Background

Electricians, contractors and users should be aware that AFCIs are installed in locations that the standard circuit breakers are installed. They can be retrofitted into existing loadcenters and panelboards. Electrical connections are similar to those of a circuit breaker GFCI in that they have a load-neutral connector and a pigtail connection to the panel neutral bus.

Photo 1. Branch/circuit-breaker type AFCI

It should be very difficult to cause an unwanted tripping condition in a dwelling unit branch circuit. When tripping occurs, it is most likely a result of an arcing condition or an improperly wired circuit. The AFCI is designed to trip when certain conditions likely to cause a fire exist in the circuit. There has been relatively little experience in locating these conditions. This paper provides some guidelines that may be helpful. Part I of the article lists conditions under which the AFCI is designed to trip. The discussion focuses on the branch/feeder AFCI, which is the only commercially available AFCI.

Applying AFCIs under NEC 210.12

As mentioned in Part I of this article, theNEC2002 retained, with only minor revisions, the requirement of the NEC 1999 that AFCI protection be required on branch circuits that supply receptacle outlets in bedrooms. One revision confirmed that the AFCI must protect the “entire” branch circuit. Another replaced the term “receptacle outlets” with simply “outlets” and required that all outlets—including those for lights, fans and smoke alarms—be protected as well as receptacle outlets. These changes affirm that NEC Code-making Panel 2 (CMP-2) intends that fixed wiring be protected and that all wiring associated with bedrooms be covered by the rule.

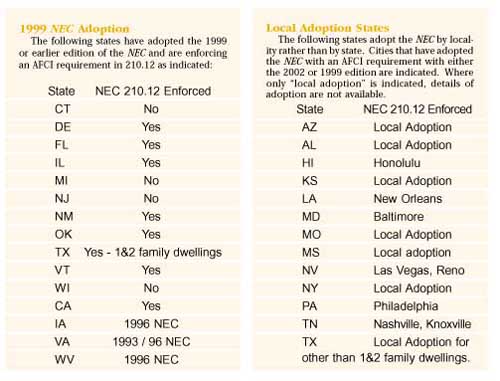

Table 1. AFCI adoption

As regards what must be protected, the requirement is clear as written: “All branch circuits that supply 125-volt, single-phase, 15- and 20-ampere outlets installed in dwelling unit bedrooms shall be protected by an arc-fault circuit interrupter listed to provide protection of the entire branch circuit.”1 This includes outlets for receptacles, for lights, for fans, and so forth in circuits that supply bedrooms.

Retrofit applications in 2-wire circuits

A branch/feeder AFCI (circuit breaker type) provides good protection for 2-wire circuits. It provides for detection of a low-level short circuit of 75 amperes or above that would not be detected by an overcurrent protective device. It also provides detection of an arcing ground fault occurrence of 5 amperes or above. Note that commercially available AFCIs actually detect arcing ground fault of 50 milliamperes and above even though 5 amperes is the standard requirement. This protection is as valid in 2-wire circuits as in 3-wire circuits that include the grounding conductor. The difference is that with the added grounding conductor in the 3-wire circuit, an arc of any level may reach the grounding conductor and be detected at levels below 75 amperes, which provides a degree of protection not available in 2-wire circuits.

Required locations under the NEC

Article 100 of the NEC defines a dwelling unit as: “One or more rooms for the use of one or more persons as a housekeeping unit with space for eating, living, and sleeping, and permanent provisions for cooking and sanitation.” AFCIs are required in specified circuits that supply dwelling unit bedrooms. The following points are from questions that have arisen regarding circuits to be protected.

Hotels and dormitories

One question that has arisen is whether hotel or motel rooms and dormitories are considered dwelling units. The rule must be interpreted by the authority having jurisdiction (AHJ). If the AHJ considers these units dwelling units, they must be so considered for NEC 210.12. One way to make this judgment is to consider whether the units would constitute a dwelling unit if the facility were placed under new ownership and occupied as apartments or condominiums.

Smoke detector circuits

Circuits supplying smoke detectors in bedrooms fall under the category of bedroom outlets. Recall that the purpose of the AFCI is to address fire causes. If the potential fire cause is in the smoke detector wiring, the first approach for protection against fire should be to clear the potential cause. Further, listed smoke detectors are required to have battery back up, so that power to the smoke detector is not dependent on the presence of power from the utility.

Bedroom closets

Whether bedroom closets are part of the bedroom is a judgment to be made by the AHJ. However, it is clear that the intent of 210.12 is to provide protection for the entire bedroom. When the closet is an integral part of the bedroom, a safe approach would call for the closet wiring to be protected just as other parts of the bedroom.

