The experience of dealing with this subject demonstrates lots of inconsistencies among the designers, installers and regulators. And the issue relates not only to a proper selection of electrical equipment and wiring methods for connection of this equipment, but to the determination of hazard and to the ability of accurately assigning specific area of classification for a particular hazardous location.

Of course, the essence of this discussion is based on the provisions of the Canadian Electrical Code on this subject.

Photo 1. Three-car residential parking garage is non-hazardous location from the CE Code perspective.

Perhaps, use of a few examples would be appropriate. Let say, you decide to build a house with a 3-car garage where vehicles that use volatile flammable liquids or flammable gases are stored. Does such garage become a hazardous location in accordance with the CE Code? And what about a small woodworking shop in a high school? And how about a boutique distillery that is set up in a typical rental unit of an industrial building? And what about an area where a diesel fueled generator is located with the fuel storage tank? And what about locations where gasoline or other similar volatile flammable liquids are stored in tanks, or locations where paints, lacquers, or other flammable finishes are regularly or frequently applied by spraying, dipping, brushing, or by other means, and where volatile flammable solvents or thinners are used? And what about a typical grain handling or sugar pulverizing plant? Or how about locations with textile mills, flax processing plants; or clothing manufacturing plants?

Examples of such locations with various industrial processes or with storages of flammable or combustible liquids are numerous. Does each such area have to be classified as “hazardous location” in accordance with the CE Code?

To answer these questions, we might want to start with the Code definition of hazardous location. It is defined as follows:

“Hazardous location (see Appendix B) — premises, buildings, or parts thereof in which

(a) an explosive gas atmosphere is present, or may be present, in the air in quantities that require special precautions for the construction, installation, and use of electrical equipment;

(b) combustible dusts are present, or may be present, in the form of clouds or layers in quantities to require special precautions for the construction, installation, and operation of electrical equipment; or

(c) combustible fibres or flyings are manufactured, handled, or stored in a manner that will require special precautions for the construction, installation, and operation of electrical equipment.”

Photo 2. Paint spraying is Class I hazardous location.

Appendix B Note on this definition provides the following clarification:

“Hazardous location

In this definition, “special precautions” refers to the special features of electrical equipment design, installation, and use that are intended to prevent the equipment from igniting flammable vapours, dust, fibres, or flyings. See Section 18 for more specific requirements on hazardous locations.”

Now, it is the appropriate time to visit Section 18 of the CE Code. Scope of Section 18 indicates that this Section applies to locations in which electrical equipment and wiring are subject to the conditions indicated by classifications of types of hazard. The scope of Section 18 also statesthat this Section supplements or amends the general requirements of the CE Code. This means that provisions of Section 18 are additional to the general requirements of the electrical installation Code and in some cases — are different from the general rules of the Code. Such additional or different provisions have been introduced in Section 18 — in order to address specific safety concerns in respect to the installation of equipment and wiring methods in hazardous locations.

Photo 3. Gasoline dispensing and service station is Class I hazardous location.

Rules 18-004 – 18-010 of the CE Code provide a clear criteria for classification of particular hazardous locations – by identifying Classes of hazardous locations based on a potential for flammable gases or vapours being present in the air in quantitiessufficient to produce explosive gas atmospheres, or on a potential for existence of combustible or electrically conductive combustible dusts in the air, or on a possibility of easily ignitable fibres or flying in the air – to produce ignitable mixtures. These Rules further subdivide such identified Classes into specific Zones or Divisions. This precise fragmentation of each Class into a specifically identified Zone or Division becomes a fundamental criteria for selection of the appropriate electrical equipment and wiring methods for each type of hazardous location.

Only when any such potential for creating above highlighted hazardous conditions exists, such areas have to be classified as hazardous locations.

Let’s take a look on Subrule 18-004(a) and on Rule 18-006, which cover Class I hazardous location.

“18-004 Classification (see Appendix B)

Hazardous locations shall be classified according to the nature of the hazard, as follows:

(a) Class I locations are those in which flammable gases or vapours are or may be present in the air in quantities sufficient to produce explosive gas atmospheres;”

Photo 4. Propane storage is Class I hazardous location.

