Fire stop requirements have become a source of concern lately among the stakeholders of electrical safety (among the electrical designers, contractors, and electrical safety regulators).

A puzzled reader might ask, “What is the problem, and why now?”

Let me elaborate a step-by-step.

The Canadian Electrical Code, Part I (CE Code) states the following in Rule 2-128:

“2-128 Fire spread (see Appendices B and G)

1) Electrical installations shall be made so that the probability of spread of fire through firestopped partitions, floors, hollow spaces, firewalls or fire partitions, vertical shafts, or ventilating or air conditioning ducts is reduced to a minimum.

2) Where a fire separation is pierced by a raceway or cable, any openings around the raceway or cable shall be properly closed or sealed in compliance with the National Building Code of Canada.”

Clarification Note of Appendix B offers the following explanation of this building code requirement:

“Appendix B Note on Rule 2-128

Specific requirements pertaining to penetration of fire separations in buildings can be found in Subsections 3.1.7 and 3.1.9 of the National Building Code of Canada or in the appropriate provincial/territorial legislation. “

This CE Code requirement means that when a raceway or a cable completely penetrates a required fire separation (i.e. penetrates an assembly required to have a fire-resistance rating), then an electrical contractor must ensure that any openings around the raceway or cable in this fire-rated assembly, are properly closed or sealed at the penetration by a fire stop that complies with the applicable provisions of the National Building Code (NBC).

Appendix G of the CE Code provides a cross-reference between applicable provisions of the CE Code and relevant requirements of the NBC. Scope of Appendix G of the CE Code states the following:

“Appendix G — Electrical installations of fire protection systems

Note: This Appendix is an informative (non-mandatory) part of this Standard.

G1 Introduction

G1.1

This Appendix lists requirements related to electrical installations that are not governed by Rules of the Canadian Electrical Code, Part I but are required by the National Building Code of Canada.

G1.2

References listed in this Appendix are associated with electrical installations that are a part of the fire protection requirements contained in the National Building Code of Canada.

G2 Application

G2.1

The intent of this Appendix is to advise Canadian Electrical Code, Part I users of performance requirements for electrically connected fire-protective equipment required by the National Building Code of Canada.

G2.2

Special fire protection requirements, such as use of thermal insulation, fire spread, flame spread requirements for electrical wiring and cables, flame-spread requirements for combustible raceways, and construction of electrical equipment vaults are covered by this Code (e.g., Rules 2-126, 2-128, 2-130, 2-132, 26-354, etc.).

G2.3

Provincial and municipal building codes may deviate from the National Building Code of Canada, and users of this list should also check those codes.“

Rule 2-128 of the CE Code is cross-referenced with the appropriate NBC requirement as follows:

| CE Code Sections and Rules | NBCC Sections, Articles and Sentences (unless otherwise stated, references refer to Division B of the NBCC) |

| Rule 2-128 | 3.1.9.1.(1) and (2), Fire stopping of service penetration through fire-rated assembles or fire separations |

Let’s now review what requirements are mandated by Article 3.1.9.1. of the NBC.

These relevant requirements are shown below as follows:

“3.1.9.1. Fire Stops

1) Except as provided in Sentences (2) to (5) and Article 3.1.9.4., penetrations of a fire separation or a membrane forming part of an assembly required to have a fire-resistance rating shall be

-

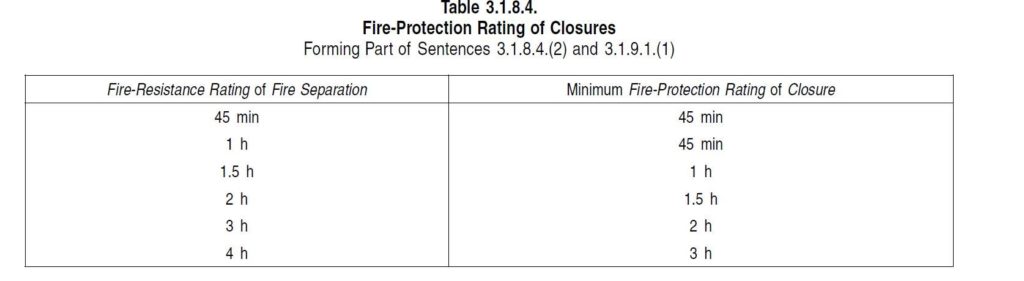

- a) sealed by a fire stop that, when subjected to the fire test method in CAN/ULC-S115, “Fire Tests of Firestop Systems,” has an F rating not less than the fire-protection rating required for closures in the fire separation in conformance with Table 3.1.8.4.,

2) Penetrations of a firewall or a horizontal fire separation that is required to have a fire-resistance rating in conformance with Article 3.2.1.2. shall be sealed at the penetration by a fire stop that, when subjected to the fire test method in CAN/ULC-S115, “Fire Tests of Firestop Systems,” has an FT rating not less than the fire-resistance rating for the fire separation.

3) Penetrations of a fire separation in conformance with Sentence 3.6.4.2.(2) shall be sealed by a fire stop that, when subjected to the fire test method in CAN/ULC-S115, “Fire Tests of Firestop Systems,” has an FT rating not less than the fire-resistance rating for the fire separation of the assembly.“

Let’s try to interpret these NBC requirements for the electrical safety stakeholders.

Sentence 3.1.9.1.(1)(a) above means that a fire stop around a cable or raceways that penetrates a fire separation must have a fire-resistance rating (when subjected to the fire test method in CAN/ULC-S115, “Fire Tests of Firestop Systems,”) not less than the rating of the closures indicated in Table 3.1.8.4.

