Working space requirements for electrical equipment first appeared as two rules in the first edition of the Canadian Electrical Code Part I (CE Code) dated 1927. Rule 2001 “(a) Adequate clear working space with secure footing shall be provided about all electrical equipment which requires adjustment or examination during operation or while danger of shock is present.” and Rule 7001 (f) “Passageways around such machinery and equipment as generators, transformers and switchboards shall be kept clear of any obstructions and so arranged as to give

authorized persons ready access to all parts requiring attention.” These rules remained unchanged until the fourth edition of the CE Code dated 1939 where the words “during operation” were moved to the end of Rule 2001(a) “or examination while danger of shock is present during operation or otherwise.” This change required the working space for equipment only during adjustment or examination.

Photo 1. 5-kV indoor switchgear with two means of egress.

Between 1939 and 1969 these rules were moved four times resulting in Rule 2001(a) as Rule 2-072, and Rule 7001 as Rule 2-076. During the rule relocation in the 1969 CE Code both rules were reworded.

Photo 2. 27.6-kV outdoor switchgear with one means of egress.

Photo 3. Low voltage electrical room with one means of egress, and a 600-V 800-Amp main distribution switchboard and a 225-kVA transformer.

2-072 Working Space about Electrical Equipment (Low Potential)

“A minimum working space of three feet with secure footing shall be provided and maintained about all electrical equipment which may require adjustment and maintenance while danger of electric shock is present, except that working space is not required behind assemblies such as dead-front switchboards or motor control centres where there are no renewable parts such as fuses or switches on the back and where all connections are accessible from locations other than the back.” This rule rewording had three significant changes, one was the excepting not requiring

working space behind dead-front switchboards and motor control centres where there are no renewable parts such as fuses or switches on the back and where all connections are accessible from locations other than the back. Second was that the working space was required to be maintained, not just during adjustment or examination. Third was the introduction of a measurement of 3 feet. The intent of the 3 feet of working space with secure footing is to provide adequate space for maintenance of the electrical equipment.

2-076 Accessibility for Maintenance

“Passageways and working space around electrical equipment shall not be used for storage and

shall be kept clear of obstructions and so arranged as to give authorized persons ready access to all parts requiring attention.” The main change here is the removal of “such machinery and equipment as generators, transformers and switchboards” requiring passageways and working space for all electrical equipment.

In addition to the changes to these two rules, a new rule [Rule 2-074] was added regarding a requirement for entrances to working spaces.

2-074 Entrance to Working Space

“(1) At least one entrance of sufficient area shall be provided to give access to the working space about electrical equipment.

(2) Doors or gates of suitable material may be provided but they shall be capable of being readily opened from the equipment side without the use of a key or tool.”

In the eleventh edition dated 1972, Rule numbers 2-072 and 2-074 were changed to 2-308 and 2-310. Subrule (2) was also added to Rule 2-308: “(2) The minimum head room of working space about switchboards or motor control centres where bare parts are exposed at any time shall be 7

feet.”

In the next edition, dated 1975, the title of Rule 2-308 was changed to: 2-308 Working Space About Electrical Equipment (Low Voltage), and Subrule (2) of Rule 2-310 was renumbered to Subrule (4), and Subrule (1) was replaced with Subrules (1), (2), and (3):

2-310 Entrance To, and Exit From, Working Space

“(1) Each room containing electrical equipment and each working space about equipment shall

have suitable means of exit and entrance, which shall be kept clear of all obstructions.

(2) An exit may also be used as an entrance.

(3) If the plan of the room or space and the characteristics and arrangement of equipment are such that an accident would be liable to close or make inaccessible a single exit, a second exit shall be provided.

(4) Doors or gates shall be capable of being readily opened from the equipment side without the use of a key or tool.”

Subrule (3) was the first requirement in the CE Code for a second exit from an electrical room.

The only change in the thirteenth edition, dated 1978, was to change the imperial measurements to metric.

