Customers have expressed concerns about products entering the market that do not always comply with existing standards. We have prepared this document to address these concerns.

The listing mark from Underwriters Laboratories (UL), or any other nationally recognized testing laboratory (NRTL), is considered an industry stamp of approval. While UL has a good follow-up program to monitor the performance of listed products on an ongoing basis to ensure compliance and to identify any unscrupulous activity, UL — or any other NRTL — is tremendously challenged to perform this task in today’s global market. Further, each NRTL has its own follow-up procedures and practices to monitor the performance of its listed products. Deviations in these practices among the NRTLs could also affect their practices to list and monitor the listing for a given product. So, what should designers and installers do to ensure that the products specified, purchased and installed on their projects comply with the law and the spirit of the UL Mark?

The answer lies in the adage, “Knowledge is power.” One needs to understand the details: What requirements are met to earn the listing mark? Who holds the mark? When and where is it applied on the product? What other assurances or supportive information are provided by the holder of the mark? These and other relevant details can help the user to make more judicious decisions.

An informed user is a better customer for any reputable manufacturer. In that spirit, the following details are provided here for Type XHHW-2 conductors. Similar details can be prepared for any other listed product.

UL File Number

UL assigns a unique file number to each manufacturer that has the listing for Type XHHW-2 product. (Alcan Cable is assigned the file number E39406, and it covers Types RHH, RHW, RHW-2, XHHW and XHHW-2 conductors.)

The UL File Number is assigned to the manufacturer. The manufacturer also is required to identify the location where the product was manufactured in the print legend on the product and package. Because these details can be abbreviated and are not made public by UL for each file number, the user may assume that the product is manufactured where the manufacturer associated with the file number is based. Hence, the responsible user should verify the product’s abbreviation mark with the manufacturer to confirm that its manufacturing location meets the project owner’s requirements. Typically, public projects and some private projects require the product be manufactured in permitted locations only.

Conductor Material

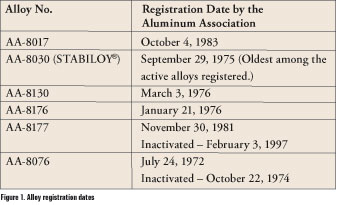

It has to be the recognized AA-8000 Series aluminum alloy conductor material per NEC 310.14. (Example: AA-8030 with brand name STABILOY® is used by Alcan Cable.) The Aluminum Association Inc. has recognized the numbers in figure 1.

Figure 1. Alloy registration dates

Conductor Properties

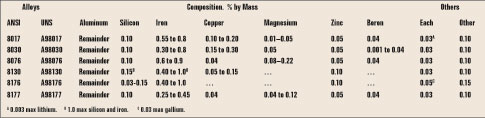

Alloy chemistry of these AA-8000 series aluminum alloys and the manufacturing processes affect the physical properties (conductivity, tensile strength, elongation, etc.) of the conductor. Table 2 of ASTM B 800 Standard Specification for 8000 Series Aluminum Alloy Wire for Electrical Purposes – Annealed and Intermediate Tempers provides the details about the chemical composition for these alloys (see figure 2).

Minimum elongation of 10 percent for the conductor is critical as is the maintenance of both tensile strength (18,675 +/- 4,425 psi) and conductivity (maximum resistance specified in the UL Standard for each size) within specified limits, which differentiates AA-8000 series aluminum alloy conductors from other alloys.

For reliability of connections with STABILOY conductors see: Ganatra, R. and McKoon, T. “Reliability of Connections: A Comparison of Aluminum Alloy Stranded Conductors and Electrically Equivalent Copper Conductors.” Wire Journal International 31:77, Wire Journal, 1998, pp. 112-123.

Insulation Properties

Type XHHW-2 designation is recognized in Table 310.13 of theNEC. The physical, electrical and flame or fire test requirements are evaluated in accordance with UL 44 theStandard for Thermoset-Insulated Wire and Cables.

Figure 2. Alloy compositions

The physical properties of the insulation that are evaluated for listing and ongoing follow-up by UL include tensile strength, elongation, thermal aging performance, cross-linking characteristics, sunlight resistant capability, cold temperature bending and impact test performance, etc. Collectively these tests provide an assessment of required mechanical properties for product installation, and they complement the applicable installation requirements of the NEC for these products in a given wiring method.

The electrical properties include short-term and long-term insulation resistance performance. As a cross-linked polyolefin or EPCV, the XHHW-2 insulation provides exceptional insulation resistance properties. For example, the dielectric constant and the power factor (%) for XLPE can be

The flame or fire test performances are a specific requirement for various insulation types and for specific applications in accordance with the installation requirements in theNEC. Typically, the products are required to meet a flame test. Additional fire tests are optional for specific applications. To meet these requirements, additives are added to the insulation materials such that the physical and electrical performance requirements are not compromised. For example, the cost of the insulating material for XHHW-2 marked “For CT Use” (to install it in cable trays) can be up to three times more than the cost of the material for XHHW-2.

Lastly, every listed product has specific requirements for markings on the products and their packages. For example, some XHHW-2 conductors have a “90°C” marking in their print legends. Although the insulation material is suitable for this rating, it was not permitted until recent harmonization of standards. It is now an “optional” marking. It could imply to the user that he/she is permitted to use the ampacity ratings associated with this temperature rating in all installation conditions. Such direct or implied understanding can undermine the performance of the installation and create a dangerous situation for the project owner. All 600 V rated devices, transformers, meter boxes and panelboards are listed for 75°C in accordance withNEC110.14. Hence, there is potential for misuse. No reputable manufacturer will agree to provide a warranty for such misuse of the requirements.

Summary

To remain trustworthy, every listing mark needs to be defended by the issuer, the manufacturer and the user. Generally, the issuer and reputable manufacturers have a clear understanding of what it means to obtain and maintain the listing mark. Users should know these details in order to make better informed decisions. Another adage comes to mind: “Buyer beware.” It should be changed to: “Buyer be informed.”

Find Us on Socials