Building code experts (architects or fire protection consultants) would have to advise a tradesperson who will apply fire stops around raceways or cables what fire-resistance rating of a fire separation is required. This tradesperson will also apply such a fire stop, which will have fire-resistance rating appropriate for the closure in such fire separation.

Sentence 3.1.9.1.(2) above means that a fire stop around a cable or raceway that penetrates a firewall or a horizontal fire separation, which is required to have a fire-resistance rating in conformance with Article 3.2.1.2. (see below) must (when subjected to the fire test method in CAN/ULC-S115, “Fire Tests of Firestop Systems,”) have a rating not less than the fire-resistance rating for that fire separation.

Article 3.2.1.2. applies to fire separations required for an attached storage garage when such a storage garage is considered as a separate building. And again, building code experts (architects or fire protection consultants) would have to advise a tradesperson who will apply fire stops around raceways or cables – what fire-resistance rating of a fire separation is required in this particular case, and this tradesperson will apply such fire stop which will have an appropriate fire-resistance rating.

Sentence 3.1.9.1.(3) applies to fire separations for horizontal service spaces. And as was indicated earlier, building code experts (architects or fire protection consultants) would have to advise a tradesperson who will apply fire stops around raceways or cables – what fire-resistance rating of a fire separation required for horizontal service spaces, and this tradesperson will apply such fire stop which will have an appropriate fire-resistance rating.

The most important aspect of this exercise is to understand that the electrical contractor does not have to know these intricacies. The electrical practitioner would only hire a certified fire stop tradesperson, who would obtain relevant information on the required fire-resistance rating of the fire stop used to seal openings around cables or raceways that penetrated applicable fire-rated assemblies.

Hopefully, so far – so good. But what about metal enclosures of electrical equipment (panelboards, emergency phones, luminaires, outlet boxes, etc.) which do not completely penetrate a fire-rated assembly, but are installed recessed in such fire-rated assembly?

Article 3.1.9.2. of the NBC appears to address such recessed installations of electrical equipment as follows:

“3.1.9.2. Combustibility of Service Penetrations

Except as permitted by Articles 3.1.9.3. and 3.1.9.5., pipes, ducts, electrical outlet boxes, totally enclosed raceways or other similar service equipment that penetrate an assembly required to have a fire-resistance rating shall be noncombustible, unless the assembly was tested incorporating that service equipment“

So, while this NBC requirement states that such non-combustible panelboards, emergency phones, luminaires, outlet boxes, etc., intended for recessed installation in fire-rated assemblies, are permitted to be installed in fire-rated assemblies, this requirement is silent whether the fire stops mandated by Article 3.1.9.1. are necessary, since these recessed metal enclosures do not completely penetrate such fire protection assemblies, and in such installations, there will be no openings through which fire can move across a fire separation.

It is interesting to note that Clause 5.11.3 of the CSA safety standard for electrical products “General requirements” states that metal enclosures of electrical equipment are deemed to be non-combustible for the purpose of Article 3.1.9.2. of the NBCC (see below):

“5.11.3

Where electrical equipment is installed in an aluminum, iron or steel enclosure that is in accordance with a safety Standard listed in Appendix A of the CE Code Part I, such enclosures are deemed to be non-combustible for the purpose of article 3.1.9.2. of the National Building Code of Canada. Note: Individual Technical Committees may define additional criteria for determining non-combustibility of material(s), as it may be deemed appropriate for specific products or product categories”.

It should also be noted that Sentence (5) of the NBC Article 3.1.9.3. “Penetration by Wires, Cables and Outlet Boxes” states the following in respect to combustible (non-metallic) outlet boxes:

“(5) Combustible outlet boxes are permitted in an assembly required to have a fire-resistance rating without being incorporated in the assembly at the time of testing as required by Article 3.1.9.2., provided the opening through the membrane into the box is not more than 0.016 m2.“

So, it appears from this NBC permission that even combustible (non-metallic) boxes are allowed to be used for recessed installations in fire-rated assemblies if openings required for these outlet boxes don’t exceed 0.016m2, but it is not clear whether these boxes are allowed to be installed without fire stops.

Clarity in this regard is provided by the new Article 3.1.9.4. of the NBC (an article added in the NBC 2015).

This newly added NBC article states as follows:

“3.1.9.4. Penetration by Outlet Boxes

1) Except as provided in Sentence (2), outlet boxes are permitted to penetrate the membrane of an assembly required to have a fire-resistance rating, provided they are sealed at the penetration by a fire stop that has an FT rating not less than the fire-resistance rating of the fire separation when subjected to the fire test method in CAN/ULC-S115, “Fire Tests of Firestop Systems.”

2) Except as provided in Sentences 3.1.9.1.(2) and (3), noncombustible outlet boxes that penetrate a vertical fire separation or a membrane forming part of an assembly required to have a fire-resistance rating are permitted to be waived, provided

-

- a) they do not exceed

- i) 0.016 m2 in area, and

- ii) an aggregate area of 0.065 m2 in any 9.3 m2 of surface area,

and

-

- b) the annular space between the membrane and the noncombustible electrical outlet boxes does not exceed 3 mm.“

So, now it is clear that only non-combustible (metal) boxes that do not exceed conditions (i), (ii) and (b) indicated above, are allowed to be installed recessed in a fire-rated assembly without fire stops.

This fact drastically complicates the installation of recessed electrical equipment in fire-rated assemblies, as use of fire stops around such recessed electrical equipment does not appear to be logical since such equipment does not fully penetrate a fire rated assembly.

Therefore, this subject should always be discussed by the electrical designers and contractors with the building code experts (with architects of fire protection consultants), as electrical safety regulators may not have expertise in this specific area.

Find Us on Socials