Canadian Electrical Code recognizes the fact that conductors used in any location must be protected against adverse effects of moisture, corrosive action, temperature and mechanical impact. Rules 4-006 and 12-100 of the CE Code state that the selected conductors must be suitable for condition of use in accordance with provisions of Table 19.

Table 19 references various rules of the Code that govern installation of conductors and wiring methods. It also lists conditions for application of particular types of conductors, provides the CSA Type designation for conductors (in accordance with applicable Part II standards), and describes cable trade designation and maximum allowable conductor temperature. Table 19 offers numerous clarification notes on use of conductors in specific applications.

However, in general, conditions of conductors’ application indicated in Table 19 and spelled throughout the CE Code do not acknowledge the fact that certain conductors must also perform under exposure to fire. These particular conductors are used in conjunction with a very specific life and fire safety equipment that has to operate in a building when the building is exposed to the fire, and when a normal power supply is unavailable. Such electrical equipment (smoke control and smoke venting equipment, fire pumps, fire fighters’ elevators, fire alarm system, emergency lighting) and fire protection of conductors to this equipment are described in Subsections 3.2.6. and 3.2.7. of the National Building Code of Canada (NBCC).

Appendix G of the CE Code also provides references from rules of Sections 32 and 46—to the NBCC requirements for fire protection of electrical conductors.

Users of the 20th edition of the CEC may note that the entire subsection dedicated to fire pumps in Section 32 has been rewritten, and that Rule 32-200 now includes provision for fire protection of fire pump conductors.

Subrule 32-200 has been modified to read:

“32-200 Conductors (see Appendix B)

Conductors from the emergency power source to a fire pump shall:

(a)… ; and

(b) Be protected against fire exposure to provide continued operation in compliance with the National Building Code of Canada.”

Appendix B Note to this rule has been added as follows:

Appendix B Note on Rule 32-200:

“Intent of this rule is to protect the feeder conductors between a fire pump and an emergency power source from fire damage.

“The National Building Code of Canada requires that conductors supplying a life and fire safety equipment be protected against exposure to fire to ensure continued operation of this equipment for a period not less than 1 h.

“NFPA 20 also mandates protection of circuits feeding fire pumps against possible damage by fire. The following example illustrates acceptable methods for achieving this protection:

