The primary purpose of transfer equipment is to allow power transfer from a normal (Utility) source to an alternate (Generator) source while preventing the inadvertent interconnection of the normal and alternate source of supply during operation of the transfer equipment. During Part I of this series, we covered the fundamentals of transfer equipment used in optional standby systems and the use of key interlocks to provide a safe, simple, and reliable means of transfer. This article will explore transfer equipment options and provide additional guidance, questions to ask, and considerations for those systems.

Section 702.2 defines an optional standby system as “Those systems intended to supply power to public or private facilities or property where life safety does not depend on the performance of the system. Optional standby systems are intended to supply on-site generated power to selected loads either automatically or manually.” The choice for using either manual or automatic transfer equipment depends on the application and the amount of time acceptable for the load to experience power loss without damage to product, process, or business. The first systems we will cover provide a manual transfer function.

Manual Transfer Equipment – General Considerations

Manual Transfer – Operator Required

Since the loss of the normal source drives the need to transfer to an alternate source, the equipment access and lighting necessary to locate and operate controls to start the alternate source become a concern. A number of other questions arise if you are depending on a person to make the transfer:

1. If the loss of power occurs during the night or after normal work hours will an operator be available?

2. Can an operator safely get to the equipment?

3. What if the equipment is outside and the power loss was due to weather conditions?

4. How long does the alternate source supply the load?

5. What is the availability of fuel for the alternate source?

6. How long can the load be without power?

There are situations where a loss of power is foreseeable and operator availability to operate the transfer system can be ensured or the transfer to the alternate source can be accomplished in advance of the normal source loss. The costs of product, process, or business loss must be evaluated in comparison to the costs of having an operator available and expending alternate source fuel.

Manual Transfer – Load Selection

NEC-2008 revised Section 702.5 in order to clarify how to determine optional standby system capacity and rating. Section 702.5(A) requires that the transfer equipment be suitable for the maximum available fault short-circuit current at its terminals and 702.5(B)(1) specifies:

“Where manual transfer equipment is used an optional standby system shall have adequate capacity and rating for the supply of all equipment intended to be operated at one time. The user of the optional standby system shall be permitted to select the load connected to the system.”

Calculation of the standby system load requirements is a necessary but sometimes overlooked requirement resulting in an undersized alternate source generator and transfer equipment. New language inNEC-2008, Section 702.5(B) provides clear guidelines,

“The calculations of load on the standby source shall be made in accordance with Article 220 or by another approved method.”

The determination of the intended load is crucial to calculating the needed system capacity since for manual transfer the user is permitted to select the loads. Will the load selection or sequence of load connection to the alternate source be important? Consideration must be given to the system capacity and rating and if the user has the ability to exceed the system ratings with selectable loads then additional guidance, instructions, load management controls, or load metering may be necessary for users to properly operate the system.

Manual Transfer Equipment Options

Double Throw Safety Switch

Double throw safety switches are considered one of the most robust and reliable choices for transfer equipment and are designed to operate in residential, light commercial and industrial installations. These manufacturer assembled switches allow an operator to switch a load between the normal (Utility) and alternate (Generator) sources. Double throw switches have three handle positions, source A, off, and source B. These three positions provide a clear, built-in break before the load is switched to the new source. Double throw switches are UL 98 listed, passing rigorous mechanical endurance, short-circuit current ratings, and thermal testing requirements and are available in most enclosure types, suitable for use as service equipment, and in both fusible and not fusible configurations. An example of a double throw safety switch is shown in figure 2.

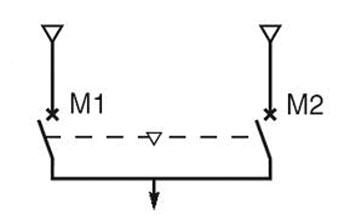

Mechanical “Walking Beam” Interlock

Cable Interlock/Rod Interlock

A rod interlock functions in the same manner as a cable interlock but uses solid steel rods to interlock the breakers. This system requires the breakers to be in a stacked configuration and located in adjacent compartments of the same section or enclosure.

Cable and rod interlock transfer equipment solutions are UL listed to the appropriate product standard, available as manufacturer- or field-installed and specific configurations may also be UL 1008 listed. Since these systems are used with circuit breakers or switches, they are suitable for use as service equipment. Figures 4 and 5 are examples of cable and rod mechanical interlocks located in a UL 891 listed switchboard.

Figure 4. Cable interlocks installed on stacked and adjacent circuit breakers

Figure 5. Rod interlock installed on two circuit breakers

Manual Transfer Switch

Manual transfer switches are similar to double throw safety switches and offer another option to consider when manual transfer between sources is desirable. The operator simply moves the switch handle from the normal source position to the alternate source position. See figure 6 for a manual transfer switch example. Unlike a double throw safety switch, a manual transfer switch does not provide an “Off” handle position with the load isolated from both sources. Manual transfer switches are UL 1008 listed. Manual transfer switches do not provide or have provisions for overcurrent, short-circuit, or ground-fault protection.

Suitable for Use as Service Equipment (SUSE):

Manual transfer switches are available which are SUSE for the utility only, or the alternate source only, or both the utility and alternate sources. For these products, service disconnect(s) with overcurrent protection are provided in the same enclosure with the transfer switch. The key is to look for the “suitable for use as service equipment” marking on the product to ensure compliance when the product is used in a service-disconnect application.

