On August 1, 1998, at approximately 8 p.m., a fire occurred at a single storey, 2,400 sq. ft. log home in a rural area of Stouffville, Ontario. The log home was of main floor open concept design with three bedrooms and three bathrooms. It was originally built in 1964 making the home 34 years old at the time of the fire. The fire originated at the front area of the home directly above the front porch at the roof level. The fire traveled upwards along the frame of the roof line resulting in significant fire damage to half the roof and subsequent heat, smoke, and water damage throughout the home. The damages were estimated at $160,000 to the building and $40,000 damage to the contents.

BACKGROUND

For purposes of this article, we will refer to the original owner of the subject log home as Ms. A and the owner of the home at the time of the fire as Mr. B.

In late 1992, Ms. A faced some major roof repairs resulting from ice damage. The poorly insulated ceiling caused considerable snow melt on the roof and ice buildup at roof edges, resulting in damage to the roof overhangs. The damage was most severe over the large overhanging front porch of the home.

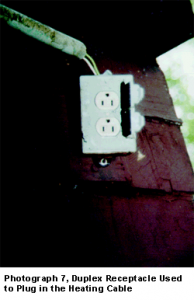

In October, 1992, Ms. A hired a contractor to replace the shingles over the damaged roof section at the front of the house, and a second contractor to install a 200 foot long, 120 VAC de-icing heating cable on the roof to prevent a recurrence. The heating cable was installed along the overhang and the eaves trough of the roof line at the front of the home. The front of the home faced southwest. No heating cable was installed on either sides or back of the house. A duplex receptacle was installed in the porch area nearest to the eaves trough, and a separate outdoor type switch was installed near the front door to control the receptacle. An additional duplex receptacle, also controlled by the switch, was installed near the front door. While the switch was not identified as to its function, surface mounted conduit used to route the wiring to both receptacles made it quite obvious that the switch controlled these receptacles. The power supply cord for the heating cable was plugged into the receptacle nearest the eaves trough. This particular circuit, protected by a 15 Amp circuit breaker, was shared with some auxiliary lighting exterior to the house.

In June, 1997, Mr. B, the owner of the home at the time of the fire, took possession. Mr. B bought the property and the home for its land potential and recognized that the log home needed some work.

Although the solid log home was well built 34 years ago, it had seen nothing more than obligatory repairs since then. Mr. B and his wife were aware of the outside circuit since it was used to control some external lights which were plugged into the receptacle near the door, but which they had chosen not to use. Therefore, the outdoor switch was usually left in the “off” position. Both Mr. B and his wife were unaware of the heating cable installed on their roof, even though the plug for the heating cable was clearly visible in the receptacle near the eaves trough. The manufacturer’s identification label was also attached to the cable power cord at the plug.

In late July, 1998, Mr. B hosted a children’s theater camp at his home. In preparation for the event, he needed power outside of the home to operate a portable hot tub (approximately 12 amp load). On Friday July 24th, 1998, Mr. B. plugged the hot tub into the receptacle near the door and turned it on, energizing the circuit. Since the heating cable was still connected to the second receptacle controlled by the switch, the total load on the circuit then exceeded 15 Amps. This caused the circuit breaker to trip about 20 minutes later. Mr. B. then removed the hot tub’s power supply cord from the receptacle and inserted it into another inside circuit via an electrical extension cord. Mr. B. also then reset the tripped circuit breaker.

The hot tub began to operate again without difficulty. However, Mr. B. did not return the switch to the “off” position, resulting in the heating cable remaining energized. The days following July 24, 1998, were hot and dry.

