Safety first. That’s been the byword for electrical codes and electrical inspectors forever — and properly so. But is that enough? For people and property, the answer is “Yes.” But for economic and enviornmental reasons, the answer is: “Maybe we should be doing more.”

Chances are that when you pick up your newspaper, turn on the TV, or have a serious conversation, the topics will often include global warming, sustainability, green living, energy conservation and energy efficiency. Chances are, too, that when you’re talking with building owners, their lessees or their tenants, the subjects will often turn to how to cut costs or how to get more bang for the buck.

None of these topics relates directly to electrical safety, but they are directly related to electrical use. Each year, we generate more than 4 billion MWh of electrical energy to power the USA — energyweare paying dearly for. And each year we emit more than 2.5 billion metric tons of carbon dioxide into the atmosphere (that’s more than 15 billion pounds a day) — the consequences of whichour childrenmay pay for.

Data

How do we deal with these issues?

The answers are simple but not easily accomplished: Generate electricity that doesn’t rely on fossil fuels, use less electricity, and/or ensure that what electricity you do use is used with maximum efficiency.

Advocates of cogeneration, solar, nuclear, hydrogen fuel cells, wind and wave power generation suggest approaches that are laudable; however, high initial costs, lengthy returns on investment and the need for government subsidies have all slowed their acceptance.

When energy conservation is discussed, recommendations for immediate solutions turn to improvements in insulation, raising the thermostat in summer and lowering it in winter, or installing more efficient lamps, motors and appliances. These are greatly important, but insufficient solutions.

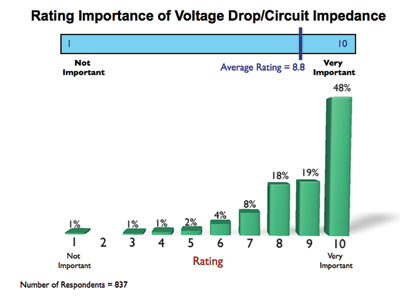

Chart 1. Rating importance of voltage drop/ciruit impedance

With respect to energy efficiency, one critical factor is routinely overlooked — energy losses in the electrical wiring itself. These losses are referred to as “voltage drop (VD),” “voltage loss,” “impedance,” “electrical conductor heating losses,” “I2R loss,” “line loss” or simply as electrical energy loss. Whatever name is used, the result is still waste, and its impact is enormous. It prevents us from maximizing the efficiency of all our electrical systems.

Waste not; want not

All types of electrical wiring systems have these losses, and these losses exist in power generation, transmission, distribution and load-side wiring. You might say that voltage drop is a system transmitted disease that infects and lays waste to our entire electrical infrastructure.

It might seem intuitive that electrical systems should be designed to limit waste; however, this is not the norm. Even in circuits properly designed to reduce losses, waste is often transferred to the electrical system by mechanical means.

An electrical motor with bad bearings can devour many times the energy needed for its optimum energy efficiency. This type of loss can be addressed by proper maintenance. But losses caused by an undersized electrical circuit cannot be resolved by maintenance and will continue for the life of the circuit.

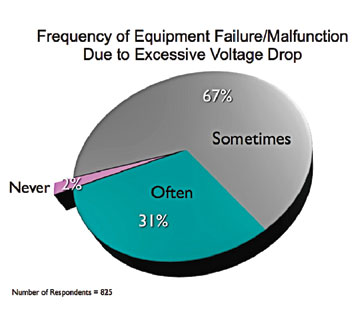

Chart 2. Frequency of Equipment Failure/Malfunction Due to Excessive Voltage Drop

And while there are increased initial costs associated with sizing conductors to maximize efficiencies and reduce energy losses, these costs can often be justified financially. Usually, less than a five-year return on investment is desirable.

What electricians and inspectors think

In a 2008 nationwide survey of electrical inspectors and electricians, 85 percent identify voltage drop/circuit impedance as a “very important issue” to them, as shown in chart 1. Voltage drop is considered to be asafetyissue by 59 percent of the respondents, anenergy efficiencyissue by 67 percent, and anequipment integrityissue by 71 percent. Voltage drop issues are considered most important for motors, wiring and wiring devices.

Ninety-eight percent of the electricians and inspectors identify excessive voltage drop as the cause of equipment failure (chart 2).

Who’s watching the store?

While the world struggles to answer its energy problems by embracing the use of alternative sources, many countries, including the USA, continue to allow electrical systems that consume excessive amounts of energy. There are governmental regulations requiring better and better fuel efficiencies for automobiles; so, why don’t we have corresponding mandates for electrical wiring efficiency?

At face value, it seems reasonable to expect that codes, such as theNational Electrical Code®, would do an adequate job of limiting electrical energy losses. However, they are designed only to provide minimum levels of safety and don’t deal with energy issues effectively.

Over the years, several attempts have been made to establish mandatory impedance maximums in theNEC. Each has met strong opposition because excessive impedance doesn’t usually constitute a safety concern. For example, other than in an emergency or life-safety situation, the failure of a motor or the dimming of a lamp doesn’t usually harm a building or its occupants.

