I still remember the day when a fellow inspector tapped me on the shoulder and said: “Be ready to leave in 20 minutes; we’re going to look at this PV.” PV, I thought to myself, What’s that? Heck I just relocated from Seattle to San Diego, did he mean PB (the locals lingo for Pacific Beach)?

I soon found out he was referring to Article 690, which I had never had the opportunity to read and apply as an electrician in Seattle. I now had 19 minutes to speed-read this and then perform an inspection. That first day was an eye opener. And, I quickly realized, 690 doesn’t address everything, and I needed to apply many other sections of the Code based on my observations.

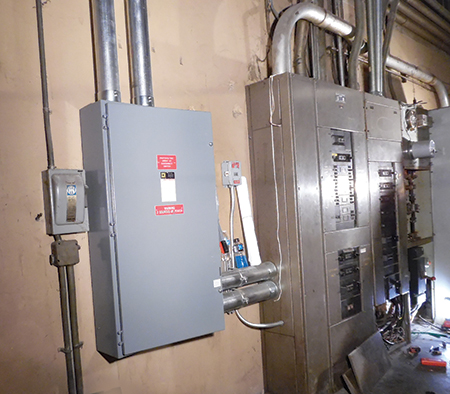

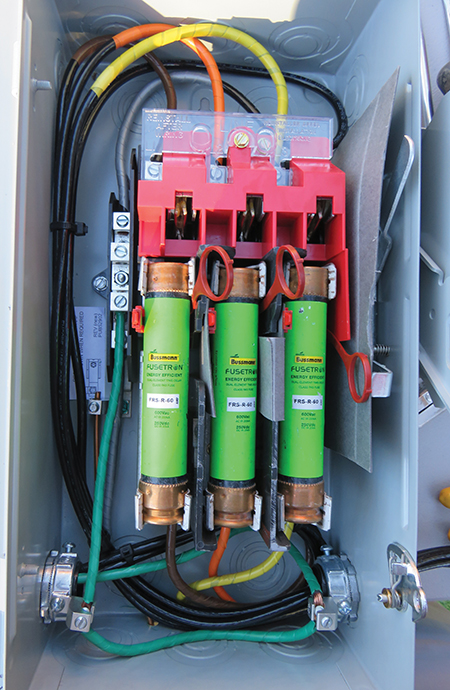

Fast forward to today where we have daily PV inspections, and some are supply-side connected. Article 705.12(A) Point of Connection (Supply-Side) points the reader to 230.82(6) for the allowance to connect to the supply side of the service disconnecting means. This article highlights the minimum code requirements and a process for supply-side connections that you may find useful to minimize risk to your client.

Recon your project

What I call recon, meaning reconnaissance, a military term for inspecting or exploring an area, is a term that can also be applied to construction. It is an action performed by the contractor/installer to initiate the planning stage for their project. This process may involve a preliminary shutdown of the equipment to photograph the location of the connection, take measurements, and plan the installation from start to finish. Some things to consider:

- How will I enter the existing service equipment?

- Is there appropriate space for additional conductors?

- Where do I terminate my new service conductors?

- Do I need conductor bracing?

- Where will I obtain any new busbar materials used for the termination?

- Is the existing equipment properly rated?

- Did the available fault current from the utility change over the years?

- Do I need a field evaluation by an NRTL?

- What will the evaluator require?

This is a partial list of what to consider, and your eyes may have popped with my mention of “new service conductors.” I am well aware that some of you may look at these PV conductors as feeders only, and I would agree, the conductors from the inverter to this new disconnect are feeders. However, the conductors to the existing service are attached ahead of the main breaker/disconnect with no overcurrent protection. That is a concern!

Plan-Check

At plan-check, my rule of thumb is that the more information I get, the better. The organization of your submittal should be in a logical order and is most likely laid out by your jurisdiction. So, let’s just drill down and focus on the connection in the existing service and the new service rated disconnect for the system. Some things to consider and check at plan-review may include:

- Rating of the equipment

- Available fault current from the utility

- Disconnect size, 230.79(D)

- Disconnect required to be service rated, 690.13(C), 705.22(4)

- Conductor size, 230.42(B)

- Are bus flags being used, and who’s sourcing the materials? Manufacturer? 508 shop? Local hardware store?

- Will new holes be drilled to accommodate the connection?

