Although I wrote an article on this subject just more than a year ago, I have received a few e-mails with questions from the electrical designers and installers. All questions received could be divided into the following groups:

- Why do electrical designers and installers have to know about this issue, as this is the requirement of the National Building Code of Canada (NBCC)?

- Which conductors are required to be protected against exposure to fire?

- If the conductors which are required to be protected and are specified by electrical designers do not comply with the circuit integrity testing requirement, how could such protection be accomplished and who is responsible for it?

Let’s try to answer these fundamental questions and, perhaps, finally clarify this controversial subject matter.

Why do electrical designers and installers have to know about this issue, as this is the requirement of the National Building Code of Canada (NBCC)?

The answer is as follows: electrical designers and installers are responsible for compliance with the applicable requirements of the CE Code. Although in general, the CE Code does not address provisions for protection of electrical conductors against exposure to fire, such requirement exists in Rule 32-200(b) and in Rule 46-204, as these Rules cover installation of life safety equipment that must function in event of a loss of normal power supply due to the fire in a building.

Appendix B Note on each of these rules provides additional clarification to the CE Code users in this regard.

Appendix G of the CE Code offers a comprehensive cross-reference between certain requirements of the Code and the relevant provisions of the NBCC.

Let’s take a look at these Rules of the CE Code.

32-200 Conductors (see Appendices B and G)

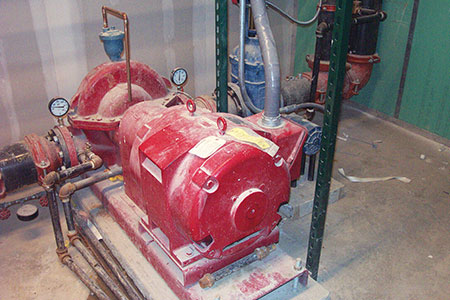

“Conductors from the emergency power source to a fire pump shall

(a) have an ampacity not less than

(i) 125% of the full load current rating of the motor, where an individual motor is provided with the fire pump; and

(ii) 125% of the sum of the full load currents of the fire pump, jockey pump, and the fire pump auxiliary loads, where two or more motors are provided with the fire pump; and

(b) be protected against fire exposure to provide continued operation in compliance with the National Building Code of Canada”.

Appendix B on Rule 32-200(b)

“The intent of this Rule is to protect the feeder conductors between a fire pump and an emergency power source from fire damage.

The National Building Code of Canada requires that conductors supplying life and fire safety equipment be protected against exposure to fire to ensure continued operation of this equipment for a period not less than 1 h.

NFPA 20 also mandates protection of circuits feeding fire pumps against possible damage by fire. The following examples illustrate acceptable methods for achieving this protection:

(a) using mineral-insulated cables conforming to fire rating requirements as specified in Clause 5.3 of CSA C22.2 No. 124;

(b) embedding the raceway containing fire pump feeder conductors in not less than 50 mm of concrete; or

(c) installing the raceway containing fire pump feeder conductors in a shaft enclosure or service space of at least 1 h fire resistance construction.

Specific requirements pertaining to the fire resistance rating of a material or an assembly of materials can be found in subsection 3.1.7 of the National Building Code of Canada or in the appropriate provincial/territorial legislation”.

46-204 Protection of electrical conductors (see Appendices B and G)

“All power, control, and communication conductors between an emergency generator as described in

Rule 46-202(3), and electrical equipment required to be installed as a part of the emergency power supply and located outside the generator room shall be protected against fire exposure to provide continued operation in compliance with the National Building Code of Canada”.

Appendix B Note on Rule 46-204

“The intent of this Rule is to protect conductors between an emergency generator and associated electrical equipment, such as the transfer switch(es), bypass switch(es), engine control panel, etc., required to be installed as a part of the emergency power supply and located outside the generator room against exposure to fire for a period not less than 1 h. The National Building Code of Canada requires that conductors supplying life and fire safety equipment be protected against such exposure. CSA C282 also mandates protection of circuits interconnecting field-installed equipment forming part of an emergency generator against possible damage by fire.

The following examples illustrate acceptable methods for achieving this protection:

(a) using mineral-insulated cables conforming to fire rating requirements as specified in Clause 5.3 of CSA C22.2 No. 124 or other cables that comply with the ULC S139 circuit integrity test and are marked “S139” and “2 h CIR”;

(b) embedding the raceway containing conductors between an emergency generator and associated equipment in concrete with a thickness sufficient to provide protection of electrical conductors from fire exposure for a period of at least 1 h in compliance with the National Building Code of Canada; or

(c) installing the raceway containing conductors between an emergency generator and associated equipment in a shaft enclosure or service space of at least 1 h fire resistance construction”.

