The Problem of Harmonics

Harmonics are generated by nonlinear components in electrical systems, which distort the sine wave. Increasing usage of power electronics causes a corresponding increase in voltage distortion, or harmonics. Electrical components like variable frequency drives, uninterruptible power supplies, and inverters all introduce harmonics of differing orders into the electrical system. When harmonics are present, they can manifest themselves with short-term and long-term consequences. High harmonic distortion can cause failures or malfunctions of electrical devices. Harmonics also cause a temperature rise in the electrical network and the equipment, resulting in losses and shorter service life. Harmonic filters will help to achieve a reduction or elimination of problematic harmonics, before any damage to the electrical system or equipment can occur.

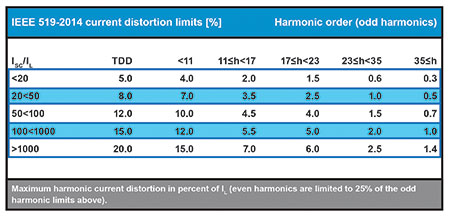

Figure 1. IEEE 519-2014 current distortion limits (%)

Electrical Power System, Harmonics Overview

In general, harmonic currents are the result of the non-linear behavior of electrical devices. The sources of harmonic currents and thus harmonic voltage in power systems are multiple and vary in size (a few KVA up to several MVA). Typically, devices with magnetic iron cores, like transformers or generators, have been a key area of harmonic concern. Today, with the demand for energy efficiency of power electronic equipment, mitigation or reduction of harmonics continues to be a priority for many commercial, industrial and industry-specific customers, such as water and wastewater treatment and oil & gas.

Numerous facilities need to meet stringent requirements in order to operate reliably and in an environmentally compliant manner. Users need to ensure the availability of the operations on a 24/7 schedule.

As the majority of electrical power supplied to the user comes from a utility source, that is, from the local utility company, most of the power problems experienced at the facility level are really derived from within the operation of the plant itself. Harmonics are commonly present within the facility power network and can present issues ranging from nuisance to catastrophic. Harmonic filtering, which can be accomplished with active or passive solutions, helps to eliminate the harmonic issues while enhancing equipment performance and the overall facility electrical power system.

IEEE-519-2014 is a widely recognized set of recommendations which includes the maximum permissible current and voltage distortion values at the point of common coupling (PCC). The distortion limit is given as a function of the system loading, i.e., the relationship between the maximum short-circuit current (ISC) and the maximum demand load current (IL) at the PCC.

When ECOsine® passive and active harmonic filters and reactors are installed in the electrical system, they will reduce the harmonics to meet the requirements of most International Standards. They unload lines and transformers upstream of the non-linear load (for example, a three-phase diode bridge rectifier) hence reducing the system overall losses and operating temperature. Additionally, the total power factor is significantly improved and will remain close to unity even at partial load.

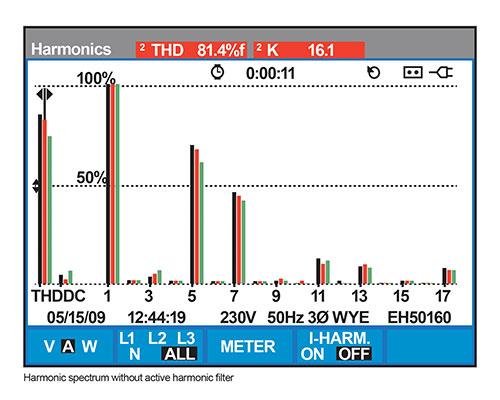

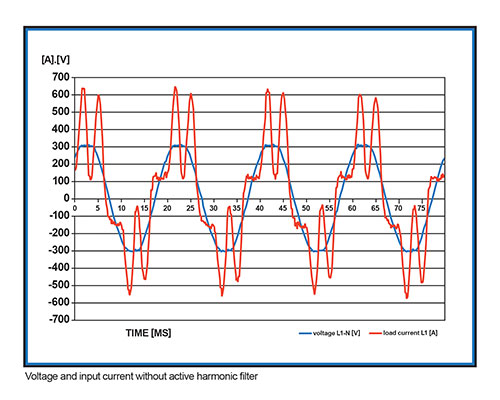

Figure 2. Harmonic spectrum without active filter

Figure 2A. Voltage and input current without active harmonic filter

Harmonics and Equipment

Frequency inverters are among the most widely used pieces of equipment for AC motor control. Such components are found in virtually every area of industry, in applications as diverse as pumps, fans, blowers, and even HVAC equipment. In the quest for ultra-compact, efficient power conversion, inverter manufacturers employ high speed semiconductor switching and pulse width modulation (PWM) techniques, which can create harmonic problems.