“18-006 Division of Class I locations (see Appendices B and J)

Class I locations shall be further divided into three Zones based upon frequency of occurrence and duration of an explosive gas atmosphere as follows:

(a) Zone 0, consisting of Class I locations in which explosive gas atmospheres are present continuously or are present for long periods;

(b) Zone 1, consisting of Class I locations in which

(i) explosive gas atmospheres are likely to occur in normal operation; or

(ii) the location is adjacent to a Class I, Zone 0 location, from which explosive gas atmospheres could be communicated; and

(c) Zone 2, consisting of Class I locations in which

(i) explosive gas atmospheres are not likely to occur in normal operation and, if they do occur, they will exist for a short time only; or

(ii) the location is adjacent to a Class I, Zone 1 location, from which explosive gas atmospheres could be communicated, unless such communication is prevented by adequate positive-pressure ventilation”

Appendix B Note on Rule 18-006 provides the Code users with a very important clarification on the criteria for identification of Zones of Class I Location as follows:

Photo 5. Combustible dust environment is Class II hazardous location.

“Rule 18-006

Typical situations leading to a Zone 0 area classification are

(a) the interiors of storage tanks that are vented to atmosphere and that contain flammable liquids stored above their flash point;

(b) enclosed sumps containing flammable liquids stored above their flash point continuously or for long

periods; and

(c) the area immediately around atmospheric vents that are venting from a Zone 0 hazardous area.

Typical situations requiring a Class I, Zone 1 hazardous locations are

(a) inadequately ventilated buildings or enclosures;

(b) adequately ventilated buildings or enclosures, such as remote unattended and unmonitored facilities, that have insufficient means of limiting the duration of explosive gas atmospheres when they do occur; and

(c) enclosed sumps containing flammable liquids stored above their flash point during normal operation.

Typical situations leading to a Zone 2 area classification are

(a) areas where flammable volatile liquids, flammable gases, or vapours are handled, processed, or used, but in which liquids, gases, or vapours are normally confined within closed containers or closed systems from which they can escape only as a result of accidental rupture or breakdown of the containers or systems or the abnormal operation of the equipment by which the liquids or gases are handled, processed, or used;

(b) adequately ventilated buildings that have means of ensuring that the length of time where abnormal operation resulting in the occurrence of explosive gas atmospheres exist will be limited to a “short time”; and

(c) most outdoor areas, except those around open vents, or open vessels or sumps containing flammable liquids.”

Subrule 18-004(b) and Rule 18-008 cover Class II location and Divisions of this hazardous location Class based on the conditions of presence of combustible dust in the air as follows.

“Rule 18-004(b) Class II locations are those that are hazardous because of the presence of combustible or electrically conductive combustible dusts”;

“18-008 Division of Class II locations (see Appendix B)

Class II locations shall be further divided into two Divisions as follows:

(a) Division 1, consisting of Class II locations in which

(i) combustible dust is or may be in suspension in air continuously, intermittently, or periodically under normal operating conditions in quantities sufficient to produce explosive or ignitable mixtures;

(ii) the abnormal operation or failure of equipment might

(A) cause explosive or ignitable mixtures to be produced; and

(B) provide a source of ignition through simultaneous failure of electrical equipment, operation of protection devices, or from other causes; or

(iii) combustible dusts having the property of conducting electricity may be present; and

(b) Division 2, consisting of Class II locations in which

(i) combustible dust may be in suspension in the air as a result of infrequent malfunctioning of handling or processing equipment, but such dust would be present in quantities insufficient to

(A) interfere with the normal operation of electrical or other equipment; and

(B) produce explosive or ignitable mixtures, except for short periods of time; or

(ii) combustible dust accumulations on, in, or in the vicinity of the electrical equipment, may be sufficient to interfere with the safe dissipation of heat from electrical equipment or may be ignitable by abnormal operation or failure of electrical equipment.”