Automatic Transfer Options – General Considerations

Automatic Transfer – No Operator Required

A benefit of automatic transfer equipment is that an on-site operator is not required to take action when a loss of normal supply occurs. This allows a pre-defined sequence of operation that includes which loads will receive power from the standby source and the ability to have load management that both sheds and picks-up load based on the application needs. The ability to automatically make these decisions by the transfer equipment is consistent, efficient, and reduces the opportunity of operator error.

Automatic Transfer – Load Management

Residential applications typically have a small standby generator used only for a few required loads. How can an automatic transfer system be installed without the expense of a load management system? One method would be to group the required loads in one small sub-panelboard and have the automatic transfer system transfer the alternate source to those loads only. From an inspection viewpoint, any case where the full intended load is grouped makes the evaluation of compliance easier.

The ease of installing, operating, and potential energy savings benefits for load management systems will drive growth in all application areas. Optional standby systems utilizing automatic transfer with load management provide all the operational improvements of automatic transfer while also allowing a reasonably sized alternate source. Figure 7 provides an example of an intelligent panelboard which provides integral load management capabilities.

Automatic Transfer Equipment Options

Automatic transfer equipment can be divided into two basic types, circuit breaker transfer systems and automatic transfer switches.

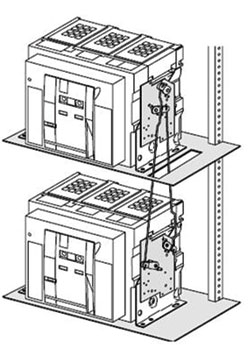

Circuit Breaker Automatic Transfer Equipment

Circuit breaker automatic transfer equipment can generally be supplied in the following types.

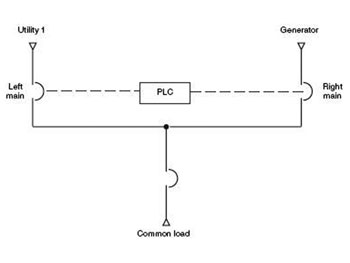

1. Programmable logic controller (PLC) based systems.

2. Intellegent/microprosessor relay control

3. Control relay based

Figure 8. Circuit breaker automatic transfer equipment with PLC control

These systems are very flexible, offer many performance enhancing options, and are easily adaptable to power systems with more than two sources. Typical systems include control or programming logic and electrical interlocking to ensure proper transfer and allow both manual and automatic transfer modes of operation. These systems benefit from having robust overcurrent protection, high fault-current interruption capability, as well as the largest operating cycle lifetime of any automatic transfer solution. In business critical applications, optional features such as closed transition “bumpless” back to the normal source, load shedding, advanced human machine interface (HMI) displays, and communications are common. Circuit breaker transfer systems are easily expandable to more than two source systems allowing additional utility, generator, UPS, and tie sources and breakers to be located and connected as needed. Circuit breaker transfer equipment systems are UL listed to the appropriate product standard usually UL 891 or UL 1558 and the basic two source systems are also typically listed to UL 1008. A means of testing the automatic transfer is usually provided. An example of a circuit breaker based automatic transfer equipment system utilizing PLC control and typical one-line diagram are shown in figure 7. These systems may be as simple as side-by-side sections in a switchboard or switchboards located in multiple areas of a facility due to placement of generators and multiple utility source locations.

Automatic Transfer Switch

Automatic transfer switches are a common solution in which there are two sources and the installation has overcurrent, short-circuit, and ground-fault protection typically provided elsewhere. See figure 9 for an automatic transfer switch example. Automatic transfer switches have similar control features and options as the circuit breaker based solutions and can contain overcurrent protection. However, expansion to more than two source applications requires the system designer to consider overcurrent and short-circuit protection and controls integration. Most automatic transfer switch manufacturers offer a bypass/isolation option for use during switch maintenance periods. Automatic transfer switches are listed to UL 1008.

Equipment Performance

Manual and automatic transfer systems have unique advantages. Consideration to each is required to adequately determine the best to use for a given application. A clear, concise and simple sequence of operation is required for proper user operation, especially for residential and commercial applications.

There are a myriad of manual and automatic transfer equipment solutions for Article 702 optional standby systems and many of these solutions can be installed as field modifications.

Plan Review and Inspection

1. Verify the application is an optional standby system as defined in Article 702.

2. What type of transfer equipment is being used? Manual or automatic transfer?

3. When the transfer equipment is serving as the service disconnect, ensure it is “Suitable for Use as Service Equipment.”

4. If it is an automatic transfer system, understand the load the alternate source will be serving in accordance withNEC220 and check for how these loads are segregated or if load shedding capability has been included as part of the transfer equipment.

5. For both manual and automatic transfer equipment, understand the sequence of operation.

6. For manual transfer equipment using key interlocks, refer to the plan review and inspection considerations provided in Part I of this series.

In addition to transfer equipment options, the system application must be considered; Part III of this series will cover choices such as three- or four-pole transfer, ground-fault protection, selectivity, and will answer questions like “What might I see in a data center, hospital, or industrial process application?”

Find Us on Socials