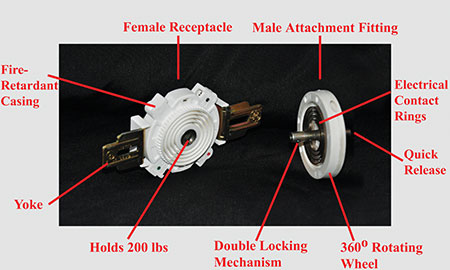

Soon you will be seeing a new receptacle type being used as a hanging support system for ceiling fans and luminaires. In short, it serves as a quick-connect and quick-disconnect for the ceiling fan or luminaire for swift and easy installation, replacement or maintenance, such as repair or cleaning. The new receptacle is installed in the outlet box and the compatible attachment fitting is factory-installed on the listed luminaire or ceiling fan. The receptacle is a locking support and mounting receptacle and it is always used in combination with a compatible attachment fitting that is fastened to the ceiling fan or luminaire. Figure 1 details a typical support and mounting receptacle including the compatible attachment fitting. Figure 2 shows the compatible attachment fitting that is mounted on the listed luminaire in the factory. It is important for inspectors and others to be familiar with how this technology works, including what should be considered in order to properly evaluate, approve and use these devices.

Introduction to the Technology

This new technology uses a third party listed load bearing support and mounting receptacle, and compatible attachment fitting to supply, support and connect wall-mounted or ceiling-suspended luminaires, and ceiling-suspended (paddle) fans. Figure 1 shows the receptacle and attachment fitting for a luminaire.

The components of the installation are shown in figure 3. The outlet box is installed, the same as current standard installations suitable for luminaire or fan installation. Then the receptacle is mounted onto the outlet box via the receptacle’s mounting yoke. The faceplate is then installed, which eliminates access to exposed energized parts. At this point, the luminaire or fan can either be quick-connected into the receptacle for immediate use (as shown in figures 4 and 5), or a faceplate centerpiece can be clicked into the faceplate to create a cover plate to protect (from painting, dust, etc.) the receptacle and for aesthetic purposes until a later time when the luminaire or fan will be quick-connected.

At this point, the luminaire or fan can either be quick-connected into the receptacle for immediate use (as shown in figures 4 and 5), or a faceplate centerpiece can be clicked into the faceplate to create a cover plate to protect (from painting, dust, etc.) the receptacle and for aesthetic purposes until a later time when the luminaire or fan will be quick-connected.

This quick-connect and quick-disconnect method allows for safer wiring, installation and removal of luminaires and ceiling-suspended (paddle) fans. Once the receptacle and face plate are in place, there are no longer exposed energized parts. The weight and bulk are in the luminaire or paddle fan, not the receptacle. Heavy or bulky parts no longer have to be supported while making wire connections to the branch circuit. Installation, connection and maintenance of the utilization equipment (the luminaire or paddle fan) are inherently safer because heavy and bulky units do not have to be maneuvered while the receptacle is being installed, where the electrician is typically on a ladder or lift.

With the new technology, the receptacle and faceplate are small and light and easily handled during installation. Since the electrician doesn’t have to worry about holding or supporting the luminaire or paddle fan when connecting the branch circuit wiring, the electrician is free to concentrate on making up the branch circuit connection, which provides for a safer installation since the electrician is not concerned with the bulk or weight of the luminaire or paddle fan during this phase of the installation process. After installation of the receptacle and faceplate, all that has to be done is to plug the attachment fitting (which is part of the listed luminaire or appliance) into the dead front receptacle.

Figure 3 shows the luminaire and attachment fitting for a luminaire installation; Figures 4 and 5 show an electrician quick-connecting the luminaire to the receptacle. Figure 6 shows a typical ceiling-mounted luminaire.

As with most receptacle and plug combinations, this technology is load break and load make rated. Certain activities such as maintenance and repair have been proven to have an increased hazard potential because of the number of documented injuries. Where the new technology is used, maintenance and repair are safer to perform because these activities can be completed while the luminaire or ceiling fan is disconnected from the branch circuit, hence the unit is de-energized. Installation is safer because the new technology has the following four features — deadfront construction (faceplate), load break (load make feature), adequate weight handling capacity, and in addition, not having to hold or support the fan during installation.

Regarding the weight handling capacity, the double locking mechanism ensures the receptacle and attachment fitting can bear the load; the double locking mechanism holds up to 200 pounds and has been tested to failure at 900 pounds. However, the load is limited by the capacity of the outlet box, which is normally 35 pounds for ceiling fans or 50 pounds for luminaires, unless listed and labeled otherwise (e.g., indicated greater weight capacity).

Some have compared the new receptacle and attachment fitting technology to the “rosettes” that were first mentioned in electrical safety documents in the 19th century. However, this new technology is light years away from the old rosette technology, which appeared in the 1897 National Board of Fire Underwriters document (the precursor to the NEC) and continued to have requirements in the NEC until the 1993 edition.

