In this article, let us review issues concerning induced current flow in the metallic coverings of single-conductor cables. Single-conductor cables have some advantages over multi-conductor cables, especially in larger sizes. Tables 1 and 3 of the Canadian Electrical Code allow us to use smaller wire sizes for single-conductor cables than Tables 2 and 4 for multi-conductor cables. Naturally, the smaller cables are always easier to handle and install than the larger, heavier ones.

Despite these valid advantages, single-conductor metal sheathed and armoured cables come with some special problems in the form of sheath currents and eddy currents. And Rules 4-008 and 12-3024 provide solutions for overcoming the overheating problems thus created.

Sheath currents (also known as circulating currents) flow in the metal sheaths or armour of single conductor cables. They are induced by the AC magnetic fields surrounding each circuit conductor. Metallic sheaths and armour of cables are often bonded to equipment at both ends, providing a closed circuit path through metal cabinets, bonding conductors and other metallic paths when sheath currents are permitted to flow.

The induced sheath current flow causes temperature rise in metal sheaths or armour of single-conductor cables. Heat is transferred to the cable insulation with harmful effects. And unless cable loadings are reduced or the sheath currents are prevented by other means, insulation temperature ratings may be exceeded resulting in premature cable failures.

The Canadian Electrical Code recognizes this problem and provides several possible solutions to avoid sheath currents and their associated problems. Rule 4-008 specifies the following for single-conductor metal-sheathed or armoured cables when electrical loads exceed 425 amperes:

- Derating the single-conductor cables to 70 percent of the minimum conductor ampacities permitted in Tables 1 or 3; or

- With an inspector’s permission, derating the cables according to the cable manufacturer’s recommendation; or

- Isolating the metallic sheath or armour from ground at one end of the cable by entering electrical equipment through a non-metallic plate with separate bonding added to re-establish electrical continuity between equipment.

To ensure that metallic sheaths or armour are isolated from grounded metal, cables must have non-metallic jackets to ensure that sheath currents are not permitted to flow due to contact with ground-fault return paths such as cable trays, racks or structural steel.

The same magnetic fields that surround single-conductor cables also produce eddy currents in the steel enclosures which completely surround the cables. Eddy currents can overheat iron or steel cabinets, locknuts or bushings or any ferrous metal that completely encircles the single-conductor cables. This pre-sents no problem in multi-conductor cables, where the magnetic fields tend to cancel each other.

Rule 12-3024(7) and (8) of the Canadian Electrical Code provides a solution to prevent harmful eddy current heating effects:

- For loads up to 200 amperes, no special precautions are required;

