Perhaps the number one rule in advertising is for your advertisement to be seen. Thus, it is no surprise that electronic advertisements are placed wherever potential customers will come across them in spare moments. How many times have you found yourself a “target” customer held captive while filling your car with gasoline, watching the advertisements on the video screen above the gas pump? I think we have all found ourselves at such facilities, where electronic screens with audio, video, and control buttons provide “opportunities” for us to purchase additional items and services. However, unless you have wired, inspected or performed maintenance on these TV sets with gas pumps, you may not have considered that the circuits for these features are in addition to the traditional power and communications circuits used for the basic fueling activity and require in-depth review to ensure compliance with the electrical safety requirements in the NEC.

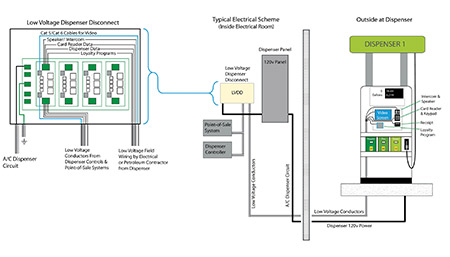

Figure 1. Block diagram of a Dispenser Disconnect System

Article 514 in the National Electric Code (NEC) provides requirements for the safe installation of wiring and equipment for Motor Fuel Dispensing Facilities. The article scope includes dispensing facilities for motor fuel, marine motor fuel, and fleet motor fuel. The NEC defines a motor fuel dispensing facility as follows:

514.2 Definition.

Motor Fuel Dispensing Facility. That portion of a property where motor fuels are stored and dispensed from fixed equipment into the fuel tanks of motor vehicles or marine craft or into approved containers, including all equipment used in connection therewith. [30A:3.3.11]

For installations falling into the scope and definition of a motor fuel dispensing facility, NEC 514.3, 514.4, 514.7, and 514.9 provide requirements for wiring and equipment based on the classification of the location. The requirements of NEC 514.11 and 514.13 are understood to provide emergency station control and maintenance and service capability of the dispensing equipment.

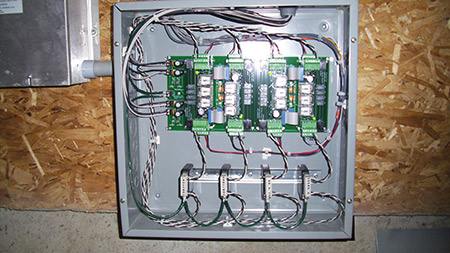

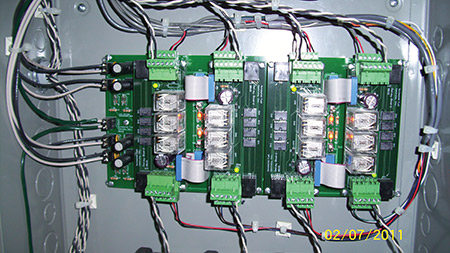

Figure 2. Practical LVDD products will provide Individual disconnects for multiple dispensers in a single package.

The fundamental safety element is removal of all potential electrical ignition sources, including all conductors for any circuits leading to or through dispensing equipment, including grounded conductors. This leads to questions about how the video, audio, and data circuits should be installed. In most cases, such systems are installed outside of the classified area but the circuits pass through the dispenser equipment. The NEC makes it clear that each dispensing device must be provided with a means to remove all external voltage sources, including power, communications, data and video circuits, and control during periods of maintenance and service of the dispensing equipment.

514.11 Circuit Disconnects.

(A) General. Each circuit leading to or through dispensing equipment, including all associated power, communications, data, and video circuits, and equipment for remote pumping systems, shall be provided with a clearly identified and readily accessible switch or other approved means, located remote

from the dispensing devices, to disconnect simultaneously from the source of supply, all conductors of the circuits, including the grounded conductor, if any.

Single-pole breakers utilizing handle ties shall not be permitted.

514.13 Provisions for Maintenance and Service of Dispensing Equipment. Each dispensing device shall be provided with a means to remove all external voltage sources, including power, communications, data, and video circuits and including feedback, during periods of maintenance and service of the dispensing equipment. The location of this means shall be permitted to be other than inside or adjacent to the dispensing device. The means shall be capable of being locked in the open position.

What do the disconnect systems look like?

From a functional block diagram standpoint, each dispenser at the station will have an ac circuit disconnect which removes all ac power, feedback/control, as well as communication and video circuit voltage. See figure 1. This is accomplished by using a low voltage dispenser disconnect (LVDD). Wiring from the station point of sale equipment and other low-voltage circuits are wired to the LVDD and then on to the dispenser. Since the LVDD is connected in series with these circuits, it will disconnect circuits for audio, video, card reader, loyalty program, and other communications circuits when the ac circuit disconnect for the dispenser is opened or when the emergency station control disconnect is activated. This approach ensures that circuits in the dispenser are de-energized, regardless of the site where the installation of uninterruptable power supply (UPS) or other battery back-up systems utilized for the low-voltage systems are provided. Functionally, this capability is expandable. Practical LVDD products will provide individual disconnects for multiple dispensers in a single package. See figures 2 & 3.

Summary

Meeting the NEC disconnect requirements at motor fuel dispensing facilities provides necessary safety for personnel and station equipment during maintenance and service activities. The current requirements in NEC 514.11 and 514.13 emphasize that the system low-voltage circuits are included and must be disconnected as well. A couple of key items for consideration:

Review the power and communication conductors that serve each pump to ensure there is a means to isolate them during maintenance of the pumps.

Figure 3. Practical LVDD products will provide individual disconnects for multiple dispensers in a single package.

Ensure the isolation means is connected to the emergency disconnecting system as well.

Providing a LVDD solution or other means to ensure that all voltage can be removed from the dispenser during this activity should be considered when reviewing these installations for code compliance. Maybe one day the gas station will redesign the drive-in theater so that we can catch a few minutes of the ball game on a 55″ TV while we fill’er-up.

Find Us on Socials