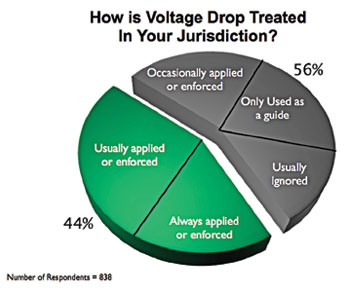

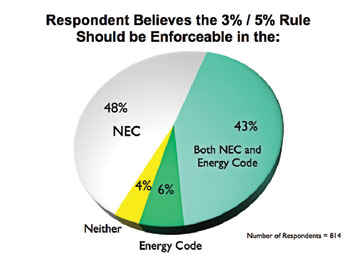

Despite the perceived importance of voltage drop/impedance issues, the inspectors and electricians surveyed indicate that, in more than half of their jurisdictions, theNECrecommendations related to voltage drop are regularly not enforced (chart 3).

What’s impeding impedance?

Whereas, an owner builder is more likely to include conservation measures in the design, speculative builders are more likely to eliminate initial costs, rather than consider energy trade-offs.

Even when a rational cost-benefit analysis for an energy conscious electrical design shows the potential of an overall savings in a reasonable time frame, initial construction costs seem to be given more weight in the decision-making process.

Unfortunately, it’s not easy to retrofit or rewire a building after it’s constructed, so prospective purchasers or lessees should have a reasonable understanding of the building’s electrical design. Otherwise, bad design decisions will cost them for the lifetime of the building.

What’s the impact?

Let’s look first at the building alone — and just the wiring. Moving up even one conductor size than is required by the NEC can mean big payoffs to the guy who pays the electrical bill. It not only increases energy efficiency by reducing I2R heat losses, it can also increase safety.

When less heat is generated by the conductors, the result is reduced energy requirements for fans and air-conditioning systems. Increased wire size can provide insurance against changing demands and offer the flexibility to accommodate new equipment or new technologies. Note, too, that some companies, as a matter of course, specify wire two or three sizes larger than minimum Code requirements in neutrals, which are often overloaded due to harmonics. This is a critical concern for most facilities.

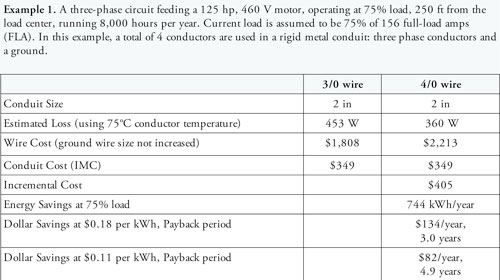

Example 1

Example 2

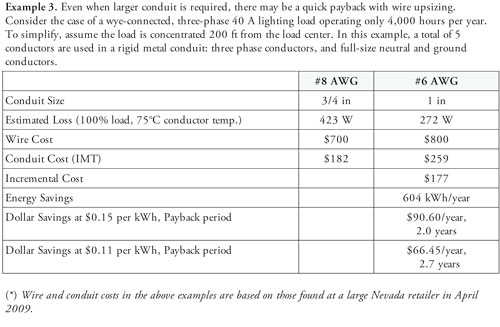

Example 3

Key elements that affect the economic incentive to install larger wire gauges, are the duty cycle, load factor and electricity price. When using the same size conduit, the increased cost of wire is minimal. As examples 1, 2, and 3 demonstrate, the payback for upsizing can be quite short (often, less than two years), even in single-phase lighting circuits, or in one- to two-shift commercial settings.

A simple way to understand the impact of wire size on energy efficiency and costs is to examine the numbers in these examples where just one wire size aboveCodeminimum is installed. Here, you can see how significant cost and energy savings can be realized by a simple upsizing, even if the wire sizes in these examples meet the voltage drop requirements of the NEC.

Consider an even bigger issue

Too often, calculating the benefits of upsizing electrical conductors only compares the current costs to the depreciated costs of the wiring system over a given time frame. However, this doesn’t take into account the cost of the excess fuel used in generation — fuel that unnecessarily depletes our resources. Another typical exclusion is the cost of environmental damage from waste heat and greenhouse gases given off into the atmosphere.

What can be done right now?

From the surveyed inspector/electrician point of view, voltage drop considerations should be enforceable both through safety regulations and energy regulations. Forty-nine percent felt that voltage drop should be made enforceable in the Energy Code. Ninety-one percent felt that voltage drop should be enforceable in theNEC.

Where do we go from here?

A good start would be to understand fully how VD affects energy consumption and the impact it has on the environment. This article only begins to tap the issue. Information gathered from field and site surveys could identify and quantify actual conditions and help to define a scoping of the problem.

Scoping should identify power losses in all sectors, including residential, commercial, industrial, generation, transmission and distribution. This is no small task. It must encompass the code and contracting communities along with the institutions responsible for energy and environmental reform. Only then can we comprehensively address the use of alternative energy sources, the reduction of energy consumption and the maximizing of energy efficiency. Already, Washington is exploring cap and trade regulations and other measures that will address generation, transmission and distribution losses.

