The National Electrical Code1 (NEC) and the National Fire Alarm Code2 (NFPA 72) have an interwoven relationship that is paramount to the proper operation of fire alarm systems. In the same way, the electrical inspector and the fire alarm inspector have common goals. This article will develop and build on the last issue’s article, “The Electrical Inspector and Fire Alarm Systems.”

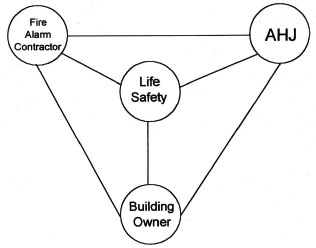

Inspectors of related trades are encouraged to work together and learn how their skills and knowledge will benefit each other. The Life Safety Triangle3 (see figure 1) is greatly enhanced when authorities having jurisdiction (AHJs) have equipped themselves with knowledge and skill. Ultimately it is their family, their friends and themselves who will utilize these facilities that have their blessing. It should be a comforting feeling to know that a fellow inspector has blessed the hotel where one’s family is spending the week.

Figure 1

It is only a minor detail, why bother?

Allowing what may appear to be small and insignificant problems to be overlooked may actually exacerbate the tenability and life safety of the fire alarm system. This is not to say that all inspections should fail because of minor code violations; it is to say that a mechanism needs to be in place that allows for thorough and complete inspection while providing for a means to ensure that minor details are identified and abated.

Typically very little, if any, additional time is required to install a fire alarm system properly, than is required to correct deficiencies of an improperly installed system. The author has witnessed many systems installed correctly the first time as well as systems that have required many attempts to correct what appeared as minor problems. Recording all discrepancies will help ensure that the system will operate correctly when needed and provide written documentation about the inspection in the event the inspector’s methods are questioned.

What makes a reliable fire alarm system?

There are four elements that help ensure a fire alarm system will operate properly when needed. The acronym EDIT will help one remember the components.

1. Proper and Listed Equipment. Is the equipment approved by the authority having jurisdiction? Is the equipment listed for use in a commercial fire alarm system? a residential fire alarm system? outdoors? hazard occupancy, including explosion proof? and the like? Many times contractors will install equipment not listed for the use intended. This is where the product specification sheets supplied with the shop drawings and available on site are compared to the actual product installed.

2. Proper Design. Did the designer consider the building occupancy and construction for the proper type of system? During the rough wire inspection one may find back boxes installed on the walls and ceiling in a swimming pool room. Are these for smoke detectors, heat detectors, or horn/strobes? If they are, then it is important to ensure these devices are listed for humid environments. Locations of horn/strobes shall provide the proper coverage per NFPA 72.

3. Proper Installation. How was the installation performed? In the above scenario does the conduit installed in these areas meet Article 348-10, as well as other articles related to damp areas? Article 760 specifically addresses the installation of fire alarm systems. Other articles, including 250 and several 300 series articles, are specifically referenced.

4. Proper Testing and Inspection. Is an inspection and testing contract in place before the witnessed acceptance test? Was the system tested according to chapter 7 of NFPA 72? These issues become more important as one’s knowledge base and responsibility change. Proper witness acceptance testing of a fire alarm system is a whole other topic and is beyond the scope of this article.

Just like the Life Safety Triangle, if one of these components is lacking then the entire system is compromised. Inspectors have a tremendous opportunity to ensure that proper equipment, proper design, and proper installation have taken place and that future testing and inspections are compliant with the code.

Making one’s own notebook

The author encourages inspectors to develop a notebook of Fire Alarm Systems. This is a valuable tool to an inspector, because it provides a reproducible method for inspections and is a constant reminder of items to check. Included are several pieces of information that the author encourages each inspector to copy and add to his notebook.