- Expanded (magnified) view of the connection on the drawing to identify:

- nuts, bolts (grade 5), washers (what type), size and additional hardware

- order of assembly

- mechanical or high press lugs

- How are we making entry to access the existing equipment for conductor connections?

- Is the one-line complete or do we need a three-line diagram?

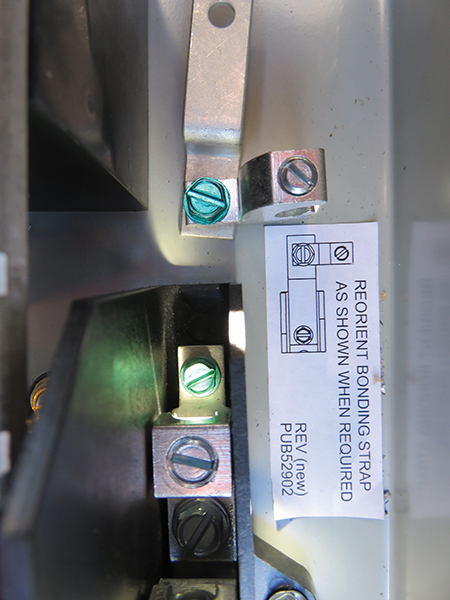

- Are grounding and bonding appropriately identified on the drawing?

- Are they in compliance with 250.24, 250.80?

- Is the disconnect location in compliance with 705.31?

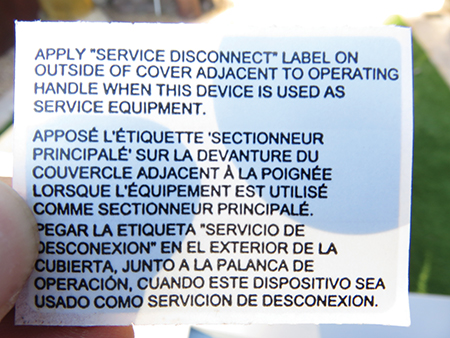

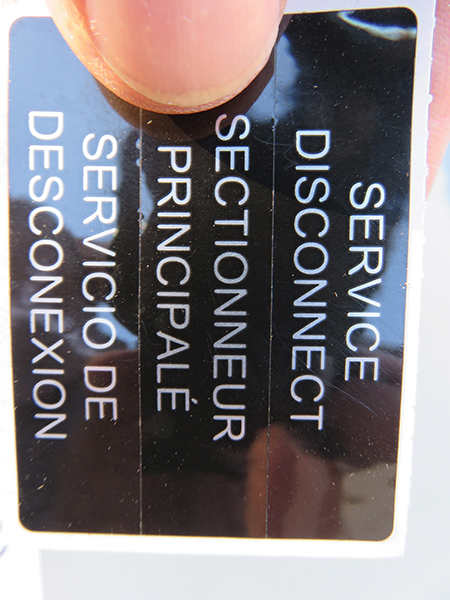

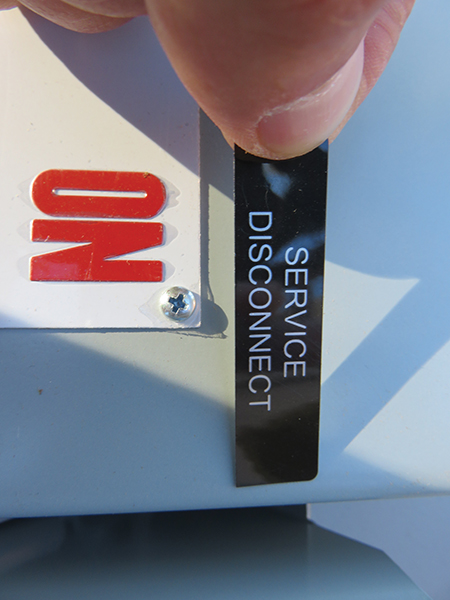

- How will the new disconnect be identified (labeled)?

- Will the AHJ require third-party NRTL review of any modifications?

- What is the evaluator’s scope?

- When will he or she be present?

- Will the conductors be located in the same vertical section as required by 408.3(A)(3)? Or are they traveling horizontally through multiple sections?

- What type of wiring method will you allow from the existing equipment to the new service rated disconnect (see 230.50)?

