This article represents a compilation of 6 answers to the questions from readers on differences between calculated loads, demand loads, demonstrated loads, and the application of demand factors in the Canadian Electrical Code, Part I (CE Code).

Question #1

What types of loads must be calculated and why?

Answer #1

Section 8 of the CE code (8-200 series Rules) applies to the calculation of loads for services and feeders in different types of occupancies (in single dwellings, apartment buildings, schools, hospitals, hotels, and in other types of occupancies, such as offices, restaurants, industrial plants, retails stores, etc.). Such load calculation requirements are based on specific criteria for different types of occupancies. Load calculations are necessary to select the appropriate size of conductors that supply such loads and the appropriate rating of overcurrent devices that protect these conductors.

The ampacity of conductors for branch circuits supplying various types of utilization equipment and the rating of overcurrent devices protecting these conductors are selected based on the ratings of utilization equipment in accordance with specific Sections of the CE Code.

For example, the ampacity of conductors for branch circuits supplying motor loads and ratings/settings of overcurrent devices protecting these conductors are selected in accordance with Section 28, ampacity of conductors for branch circuits supplying electric heating equipment and ratings/settings of overcurrent devices protecting these conductors, are chosen based on provisions of Section 62, ampacity of branch circuit conductors supplying electric welders and ratings/setting of overcurrent devices protecting these conductors, are selected based on the requirements of Section 42, etc.

Question #2

What is the correlation between the calculated loads and ampacities of conductors/ratings of O/C devices selected for such loads?

Answer #2

Subrules 8-104(1) and (2) of the CE code provide the following requirements in this regard:

“8-104 Maximum circuit loading (see Appendix B)

1) The ampere rating of a consumer’s service, feeder, or branch circuit shall be the ampere rating of the overcurrent device protecting the circuit or the ampacity of the conductors, whichever is less.

2) The calculated load in a circuit shall not exceed the ampere rating of the circuit.”

It means that under no condition will the load connected to the conductors be higher than the ampacity of the conductors supplying such load or than the rating/setting of the overcurrent devices protecting these conductors.

If the calculated load is not considered to be continuous (as in the case of loads for feeders and services supplying dwelling units under Rules 8-200 or 8-202), then the standard ampacity of feeder or service conductors supplying such calculated load or rating of the O/C devices protecting these conductors must be higher of (or equal to) the calculated load.

For example, if the load of the service to a single dwelling calculated in accordance with Rule 8-200(1) of the CE Code is 112 A, then based on provisions of Section 4, copper conductors of the consumer’s service must have a minimum ampacity of 115 A, if copper conductors in accordance with Table 2 are chosen, Therefore, 3 No. 2 AWG copper conductors would have to be selected for such consumer service to the single dwelling.

Respectively, in accordance with Rule 14-104(1)(a) and Table 13 of the CE Code, the O/C device in the service box would have to be rated at least at 125 A, and as per Rule 8-104(1) shown above, the rating of this service would be 115 A.

If, however, load calculated in accordance with applicable Rule of Section 8 is continuous, then conditions listed in Subrules 8-104(5) or (6) would have to be used for the selection of conductors’ ampacity and rating of the O/C device (see below):

“8-104(5) Where a fused switch or circuit breaker is marked for continuous operation at 100% of the ampere rating of its overcurrent devices, the continuous load as determined from the calculated load shall not exceed the continuous operation marking on the fused switch or circuit breaker and

(a) except as required by Item b), shall not exceed 100% of the allowable ampacities of conductors selected in accordance with Section 4; or

b) shall not exceed 85% of the allowable ampacities of single conductors selected in accordance with Section 4.

8-104(6) Where a fused switch or circuit breaker is marked for continuous operation at 80% of the ampere rating of its overcurrent devices, the continuous load as determined from the calculated load shall not exceed the continuous operation marking on the fused switch or circuit breaker and

a) except as required by Item b), shall not exceed 80% of the allowable ampacities of conductors selected in accordance with Section 4; or

b) shall not exceed 70% of the allowable ampacities of single conductors selected in accordance with Section 4.”