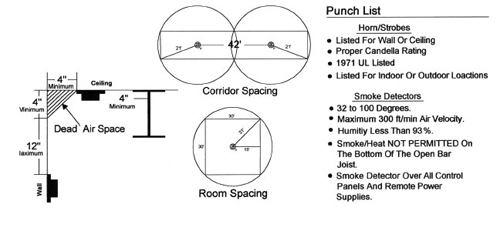

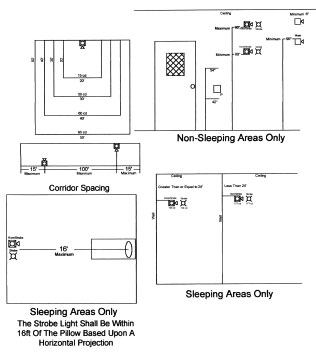

Figure 2 illustrates typical placement of smoke and heat detectors. Figure 3 illustrates horn/strobe placements. Figure 4 is a punch list for typical Code issues related to fire alarm systems. Various charts from NFPA 72 should be carried and may include ambient sound levels in various occupancies, Table A-4-3.2 Average Ambient Sound Level According To Location.

- Figure 2. Illustrates typical placement of smoke and heat detectors

I don’t care what it takes…just get the system installed!

The infamous battle cry of the General Contractor! Everyone’s emergency constitutes an emergency on the inspector’s part, or so the general contractor believes. By simply planning ahead and providing for the proper equipment, design, installation and testing of the fire alarm system most, if not all, of these headaches could be eliminated. Photos 1-15 illustrate some of these headaches.

Figure 3. Figure 3 illustrates horn/strobe placements

Photo 1. This horn/strobe is a wall mounted appliance and was installed on the ceiling. The visual coverage and the word FIRE are specifically designed for this product to be installed on the wall.

In the last issue, photo 2 showed, what appeared to be a properly located horn/strobe on the ceiling (see photo 1). This horn/strobe is a wall mounted appliance and was installed on the ceiling. The visual coverage and the word FIRE are specifically designed for this product to be installed on the wall. When brought to the attention of the contractor, he simply printed a new FIRE word and installed it over the existing word. Unfortunately this device is still in place and is located in a fire prevention office. The solution is to install the appliance in the way it was listed or install an appliance that is listed for the ceiling.

In photo 2, the face of the back box is required to be within 1/4″ of the finished surface and within 1/8″ of the side of the box. These boxes were installed because of a failed inspection and workmanlike practices were not used.

Photo 2. The face of the back box is required to be within 1/4″ of the finished surface and within 1/8″ of the side of the box

The Code requires that flexible metallic conduit shall be connected properly. The piece of conduit in photo 3 needs to be inserted further into the connector. This may help prevent the flex from slipping out.

“A picture is worth a thousand words.” Needless to say, box fill calculations were not considered in photo 4.

The contractor solved the box fill calculations by adding extension rings (see photo 5). This may have solved the box fill requirement, but it created another problem. Where are the three inches of wire that is required to extend beyond the face? This particular splice box has to be physically dissembled to permit access to all of the wire nuts for service.

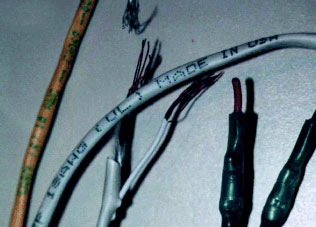

Notice the aluminum shield touching the left side of the metal box in photo 6. I pulled this wire away so I could photograph it. This wire was pressed against the inside of the cabinet by other wires. This is a great source of the ever-allusive “ground fault” ghost. Proper splicing of shielded wire eliminates these problems.

Photo 3. The piece of conduit in photo 3 needs to be inserted further into the connector. This may help prevent the flex from slipping out

Photo 7 shows that the mechanical contractor drilled a hole into the housing of the duct detector so the wire to shut down the AHU could be facilitated. The manufacturer of the duct detector does not allow the hole to be drilled into the side. This wire is required to be connected through a proper hole using the proper strain relief connection.

Close inspection of the panel in photo 8 shows that the fire alarm contractor cut the notification appliance supervision jumpers. The manufacturer of this combination burglar/fire panel permits the cutting of the jumper if the panel is NOT used for a commercial fire panel or a UL Listed burglar alarm system. By cutting the jumpers, the fire alarm contractor rendered invalid the panel’s UL Listing as a commercial fire alarm panel. These jumpers were cut because of wiring issues including t-tapping and ground faults. Proper wiring of the notification appliances would have eliminated this problem.