This list is just a sampling of what you may require, and it is debatable whether 230.71 would apply if you already have 6 main service disconnects for a building. My take is: The new conductors are connected to the service conductors inside the equipment (maybe to the service conductors themselves) and failure to indicate this new disconnect, as one of two or one of six service disconnects for the building, is extremely dangerous for maintenance personnel and first responders. I mention this because 690.13(D) has been misinterpreted in the past as an allowance for 6 additional supply-side connected disconnects for PV system. If the building already had 6 main service disconnects (or as we electricians say 6 movements of the hand), this would (in my humble opinion) be a violation of 230.71. However, the AHJ has the final say, so I wouldn’t die on this sword. Regardless of the number of disconnects, the important thing to remember is to treat this new disconnect as a service-rated disconnect to ensure it is connected, grounded and bonded properly.

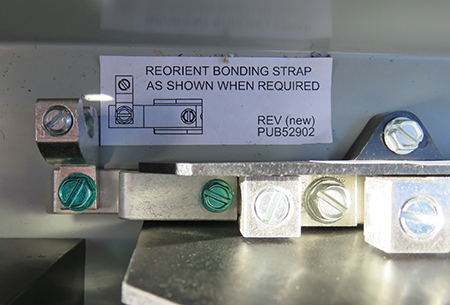

Field Evaluation

I know some of you are saying “WHAT? Field evaluation for a supply-side connection? Really? Scott needs a drug test.” However, before you hand me that cup, remember this is a modification to the equipment if it is adding an additional bus, and/or disassembling the existing bus, or drilling bus to make our connection. If the existing service contained overhead service conductors and you intercepted these at the weather head, then no evaluation would be required because you are not modifying the equipment.

However, for the purpose of this article, let’s assume we are modifying the equipment and making a connection inside the existing service equipment. The field evaluation report should indicate in writing a reference to the UL 891 Standard for Switchboards. Have the evaluator establish his or her scope of work and get your “buy-in” all in writing. This process will help avoid communication gaps and make both parties responsible for their portions of the inspection. And, there is no reason why you cannot be present for the evaluator’s portion to see how different test labs vary in their application of the standard. Being there gives you an opportunity to learn more about field evaluations. The most common scope of any evaluator is the actual connection inside the equipment, and the conductor(s) used. The approval for the field evaluation and the remainder of the installation is at the discretion of the local inspector. Again, capture this in writing before progressing to the evaluation to avoid any misunderstandings, report revisions, and angry project leaders. Here are some things the evaluator should be documenting in his or her report:

- Scope of the evaluation (tell me a story)

- Is the equipment properly listed?

- If bus flags are used, where were they manufactured and/or obtained? (The flags need to be traceable.)

- Are they electrical grade and are they the appropriate size?

- One-inch clearance around the newly installed bus

- Check for conductor damage during installation

- Was cable lashing required by the manufacturer?

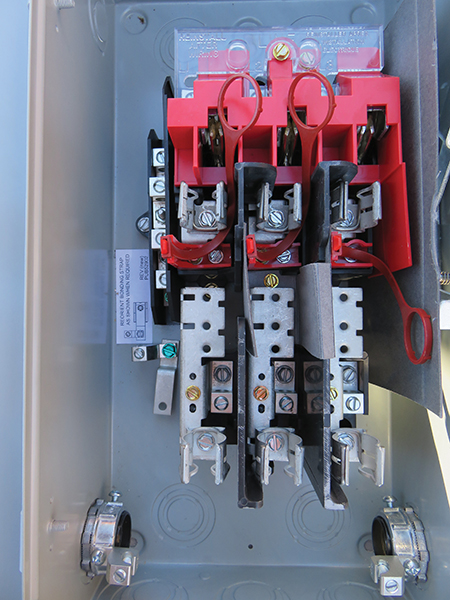

- How are we securing the new bus? Normally grade 5 hardware is used, and nut bolt washer sizes need to be identified

- Did we have full thread engagement?

- Conductor size and suitability of any crimped/high pressed connections

- Calibrated wrench used

- How were the torque values determined? Normally from the manufacturer’s specifications; did they use a calibrated wrench?

- Wire bending space checked

- Document the equipment:

- manufacturer

- model number

- serial number

- Nameplate Data (electrical ratings)

- Volts

- Amps

- Phase

- Wire

- Frequency

- Short circuit current

- Additional ratings such as Enclosure Type

- What’s not covered in the evaluation?

