The sign industry is currently using LED light sources for many applications. LEDS were first introduced to the sign industry, I believe, on power source equipment as indicators for conditions and problems. As the LEDS came to be used in different applications such as taillights for vehicles, traffic control, warning lights and indicator lights, their applications expanded. Since this article applies to their application, we shall not explain the engineering or chemistry of the LED, nor will we explain how it makes light. This information is available in other articles and from the manufacturers.

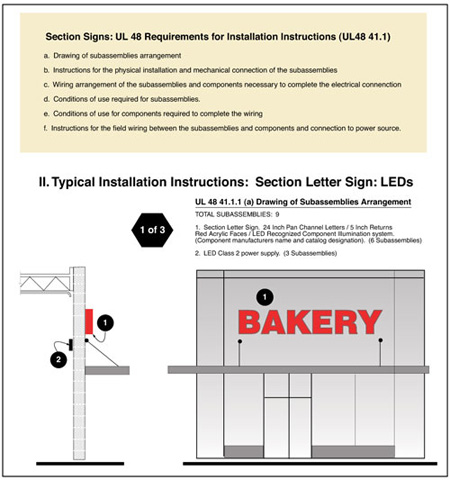

Figure 1. Typical Installation Instructions

Applications in the sign industry increased as the lumens increased, originally by driving more energy into the LED, and currently by different designs. As the power is increased, however, there is a sacrifice of some energy saving, longevity of the product and an increase in the required maintenance of the light source. As the original red color could be pumped up enough to be used either exposed or placed behind plastic for channel letters, it became a competitor to the neon tube. The light source is low-voltage and perceived safe from arcing and fire. The installation procedure is perceived to be simple compared to the complex installation of the high-voltage requirements of neon installations. Now since the natural color of LEDS is at 1 watt and soon will be higher, different considerations will be needed because of the increased heat levels.

Since LEDS provide only directional light, the applications become more difficult because you do not have the same benefit of light bounce that neon and fluorescent have to offer. Your LED partner should be able to guide you in the correct installation and configuration procedures to provide the best lumen output to match the application. Since we deal only with listed electric signs, we must remember we can only use listed and recognized components to build our electric signs and channel letters. The components are controlled in UL 879, currently Section 4.18 Class 2 LED Components, which has 14 different sections with requirements. Please review all the sections before you start your manufacturing. These sections relate to the conditions of acceptability.

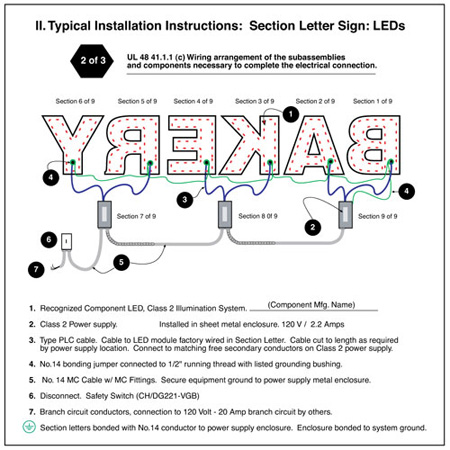

Figure 2. Typical Installation Instructions

Now where have we heard that before?

Secondary wiring is also a point of confusion. When wiring is run exposed, it must be a suitable power-limited tray (PLTC) cable or enclosed. The wire is furnished as required with the power supply and should have a means for connection supplied.

For permanently connected signs, the power supply is required to be enclosed.

Below are the installation instructions for these components; these are reprinted with permission from Underwriter Laboratories, Inc.

“4.18.4 Installation Instructions

“4.18.4.1 LED units shall be provided with installation instructions that include the following:

a) A location designation indicating the environmental condition for which the product has been evaluated (e.g., wet, damp, or dry location);

b) These products are only suitable for connection to a circuit from a Class 2 power source;

c) These products have not been evaluated for use when connected to a power source that does not comply with Class 2 voltage and energy limited supplies; and

d) For wet location products, “These products are not required to be enclosed or protected from weather.” 1

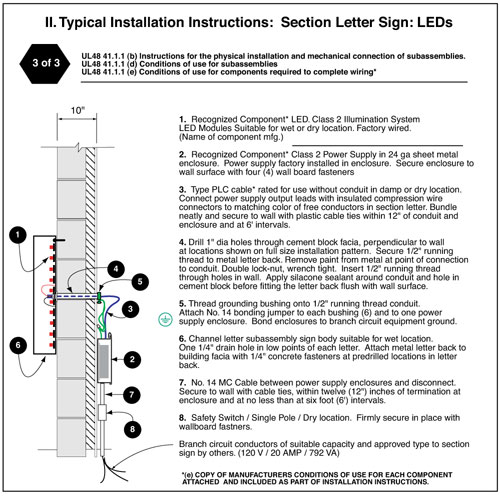

Figure 3. Typical Installation Instructions

The importance of these instructions is to insure you use the components with the correct conditions of acceptability in your listed electric sign. Each component manufacturer should have mounting, electrical, heat sink, and directional information printed either in the shipping containers or on their web site for your use.

Field installation

The next major issue is the field installation of electric signs, channel letters, and bonding and grounding connections in accordance with the National Electric Code, NFPA 70.

Chapter 6 Special Equipment

ARTICLE 600

Electric Signs and Outline Lighting

600.3 Listing. Electric signs, section signs, and outline lighting — fixed, mobile, or portable — shall be listed and installed in conformance with that listing, unless otherwise approved by special permission.

600.7 Grounding.Signs and metal equipment of outline lighting systems shall be grounded.2

These two sections are quite clear that electric signs and section signs (channel letters) are required to be listed. In addition, signs and metal equipment (channel letters) are to be bonded together and connected to the equipment grounding conductor. Without exception—and no exception is provided in Article 725—they all need to be grounded, low voltage included.

I have also included three pages from Neon Lighting, A Professional Advantage, with permission from the International Association of Electrical Inspectors, which shows typical installation instructions required to go with the LED signs and channel letters for their installation and final inspection.

In closing, there still seems to be some confusion concerning the use of different light sources. I have fielded calls from installers, manufacturers, inspectors, and some non-listed companies trying to build, install, or inspect electric signs and channel letters with LEDS. The most common question is, Must I bond and ground LED signs and letters? The standard answer is, YES. Dead metal in all electric signs and channel letters must be grounded.

Questions and commentsrandy@rkw-consulting.org

1 Reprinted from UL 879-8 June 6, 2005- revised May 24, 2006

2 Reprinted from the 2005 NEC

Find Us on Socials