It is obvious, that the CE Code users have no choice, but to understand and comply with these CE Code requirements.

These CE Code users also have to understand that Subsection 3.2.7. of the NBCC mandates emergency power for specific systems and equipment that must continue to function in the event that a regular power to these systems and equipment is interrupted. These specific systems are described in the NBCC and defined in Section 46 of the CE Code as “Life safety systems” as follows:

“Life safety systems — emergency lighting and fire alarm systems that are required to be provided with an emergency power supply from batteries, generators, or a combination thereof, and electrical equipment for building services such as fire pumps, elevators, smoke-venting fans, smoke control fans, and dampers that are required to be provided with an emergency power supply by an emergency generator in conformance with the National Building Code of Canada”

Articles 3.2.7.4. and 3.2.7.8. of the NBCC state that for emergency lighting and for fire alarm systems (including voice communication where voice communication is required to be provided as a part of a fire alarm system by Article 3.2.6.8.) – such emergency power source could be represented by batteries or generators. These NBCC Articles further specify a minimum period of time during which such power supply sources must automatically supply the connected loads. This minimum required period varies from 5 min for a building allowed by the NBCC to be equipped with a single zone fire alarm system – up to 2 hours, where such systems and equipment are installed in a high building. Although Articles 3.2.7.4. and 3.2.7.8. of the NBCC allow an option of using batteries or emergency generators as the emergency power supply source for emergency lighting and fire alarm systems, Sentence 3.2.7.9.(1) of the NBCC specifically mandates use of an emergency generator capable of operating under a full load for not less than 2 h as an emergency power supply source for a very particular life safety equipment discussed in my last article (i.e., for elevators, smoke control and smoke venting equipment in a high building and for electrical fire pumps installed in any building).

Thus, it is also obvious that in addition to the CE Code requirement for fire protection of conductors supplying a fire pump from an emergency generator or conductors between the emergency generator and the automatic transfer switch, certain conductors supplying equipment comprising life safety systems also must be protected against fire exposure. This fact leads to the answer to the second question.

Which conductors are required to be protected against exposure to fire?

This NBCC requirement is articulated in Article 3.2.7.10. as follows:

“3.2.7.10. Protection of Electrical Conductors

1) The protection of electrical and emergency conductors referred to in Clauses (a) to (c) shall conform to the requirements stated in Sentences (2) to (8):

- a) electrical conductors located within buildings identified in Article 3.2.6.1. serving

- i) fire alarms,

- ii) emergency lighting, or

iii) emergency equipment within the scope of Articles 3.2.6.2. to 3.2.6.8.,

- b) emergency conductors serving fire pumps required to be installed under Article

3.2.5.18., and

- c) electrical conductors serving mechanical systems serving

- i) areas of refuge identified in Clause 3.3.3.6.(1)(b), or

- ii) contained use areas identified in Clauses 3.3.3.7.(4)(a) and (b).

2) Except as otherwise required by Sentence (3) and permitted by this Article, electrical conductors that are used in conjunction with systems identified in Sentence (1) shall

- a) conform to ULC-S139, “Fire Test for Evaluation of Integrity of Electrical Cables,” including the hose stream application, to provide a circuit integrity rating of not less than 1 h, or

- b) be located in a service space that is separated from the remainder of the building by a fire separation that has a fire-resistance rating not less than 1 h.

3) Electrical conductors identified in Clause (1)(c) shall

- a) conform to ULC-S139, “Fire Test for Evaluation of Integrity of Electrical Cables,” including the hose stream application, to provide a circuit integrity rating of not less than 2 h, or

- b) be located in a service space that is separated from the remainder of the building by a fire separation that has a fire-resistance rating not less than 2 h.

4) The service spaces referred to in Clauses (2)(b) and (3)(b) shall not contain any combustible materials other than the conductors being protected.

5) Except as stated in Sentences (7) and (9), the electrical conductors referred to in Sentence (1) are those that extend from the source of emergency power to

- a) the equipment served, or

- b) the distribution equipment supplying power to the equipment served, if both are in the same room (see Appendix A).