- Deficiencies encountered

- Critical components list limited to the termination covered by the scope of work

This is a partial list of items most commonly documented and, depending on the scope, there could be more detail required. Some of the most common issues encountered by evaluators are as follows:

- Conductors were damaged during installation

- Installer cannot establish traceability for new bus flags

- Wrench calibration date is expired

- Suitability of replacement hardware is not grade 5

- Conductor lugs are the wrong size and/or bolt hole is too small

- Conductor set screw torque values are unknown for the mechanical lugs

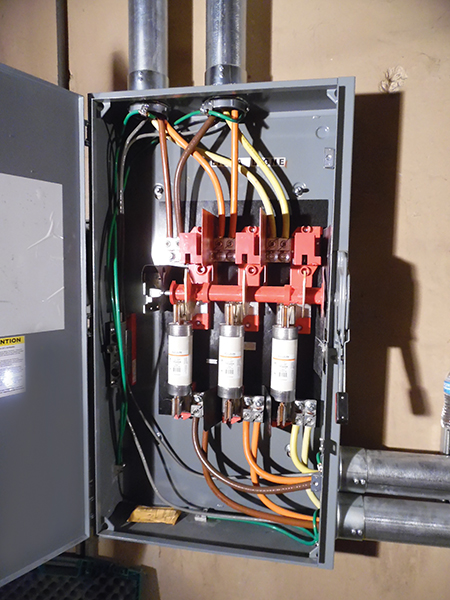

- The neutral conductors are terminated on the load side of the neutral link

- Violation of UL-891.8.8.2.1.3 – the mechanical lugs and/or high pressed terminals required the disassembly of the factory assembled parts in order to make the connection. The connection to the bus occurred at a factory joint and/or bus support not intended for field-installed terminations by the equipment manufacturer

This last deficiency is a very common error made by installing contractors, and some evaluators miss this during their evaluation. Additionally, some NRTLs do not see an issue with using the factory joint for the connection as long as it is field evaluated during the reassembly process. My take is, UL 891 would not allow this location to be used as a connection point during the certification process for the original listing/labeling of the product. In other words, disassembly of a bus could never be indicated in the installation instructions as an option because it would violate the UL 891 Standard. Moreover, the chances of things changing over the years is a possibility with the introduction of energy storage systems or other parallel power production sources. And, if the installer adds bus flags/extensions, the opportunity for future upgrades is much easier and will not require a field evaluation because the provision for additional connections was made available during the original installation and field evaluation.

AHJ Inspection

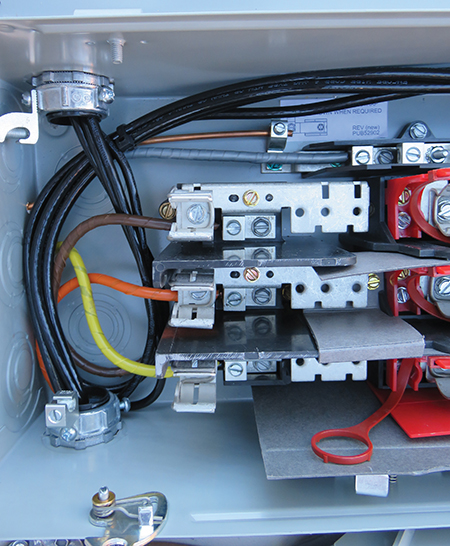

The AHJ now has the pleasure of looking at everything and if you were present for the field evaluation portion then maybe you already approved the connection and the report from the evaluator. I always approve the report first before I conduct my final inspection. For this article, let’s focus corrections to only the existing service and the new service rated disconnect. Some of the most common issues are as follows:

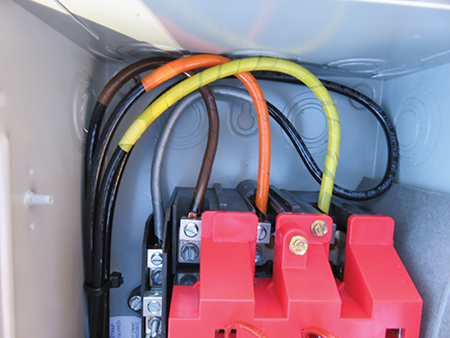

- The conductors from the existing service to the new fused service rated disconnect (SRD) are reversed. Currently, the conductors (unfused) from the utility terminate at the load side of the disconnect (bottom terminals), not the line side. When the fused disconnect is in the open position (OFF), the fuses are still energized from the utility. This situation is extremely dangerous. The current installation would require a shutdown to replace the fuses.