Appendix B Note on Rule 18-008 explains the intent of this Rule in details for the benefit of the Code users as follows:

“Rule 18-008

Class II, Division 1 locations usually include the working areas of grain-handling and storage plants; rooms containing grinders or pulverisers, cleaners, graders, scalpers, open conveyors or spouts, open bins or hoppers, mixers or blenders, automatic or hopper scales, packing machinery, elevator heads and boots, stock distributors, dust and stock collectors (except all-metal collectors vented to the outside), and all similar dust-producing machinery and equipment in grain processing plants, starch plants, sugar pulverizing plants, malting plants, hay grinding plants, and other occupancies of similar nature; coal pulverizing plants (except where the pulverizing equipment is essentially dust-tight); all working areas where metal dusts and powders are produced, processed, handled, packed, or stored (except in tight containers); and all other similar locations where combustible dust may, under normal operating conditions, be present in the air in quantities sufficient to produce explosive or ignitable mixtures.

Combustible dusts that are electrically non-conducting will include dusts produced in the handling and processing of grain and grain products, pulverized sugar and cocoa, dried egg and milk powders, pulverized spices, starch and pastes, potato and wood flour, oil meal from beans and seed, dried hay, and other organic materials that may produce combustible dusts when processed or handled. Only Group E dusts are considered electrically conductive for the purposes of classification. Metallic dusts of magnesium, aluminum, and aluminum bronze are particularly hazardous, and every precaution should be taken to avoid ignition and explosion.

Class II, Division 2 locations include those in which dangerous concentrations of suspended dust are not likely, but where dust accumulation might form on, in, or in the vicinity of electrical equipment, and include rooms and areas containing only closed spouting and conveyors, closed bins or hoppers, or machines and equipment from which appreciable quantities of dust might escape only under abnormal conditions; rooms or areas adjacent to Class II, Division 1 locations and into which explosive or ignitable concentrations of suspended dust might be communicated only under abnormal operating conditions; rooms or areas where the formulation of explosive or ignitable concentrations of suspended dust is prevented by the operation of effective dust control equipment; warehouses and shipping rooms in which dust-producing materials are stored or handled only in bags or containers; and other similar locations.

There are many dusts, such as fine sulphur dust, that cannot be equated specifically to dusts mentioned above, and in a number of cases further information may be obtained by reference to Standards included in the NFPA National Fire Codes; for example, NFPA 655 gives information on prevention of sulphur fires and explosions and makes reference to electrical wiring and equipment.”

And, finally, Subrule 18-004(c) and Rule 18-010 deal with the criteria for identifying Class III location and appropriate Divisions of Class III location as follows:

“18-004(c) Class III locations are those that are hazardous because of the presence of easily ignitable fibres or flyings, but in which such fibres or flyings are not likely to be in suspension in air in quantities sufficient to produce ignitable mixtures.”

“18-010 Division of Class III locations (see Appendix B)

Class III locations shall be further divided into two Divisions as follows:

(a) Division 1, consisting of Class III locations in which readily ignitable fibres or materials producing combustible flyings are handled, manufactured, or used; and

(b) Division 2, consisting of Class III locations in which readily ignitable fibres other than those in process of manufacture are stored or handled.”

Appendix B Note on Rule 18-010 provides necessary clarifications in respect to Class III Locations.

“Rule 18-010

Class III, Division 1 locations include parts of rayon, cotton, and other textile mills; combustible fibre manufacturing and processing plants; cotton gins and cotton-seed mills; flax processing plants; clothing manufacturing plants; woodworking plants; and establishments and industries involving similar hazardous processes or conditions.

Readily ignitable fibres and flyings include rayon, cotton (including cotton linters and cotton waste), sisal or henequen, istle, jute, hemp, tow, cocoa fibre, oakum, baled waste, kapok, Spanish moss, excelsior, and other materials of similar nature.”

Of course, these Code selection criteria for the appropriate hazardous locations (and explanatory Notes in Appendix B) are very helpful to the users. However, practice has demonstrated that the electrical designers, installers and regulators are not necessarily the ultimate experts of various processes associated with potential for flammable gases or vapours being present in the air in quantities sufficient to produce explosive gas atmospheres, or on a potential for existence of combustible or electrically conductive combustible dusts in the air, or on a possibility of easily ignitable fibres or flying in the air – to produce ignitable mixtures.