Arc furnaces and welders, including welding robotics, are usually very large power consuming applications. This high power, combined with a highly nonlinear voltage-current, produces substantial amounts of harmonic distortion. From a technical standpoint, arc furnaces operate in different phases (melting, air refining, refining) with different levels of harmonics. Additionally, the equipment has a combination of ignition delays and rapid voltage changes caused by random variations of the arc. This leads to an unusual harmonic spectrum with even and odd multiples of the fundamental frequency.

The electronic components within a CNC machine, for example, are particularly sensitive to “electrical imperfections” found in the power distribution system. Problems here can include malfunction of the equipment or program, along with damage to the parts and material. This can lead to missed deliveries and potential quality issues, unsatisfied customers and financial concerns for a company.

The use of variable speed drives for pumps and fans generates a harmonics content of the current in the supply that can lead to thermal overload of the electrical infrastructure and to malfunctions of sensitive equipment and components. In many water and wastewater treatment facilities, new biological stages working with bacteria are implemented. This leads to the installations of very powerful VFD-driven air compressors as bacteria need air to be able to do the job required. These VFDs are creating very high and unacceptable harmonic distortion.

Harmonics can wreak havoc on the electrical power network, causing circuit boards in PLCs to fail, tripped circuit breakers, blown fuses, overheating of motors and transformers, insulation breakdown, and reduced service life of equipment. Furthermore, production downtime/restart-time and shipment (revenue) loss, along with repair costs may result in reduced company profits.

A harmonic site survey (use of meters/analyzers) or a full engineering study may be necessary to completely determine existing harmonics (and other PQ issues), in order to provide a recommended solution to the user. In many, but not all cases, IEEE 519 (2014) guidelines are followed for the acceptable level of distortion. A complete review of the existing system, new/planned or retrofitted equipment along with any plant expansions should be considered.

Passive Harmonic Filters

One solution to mitigate harmonics would be to utilize passive harmonic filters. Such series-connected filters are typically installed “one-on-one,” in other words—one filter for each VFD. A larger passive filter can be designed to accommodate multiple drives, if required.

The most logical installation point at which to eliminate harmonics is right at the source-individual non-linear load. A passive filter provides a low impedance path for harmonic currents, required, as an example by a rectifier. This significantly reduces the amount of harmonics flowing throughout the electrical power system. The end result is the non-linear load drawing sinusoidal current from the power source/grid.

The installation of passive harmonic filters will be immediately beneficial to the electrical system, since they will help to limit the amplitudes of the current harmonics and thus reduce losses, and to operate equipment more efficiently and reliably. Additionally, they help to maximize utilization of the electric system capacity.

In a typical drive system, the total harmonic current distortion is reduced to acceptable limits and meeting IEEE 519 where applicable. Passive filters should be able to provide optimal performance at both full and lightly loaded conditions.

Passive filters can be found in two design types: 1) <5%THDi and 2) 7-10%THDi. Many times IEEE 519 is followed; however, there are applications where, say, 7 or 8% THDi improvement meet the needs of the end user. As a general “rule,” passive filters tend to be more economical than active filters, though they may not effectively mitigate a wide range of harmonic orders like active filters.

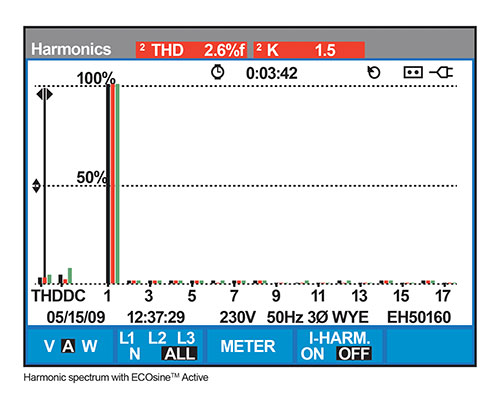

Figure 3. Harmonic spectrum with ECOsine TM Active

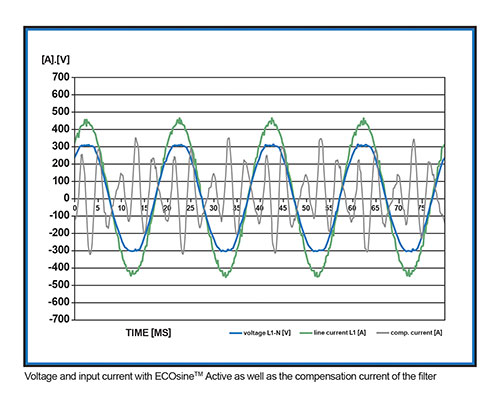

Figure 3a. Voltage and input current with ECOsine TM Active as well as the compensation current of the filter

Active Harmonic Filtering Solution

Another solution to mitigate harmonics is the use of active harmonic filters (AHF), power quality devices that permanently monitor the nonlinear load and dynamically provide precisely controlled current, helping to prevent distortion in a power network. This current has the same amplitude of the harmonic current but is injected in the opposite phase-shift, canceling out the harmonic currents in the electrical system. As a result, the current supplied by the power source will remain sinusoidal since the harmonics will negate each other, and the harmonic distortion is reduced to less than 5% THDi, meeting all standards. In addition, the AHF power electronics platform is designed to operate at levels that continuously adapt to rapid load variations. With load conditions creating harmonics up to the 50th order, active filters operate in a wide frequency range, adapting their operation to the resultant harmonic spectrum.