For example, if the calculated load of a CRU intended to be occupied by a restaurant is 165 A, the CRU with the restaurant is fed from 120/208 V solidly grounded distribution system, and the circuit breaker protecting panelboard supplying branch circuits of the restaurant electric loads is marked for continuous operation at 80% of the ampere rating of its overcurrent devices, the continuous load as determined from the calculated load is not permitted to exceed the continuous operation marking on the circuit breaker (i.e. cannot exceed 80% of the circuit breaker rating).

Of course, this calculated load cannot exceed 80% of the allowable ampacities of conductors selected in accordance with Section 4.

It means that for the calculated load of 165 A in our example above, a 225 A-rated panelboard would have to be selected, and a 225 A-rated circuit breaker protecting the conductors supplying the panelboard would have to be chosen.

If Table 2 is used for the selection of conductors, then 4 #4/0 copper feeder conductors (three phase and one neutral) with 230 A ampacity as per 75 Deg. C. column of Table 2, would have to be selected in conformance with Rule 8-104(6).

Question #3

What is the difference between the demand load (or connected load) and the calculated load?

Answer #3

The calculated load for services and feeders is based on specific provisions of Section 8, but the demand load (or connected load) in existing installations is measured for a certain period. In fact, Subrule 8-106(8) of the CE Code recognizes the use of demand loads under the following condition:

“8-106(8) Where additional loads are to be added to an existing service or feeder, the augmented load shall be permitted to be calculated by adding the sum of the additional loads, with demand factors as permitted by this Code, to the maximum demand load of the existing installation as measured over the most recent 12-month period, but the new calculated load shall be subject to Rule 8-104 5) and 6).”

It should be noted that based on the historical data, in a typical residential building, a demand load is about 65% of a load calculated in accordance with Rule 8-200 or Rule 8-202 of the CE Code.

Question #4

What are the rules for the use of demand factors?

Answer #4

The scope of Section 8 of the CE Code applies not only to load calculations but to the use of demand factors. Rule 8-106 of the CE Code governs the application of demand factors in the calculation of loads for feeders and services, and this Rule provides specific conditions under which demand factors could be used in different types of installation.

In calculations of loads or feeders in apartment buildings or in row housing buildings containing two or more dwelling units, Rule 8-202(3)(a) offers the use of the following demand factors:

“8-202(3) The calculated load for the consumer’s service or feeder supplying two or more dwelling units shall be based on the calculated load obtained from Subrule 1) a) and the following:

a) excluding any electric space-heating loads and any air-conditioning loads, the load shall be considered to be

i) 100% of the calculated load in the unit having the heaviest load; plus

ii) 65% of the sum of the calculated loads in the next 2 units having the same or next smaller loads to those specified in Item i); plus

iii) 40% of the sum of the calculated loads in the next 2 units having the same or next smaller loads to those specified in Item ii); plus

iv) 25% of the sum of the calculated loads in the next 15 units having the same or next smaller loads to those specified in Item iii); plus

v) 10% of the sum of the calculated loads in the remaining units;…”

Section 8 also references demand factors allowed by Section 62 for load calculations of all the electric space-heating loads if electric space heating is used.

In addition to occupancies that are specifically listed in Section 8, such as single dwellings, apartment buildings, schools, hotels, and hospitals, Rule 8-210 applies to load calculations in other types of occupancies (i.e., offices, restaurants, commercial, industrial, and similar occupancies), and Subrule 8-210(b) offers the following provision for use of demand factors:

“8-210(b) special loads such as electric space-heating, air-conditioning, motor loads, show window lighting, stage lighting, etc., based on the rating of the equipment installed with demand factors permitted by this Code…”