Doing nothing does nothing

While it can be argued that the electrical losses of generation, transmission and distribution of supply electricity cannot be remedied without great expense, we can do something — especially in the areas of building and premises wiring. Doing nothing does nothing to help reduce waste.

Let’s become committed to limiting electrical demand through reducing electrical losses at the user end — in our homes and plants and buildings. It’s a beginning that will not only help our economy, it will also go a long way toward resolving fuel waste issues and address some of the environmental concerns facing the USA today and tomorrow.

References

The sources for the illustrative support are as follows:

1. Data Box:U.S. Green Building Council, 2008

2. Sidebar and Examples 1–3:Travis Lindsey Consulting Services Inc., 2009

3. Charts 1–4:Nationwide surveys of electrical inspectors and electricians, Irwin P. Sharpe & Assoc., 2008.

How big a difference does voltage drop make?

Concern about voltage drop has always been important, just how important depends on the particular use of the voltage and the needs of the user. While the dimming of lights may not be a big concern for the homeowner reading a book, it could have serious consequences to equipment or operators in an industrial shop. Failure to accommodate inrush or start-up loads may trip breakers and cause a domino effect throughout the system. Many electronic devices cannot perform properly when voltages sag or harmonics run rampant. But the biggest point to consider is that it takes a big toll on energy consumption — so, the less, the better.

Voltage Drop

2•K•I•L / CM = VD

Where

K = Resistance per foot of wire x CM area at a given temperature (Values may be found in Table 8,NEC®)

I = Amperes

L = Length of run to load

CM = Circular mils

VD = Voltage drop for single-phase circuits

(Source:National Electrical Code, 2008)

Using the above formula from theNEC, let’s look at a couple of examples of voltage drop situations and what dramatic effect a simple upsizing of a circuit’s conductors can have. Remember, voltage drop can never fall below the minimum requirements of the manufacturer. What we do here is further assurance against coming too close to that threshold.

Example 1. The retail cost of 14-2 NMB cable is $0.1008 per ft x 70 ft = $7.05; a 12-2 NMB cable is $0.1540 per ft x 70 ft = $10.78.* To determine the cost increase, we subtract the cost of the 14 gauge from the 12 gauge and get $3.73.

The 2.40 V in Example 1 is subtracted from 3.86 V, leaving 1.46 V; 1.46 V x 9 A = 13.14 W. Assuming the circuit is on 10 hours a day, 120 days per year, this would result in 15.77 kWh of lost energy per year.

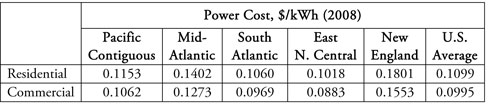

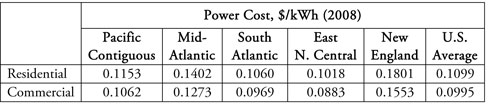

Using the U.S. average residential power rate, $0.1099, the payback is $0.1099 x 15.77 kWh = $1.73 per year; and for the East North Central area, $0.0883 x 15.77 = $1.39. In either case, the original $3.73 investment would be returned within three years. It is worthy to note that the financial payback occurs at levels even lower than theNECrecommended levels.

Example 2.

A retail center parking lot circuit consists of 8 400-W metal halide lamps (460 W ballasts) on 30 ft tall poles. The circuit length is 200 ft to the farthest pole. The circuit load is 15.3 A (8 x 460 W/240 V). At 240 V using 10 AWG solid copper, the voltage drop is 8.5 V or 3.5%. If we use 8 AWG wire, the voltage drop is 5.34 V at 2.3%.

Example 2

Source: Energy Information Administration, U.S. DoE, Dec. 2008.

InExample 2, the cost difference between 10 AWG and 8 AWG is $0.05 per ft. Assuming the conduit size remains the same: 230 ft (200 ft run plus 30 ft pole height) x 2 x $0.05 = a $23.00 increase in cost.

The 5.34 V in Example 2 is subtracted from 8.5 V leaving 3.16 V. 3.16 V x 15.3 Amps = 48.34 W. Assuming the lighting is on 8 hours per day, 365 days per year, 48.34 W x 8 hrs x 365 days = 141.15 kWh lost per year. The one-year payback using the U.S. average commercial rate of $0.0995/kWh would be $14.04; while in New England, the one-year payback would be $21.92. The national average payoff for going to the increased size is less than two years, and the New England payoff is about one year.

What’s more, after the initial investment is recaptured, the savings paybacks continue year after year for the life of the circuit. Imagine if in only two examples there is a saving that can be made, what savings are available from the millions of circuits in the USA today!

(*)Wire costs are based on those found at a large Nevada retailer in April 2009.

Note: We are assuming a unity power factor and, therefore, using watts (W) instead of volt-amps (VA) in the above examples.

Find Us on Socials