal limits when operated with the proper lamps. With the same lamps, an abnormal test is also conducted, where the thermal protector must operate when insulation is placed around the luminaire.

This double testing program allows the luminaire to be used in either IC or non-IC installations, allows a higher wattage lamp to be used when the luminaire is installed in a non-IC condition and ensures proper thermal protector operation when an improper lamp is used.

Marked Spacing Type Luminaries

Marked spacing type luminaries are non-Type-IC luminaires that require special spacing to enclosing building members in order to operate within thermal limits. They are marked with minimum spacing dimensions between the center of the luminaire and adjacent luminaires and between the center of the luminaire and side walls and between the top of the luminaire and overhead building members. The dimensions of the UL 1598 normal temperature test box are based on the marked spacing. UL 1598 requires two abnormal tests. One is identical to that required for non-Type-IC luminaire. The other is conducted with the luminaire installed in a closed box constructed from 1/2 in thick plywood having walls and top spaced 1/2 in. from the luminaire. The luminaire is attached to the inside bottom of this box and the luminaire reflector trim passes through a hole in the plywood. The bottom surface of the luminaire and the portion of the luminaire that passes through and finishes off the hole are in contact with the plywood. The luminaire is operated in accordance with its lamp (bulb) and input power ratings. During this abnormal test, the thermal protector must cycle within three hours.

Non-Combustible Construction Only

Luminaires marked “INSTALL IN BUILDINGS OF FIRE-RESISTIVE CONSTRUCTION – MOUNT ON NONCOMBUSTIBLE MATERIAL” or with an equivalent statement produce temperatures greater than 90°C (194°F) at point in contact with building members. Such products are allowed by NEC Section 410-65(b) which states: ” Where a fixture is recessed in fire-resistant material in a building of fire-resistant construction, a temperature higher than 90°C (194°F) but not higher than 150°C (302°F), shall be considered acceptable if the fixture is plainly marked that it is listed for that service.” Accordingly, during UL 1598 normal operation tests, temperatures of combustible materials surrounding and in contact with parts of the luminaire must remain at or below 150°C (302°F).

Special Application

Luminaires marked “FOR USE IN CONCRETE ONLY” or “SUITABLE FOR GROUND-MOUNTED RECESSED ONLY” are restricted to installation in accordance with their marking. Such luminaires are tested while encased in a medium that simulates the intended application. Therefore, there are no combustible material temperature measurements recorded. It should be noted that a luminaire may have dual ratings, such as non-Type-IC and “FOR USE IN CONCRETE” or “SUITABLE FOR GROUND-MOUNTED RECESSED.” The absence of the word “only” from the special application marking indicates that the particular application is an acceptable option for the luminaire and not a restriction. Accordingly, the most stringent applicable UL 1598 normal and abnormal temperature tests are conducted to qualify the luminaire.

Summary

As we have reviewed, the product standard contains test requirements to list recessed luminaires and comply with code requirements addressing combustible material clearance. Both the product standard and Code address several clearance ratings that apply to recessed luminaires. The standard also has specific marking requirements, reviewed in Table 1, which are provided to advise the installer on the installation clearance requirements.

1 Section 410-66, Clearance and Installation. National Electrical Code, NFPA 70-1999 (Quincy, MA: National Fire Protection Association, 1999), p70-233.

2 Section 410-65(a), Combustible Material. National Electrical Code, NFPA 70-1999 (Quincy, MA: National Fire Protection Association, 1999), p70-232.

3 Section 410-68, Temperature. National Electrical Code, NFPA 70-1999 (Quincy, MA: National Fire Protection Association, 1999), p70-233.

Find Us on Socials