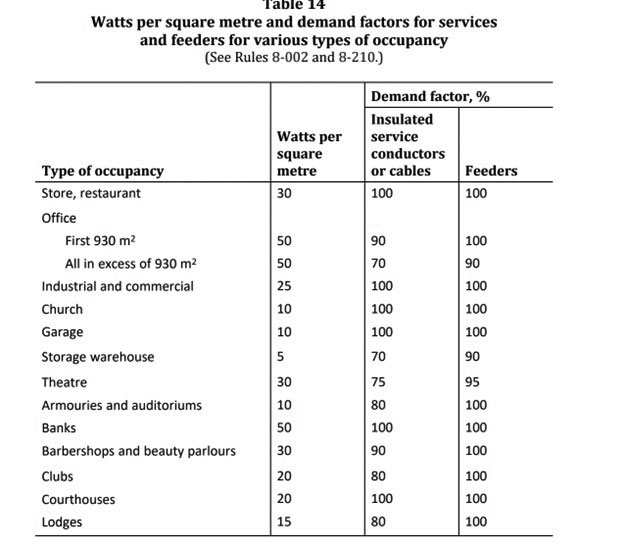

Table 14, which is used in conjunction with Rule 8-210, allows specific demand factors for the calculation of basic loads for services and feeders:

Question #5

What other Sections of the CE Code allow the use of demand factors?

Answer #5

Certain Sections of the Code allow to select ampacity of conductors supplying specific equipment based on the value of the ampere rating of the equipment, multiplied by applicable factor.

For example, Section 28, which applies to motors and generators, uses the terminology “service factor” for different duty services of the motor, as follows:

“Service — Continuous duty service — any application of a motor where the motor can operate continuously with load under any normal or abnormal condition of use.

Non-continuous duty service — an application of a motor where the apparatus driven by the motor has the characteristics described in Section 0, Definitions, under Duty, as Short-time duty, Intermittent duty, Periodic duty, and Varying duty.

Service factor — a multiplier that, when applied to the rated horsepower of an ac motor, to the rated armature current of a dc motor, or to the rated output of a generator, indicates a permissible loading that may be carried continuously at rated voltage and frequency.”

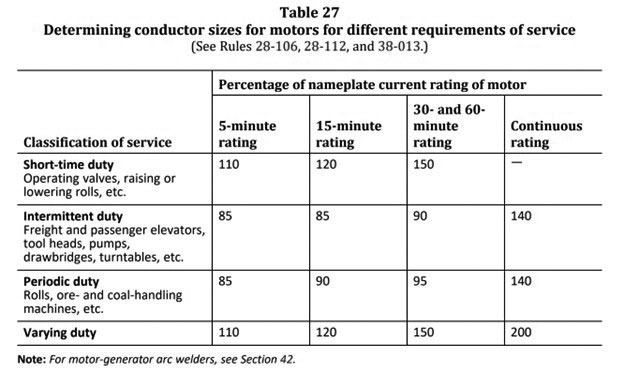

Depending on the type of duty, the ampacity of conductors is allowed to be based on the value of the full load current rating of the motor, multiplied by the applicable percentage of the nameplate current rating of the motor, as indicated in Table 27.

Rule 28-106 of the CE Code states the following:

“28-106 Insulated conductors — Individual motors

1) The insulated conductors of a branch circuit supplying a motor for use on continuous duty service shall have an ampacity not less than 125% of the full load current rating of the motor.

2) The insulated conductors of a branch circuit supplying a motor for use on non-continuous duty service shall have an ampacity not less than the current value obtained by multiplying the full load current rating of the motor by the applicable percentage given in Table 27 for the duty involved, or for varying duty service where a deviation has been allowed in accordance with Rule 2-030 by a percentage less than that specified in Table 27.”

Table 27 lists such percentage factors for each type of service classification.

Section 42, which applies to electric welders, offers a very specific terminology, in conjunction with use of welders, as follows:

“42-002 Special terminology

In this Section, the following definitions shall apply:

Actual primary current — the current drawn from the supply circuit during each welder operation at the particular heat tap and control setting used.

Duty cycle — the ratio of the time during which the welder is loaded to the total time required for one complete operation.

Rated primary current — the kilovolt-ampere rating of the welder as shown on its nameplate, multiplied by 1000 and divided by the rated primary voltage shown on the nameplate.”

This terminology is used in conjunction with the selection of conductors’ ampacity for types of welders (for transformer arc welders and inverter welders, for motor-generator arc welders, or for resistance welders).

