As an electrical inspector since 1985, I have witnessed many changes to the National Electrical Code (NEC), each designed to improve electrical safety in the built environment. For me, enforcing those codes and standards has been more than a job—it’s been a calling and a lifelong commitment to public service while working for county and city governments.

But even after decades of progress, one issue persists: a requirement that’s been in the NEC for over 30 years yet remains one of the most overlooked. That requirement is found in Section 300.4, Protection Against Physical Damage, in the 2023 edition and 300.6 in the 2026 edition.

The Intent of Section 300.4

Section 300.4 has a simple goal: to keep wiring protected from damage and potential fastener penetration—or to protect it when that clearance isn’t possible. When screws or nails hit unprotected conductors inside walls, the results can be serious: damaged wire, short circuits, shock hazards, or even fire.

Here is the 2023 NEC paraphrased for your reference, or please look it up.

(A) Cables and Raceways Through Wood Members

(A)(1) Bored Holes: When installed through bored holes in joists, rafters, or other wood members, the edge of the hole must be at least 1¼” inches from the nearest edge of the wood. If that spacing isn’t possible, the wiring must be protected by a steel plate or bushing at least 1/16 inch thick, sized to cover the appropriate length and width of the exposed wiring.

(A)(2) Notches in Wood: When wiring passes through a notch cut in a wood member, additional protection is required. A 1/16-inch steel plate must completely cover the area where the cable or raceway is exposed, and the appropriate length and width of the exposed wiring, 1¼” inches from the nearest edge of the wood.

(B) Nonmetallic- Sheathed Cables (NMS) and Electrical Nonmetallic Tubing (ENT) Through Metal Framing Members

(B)(2) (NMS) and (ENT) Wires must be protected with a steel plate at least 1/16 inch thick, extending 1 1⁄4 inches from the nearest edge of the framing member.

(D) Cables and Raceways Parallel to Framing Members and Furring Strips

When installed parallel to framing members or furring strips, wiring must maintain the 1 1⁄4-inch clearance—or be protected by a steel plate if clearance can’t be maintained.

In plain language: whether the cable goes through, across, or along a framing member, if it’s in that 1¼-inch danger zone, it needs protection.

Why Is It Still Overlooked?

The rule has been part of the NEC since 1990, yet enforcement is inconsistent. Here’s why:

- Misinterpretation of the Rule: Some electricians believe protection is required only on the face of a framing member. They overlook that the cable is still within the 11/4” inch penetration zone on the left and right side of the stud or furring strip as it enters/ exits the wood. The intent is to protect wiring anywhere damage is likely which is within the 1¼” inches of the wood edge.

- Lack of Solutions in the Past: For years, there were no products designed for these situations. Your current protection plates don’t always comply, as the wire is not protected the 1-¼” inches through the furring strip or framing member. So, electricians or installers often neglect the protection, and electrical inspectors [and I am one] have overlooked the enforcement of the NEC code requirement.

Why This Matters: The Fire Risk Is Real

Ignoring Section 300.4 is not just a code violation—it’s a safety hazard. Damaged wires hidden in walls have been linked to short circuits, shocks, and fires.

According to the NFPA (February 2022 report by Richard Campbell):

- U.S. fire departments responded to an estimated 32,620 home fires per year (2015–2019) involving electrical distribution and lighting equipment.

- Fires most often originated in:

- Bedrooms: 16%

- Attics or ceilings: 11%

- Wall assemblies or concealed spaces: 8% (2,608 fires annually)

These wall assemblies & concealed spaces are exactly where Section 300.4 applies—and where enforcement often falls short.