THE FIRE

On August 1, 1998, the day after the conclusion of the children’s theater camp hosted by Mr. B., the fire occurred. At approximately 8:15 p.m., Mr. B was outside, approximately 150 feet southwest of the house. He became alarmed by a nauseous smell that became more intense with time. It was described as “a smell similar to burning tires.” Mr. B investigated to see if the odour was emanating from his home. At that time, Mr. B’s daughter came out of the front door of the house. When Mr. B turned to talk to his daughter, he noticed smoke coming from the outside of the roof above the front porch eaves trough and down spout. He ran back toward the house and with a closer view, noticed a small flame above the eaves trough and smoke from a radius of approximately two feet coming from leaves on the roof. Within a couple of minutes, Mr. B brought a bucket of water and his garden hose to the front porch. The roof was too high for him to reach and suppress the fire. He threw the running hose onto the roof and proceeded to call 911, advising the fire department of a small fire on his roof that he was trying to bring under control.

During an interview with Mr. B, he explained the fire continued to spread in spite of the running water from the garden hose (There wasn’t much water pressure). Mr. B climbed up the T.V. tower at the northeast side of the home, and proceeded to the area of the fire. He noticed burnt and smoldering leaves one to two feet from the readily apparent flame. The leaves did not appear to be burning. Mr. B directed the garden hose to the base of the flame which appeared to have originated from inside the eaves trough, however the flame and the risk of falling off the roof, kept him at a distance.

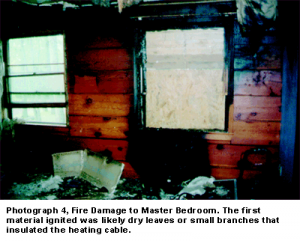

Mr. B called 911 a second time when it was apparent the fire was out of control. The flames extended 4-6 inches above the eaves trough. Minutes later, the flame burned through the fascia board of the roof and traveled into the roof and attic space. Mr. B could hear the draft of air being drawn by the fire into the roof and attic and observed smoke coming out of a roof vent nearby. He quickly alerted his family to evacuate the building. Mrs. B shut off the main power switch of the electrical breaker panel on her way out. The master bedroom, immediately adjacent to where the fire started, also caught fire. The newly installed security system, including smoke and rate of rise heat detectors, began to alarm shortly after the bedroom caught fire. By the time the fire department arrived, the roof was fully engulfed in flames. It took more than 30 minutes to put the fire out. There were no injuries.

INVESTIGATION

Investigation based on fire damage and burn patterns revealed the area of fire origin to be at the roof level, adjacent to the eaves trough, directly above the front porch.

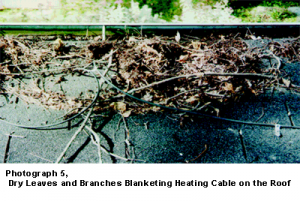

The eaves trough was made of metal with a plastic leaf screen. The top of the roof over the eaves trough, where the heating cable was installed, was blanketed with a few inches of dry leaves and small broken twigs and branches. The fire traveled upwards along the frame of the roof line. However, in addition to the fire damage to the roof, the master bedroom and adjacent bedrooms sustained severe heat and fire damage as a result of drop burning.

The heating cable was installed along a 38 foot length of the front roof line, southwest side of the home. There was no heating cable installed on either sides or back of the home. Approximately 29 feet of the front, southwest roof line was occupied by heating cable which was intact. This 29 foot length of roof occupied approximately 83 feet of heating cable which appeared to be properly installed. However, not including the length of heating cable running through the down spout, the remaining 9 foot length of roof (38-29) in the area of fire origin, occupied the remaining 78 feet of heating cable. The entire length of heating cable measured 200 feet long. There was no evidence to suggest that the remaining 78 feet of heating cable on the roof, in the area of fire origin, was correctly installed. Examination of and sifting through fire debris revealed no evidence of mounting clips used for securing the heating cable to the roof shingles. Furthermore, there was only 9 feet of roof line remaining to install 78 feet of heating cable. Based on the roof construction, it appeared the entire remaining length of heating cable was applied to the 9 foot section of roof directly above the front porch, an amount of cable in excess of what should have been applied to this area.

Electrical continuity testing confirmed that the duplex receptacle the heating cable was plugged into was operated by the remote switch mounted on the exterior wall. There was no identification on the switch indicating it operated heating cable installed on the roof. In an interview with Mr. B, he confirmed the exterior wall mounted switch was on and the heating cable was plugged into the duplex receptacle at the time of the fire.