Commercial applications

Although not required under the NEC, AFCIs are suitable for use in commercial applications in circuits for which they are rated.

Tripping Causes on Installation

Photo 2

Causes of tripping of branch/feeder AFCIs are listed in Part I of this article. Understandably, it is frustrating to install a device and find that it trips as soon as it is turned on. It is important to understand that where single-pole AFCIs are used, the neutrals of two or more circuits cannot be shared, mixed or crossed. Also, if the neutral is grounded on the load side of the AFCI, the AFCI may trip.

Because there were a significant number of reports of AFCIs tripping on installation, Square D re-contacted those who had reported the tripping after the initial inquiry from them. The following is a list of the findings.

- 4 cases were unresolved.

- 1 was an application problem in which equipment of two manufacturers was mixed on the job. The AFCI worked fine and continues to do so.

- 6 were resolved by reading the instructions. The callers had not initially understood how the AFCI was to be used.

- 1 was a bad appliance, a room air conditioner.

- 23 were wiring problems broken down as follows.

1 problem at a connector in which wires were too close

4 crossed neutrals

7 shared neutrals

9 grounded neutrals

2 shared neutrals also grounded

Crossed neutrals are defined here as neutrals from multiple circuits either crossed or touching. Shared neutrals are defined here as multi-circuit neutrals.

Reported difficulties in troubleshooting installation problems are an indication of a learning curve and are not a reflection on poor performance of the AFCI. Today’s AFCIs are performing their detection function properly and are finding problems that should be corrected. There is some resistance to this change as is to be expected with any change. However, this small and informal survey indicates that installers are learning the issues that are uncovered by AFCIs and that they can be found and corrected. When the circuit is corrected, not only is the circuit correct, it also has additional AFCI protection operating to help retain it free of hazardous arcing.

Shared neutrals

Single-pole AFCIs cannot protect circuits in which the neutral (grounded circuit) conductor is shared or mixed. The reason is that current flowing out and returning is monitored for the presence of arcing faults. When single-pole AFCIs are applied, the circuit must have a distinct hot and a distinct neutral conductor. Otherwise, the AFCI cannot distinguish arcing ground-fault occurrences.

Table 2. 1999 adoptions and adoption states (2002 and 1999)

Contractors and users should understand that thereare some drawbacks to using shared neutrals. For example, if a 2-pole, common-trip version is used, then both circuits are interrupted during a fault. If the 2-pole, common-trip version is used, then both circuits are interrupted during a fault. If the 2-pole circuit breaker has independent trip, then when a circuit is tripped and an outlet device is removed (assuming a dead circuit), if the home run is split at that point, the wiring in the box is not really dead. Another example of shared neutral wiring disadvantages is the result if the home run neutral is lost—a motor load will take one side of the circuit to zero, putting the loads on the other side to 240 volts. This tends to play havoc with many 120-volt devices. Further, cable manufacturers are apparently planning cables that contain four wires plus ground for exactly this kind of application.

Test equipment

Availability of test equipment has been questioned for three purposes:

a. To verify that the circuit has been installed properly so that contractors can demonstrate that their work has been done competently.

b. To verify that the AFCI is functioning properly.

c. To trip an AFCI from a load circuit in order to identify which AFCI is in the circuit.

We will discuss each item briefly.

Verification of the installation

The authors are not aware of special equipment available to test the circuit for proper installation beyond that which has been available without the AFCI. If wiring is installed competently, there should be no reason for any testing that is not done for a circuit without an AFCI. However, there are two possible practices that can be used to test the installation, if a test is desired.

1) Probably the best test is to install an AFCI, at least temporarily in the circuit. For this test to be effective, the circuit must be complete, since it must be energized as in service with 120 volts. Use the test button to verify that the AFCI is functioning properly. Then leave the AFCI in the energized circuit for some period of time. If it does not trip, that is an indication that the circuit is acceptable.

2) As with any installation, an insulation resistance (Megger device) test can be done to verify that the wiring and connections are properly insulated. With this test, high voltages are applied. Be sure to keep personnel away from circuits being tested and follow safety practices described in NFPA 70E, Part II.

To perform this test, disconnect all loads and verify that unconnected wire ends are insulated. Disconnect the load wire to any AFCI or GFCI in the circuit because these devices may be damaged by high voltage. Use an insulation resistance tester that will apply a direct current voltage of at least 500 volts to the circuit under test. All resistance readings should be at least one megohm (1,000,000 ohms). A successful test will indicate that the insulation is intact and initiation of an arc would be highly unlikely for the portion of the circuit tested.

Recognize that neither of these tests will identify loose connections. Good workmanship is required as always.

