AFCIs and GFCIs

GFCIs

What is a GFCI?

Do you feel like you have a full understanding of how ground-fault protection works? If not don’t worry about it; we hope this discussion with help you and your co-workers further understand the basics.

There are two different types of ground-fault protection required in the NEC, ground-fault protection for people and ground-fault protection of equipment. Both work in a similar manner, but the protection levels are quite different. We will focus on ground-fault protection for people, provided by a device called a ground-fault circuit interrupter (GFCI). Article 100 in theNECincludes a definition for GFCIs.

Ground-Fault Circuit Interrupter (GFCI). A device intended for the protection of personnel that functions to de-energize a circuit or portion thereof within an established period of time when a current to ground exceeds the values established for a Class A device.

Informational Note: Class A ground-fault circuit interrupters trip when the current to ground is 6 mA or higher and do not trip when the current to ground is less than 4 mA. For further information, see UL 943,Standard for Ground-Fault Circuit Interrupters.

The Informational Note describes two very important performance criteria for GFCIs, namely that they will not trip if the leakage current to ground is less than 4 mA and will definitely trip if the leakage current is 6 mA or higher. The 4 mA level is necessary to prevent unwanted tripping due to the natural leakage in appliances, tools and other connected loads, and in the wiring itself.

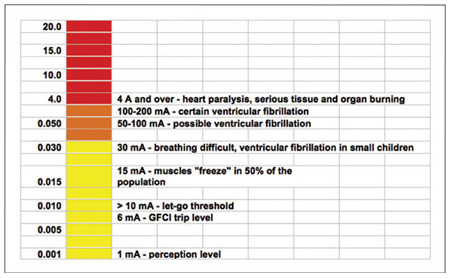

Figure 1. Effect of current on the human body

The 6 mA must-trip level is important due to the amount of electrical current a human body can withstand without serious physical harm. Although physical effects will vary from person to person depending on whether they are male or female, an adult or a child, in general people will be able to sense electrical currents as low as 1 mA. At about 10 mA they may not be able to “let go” if they come into contact with an energized conductor. Current flow as low as 30 mA may cause breathing difficulty and heart fibrillation in small children. Fibrillation is almost certain for currents in the 100–200 mA range and current over 4 A will cause heart paralysis and tissue burning (see figure 1).

The ANSI/UL 943 standard defines the requirements for GFCI performance in the U.S. and is a tri-national standard, meaning that it is harmonized with CSA C22.2 No. 144.1 in Canada and ANCE NMX-J-520 in Mexico.

How does a GFCI work?

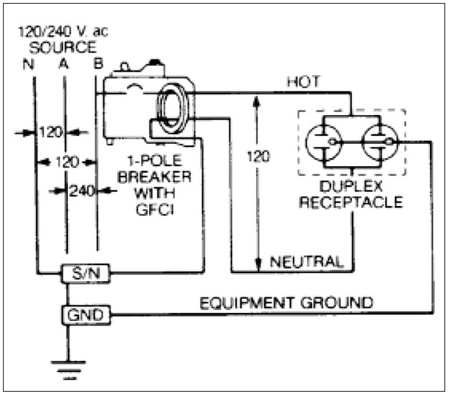

Figure 2. If there is an imbalance, an electronic circuit will determine if the leakage is enough to necessitate an interruption of the current flow.

The operation of a GFCI is really quite simple. It compares the amount of current going out to the load with the amount of current coming back from the load. In a single-phase device both the hot and neutral conductors pass through a current transformer (CT). This is why the load neutral conductor must be connected to a GFCI circuit breaker. If the current going out to the load equals the current coming back, there is no leakage to ground and the output from the CT is zero, but if there is an imbalance, an electronic circuit will determine if the leakage is enough to necessitate an interruption of the current flow, see figure 2.

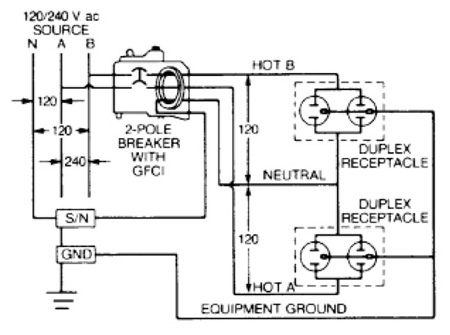

In a two-pole GFCI circuit breaker, if single-phase (120 V) loads are to be served, both of the hot conductors, and the neutral conductor, must pass through the CT; therefore, the load neutral conductor must be connected to the circuit breaker, see figure 3. Three-pole (three-phase) GFCI circuit breakers are only suitable for protection of a three-phase load; hence, only the three-phase conductors must pass through the CT.

The white “pigtail” wire on a GFCI circuit breaker serves two functions. It completes the connection to the panel neutral bar for the neutral load conductor and also completes the power supply circuit for the electronics. This means that even in installations where there is no load neutral conductor, the white pigtail wire must still be connected to the neutral bar in the load center or panelboard in order for the electronic ground-fault protection circuit to function. (Note: Some manufacturers may offer circuit-breaker GFCIs with a plug-on neutral connection rather than a pigtail.)

