The answer to this question is yes and no. That sounds like an answer from an inspector, doesn’t it? Yes, it is just a large container of water, but when you mix electrical equipment, such as pumps, heaters, and lighting with this large container of water, there can be problems. Article 680 addresses “…all swimming, wading, therapeutic, and decorative pools; fountains; hot tubs; spas; and hydromassage bathtubs, whether permanently installed or storable…” (680.1 Scope).

Pools are pools, why keep changing the Code?

Photo 1. Typical forming shells used for underwater lighting being bonded to the equipotential bonding grid. Ground clamp used in this fashion needs to be listed for direct burial.

I have been around the construction business my whole life, beginning as the son of a general contractor, then as a journeyman electrician, and for the last twenty years as an inspector and a plan check engineer. During this time, I have observed many changes within the industry. New methods and materials are continually being developed and used in all types of construction.

The construction of swimming pools is no different. Most people understand the obvious dangers involved with a swimming pool. In the Phoenix metro area, there were around 52 fatal drowning incidents in residential backyard pools this past year. Fire Departments continue to preach the need for pool fencing and other safety measures to keep small children away from pools and for adults to supervise children around pools. Most cities have adopted very strict pool fencing ordinances that require fences, self-closing gates and doors, alarms on doors and windows or pool covers. Of all the public service announcements on pool safety every year, I have yet to hear one that addresses electrical safety. Most pool owners take it for granted that their pool is safe from electrical hazards. I imagine they are not concerned about their pool’s safety, since there are not as many newspaper articles that document deaths or injuries directly attributed to electrical problems. I would like to think that the low numbers of these accidents are because of the electrical installation requirements of theNECand good inspection practices.

In this article, we will discuss some new materials and practices currently being used for pool construction. How do we keep up with all of these changes and make sure that the pools we inspect are electrically safe? First, we need to keep up on Code changes by attending code update classes conducted by IAEI. Second, we also need to adopt the most current edition of theNECavailable; and, third, we need an understanding of the problems related to electrical hazards around pools. In the 2005NECamendment process, there was a rewrite of the bonding requirements for pools in NEC 680.26, but even with our best efforts, the re-write was hard to understand, so a tentative interim amendment (TIA) was issued to clarify the requirements of this section. If you have adoptedNEC-2005, you need to get a copy of NFPA 70, TIA 05-2 to understand this section clearly. InNEC-2008, the language was tweaked even further to address additional testing data and to zero in on the whole intent of this section.

How are pools different today?

Photo 2. Gunnite (concrete) permanently installed pool with concrete deck using bare structural steel reinforcing embedded within the concrete. The belly and deck steel will serve as the equipotential bonding grid.

When I first started as electrician about thirty years ago, pools were built pretty much the same way. Usually, they consisted of gunnite (concrete) walls, concrete Kool Deck that used bare structural steel reinforcing embedded within the concrete. The reinforcing steel usually consisted of #3 (3/8″) rebars spaced at 12″ on center, both horizontally and vertically, around the shell of the pool and extended from the pool wall into the deck surface. They usually had a filter, chlorination system, and lights with metal light niches; sometimes they included a gas heater, diving board or a slide.

Pools are now being designed and built for salt-water use or with salt-based chlorination systems, which can corrode the bare reinforcing steel embedded within the concrete. Lighting is now being provided using fiber optic lighting systems or low-voltage lighting systems. Kool Decks are sometimes made of pavers or stone without reinforcing steel. The steel used within the pool walls is not always being tied into the Kool Deck reinforcing in order to address expansive soil conditions. Pools shells and Kool Decks are also being built out of fiberglass reinforced concrete that has no steel reinforcement, or the steel reinforcing is epoxy coated to address corrosive environments. We have been discussing conductive pool shells and decks so far, but pools are also being built completely out of fiberglass, or pool shells have vinyl liners over the structure itself.

What are the requirements of Article 680 that address these new types of installation?