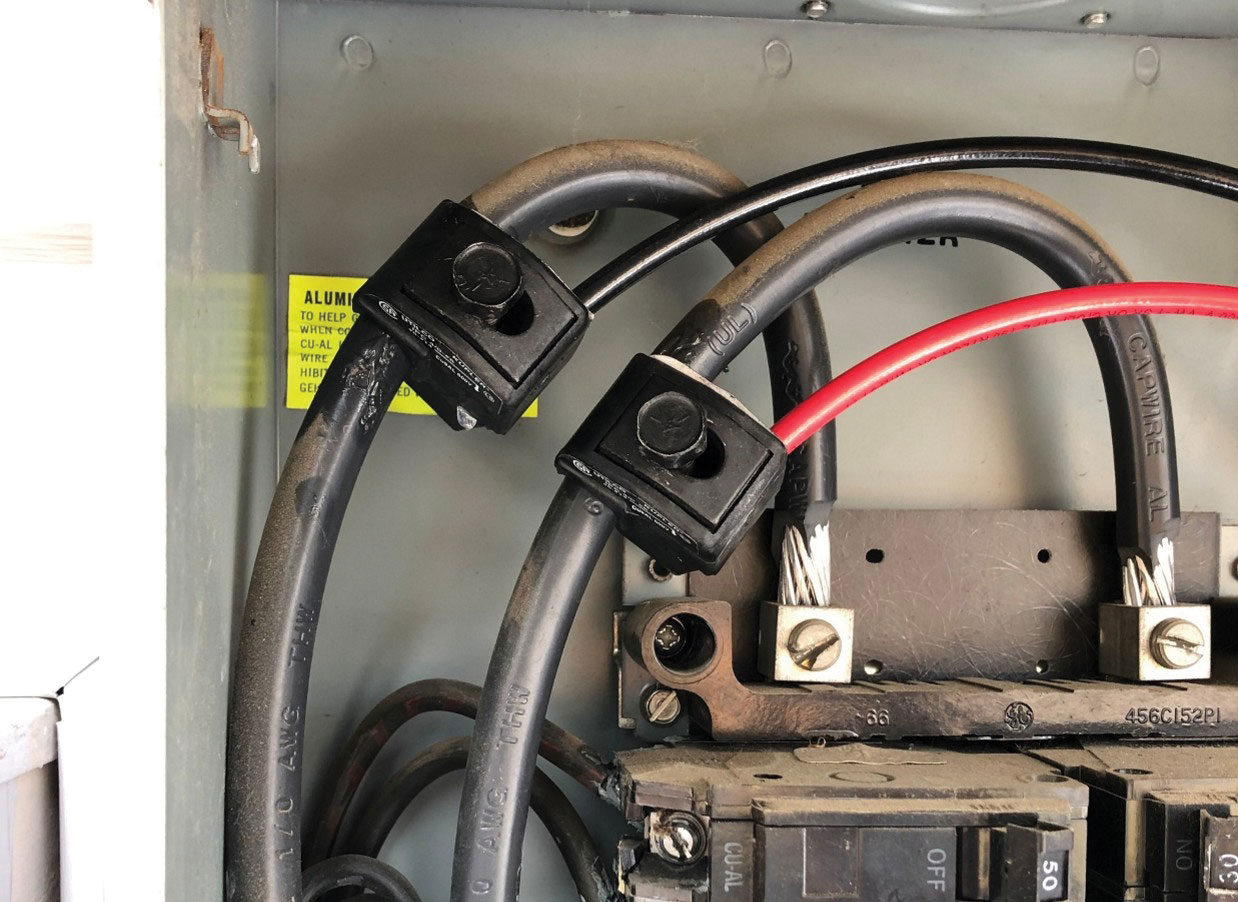

- For loads over 200 amperes, cables must enter all metal enclosures through a non-ferrous plate (normally aluminum), and any connectors, bushings, etc., that completely surround the conductors must be of non-ferrous materials.

At one time, slotting the wall of an electrical equipment enclosure between the cable openings was considered an acceptable way to reduce the effects of eddy currents. This is no longer desirable, since equipment enclosures may fail when weakened by slotting.

Heavier electrical loads often involve both sheath current and eddy currents. In this case, Rules 4-008 and 12-3024 for single-conductor cables can be summarized as follows:

- For loads up to 200 amperes, no special measures are required by the electrical code;

- For loads over 200 amperes, cables must enter electrical equipment through non-ferrous plates and all locknuts, bushings, etc., must be of non-ferrous materials;

- For loads over 425 amperes, single-conductor cables may be derated; or

1. Cable sheaths, armour and concentric bonding wires are bonded to ground, and cables enter the equipment through a non-ferrous plate, usually at the supply end; and

2. Cables enter electrical equipment at the load end through a non-metallic plate; and

3. All metal hardware encircling the cables is non-ferrous metal; and

4. Cable armour, sheaths and concentric bonding conductors are isolated from ground by cable jackets, taping, etc.; and

5. The bonding continuity between electrical equipment is re-established by a separate bonding conductor sized to the minimum requirements of Table 16.

As usual, you should consult the electrical inspection authority in each province or territory as applicable for a more precise interpretation of any of the above.

Find Us on Socials