In the fourteenth edition, dated 1982, the title of Rule 2-308 was changed removing the reference

to low voltage, Subrule (2) of Rule 2-308 was renumbered as Subrule (4), and Subrule (1) was reworded adding “such as switchboards, panelboards, control panels, and motor control centres that are enclosed in metal,” to the working space requirements. It is interesting to note that transformers and other equipment that are not required functions of adjustment, control or operation have not been included in the list of equipment requiring the working space. In addition new Subrules (2) and (3) were added with consideration for drawout-type equipment, the need to open enclosure doors to at least 90⁰, and introduction of Table 56 detailing the minimum working space around electrical equipment having exposed live parts.

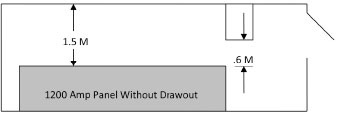

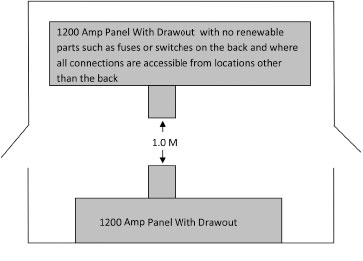

Drawing 1 showing an unacceptable egress path width of 0.6 m

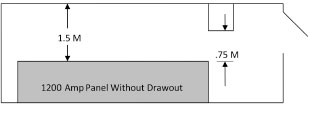

Drawing 2 showing an acceptable egress path width of 0.75 m.

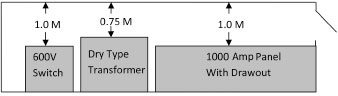

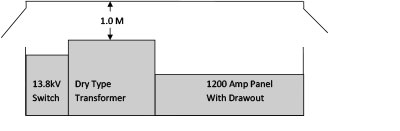

Drawing 3: With equipment rated less than 1200 Amp and less than 750 V the transformer is not considered when determining the working space, but the egress path must not be less than 0.75 M.

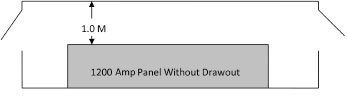

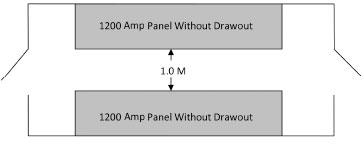

Drawing 4: With two exit doors located so as to allow exit from the working space without passing any possible failure point in the equipment, the minimum depth of working space is 1.0 m.

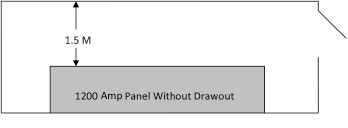

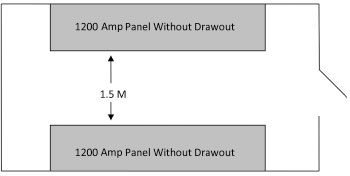

Drawing 5: With only one exit door not located so as to allow exit from the working space without passing any possible failure point in the equipment, the minimum depth of working space is 1.5 m.

2-308 Working Space Around Electrical Equipment

“(1) A minimum

working space of 1 m with secure footing shall be provided and maintained about electrical equipment such as switchboards, panelboards, control panels, and motor control centres that are enclosed in metal, except that working space is not required behind such equipment where there are no renewable parts such as fuses or switches on the back and where all connections are accessible from locations other than the back.

(2) The space referred to in Subrule (1) shall be in addition to the space required for the operation of drawout-type equipment and shall be sufficient for the opening of enclosure doors and hinged panels to at least 90°.

(3) Working space with secure footing not less than that specified in Table 56 shall be provided and maintained around electrical equipment such as switchboards, control panels, and motor control centres having exposed live parts.

(4) The minimum headroom of working spaces around switchboards control panels and motor control centres where bare live parts are exposed at any time shall be 2.2 m.”