What different types of GFCIs are available?

GFCIs are available in two different forms, circuit breakers and receptacles. Circuit-breaker GFCIs are dual listed as UL 489 circuit breakers and UL 943 ground-fault circuit interrupters, see figure 4. Receptacle-type GFCIs are listed as UL 943 ground-fault circuit-interrupter receptacles. The receptacle portion of the device must meet the requirements of UL 498.

In circuit breakers, the main circuit breaker contact(s) perform the interruption task when a ground-fault of sufficient magnitude is detected. In receptacles, a set of contacts performs the interruption task.

The terminals of circuit-breaker GFCIs are marked “Line” and “Load,” so they are not suitable for backfeeding. The terminals of receptacle-type GFCIs are similarly marked to insure that when properly wired the GFCI will also protect downstream receptacles should the installation so require.

Where are GFCIs required?

Figure 3. In a two-pole GFCI circuit breaker, if single-phase (120 V) loads are to be served, both of the hot conductors, and the neutral conductor, must pass through the CT; therefore, the load neutral conductor must be connected to the circuit breaker.

TheNECand Canadian Electrical Code (CEC) require GFCI protection in a large number of applications. The fundamental GFCI requirements are found in Section 210.8 of the NEC, although many other sections require them as well. Suffice it to say wherever electricity may be supplied in a potentially wet location, such as kitchen countertops, near sinks or outdoors, there is a good chance that GFCI protection is required there. A key revision to the 2011 NEC introduced a requirement for GFCIs to be readily accessible for monthly testing. Make sure you keep those receptacles located so as to not create an issue with this new requirement. If you are using a GFCI circuit breaker installed in a panelboard, this revised language is a nonissue.

What’s on the horizon for GFCI Protection?

A proposal to add an auto-monitoring function to the UL 943 GFCI standard is currently being considered by the industry. If adopted, this proposal will require that a GFCI be able to test itself, with the exception of the contact opening function. If a failure is detected, the GFCI will open the contacts (if possible) and deny power to the load. This new function was requested by the US Consumer Products Safety Commission because too few people regularly test their GFCIs. But even with auto-monitoring, users will still need to periodically test their GFCIs to insure that the contact opening function continues to work properly.

AFCIs

What is an AFCI?

Article 100 in theNECincludes a definition for AFCIs.

Arc-Fault Circuit Interrupter (AFCI).A device intended to provide protection from the effects of arc faults by recognizing characteristics unique to arcing and by functioning to de-energize the circuit when an arc fault is detected.

The ANSI/UL 1699 standard defines the requirements for AFCI performance in the U.S. While CSA does certify AFCIs, a CSA standard has yet to be approved.

How does an AFCI work?

The operation of an AFCI is far more complex than that of a GFCI. Note that the NEC Article 100 definition states that an AFCI recognizes characteristics that are unique to arcing. Unfortunately, there is no single characteristic that is unique to hazardous arcs, so an AFCI must look for multiple characteristics, usually occurring at the same time or within a short period of time, to determine whether or not to interrupt the current flow. This usually involves monitoring both the current and the voltage.

Figure 4. Circuit-breaker GFCI certification label

We are using the term hazardous arcs in order to distinguish from operational arcs that naturally occur in an electrical system such as when switches or motors are operated. This greatly complicates the protection task. Not only must the AFCI detect whether arcing is taking place, but it must determine whether it is an operational arc or hazardous arc.

Because of this, the UL 1699 standard is unlike the GFCI or overcurrent protection device standards. In those standards, the device must operate when a specified level of current has been exceeded for a specified period of time. The UL 1699 standard, on the other hand, requires that various types and lengths of cable be intentionally damaged so as to create a hazardous arcing condition that must either be interrupted in a specified period of time or before a fire indicator is ignited.

Further, the UL 1699 standard requires that unwanted tripping tests be conducted using various loads that naturally arc or generate waveforms that might be mistaken for hazardous arcing. Masking tests are also conducted to insure that loads do not interfere with the ability of the AFCI to detect hazardous arcs.

Like in a GFCI, both the hot and neutral load conductors must be connected to the AFCI, and as is also the case with GFCIs, the white “pigtail” wire completes the connection to the panel neutral bar for the load neutral conductor which is terminated on the circuit breaker and also completes the power supply circuit for the electronics. (Note: Some manufacturers may offer AFCIs with a plug-on neutral connection rather than a pigtail.)

What different types of AFCIs are available?

AFCI circuit breakers of 15- and 20-amps are available for installation in load centers and panelboards. They are dual listed as UL 489 circuit breakers and UL 1699 arc-fault circuit interrupters (see figure 5).

Single-pole AFCI circuit breakers are available for 120-V branch circuit protection. Two-pole versions are also available from some manufacturers for the protection of 240 V loads (with common trip) or 120 V shared neutral loads (without common trip).