Verification of the AFCI

The most effective test is the self-test supplied with the AFCI. See the instructions supplied with the AFCI by the manufacturer. In accordance with UL 1699, this test “simulates an arc such that the arc detection circuit or software is caused to detect the simulated arc.” By doing so, it tests all of the AFCIs systems and tripping parts. An external tester is not necessary.

The authors are not aware of commercially available testers other than those mentioned below that trip the AFCI by applying a ground fault.

Tripping the AFCI from a load

There are several devices being marketed that will trip the AFCI by applying a ground fault on the system. Be aware that devices that are not listed for this purpose may be creating a potential shock hazard by creating a ground fault of sufficient current to trip the AFCI.

Finding the cause of AFCI tripping

One of the most frequently asked questions is about how to find the cause of tripping when an AFCI trips. There is no single correct answer to this question. An orderly search is probably the best approach. We are not aware of specialized equipment that would help locate a problem. The skill and experience of the electrician will help. Remember that the circuit breaker AFCI will trip from an overcurrent sensed by the circuit breaker or from an arcing occurrence sensed by the AFCI function, including a ground fault.

The AFCI function will be sensing an arc that occurs because insulation or isolation is not adequate. The problem or fault may be in one or a combination of these three conditions:

1) Line-to-ground

2) Line-to-neutral

3) Series arc in broken or separated conductor (could be a loose connection). Note that the branch/feeder AFCI will not generally detect a series arc because series current is usually below the detection level.

Here are some steps that may be useful:

a) Gather information from people who have used the circuit regarding any buzzing noises, visible arcing, the odor of smoke, or similar indications of improperly operating or defective appliances or equipment. This information may lead to the fault location. If arcing is suspected in an extension cord or a cord-connected appliance, immediately unplug the suspected unit.

b) The most likely cause of tripping in a new installation is wiring. Check for neutral (grounded circuit) conductors that are shared or crossed with those of other circuits, or neutral conductors that are grounded on the load side of the AFCI.

c) Unplug all appliance and extension cords connected in the circuit. If tripping continues to occur when the AFCI is turned on, the fault is in the fixed wiring system.

d) Similarly, turn off all fixed appliances such as lights and ceiling fans that have switches. Since these circuits cannot be fully disconnected (line, neutral and ground), tripping occurrences with their switches turned off does not necessarily mean that they are fault free.

e) If the AFCI does not trip when all plugs are disconnected, turn on the AFCI again and reconnect the plugs one by one. Then turn on fixed lights and appliances. This procedure may locate the faulted cord or appliance.

f) Because arcs are sometimes sporadic, turning off the circuit may temporarily clear the arc and it may not immediately reappear when the circuit is re-energized. For this reason, the arc may not be located by unplugging and reconnecting appliances. If the arc has been located to be in the fixed wiring system, or if the arc has not been located by removing plug-in loads, some of the following techniques may be helpful.

- Examine appliance cords, plugs and equipment carefully for indications of damage.

- With the circuit de-energized, examine connections to the AFCI, receptacles, lighting fixtures and other appliances.

Note: De-energize the load center by turning off the main disconnect, if possible, before conducting the following checks. By means of a reliable voltmeter, verify that voltage is not present.

g) Apply the insulation resistance test described in a response to a question above to check for insulation adequacy line-to-neutral, line-to-ground and neutral-to-ground. Alternatively, use an ohmmeter to check for electrical continuity line-to-neutral, line-to-ground and neutral-to-ground. Continuity indicates presence of a fault. The insulation resistance check is the preferred method.

h) Indication of adequate insulation in a circuit that has been identified as having an arc fault may point to a series fault, that is a broken conductor or a loose connection.

i) The line-to-ground sensing is for small leakage current of about 50 milliamperes (0.050 amperes) and above. It may not be visible as an arc. Any technique used to find a ground fault would be useful for locating an arc to ground.

j) Once the fault is located, damage must be repaired or improperly operating equipment or appliances must be replaced.

k) In most cases, the steps noted above will help locate the fault. It is important to recognize that the AFCI has provided an indication of a condition that could become a fire hazard. Do not continue to use the circuit without a correction.

The introduction of AFCIs is a change. There is a learning curve for the entire industry. Through this change, it is clear that AFCIs are finding problems with installations, both in older upgrades and in new construction, in fixed wiring as well as in extensions to loads. The data indicates that there are many potential fire causes that the AFCI will help avoid becoming fires. When they are applied as intended, we will see results in more potential fire causes corrected.

1 Section 210.12(B),National Electrical Code2002, (National Fire Protection Association, Quincy, MA), p. 70-54.

Find Us on Socials