Field Examples Where Compliance Fails

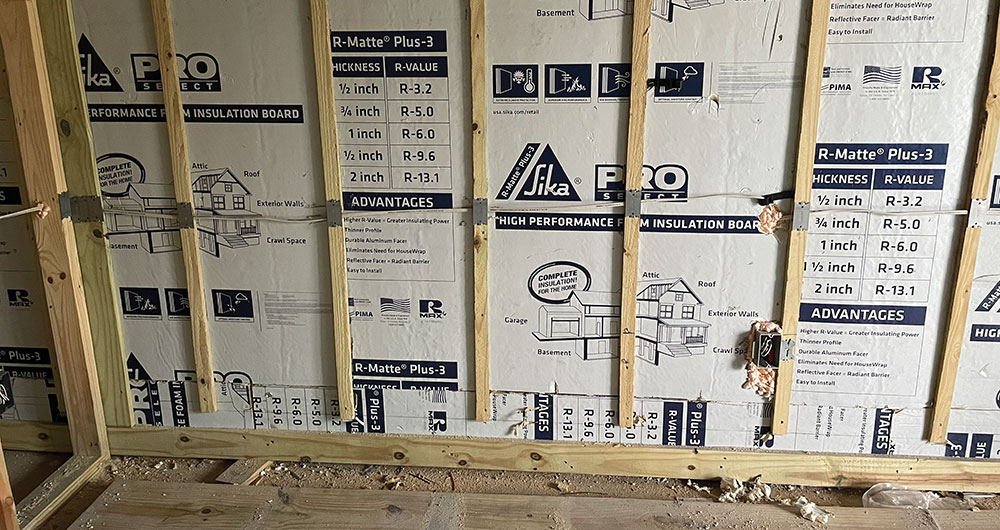

- Furring Strips on Block Walls: No clearance as the furring strips are normally only ¾” inches thick which makes it impossible to achieve the 1¼” inch clearance. The protection is only over top of furring with no protection within the 1¼” inches of either side.

- Bored holes are not in the center of the 2×4 framing to get the 1-¼ inch spacing. The only protection is over the top of the framing member. No protection to either side as the wire enters or exits the framing member.

- Notches in Wood. When wiring passes through a notch cut in a wood member, a protection plate is used over the top of the notch, but no protection is found within 1-¼ inches to either side as the wire enters or exits the framing member.

Result: cables and raceways remain unprotected, even in areas most at risk for damage.

Solutions: Closing the Gap & Call to Action

How do we fix this? It starts with three key actions:

Electrical Contractors protect your work – plan for compliance. You will save time and money with fewer callbacks when your branch circuit gets damaged and shorts out, or worse, starts a fire in the home or business. Add steel plates for protection where wiring is too close to the edge of framing members without proper clearance of 1¼” inches on both sides.

Even on remodels for older homes or businesses, where you might have existing wiring where drywall was removed due to a flood. Exposing the wire stapled to the side of a furring strip, or it may be too close to the face of a 2×4. It’s a violation of 300.4, Protection Against Physical Damage. It really doesn’t matter if you didn’t run the wire; it’s exposed now and can be protected. Move the wire, use a standoff, or protect it with a protection plate, and be safe.

Electrical Inspectors enforce the full intent of the NEC Article 300.4 and don’t pass installations where wiring is too close to the edge of framing members without proper clearance of 1-¼” inches with a steel plate 1/16” inch thick on both sides.

New Products are emerging to address these problems for a code-compliant answer to wiring homes and businesses.

NFPA gives us the NEC code, and it’s up to all of us (The Independent Alliance of the Electrical Industry) to bring awareness across the country for a better, safer built environment..

Looking Ahead: Possible Clarification for 2029 NEC

Clearer language could help eliminate ambiguity in the Code. For example, a code change in wording within 300.6 of the 2026 edition.

“Steel protection plates shall extend 1¼ inches on either side of the framing member or furring strip where wiring crosses it.”

This wording / proposal does not change the technical requirement- it simply clarifies the intent already present in 300.4 for decades.

The Bottom Line

Section 300.4 has been in the NEC for more than 30 years because the hazard it addresses is real and persistent. Yet compliance remains inconsistent. With better planning, enforcement and product innovation,we can reduce the number of fires that start in concealed spaces and build safer homes and buildings for everyone.

Find Us on Socials