- The grounded conductor from the parallel power production source to the new (SRD) is not bonded at the new SRD and passes straight through and continues to the existing service. This process is a violation of 230.75 and 250.24(C)

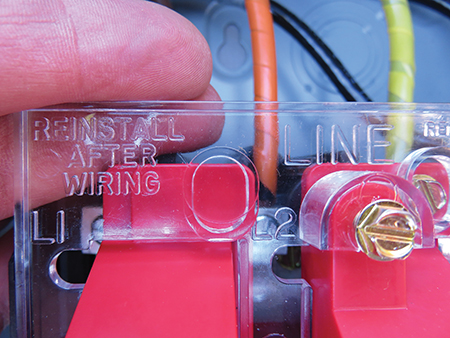

- The main bonding jumper is not installed within the new SRD. The green screw provided by the manufacturer to use for this connection (bond) is still in the manila envelope located in the bottom of the enclosure, violation of 250.28

- The grounding electrode system is absent from the new SRD, violation of 250.24(D)

- The new EMT raceway from the new SRD to the existing service is not bonded properly as required by 250.92(B)

- The new raceway (containing the new service conductors) from the existing service to the new SRD has a metallic pull box installed where the grounded conductor is not bonded to the enclosure as required by 250.80

- The new SRD is located 20 feet away from the existing service where the conductors are connected, violation of 705.31

- The one line diagram/drawings approved by the plan checker are incorrect. Currently, the diagram does not show and/or incorrectly depicts the following:

- Grounding electrode system is not shown.

- Conduit #3 (new EMT raceway from the existing service to the new SRD) identifies parallel equipment grounding conductors being run with the new service conductors. Currently, the grounded conductors and the equipment grounding conductors (EGC) are in parallel. In this case, the EGC is now a current-carrying conductor (connected together at both ends)

- System labeling is absent; what are we calling this new disconnect?

This situation is just a sampling of what is seen in the field. Additionally, one more interesting thing I have seen (which is not really a code violation, but is still a big ‘whoopsie’) is when the supply-side connection in the existing service equipment was made on the line-side of the CTs, and as a result, the customer was not receiving generation credits. This situation was missed by plan-check, the third-party NRTL, and the local inspector.

One more detail I alluded to regarding labeling — do we call this new service rated disconnect “one of two” or “six of six”? Remember, these large commercial systems will typically have additional power requirements downstream to power 480v/240v trackers, 120v weather stations, various communications, alarms and cameras. This new disconnect is providing power for additional loads located in, on or around the building based on the design. The first responders need to know this disconnect exists to avoid any electrical injuries and/or fatalities. I would suggest communicating with your fire marshal to avoid any gaps and/or assumptions within your team.

In Closing

I am sure this article will receive some criticism or at least spark a water cooler conversation about— What to call these supply side connected conductors? I agree that by definition (Article 100) these are not service conductors. However, we need to treat these like we treat service conductors to ensure a safe installation. And, we need to verify the equipment is properly grounded and bonded to ensure the proper operation of any overcurrent protective devices. It seems that UL agrees with my logic. See the UL website under Field Services, Additional Resources, UL Line Side Taps – Installation Guidelines http://services.ul.com/service/field-evaluation

Additionally, I only focused on the most common method of connection. There are others, such as mentioned in Article 230.2(A)(5), which would allow the second service just for the parallel power production system(s); and, by definition, we really would have service conductors. Or, 4160v/12kV connections for large commercial megawatt(s) systems. Also, I have had AHJs and installers apply the tap rules located in Article 240 for this installation. However, these rules apply to feeders and should not be used for any unfused conductor(s) associated with a parallel power production supply-side connection. The confusion is the term used for the actual connection to the bus and/or conductor called a “tap connection.” This term is not to be confused with the connection to the bus, which we call a tap.

If this article has generated any additional questions and/or comments, please contact the author by phone 619-318-7310 or email at shinspections.inc@cox.net

Find Us on Socials