For example, Rule 42-014 mandates the ampacity of conductors supplying resistance welders to be based on the following conditions:

“42-014 Supply conductors for resistance welders

The ampacity of insulated supply conductors shall be as follows:

a) where an individual seam resistance welder or an individual automatically fed resistance welder is operated at different times at different values of primary current or duty cycle, the insulated supply conductors shall have an ampacity of not less than 70% of the rated primary current of the welder;

b) where an individual manually operated non-automatic resistance welder is operated at different times at different values of primary current or duty cycle, the ampacity of the insulated supply conductors shall be not less than 50% of the rated primary current of the welder;

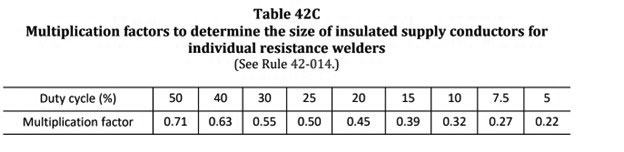

c) where an individual resistance welder operates at known and constant values of actual primary current and duty cycle, the insulated supply conductors shall have an ampacity of not less than the value obtained by multiplying the actual primary current by the applicable factor from Table 42C; and

d) where there is a group of resistance welders, the insulated supply conductors shall have an ampacity of not less than

i) the sum of the values obtained from Item a), b), or c) for the largest welder in the group; and

ii) 60% of the values obtained for all the other welders in the group…”

It is interesting to note that Table 42C allows the use of the following multiplication factors for the determination of conductors’ ampacity:

Question #6

When demonstrated loads are allowed to be used instead of calculated loads?

Answer #6

Yes. C22.2 No. 141 applies to a central battery system and to a unit equipment for emergency lighting as a power supply so

“Demonstrated load” is the defined term in Section 8. It means the following:

“Demonstrated load — historical maximum demand watt information recorded over at least a 24-month period for the same type of facility as the one in question, equated to watts per m2…”

Use of demonstrated load instead of the calculated load is recognized by Rule 8-106(9) as follows:

“8-106(9) For loads other than those calculated in accordance with Rules 8-200 and 8-202, feeder and service load calculations shall be permitted to be based on demonstrated loads, provided that such calculations are performed by a qualified person, as determined by the regulatory authority having jurisdiction.”

Appendix B Note on Rule 8-106(9) clarifies the objective of this Rule as follows:

“Appendix B Note on Rule 8-106 9)

It is intended by this Subrule that demonstrated load data could be used for the purpose of sizing of services or feeders. It is also intended by this Subrule that the qualified person, as determined by the regulatory authority having jurisdiction, who is responsible for the design should be able, upon request, to demonstrate to the regulatory authority having jurisdiction that historical data related to actual demand substantiates the fact that this historical demand is the maximum possible demand for the specific application.”

It means that the AHJ may allow a seasoned professional with an excellent track record – to use demonstrated loads instead of calculated loads for the determination of ampere rating of feeders and services for certain types of occupancies (for large retail stores, industrial plants, schools, and hospitals, when it could be demonstrated that such similar types of occupancies designed by that professional previously, demonstrated consistent historical maximum demand recorded over the period of not less than two years.

It should also be noted that Rule 8-106(5) allows a qualified person (i.e., a Professional Engineer with an excellent track record) to determine and to use a demand factor not listed in the CE Code under provisions of Rule 2-030 (under a deviation or postponement/special permission Rule, shown below):

“2-030 Deviation or postponement

In any case where deviation or postponement of these Rules and regulations is necessary, special permission shall be obtained before proceeding with the work, but this special permission shall apply only to the particular installation for which it is given.”

When such special permission is granted by the AHJ regarding specific installation, the qualified person may apply Rule 8-106(5), as follows:

“8-106(5) Where a feeder or service supplies motor or air-conditioning loads, a demand factor as determined by a qualified person shall be permitted to be applied to these loads, provided that a deviation has been allowed in accordance with Rule 2-030.”

Hopefully, this article helps with the subject at hand. And as usual, local AHJ should be contacted for specific questions related to each particular installation.

Find Us on Socials