Active harmonic filters can also correct poor displacement power factor by compensating the system’s reactive current. The filter also balances the loads of the phases. These sophisticated devices are equipped with insulated gate bipolar transistors (IGBT) and digital signal processing (DSP) components. Generally, active harmonic filters can be installed at any point in a low-voltage AC network (parallel device), and they usually offer much more functionality than their passive filter counterparts.

Active harmonic filters combine these features with their small physical size and efficient operation, which makes them ideal choices for a wide variety of applications. Active filters can be provided for 3-wire or 4-wire connections (3-wire is the most common in North America). Current transformers deliver a signal to the filter, which can be applied to either the line or load side of the power network.

Active harmonics filters can be applied to a single or a group of nonlinear loads. Possible AHF installations include power factor correction in harmonic-rich environments in which filtering cannot be suitably achieved by the use of capacitors; where both power factor and harmonic correction are required; and where emergency power or distributed generation are present in the electrical network.

In general, active harmonic filters are available in several ratings. These ratings can include individual units for 50, 100, 200, 250 or 300 amperes. Different configurations such as open type, or various NEMA enclosure protection ratings and the ability to parallel multiple active filters, for higher current applications are typical. Installation voltages are mostly 480 vac and 600 vac. The 600 vac requirements can utilize a step-down (600/480 vac) transformer with the active harmonic filter, or use a “purpose built” active filter rated for 600/690 vac, where a transformer is not necessary. Active filters will include keypad controls and operator display communications such as RS485 and TCP/IP Ethernet, along with software for communications and monitoring through a Windows-based product.

Active filter is best utilized with 6-pulse VFDs. These VFD products are the most economical, highly common and readily available. One AHF can be used for multiple drives of any horsepower rating and any manufacturer. Drives of 18-pulse tend to have a much higher price point and, with its transformer, occupy more (valuable) space. Additionally, should an 18-pulse drive fail, it is “out of production,” whereas should an AHF fail or require service, the VFD continues to operate.

Where machinery and equipment are electronically controlled and need to meet exacting production standards, sensitive electronic components need to be protected from harmonics driven by the facility’s electrical power distribution system. The use of active harmonic filters can achieve the reliable functioning of the machinery and assure the process quality, while helping to support the financial bottom line.

Application Example with Active Filters

Power factor correction (PFC) equipment suffered from significant additional losses caused by harmonics. The installation of the AHF with a compensation current of 500 A brought the required electrical and thermal relief to the PFC, which considerably improved power quality and also made it possible for the installation of a backup generator in case of an outage. Adding the generator was previously impossible because of the prevalent harmonic content. The AHF’s unique capability to adapt to the situation of grid and load at any one time ideally helped to guarantee the continuous reliable operation of the wastewater treatment plant.

Where machinery and equipment are electronically controlled and need to meet exacting production standards, sensitive electronic components need to be protected from harmonics driven by the facility’s electrical power distribution system. The use of active harmonic filters can achieve the reliable functioning of the machinery and assure the process quality while helping to support the financial bottom line.

Final Comment

After harmonics have been identified and it’s determined a mitigation solution is required, the proper equipment selection will need to be reviewed and implemented. With the many problems associated with harmonics (equipment failure, replacement and maintenance costs, improper component or system operation, production downtime, etc.), it is suggested to keep records on these costs, to help with the ROI of any future mitigation equipment.

References:

- Schaffner Introduces Integrated Standard Active Harmonic, http://www.arisind.com/schaffner-introduces-integrated-standard-active-harmonic- (accessed September 17, 2015).

- Handling Harmonics – Canadian Industrial Machinery, http://www.cimindustry.com/article/management/handling-harmonics (accessed September 17, 2015).

- Brochure ECOsine passive mitigationEN – TRANSMISIONES, http://www.transmisiones.de/PDF/EcoSine_Pasive_EN.pdf (accessed September 17, 2015).

- Application Note Sine wave filter solutions for motor drive …, http://schaffner.com/en/downloads/file-download/file/sine-wave-filter-solutions- (accessed September 17, 2015).

Find Us on Socials