As such, their ability to accurately determine the most appropriate area of classification could be limited without additional information contained in the National Fire Code of Canada (NFCC) and certain NFPA standards. For example, Part 4 of the NFCC deals with Properties of Flammable and Combustible Liquids; NFPA 497 covers Recommended Practice for the Classification of Flammable Liquids, Gases, or Vapors and of Hazardous (Classified) Locations for Electrical Installations in Chemical Process Areas, etc.

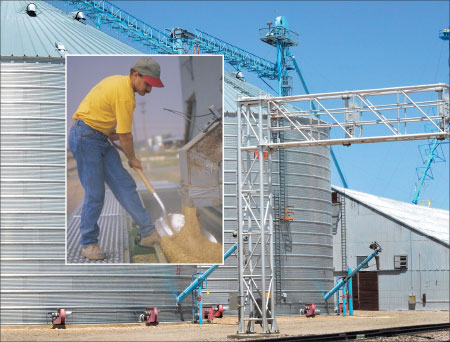

Photo 6. Grain handling is Class II hazardous location.

The CSA is considering to develop a guide which will help the Canadian Electrical Code users to determine areas of classification with a much better accuracy. Meanwhile, the electrical Code users have to seek assistance from the process specialists, in order to evaluate locations and processes for a need to properly select electrical equipment and wiring in the areas that are deemed to be hazardous locations in accordance with the CE Code.

After reviewing the referenced rules of Section 18 of the CE Code, the readers may be able to confirm that a 3-car attached garage of a dwelling is not considered as a hazardous location.

Similarly, an area that contains a diesel fueled generator also should not be considered as a Class I hazardous location (diesel is not a flammable fuel). And, certainly, some areas in a typical distillery must be treated as Class I locations. Of course, areas containing a paint spray operation or dispensing or storage of gasoline or compressed gas would represent Class I locations. Similarly, sugar pulverizing and grain handling facility would be classified as Class II location, and a woodworking shop, textile mill or a flax processing plant might have to be classified as Class III location, unless it could be demonstrated that readily ignitable fibres will not be present in the air, as a result of operation of a dust collection system.

Photo 7. Cotton mill is Class III hazardous location.

There could be, however, certain conditions where no specific equipment suitable for the purpose is available. In this case, Rule 18-070 allows installation of electrical equipment suitable for non-hazardous locations — in a Class I, Zone 2 hazardous location and electrical equipment suitable for Class I, Zone 2 hazardous locations — in a Class I, Zone 1 hazardous location, but such relaxation is allowed by this Rule of the Code under very stringent conditions as follows:

“the equipment, during its normal operation, does not produce arcs, sparks, or hot surfaces, capable of igniting an explosive gas atmosphere; and the location is continuously monitored by a combustible gas detection system that will

(i) activate an alarm when the gas concentration reaches 20% of the lower explosive limit;

(ii) activate ventilating equipment or other means designed to prevent the concentration of gas from reaching the lower explosive limit when the gas concentration reaches 20% of the lower explosive limit, where such ventilating equipment or other means is provided;

(iii) automatically de-energize the electrical equipment being protected when the gas concentration reaches 40% of the lower explosive limit, where the ventilating equipment or other means referred to in Item (ii) is provided;

(iv) automatically de-energize the electrical equipment being protected when the gas concentration reaches 20% of the lower explosive limit, where the ventilating equipment or other means referred to in Item (ii) cannot be provided; and

(v) automatically de-energize the electrical equipment being protected upon failure of the gas detection instrument.

The Code users should be aware that the relaxation to apply the less restrictive provisions for electrical equipment (i.e., equipment suitable for non-hazardous locations, when it is installed in Class I, Zone 2 location, etc.) by no means allows re-classification of the originally determined hazardous area.

Thus, if (as shown in example above), “the equipment suitable for non-hazardous area is allowed to be installed in Class I, Zone 2 hazardous location under conditions of Rule 18-070, the area of classification still remains Class I, Zone 2.”

However, as usual, all issues related to the electrical design and installations should be discussed with the local AHJs that administer the Canadian Electrical Code in the area of the intended design and installation.

Find Us on Socials