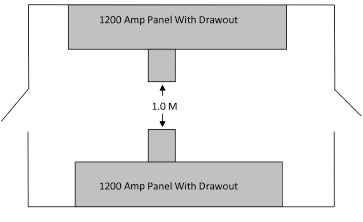

In the sixteenth edition of the CE Code, dated 1990, Subrule (2) of Rule 2-308 was reworded adding more details for drawout-type equipment in either the connected, test, or fully disconnected position.

“(2) The space referred to in Subrule (1) shall be in addition to the space required for the operation of drawout-type equipment in either the connected, test, or fully disconnected position and shall be sufficient for the opening of enclosure doors and hinged panels to at least 90°.”

Subrules (2) and (3) of Rule 2-310 were replaced in the eighteenth edition, dated 1998, with more specific requirements detailing when the working space referred to in Rule 2-308 needs to be increased to 1.5 m.

“(2) Where a room or space referred to in Subrule (1) contains equipment that has a rating on the equipment that is rated 1200 A or more, or rated over 750 V, and consists of transformers, overcurrent devices, switchgear, or disconnecting means, such equipment shall be arranged

so that, in the event of a failure in the equipment, it shall be possible to leave the room or space referred to in Subrule (1) without passing the failure point, except that where this cannot be done, the working space requirement of Rule 2-308(1) and (2) shall be not less than 1.5 m.

(3) For the purposes of Subrule (2), the potential failure point is any point within or on the equipment.” These new subrules require the room or space be such that it is possible to leave the room or space without passing any part of equipment rated 1200 A or more, or rated over 750 V. Where it is not possible to leave the room or space without passing any part of the equipment, the working space must then be increased to 1.5 m. Another significant change to note is that Subrule (2) includes transformers indicating that when a room or space with equipment rated 1200 A or more, or equipment rated over 750 V includes a transformer the working space about the

transformer must also be considered.

These rules remained unchanged until the twentieth edition dated 2009 were Subrule (1) of Rule 2-310 was changed to read: (1) Each room containing electrical equipment and each working space around equipment shall have unobstructed means of egress in compliance with the National Building Code of Canada. In addition to this subrule change, the following note was added to Appendix B: Specific requirements pertaining to unobstructed means of egress can be found in Articles 3.3.1.23 and 9.9.5.5 of the National Building Code of Canada. Both Articles 3.3.1.23 and 9.9.5.5 of the National Building Code of Canada restrict the width of a normal means of egress from

any part of a floor area to less than 750 mm. As an example, Drawing 1 shows an electrical room with egress path from the working space about the 1200 Amp panel limited to 0.6 m. This example does not meet the requirements in the building code for an egress path with a minimum width of 0.75 m.

Subrule (2) for Rule 2-310 was revised again in the twenty-second edition of the 2012 CE Code, and added wording regarding the rating on the nameplate.

“(2) Where a room or space referred to in Subrule (1) contains equipment that has a rating on the equipment nameplate of 1200 A or more, or is rated over 750 V, and consists … This change was a result of an interpretation request asking if this rule applied to equipment that has a maximum name plate rating of 1200 A and a main overcurrent device that is less than 1200 A. The answer shown in the 2009 CE Code is yes. The change to Subrule (2) was to clarify the intent of the subrule is to apply based on the nameplate rating of the equipment.

Drawing 6: With two exit doors located so as to allow exit from the working space without passing any possible failure point in the equipment, the minimum depth of working space is 1.0 m.

Drawing 7: With only one exit door not located so as to allow exit from the working space without passing any possible failure point in the equipment, the minimum depth of working space is 1.5 m.

Drawing 8: With two exit doors located so as to allow exit from the working space without passing any possible failure point in the equipment. The minimum depth of working space is 1.0 m with the drawout-type equipment fully drawn out and with sufficient for the opening of enclosure doors and hinged panels to at least 90°.

Drawing 9: With no renewable parts such as fuses or switches on the back and where all connections are accessible from locations other than the back, the space between the wall and the panel is not required to be 1M.

Drawing 10: With equipment rated 1200 Amp or greater or with high voltage equipment, the transformer must be considered when determining the working space.

Find Us on Socials