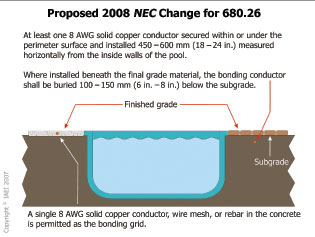

Figure 1. The above is a slide from the upcoming Analysis of Changes NEC-2008. The Code is consistently evolving to encompass the latest methods and materials to provide the safest environment possible for users of such things as swimming pools. This sect

There have been many reports of stray currents being felt by swimmers in pools. These stray currents can come from many sources; some are from faulty wiring or equipment around pools, and others are currents caused because of a failure of current-carrying conductors in the utility service laterals. No matter what the cause of these stray currents, they need to be safely handled to keep swimmers from becoming grounding conductors themselves.

InNEC-2005, the bonding requirements of Article 680 were expanded, and equipotential bonding was introduced in Section 680.26. In 680.26(A), there is an explanation as to what the intent of this bonding system is. Its purpose is “to eliminate voltage gradients in the pool area”; it is not designed to eliminate current flow, but to control it.

NEC 680.26 addresses this by creating an equipotential bonding system within and around the pool area. This system as required in 680.26(B) includes the bonding of metallic structural components of the pool and deck. This requires all of the metal structural steel within the pool shell, coping stones, and deck to be bonded together using approved connections. This section also requires that if reinforcing steel “is encapsulated with a nonconductive compound,” such as epoxy-coated rebar, “an alternate means to eliminate voltage gradients” is to be provided. This alternate means is specified in Section 680.26(C)(3). Article 680.26 also requires that forming shells used for underwater lighting, certain metal fittings, all metal within 5′ of the pool, and electrical equipment associated with the pool be bonded together using a #8 copper conductor and approved connectors. All lugs or connectors need to be listed for their application. When a connector is buried within concrete or underground, it needs to be listed for concrete encasement or for direct burial.

In Article 680.26(C), the equipotential bonding grid is outlined. In order to understand this section better, remember to refer to TIA 05-2, which was approved to add clarity. This section requires that an equipotential bonding grid be established under or within the bottom and sides of the pool shell and also extend 36″” from the walls of the pool within or under paved walking surfaces of the pool deck. The TIA eliminates the requirement for the equipotential bonding grid being installed behind the walls and bottom of a pool made completely of fiberglass or a pool that is completely lined with a vinyl polymer.

Section 680.26(C)(1) requires that the bare structural reinforcing steel of the pool structure be bonded as required by 680.26(B)(1) and requires this steel to be bonded to the deck reinforcing steel using a #8 copper conductor. Section 680.26(C)(2) requires the walls of a metal pool to be part of the equipotential bonding grid. Section 680.26(C)(3) addresses the alternate means of bonding required when structural steel is not used in the pool structure or deck or when the structural steel is encapsulated with a nonconductive compound. This alternate system requires a grid of bare #8 AWG wire to be installed within or under the pool shell and to extend 36″ beyond the pool walls under the deck. This grid is laid out in a 12″ by 12″ pattern, similar to the pattern usually required for reinforcing steel.

Conclusion

If we do not adopt and enforce the latest electrical codes that address these new materials and practices, incidents of electrical accidents may increase in the future. Pools are now being constructed differently and require the NEC to keep up with these new methods and materials and to require electrical installations that are safe. If you are under an NEC edition older than 2005 and an alternate material or method is proposed for pool construction that would pose a problem addressed by NEC-2005 requirements, you may wish to stipulate the requirements of NEC-2005, Article 680, in the letter of modification approved for using these alternate methods and materials, as allowed in the building code.

We all need to keep up with the changing times and the new methods of construction that are being developed. In order to keep up, the NEC is updated at least every three years, and even with this three-year-cycle it seems like we are always behind the new technology being developed. Having participated in the 2008 NEC Report on Proposals (ROP) and Report on Comments (ROC) processes, I can just say that changes are still on the way for this section, not only to clarify the code language but also to address new problems presented during this new cycle.

Find Us on Socials