There are many places in the Canadian Electrical Code, where wiring requirements are dependent on provisions of theNationalBuilding Code of Canada (NBCC). For example, wiring methods for a fire alarm system must comply with Rule 32-102, if a fire alarm system is required in a building by the NBCC. A similar condition is applied for wiring methods between an emergency power supply and life safety system by Rule 46-108, if the NBCC requires such emergency power for life safety systems. Wiring to an electrically connectedfire pump is no exception, when use of a fire pump is mandated by the building code. All electrical practitioners are aware that the NBCC sets out requirements for combustible and non-combustible construction, and that wiring methods specified by the CEC are dependent on a type of a building construction.Appendix G of the CE Code established correlation with the NBCC in this regard and in respect to many other areas that relate to the installation of electrically connected life safety systems.

There are many places in the Canadian Electrical Code, where wiring requirements are dependent on provisions of theNationalBuilding Code of Canada (NBCC). For example, wiring methods for a fire alarm system must comply with Rule 32-102, if a fire alarm system is required in a building by the NBCC. A similar condition is applied for wiring methods between an emergency power supply and life safety system by Rule 46-108, if the NBCC requires such emergency power for life safety systems. Wiring to an electrically connectedfire pump is no exception, when use of a fire pump is mandated by the building code. All electrical practitioners are aware that the NBCC sets out requirements for combustible and non-combustible construction, and that wiring methods specified by the CEC are dependent on a type of a building construction.Appendix G of the CE Code established correlation with the NBCC in this regard and in respect to many other areas that relate to the installation of electrically connected life safety systems.

Some general rules of the CECode specifically reference the NBCC in respect to electrical wiring and cables, and this article will concentrate onsuch general rules.

Our first stop is Rule 2-124.This rule states that:

“(1) Electrical installations shall be made so that the probability of spread of fire through fire stopped partitions, floors, hollow spaces, firewalls or fire partitions, vertical shafts, or ventilating or air-conditioning ducts is reduced to a minimum.”

“(2) Where a fire separation is pierced by a raceway or cable, any openings around the raceway or cable shall be properly closed or sealed in compliance with the National Building Code of Canada.”

What does this requirement mean for the electrical folks? Not much.Electrical designers, installers and inspectors are not real experts on the subject of fire spread and fire stop. So, how to comply with this appeared to benon-electrical requirement? Appendix BNote on thisrule intends to clarify this issue. This note explainsto the CE Code users that the specific provisions that relateto penetration of fire separations in buildings are located in Subsections 3.1.7. and 3.1.9. of the NBCC. Do you feel better already? This is still a foreign language to the electrical experts. However, the intent of this requirement is to ensure that the electrical installers arefully responsible for fire stopping around their wiring and cables,when such wiring and cables penetrate fire rated assembly. This means that the electrical installers must rely on a specialized trade who will apply fire stop systems in fire separations. So far, so good. Let the fire stop experts deal with this issue.

However, there is a little surpriselurking in the building code for the electrical installers. Sentence 3.1.9.3.(2) of the NBCC makes an “innocent” statement that optical fiber cables or other electrical conductors(that are allowedby the CE Code to run without being installed in totally enclosed non-combustible raceways) could be permitted to penetrate a fire rated assembly without being incorporated in the assembly at the time of testing, provided that such wires do not exceed 25 mm in diameter and their combustible insulationor jackets conform to the requirements of Article 3.1.5.18.

Let’s translate this statement into the language understood by the electrical folks. This means thatall conductors that are permitted by the CEC to be installed without a metal raceway (i.e., non-metallic sheathed cable in combustible building and communication, optical fiber, community antenna and Class 2 circuit conductors in combustible and non-combustible buildings)could penetrate a fire rated assembly if such conductors are not more than 25 mm in diameter and if such conductors have FT 4 rating. (Compliance with Article 3.1.5.18. of the NBCC means that the conductors must be marked FT 4). So, what’s surprising here?you might ask. The answer will depend on whether the installation is done in a combustible or non-combustible building.