6) If a fire alarm transponder or annunciator in one fire compartment is connected to a central processing unit or another transponder or annunciator located in a different fire compartment, the electrical conductors connecting them shall be protected in accordance with Sentence (2).

7) Fire alarm system branch circuits within a storey that connect transponders and individual devices need not conform to Sentence (2). (See Appendix A.)

8) Except as permitted in Sentence (9), if a distribution panel supplies power to emergency lighting, the power supply conductors leading up to the distribution panel shall be protected in accordance with Sentence (2).

9) Conductors leading from a distribution panel referred to in Sentence (8) to emergency lighting units in the same storey need not conform to Sentence (2).”

If one would carefully examine Article 3.2.7.10. of the NBCC, it could be seen from this Article that the NBCC mandates protection of certain electrical conductors for a period of not less than 1 h and certain electrical conductors for a period of not less than 2 h. For example, it could be seen that in a high building riser conductors supplying fire alarm system and emergency lighting from an emergency power source or conductors supplying elevators, smoke control fans and dampers from an emergency generator, must be protected against exposure to fire for a period of not less than 1 h. It could be also seen that such 1 h fire protection is required between an emergency generator and a fire pump in any building where an electrically connected fire pump is installed.

It could be seen as well that the conductors supplying the mechanical ventilation equipment installed in areas of refuge in compartments that contain operating or delivery rooms or intensive care units in a health care facility (regardless whether the building containing such facilities is classified as a high building or not) or conductors supplying the mechanical ventilation equipment installed in a contained use such as of a jail/prison – must be protected against exposure to fire for not less than 2 h. So, a detailed analysis of the NBCC Article will help the electrical designers and installers to make a correct decision in protecting electrical conductors against fire exposure.

Now is the time to deal with the third question.

If the conductors which are required to be protected and are specified by electrical designers do not comply with the circuit integrity testing requirement, how could such protection be accomplished and who is responsible for it?

It could be also seen from Article 3.2.7.10. of the NBCC that the required fire protection of conductors could be accomplished by two methods:

- By selecting conductors that conform to the “Fire Test for Evaluation of Integrity of Electrical Cables” prescribed by the standard ULC S139 or by placing the conductors required such fire protection in a “service space” separated from the remainder of the building by a fire separation that has a fire resistance rating not less than 1 h (or not less than 2 h in case of conductors supplying mechanical ventilation equipment in refuge areas of health care facilities or in contained use areas of a jail).

Of course, it is a responsibility of electrical designers to specify conductors required such fire protection that conform to the ULC S139 fire test and to ensure that such conductors are marked: “CIR” 2 h ULC S139”.

It should be noted that the ULC has re-instated its certification program for circuit integrity cables and that in addition to a MI cable, other available circuit integrity cables on the market (i.e., “Draka”, Lifeline”, etc.) with the above referenced marking on the cable outer jacket are deemed to be considered as being protected against exposure to fire for 2 h in accordance with Clause 6.1A of ULC S139.

The link below provides the latest information on UL/ULC listing of cables that have been tested to ULC standard ULC S139. When such cables are specified in electrical design, these cables do not have to be placed in 1 h rated service spaces. http://database.ul.com/cgi-bin/XYV/cgifind.new/LISEXT/1FRAME/srchres.html

- By discussing with the building code experts (with architects or building code engineers)the best appropriate means to install such conductors in “service spaces”. It should be noted that a term “service space” is defined by the NBCC as follows: “service space means space provided in a building to facilitate or conceal the installation of building service facilities such as shuts, ducts, pipes, shafts or wires”. Use of this defined term in conjunction with requirements of Sentences 3.2.7.10.(2)(b) or (3)(b) as shown above has created further confusion in the industry. If these protected conductors must be located only in service spaces, and such service spaces do not include service rooms (where life safety equipment or where emergency distribution equipment to which such conductors have to be connected), then it appears that the conductors’ required fire protection against exposure to fire cannot be installed in the electrical service rooms. The proposal to revise these two Sentences of Article 3.2.7.10. by including “service rooms” in these sentences has been sent to the NRC technical staff. Meanwhile, the industry practitioners consider that fire-rated service rooms that contain emergency distribution equipment or life safety equipment to which such conductors must be terminated, meet the NBCC provision for protection of electrical conductors against exposure to fire.

In conclusion it should be noted that specific requirements of the local Codes, By-Laws, Bulletins, Directives or regulatory interpretations on the subject of protection of electrical conductors against exposure to fire must be taken into account.

Find Us on Socials