Photo 4. “A picture is worth a thousand words.” Needless to say, box fill calculations were not considered

Splice connectors are listed for specific size wires. The connectors in photo 9 are listed for 14-16 gauge but are connecting 18-gauge wire together. This problem is eliminated by using the proper connectors.

Photo 10 shows an indoor horn installed outside. It is mounted to an outdoor back box. Close examination revealed that the appliance does not mount properly to the outdoor back box. Caulk was used to seal the joints. The manufacturer does not list this appliance and the outdoor back box together. These problems can be checked by examining the product specification sheets that are part of the shop drawings required to be on site.

Installing devices or appliances without the proper screws supplied by the manufacturer may lead to pinched wires as shown in photo 11. Following the manufacturer’s instructions and using equipment provided will help eliminate this problem.

Photo 5. The contractor solved the box fill calculations by adding extension rings

It is imperative that proper back boxes be used in damp locations. While I was doing this inspection, the cleaning crew started to hose the wall down while I was standing there. I asked them if this was common practice or a one-time occurrence. They stated that this happened every day. Then I understood why the outdoor box without the proper gaskets and installation methods had allowed this device to corrode (see photo 12).

Photo 6. Notice the aluminum shield touching the left side of the metal box

Installing fire control panels outside is not acceptable when the temperature falls below 32°F or rises to greater than 120°F. Always follow the manufacturer’s instructions. The panel in photo 13 is subject to sub zero temperatures.

Photo 7. Photo 7 shows that the mechanical contractor drilled a hole into the housing of the duct detector so the wire to shut down the AHU could be facilitated

Homemade portable fire alarm panels are not acceptable and neither is the use of air conditioning cords to supply them, see photo 14.

In photo 15, I thought my fellow wood workers would enjoy the skill of the trim carpenter who scribed and coped this crown molding to the heat detector. And yes, texturing and painting heat detectors are NOT acceptable practices.

Conclusion

As electrical inspectors or fire inspectors doing inspections, we have a tremendous opportunity to be a real asset to the owner. The owner is counting on us and our independent, non-biased view. There is always a possibility that you or I will be sitting in the witness stand defending our actions and/or inaction. Having a systematic and consistently applied inspection procedure will greatly help us in providing our services. Our acronym EDIT, proper equipment, proper design, proper installation and proper testing and inspection, will help us as we venture into the inspection of fire alarm systems.

Photo 8. Close inspection of the panel shows that the fire alarm contractor cut the notification appliance supervision jumpers

I encourage inspectors to use the information in this article, follow other inspectors in different disciplines, and become involved in local chapters of the IAEI. Read and study the bi-monthly IAEI News. This is a great way to discuss and develop common application and procedures to field problems.

The tools of the inspector’s trade are our many years of experiences, our education and the most powerful one of all…our minds. Let’s use them for a noble purpose, the preservation of LIFE. Happy Inspection.

Photo 9. The connectors in photo 9 are listed for 14-16 gauge but are connecting 18-gauge wire together

Photo 10. Shows an indoor horn installed outside

Photo 11. Installing devices or appliances without the proper screws supplied by the manufacturer may lead to pinched wires

Photo 12. Then I understood why the outdoor box without the proper gaskets and installation methods had allowed this device to corrode

Photo 13. The panel in photo 13 is subject to sub zero temperatures

Photo 14. Homemade portable fire alarm panels are not acceptable and neither is the use of air conditioning cords to supply them

Photo 15. I thought my fellow wood workers would enjoy the skill of the trim carpenter who scribed and coped this crown molding to the heat detector

1. National Electrical Code, 1999 Edition, National Fire Protection Association, One Batterymarch Park, Quincy, Massachusetts 02269.

2. National Fire Alarm Code, 1999 Edition, National Fire Protection Association, One Batterymarch Park, Quincy, Massachusetts 02269.

3. “Codes and Standards,” Fire Alarm Systems…Made Simple, Mark A. Campbell, CET, Third Edition, 1997, Denver, Colorado 80249.

Find Us on Socials