CONCLUSION / RECOMMENDATIONS

The installation of the heating cable was not in compliance with the manufacturer’s instructions, however it was used on a metal eaves trough as recommended.

Information provided by the owner revealed the heating cable installation was unknown by him as he was not notified of the heating cable by the previous owner. Not knowing what the problem was at the time the circuit breaker tripped while operating the portable hot tub, Mr. B re-set the circuit breaker and plugged in his hot tub to another receptacle. The switch he turned on, remained on for eight days, effectively energizing the heating cable for the eight days prior to the fire. If the owner had known what the switch was operating, he likely wouldn’t have left it on. The combination of a dry warm summer, and dry combustible leaves and branches blanketed over the electrical heating cable, coupled with the poor installation and the accidental energizing of the heating cable switch, are the most likely cause of this fire.

As a result of the subject fire, the CSA International, Audits and Investigations Department at the Canadian Standards Association reviewed its computer data base and confirmed this type of incident was the first of its kind. However, a recommendation was forwarded to the sub-committee responsible for CSA International Standard CAN/CSA-C22.2 No. 130.2-93 – “Heat Cable Systems for Use in Other Than Industrial Establishments” to review this information and consider implementing amendments to the referenced standard to prevent a fire recurrence.

The recommendation is currently being reviewed by the sub-committee for action as deemed necessary.

Use and Care of Heating Cables

At least part of the reason for this fire was the improper use and care of the heating cable installation. The build-up of leaves and twigs on the heating cable thermally insulated it and may have led to overheating. Heating cable manufacturers recommend that cables be checked annually to ensure they are in proper working order and capable of performing as expected. Certainly, leaves covering a roof de-icing cable will impede the proper operation of the cables, as heat from the cables will be insulated by the debris, thereby allowing ice to form above the leaves.

Similarly, pipe freeze protection cables must be inspected annually for proper operation and installation. If insulation surrounding pipe heating cables has deteriorated, or if the cable has been damaged in any way, the installation should be disconnected.

If a heating cable, or any other electrical device, is connected to a ground fault protected circuit/receptacle, and the ground fault device trips when the heating cable is connected, the heating cable likely has been damaged and must be removed from service.

It is also important for new homeowners to fully familiarize themselves, not only with any heating cables, but with all electrical devices which may be installed on or in the home. If a new homeowner is unsure about any such electrical devices, a qualified electrician should be consulted for appropriate advice. Similarly, the previous homeowner, or the homeowner’s agent/seller, should also ensure the operation of any non-standard electrical items, such as heating cables and saunas, is appropriately communicated to the new homeowner.

Ground Fault Protection for Heating Cables

The 1998 version of the Canadian Electrical Code Part 1 (CEC), Rule 62-300, provides requirements for ground fault protection for fixed heating cable installations, including those heating systems for melting snow and ice on roofs. In addition, most manufacturers strongly recommend the use of such a device with their products. Most outdoor receptacles on houses constructed since about 1980 contain ground fault devices, which will help to prevent damaged heating cables from being energized. Note, however, that overheating caused by improper heating cable maintenance will not necessarily be prevented by ground fault protection devices, as likely evidenced by this fire. Furthermore, homes built prior to about 1980 may not contain any ground fault protection devices. For these situations, some heating cable companies offer a convenient, economical plug-in ground fault protection device, which can easily be connected by the homeowner (just plugs in to existing receptacle).

Electrical Fire Reporting System

The forwarding of information to CSA International regarding fires involving CSA certified electrical products aids in the facilitation of improving Canadian Standards. Even though fires are reported to a fire department or fire marshal, and the most likely cause of the fire identified and documented, these reports do not always get forwarded to CSA International. This was the case with the fire described in this article, where CSA International were only notified of this fire by a letter from the homeowner written directly to CSA International concerned about how this fire could have happened. It is important that all fires involving electrical products be reported to CSA International’s Audits and Investigations Department. This will ensure that incidents such as this one are properly investigated and documented in the Audits and Investigations computer data base.

Find Us on Socials