If a building is non-combustible, then in accordance with Rule 2-126 of the CEC (and we’ll touch on this subject a bit later) all wires that are installed in a building without a raceway: communication, computer, Class 2 circuitwiring — would be required to have FT 4 rating, and there is no unpleasantsurprisefrom the requirement of Sentence 3.1.9.3.(2) of the NBCC, aswhen these communication conductors have to penetrate a fire rated assembly, they would be allowed to do it with no problem,since their combustible jackets already have FT 4 marking.

But what if it is a combustible building, and an electrical contractor bought miles of NMD 90 (non-metallic-sheathed cable) which comes only with FT1 rating? And what if this NMD 90 has to penetrate a fire rated assembly in such combustible building? In this case, the electrical contractor is for a big surprise, as a building inspector could invoke the requirement of Sentence 3.1.9.3.(2) of the NBCC and could mandate that this NMD 90 must be FT4 marked. The problem is that nobody manufactures FT 4 rated NMD 90. In this case, our contractor is stuck. He has to use conductors in a metal raceway or armoured cable to penetrate such fire rated assembly. This will certainly cost lots of time and money to an unsuspecting electrical contractor. However, the Electrical Code users can relax, as recently an interpretation was provided on this subject by the experts from the NationalResearchCouncil which is responsible for the NBCC. This interpretation stated that the requirement of Sentence 3.1.9.3.(2) for FT 4 rating of conductors penetrating a fire rated assembly is intended to apply only to conductors in buildings of non-combustible construction, and that in a typical combustible (wood frame) building a non-metallic-sheathed cable (NMD 90) marked FT1 is allowed to penetrate fire rated assembly.

Let’s make another stop and re-visit Rule 2-126, which we discussed a bit earlier. TheElectricalCode users are familiar with the requirements of this rule, as it has been in the CE Code for quite some time now. However, FT marking of communication conductors installed in plenum spaces without a metal raceway would have to now be marked FT6 instead of FT 4. This new requirement hasoriginated from the 2010 edition of the NBCC.

Sentence 3.1.5.18.(2) of the NBCC now requires that all communication conductors installed without metal raceways and located in plenums of buildings required to be of non-combustible construction must be FT6 rated. Respectively, all such communication conductors located in plenums of combustible buildings must have FT4 rating.These new NBCC requirements have not been reflected in the CE Code, but a proposal has been already submitted to amend Appendix B Note on Rule 2-126 accordingly.

Our finalexample of the impact of the NBCCon electrical wiring deals with protection of electrical conductors against exposure to fire.

The CEC has a few such requirements already. One of them relates to the emergency conductors supplying a fire pump. Rule 32-200(b) requires that conductors of a fire pump emergency feeder (feeder between an emergency generator and the fire pump) be protected against exposure to fire in accordance with provisions of the NBCC. A new requirement for suchfireprotectionof conductors has been placed in Section 46 of the 2012 edition of the CEC. Rule 46-204 now mandates such protectionof conductors installed between an emergency generator and electrical equipment that comprises a part of the electrical emergency supplybut that is not located in the same fire rated service room as the generator. A typical exampleof such equipment is a transfer switch which could be located in a different fire compartment than an emergency generator. In this case conductors between the generator and the transfer switch would have to be protected against exposure to fire for a period of not less than 1 hour. The 2010 edition of the NBCChas dedicated the entire Article 3.2.7.10 to the requirements for such fire protection of conductors.

This article mandates that in a high building all conductors that serve fire alarm systems, smoke control and smoke venting equipment or emergency lighting must provide circuit integrity ratingof not less than 1 hour in conformance with ULCS139 or be located in a service space separated from the remainder of the building by a fire separation with a fire resistance rating of not less than 1 hour. This article also requires that the electrical conductors supplying mechanical systems that provide air supply: (a) tothe areas of refuge from the operating rooms, intensive care units or recovery rooms in a hospital; or (b) tothe contained use areas in a jail— must have circuit integrity rating in accordance with ULC S139 for not less than 2 hours or be located in a service space that is separated from the reminder of the building by a fire separation with a fire resistance rating of not less than 2 hours. The Electrical Code users should be cognizant of this new requirement, as the fire protection of the electrical conductors for at least 2 hours has never been mandated by the building code before.