UL also lists AFCIs and leakage-current detector-interrupters (LCDIs) as a part of cord sets for use on appliances such as window air conditioners to meet the requirement in NEC 440.65.

While UL has a standard (UL 1699A) for outlet branch-circuit arc-fault circuit interrupters (OBC AFCI) and has listed one or two products, as of this writing none are commercially available.

In circuit breakers, the main circuit breaker contact(s) perform the interruption task when an arc fault is detected. In OBC AFCIs or cord-type AFCIs and LCDIs, a set of contacts performs the interruption task.

The terminals of circuit-breaker AFCIs are marked “Line” and “Load,” so they are not suitable for backfeeding.

When AFCI circuit breakers were first introduced, only the branch/feeder type was available. A branch/feeder type AFCI provides protection for parallel arc-faults that occur line-to-line or line-to-ground. The 2005NECrequired the use of combination-type AFCIs beginning January 1, 2008. Subsequent editions of theNEChave required the use of only combination-type AFCIs.

Figure 5. Circuit-breaker AFCI certification label

The UL 1699 standard requires that a combination-type AFCI provide protection against both parallel and series arc-faults. Series arc-faults are those that might occur due a break in a line or neutral conductor.

The certification label on the circuit breaker will identify if it is a branch/feeder or combination-type AFCI (see figure 3). The color of the test button is also a way to identify if a circuit breaker is a GFCI, branch/feeder or combination AFCI; however, as the standards do not define test button colors, each manufacturer has their own scheme for GFCI and AFCI test button colors.

Speaking of test buttons, it is important that users periodically test their AFCIs by pushing the test button.

Where are AFCIs required?

Section 210.12(A) of the 2011 NEC requires arc-fault protection of all 15- and 20-A 120-V branch circuits in dwelling unit “family rooms, dining rooms, living rooms, parlors, libraries, dens, bedrooms, sunrooms, recreation rooms, closets, hallways, or similar rooms or areas.” Section 550.25 requires AFCI protection in the same rooms in modular and mobile homes. An OBC AFCI may be installed at the first outlet in a branch circuit if a steel wiring method is used to protect the home run or if the home run is imbedded in at least 2 inches of concrete (see 210.12 Exceptions 1 and 2). Exception 3 allows AFCI protection to be omitted if a fire alarm circuit is encased in a steel wiring method.

Section 210.12(B) requires AFCI protection where a 15- or 20-A 120-V branch circuit “is modified, replaced, or extended.”

AFCIs and the 2014 NEC

A couple of key revisions to the NEC-2014 AFCI requirements are being considered by Code-Making Panel 2. The expansion of arc-fault protection to 15- and 20-A branch circuits serving kitchens and laundry rooms has been proposed. It is common to find AFCI protection on at least one of the kitchen branch circuits today when the dining area, which is required to have AFCI protection, is also serving the kitchen.

There is also consideration being given to permit a branch-circuit breaker to provide parallel arc-fault protection for a home run feeding an OBC AFCI installed in the first outlet without being enclosed in a steel wiring means or in concrete. A number of key conditions are essential for this protection system to work based on a recently issued UL research report:

- The instantaneous trip level of the circuit breaker must not exceed 300 A.

- The home run must have a limitation on its maximum length.

- The first outlet box must be identified.

The most significant challenge for this proposal may land in the lap of the contractor and electrical inspector. Will you be able to effectively meet and enforce these parameters? How will you know which circuit breaker has the appropriate instantaneous trip level? (Today, the instantaneous trip level of a branch-circuit breaker is not controlled by a standard and, therefore, can range well above the maximum 300-A level. Indeed, some applications require a higher trip level in order for the loads to operate.) The Code Panel rejected the fundamental requirement for a circuit breaker used in this application to have a Listed marking indicating suitability. How will you know the home run length? How will you know that the OBC AFCI was installed in the first outlet? You may want to review this proposal and provide your thoughts through an NEC comment to the Code Panel.

Summary

GFCIs and AFCIs continue to provide the protection envisioned by the electrical industry when they were first introduced in the 1960s and 1990s respectively. Here are a few items to consider as we wrap up this discussion:

- Having a fundamental understanding of the basic functionality of GFCIs and AFCIs will ensure you are not only properly protecting people and the circuit but it also gives you the foundation to figure out why the GFCI or AFCI opened.

- When a GFCI or AFCI opens, always ask the question, “What was it protecting against?” Dismissing the opening as a nuisance trip for either a GFCI or AFCI fundamentally means you just closed the breaker or receptacle back into the same potential hazard if you didn’t address it.

- The requirements for GFCIs and AFCIs continue to be revised in the NEC. Make sure you are keeping up-to-date on the latest requirements.

- Stay engaged with the future development of GFCI and AFCI requirements in the NEC. Provide your input by submitting a comment to NFPA.

Find Us on Socials