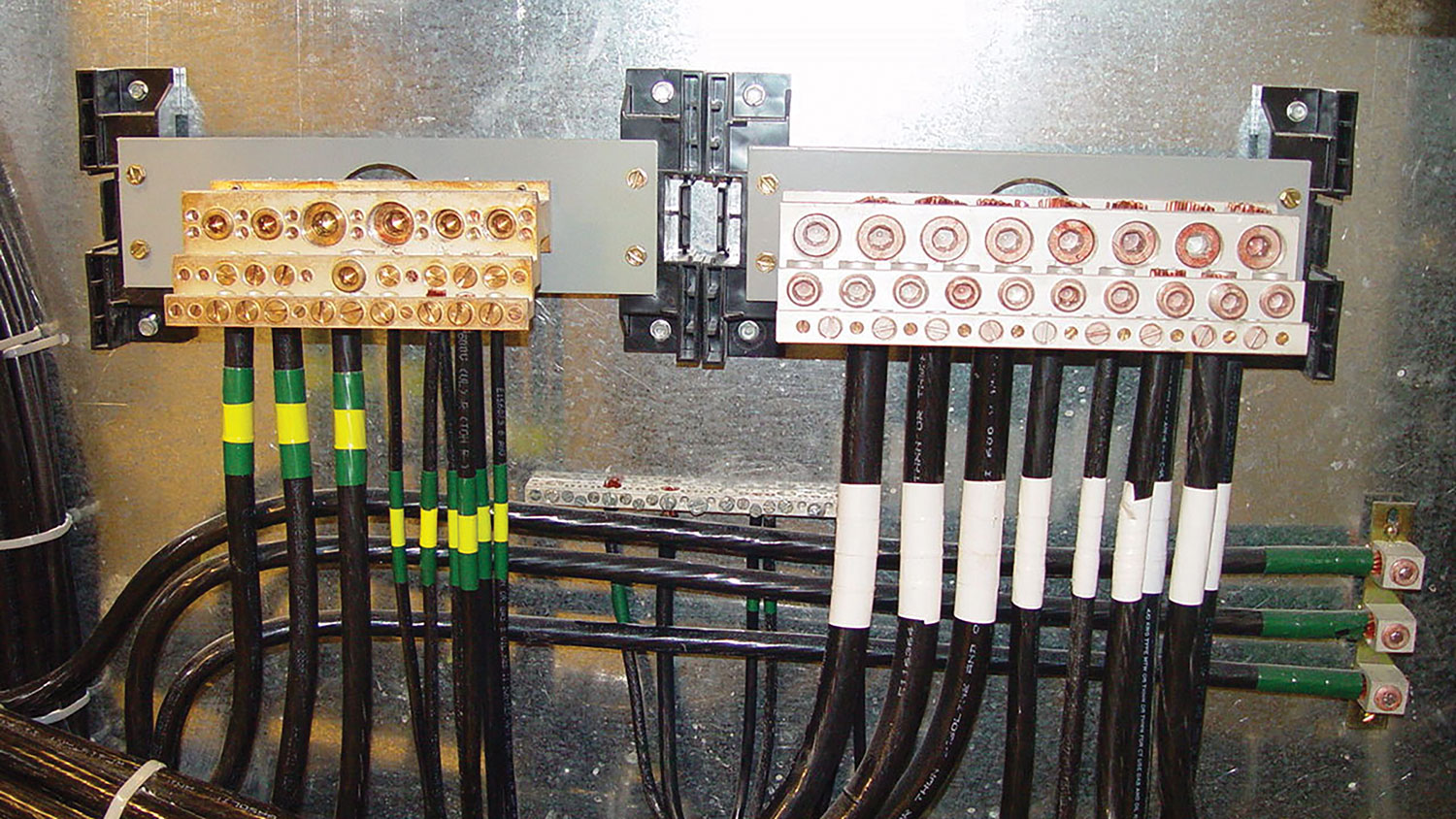

a. Using mineral insulated cables conforming to fire rating requirements as specified in Clause 5.3 of the CSA Standard C22.2 No. 124 “Mineral Insulated Cable”;

b. Embedding the raceway containing fire pump feeder conductors in not less than 50 mm of concrete;

c. Installing the raceway containing fire pump feeder conductors in a shaft enclosure or service space of at least 1hour fire resistance construction.

“Specific requirements pertaining to the fire resistance rating of a material or an assembly of materials can be found in subsection 3.1.7 of the National Building Code of Canada or in the appropriate Provincial/Territorial Legislation.”

It is obvious that the users of the CE Code must closely communicate with the NBCC practitioners (with architects, fire protection experts, etc.) in order to clearly understand provisions of the NBCC regarding fire protection of electrical conductors.

It should be noted that when a floor is consumed by the fire, protection of fire alarm components or smoke removing equipment installed on that floor is meaningless.

The intent of the NBCC is only to provide protection of riser conductors that interconnect a fire alarm control unit and a fire alarm annunciator with components of a fire alarm and voice communication system installed in a high building, and riser conductors for smoke control and smoke venting fans and dampers.

Conductors running to this fire safety equipment on individual floors are not intended to be protected by the NBCC against exposure to fire. The NBCC intends only to protect riser conductors from potential pressurized hot gases which could travel inside the electrical conduits originating from the fire floor.

However, conductors that supply fire fighters’ elevators and fire pumps (the latter could be seen in Rule 32-200 of the CEC) are intended by the NBCC to be protected from the source of the emergency power supply (emergency elevator) to the terminals of a fire pump or elevator motors.

Electrical designers and contractors should consider specific methods of the conductors’ protection against exposure to fire selected for the particular project.

In a sprinklered building, for example, authorities having jurisdiction (AHJ) responsible for acceptance of the selected methods for the protection of electrical conductors from fire exposure—to ensure operation of the life and fire safety equipment for a period of at least one hour may accept the following methods of conductors protection:

1. Use of mineral insulated cables or cables meeting circuit integrity tests in conformance with the ULC standard S139.

2. Provision of a minimum cover over the conduit of at least 100 mm in concrete floor slabs or walls that form part of fire separations.

3. A minimum cover over the conduit of at least 125 mm in concrete columns, beams or walls that are not forming part of a fire separation.

Electrical designers and contractors should take into account the following conditions:

1. The satisfactory operation of electrical equipment supplied by protected conductors while operating at temperatures in excess of 30 degrees C. It should be noted that derating of a conductors’ ampacity may be required;

2. Access to electrical riser conductor junctions for maintenance or testing. It should be noted that any junction boxes or access points required for the protected conductors must be protected with listed access panels which have been tested to limit the temperature rise on unexposed side to less than 90 degrees C for one hour. An air space must be provided between the access panel and the conductors—to ensure that there will be no contact. Designers and contractors should also note that location of riser conductors’ junctions in exit stairwells is not permitted by the NBCC.

3. Conduits leading from protected enclosures to branch circuits must be protected at junction boxes at both ends of the connecting conduit. It should be noted that such protection will consist of plugging the conduits to a depth of at least 12 mm with an approved firestop caulking. As an alternative to this protection an AHJ might consider acceptance of a sealing fitting at the protected enclosure end.

While in some jurisdictions inspection authorities combine coordinated expertise of building and electrical inspectors and can easily evaluate compliance of installations with provisions of the building and electrical codes, in other jurisdictions such assessment may require additional expertise.

However, electrical designers and contractors must always consult the respective AHJ prior to selection and execution of the fire protection methods for conductors that supply the emergency equipment.

Find Us on Socials