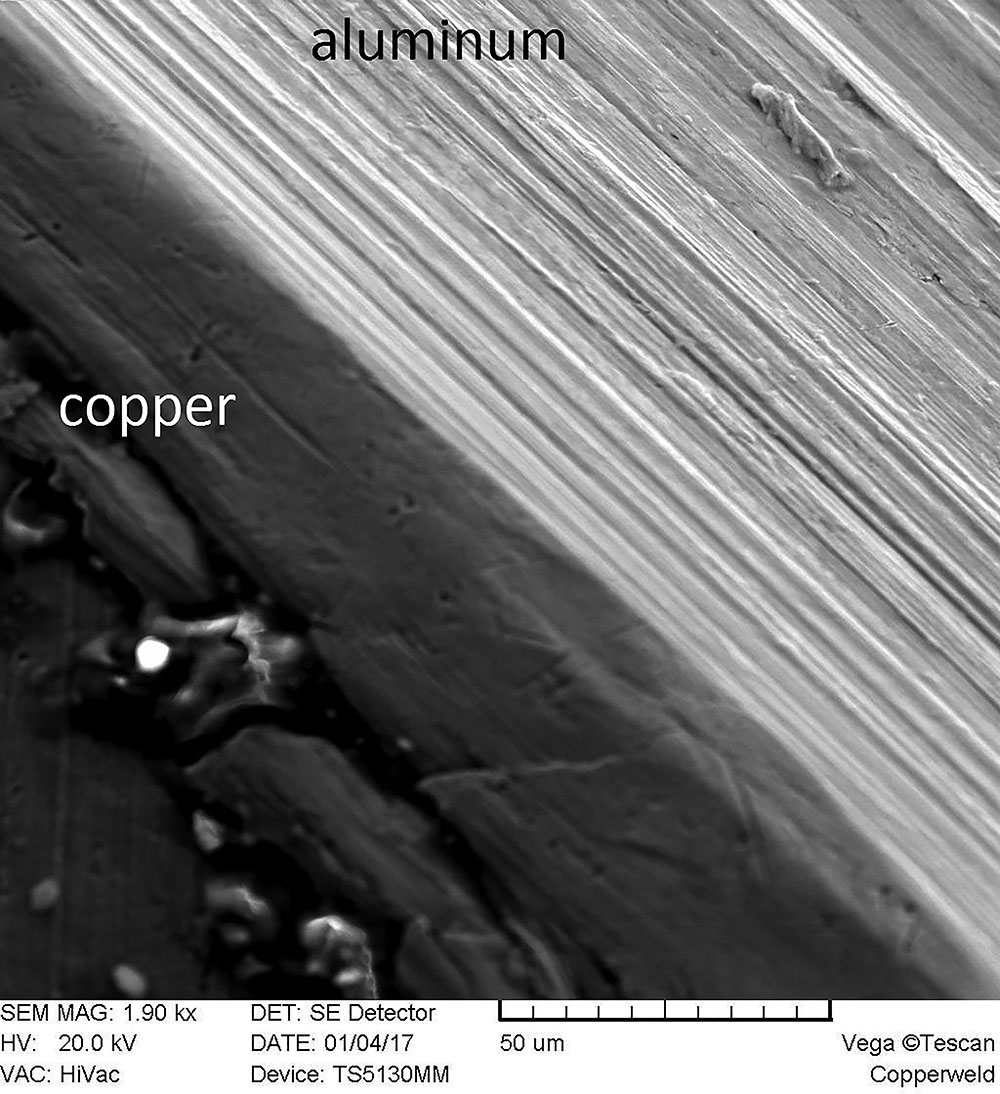

The CE Code users should be aware that ULC S139 is the standard that describes a fire test for evaluation of integrity of electrical cables, and there are circuit integrity cables on the market that are marked “CIC ULC S139 2 h”.

This marking means that a cable is the circuit integrity cable conforming to the ULC S139testthat indicates integrity of the circuit for a period of 2 hours.

It is interesting to note that while the NBCC mandates a fire protection of fire alarm system conductors against exposure to fire for a period of not less than 1 h only in high buildings, ULC standard S524 imposes such requirement for data communication link conductors interconnecting control units and transponders in a large scale network system regardless whether such systems are installed in a high building or not.

Therefore, the designers and installers should discuss these (and other relevant) requirements with the AHJ, in order to obtain their clarification and acceptance on the issues thatrelate to inconsistent requirements of the various codes and standards.

Find Us on Socials