Injury Data Justified Use of the New Technology

The Consumer Products Safety Commission (CPSC) data from the National Electronic Injury Surveillance System (NEISS) show some enlightening statistics involving ceiling luminaires, proving that seemingly routine activities can be dangerous (see below). The data totals cited cover the period from 2011 to 2013, and document the number of trips to emergency rooms (ERs) across the U.S. These data may just be the tip of the iceberg, intuitively considering the number of injuries that may have gone unreported because they did not involve a trip to the emergency room. The surprising data below provides a glimpse at the depth and extent of the documented hazard.

Changing a light bulb. A seemingly simple task, changing a light bulb, is reported to have resulted in over 16,000 injuries from a fall or shock or both. Use of the new technology removes two hazard factors while changing a light bulb: elevation and energized parts (luminaire electrification). For those units with the new technology installed, the luminaire could simply be disconnected before a bulb is replaced, minimizing the time and work performed while elevated. Because the luminaire is disconnected, it is de-energized therefore no shock from contact with the luminaire is possible, and the light bulb can be installed while at floor level. This really improves safety when replacing a broken bulb, especially when pliers are necessary.

Installation. During installation of a luminaire, approximately 1,600 injuries are sustained resulting from a fall or shock or both. A likely cause of some of these incidents is the simultaneous support of the heavy and bulky appliance while performing the connection of the wiring at an elevation. During the installation, the electrician has to do the wiring at an elevation while he or she, someone else (or some other means) is used to support the bulky luminaire or fan. A method for reducing this hazard is to use this technology: the small receptacle is installed to the ceiling outlet box, completing the wiring of the branch circuit through the receptacle unit. The electrician then installs a faceplate, just as with other receptacle types. To complete the installation, the luminaire or fan with the attachment fitting is simply quick-connected into the receptacle and the luminaire or ceiling fan installation is complete. Wiring will no longer require the luminaire or fan to be held or supported nearby, oftentimes while on a ladder or lift. By removing the bulky luminaire or ceiling fan from the initial equation, safety and efficiency is increased.

Maintenance – Cleaning. During luminaire cleaning, in the cited period, there were approximately 500 injuries sustained resulting from fall or shock or both. In the lifespan of the luminaire, maintenance (including repair and cleaning) are often performed. Use of the new technology would minimize or eliminate the anticipated hazard factors during cleaning or repair of the luminaire: elevation and luminaire electrification. For those units with the new technology installed, the luminaire could simply be disconnected and cleaned or repaired at floor level. Because the luminaire is disconnected, it is de-energized therefore no shock from the luminaire itself is possible, and maintenance of the luminaire can be done at floor level.

Falling Luminaires. There were over 2000 ER visits resulting from falling fixtures. Considering the double-locking mechanism of the new technology, one can reasonably assume that in many of these cases, if the technology were used, the luminaires would’ve been sufficiently secured to stay in place, thereby lessening the hazard.

Device Categorization and Listing

When the technology was first presented for listing, it took the listing organization over two years to categorize it in the “receptacle” category, ultimately allowing the technology to be listed to UL 498, Standard for Attachment Plugs and Receptacles. The listed receptacle and compatible attachment fitting technology is suitable for use with both listed luminaires and listed ceiling suspended paddle fans.

The Techonology Is Permitted By the NEC®

During this most recent revision cycle, various NEC Code-Making Panels clearly indicated that nothing in the NEC precludes the use of the receptacle and attachment fitting technology. Further, it is anticipated that the technology will be addressed in the upcoming 2017 edition of the NEC through the addition of new or modified text.

What to Check for During Inspection

The inspection for the new technology is much like that performed for the current methods of installation, with two minor additions: ensuring the receptacle is listed for its intended purpose, and that the volume calculation is accounted for in accordance with 314.16.

When the new technology is encountered in the field during the inspection of a ceiling fan or luminaire, it is important to check that the receptacle is listed for the purpose. Since the receptacle is installed first, it might be encountered without the addition of the associated luminaire or fan. While the faceplate is in place, the installation is safe, just as with any standard receptacle. When the faceplate centerpiece is installed, the faceplate becomes a full cover plate as shown in figure 3.

An inspection should be performed to ensure the outlet box is listed for fan or luminaire installation, and that the weight rating is compatible with the weight of the associated ceiling fan or luminaire. It is important to assure that the outlet box used is marked by the manufacturer as suitable for the use with a luminaire or fan and has the correct weight capacity. Also it is important to ensure that the screws supplied with the listed outlet box are used. If the luminaire or fan is installed, it can be easily disconnected and the faceplate removed to allow for inspection.

Conclusion

It is important for inspectors and others to be familiar with how this technology works and what should be considered in order to properly evaluate, approve and use these devices. Increased usage of this technology is anticipated, based on availability and recognition. It is prudent for inspectors and others to become familiar with the new technology, such as that of the locking support and mounting receptacle and compatible attachment fitting combination, to stay current.

Author Affiliation: Ms. Cronin and Mr. Fontaine wrote this article while representing Safety Quick Lighting and Fans Corporation.

Find Us on Socials