Do you ever find yourself thumbing through the National Electrical Code® (NEC®) trying to find what you think is a basic code requirement, one you use every day on the job but seems to have you stumped? Take a look at Article 300 General Requirements for Wiring and Materials. In the many years I have spent teaching apprenticeship classes and exam prep courses, I have always suggested that when you’re having difficulty finding what seems to be a simple requirement, start flipping through the pages of Article 300.

If the company you work for performs residential work, it is likely that one of the first things you did in your apprenticeship was grabbing a drill with an auger bit and start drilling out the studs of the home. And did you know that when your boss told you to drill out the center of the stud, you were receiving your first introduction to the NEC and Article 300? The outcome your boss wanted was to ensure that Section 300.4(A)(1) was met, in that the closest edge of the hole was at least 1 ¼” away from the closest edge of the stud. That way, that pesky drywall screw would have less of a chance of damaging the newly installed wire that was run through the hole. As drilling holes in studs are at the first-laid foundation of your career, Article 300 lies at the very bedrock of the NEC. If the pages of the NEC are like a fine wine, Article 300 is like a case of the most vintage.

Although the premise for many code requirements spelled out within Article 300 has been with the NEC since it was first printed in 1897, the 1937 edition of the NEC is the first time we saw Article 300 packaged and presented in a manner similar to what we see in today’s NEC. Following the publishing of the 1935 NEC, where wiring methods were contained within then Article 5, the 1937 NEC saw a major reorganization that brought in chapters and articles within those chapters, similar to the layout of the NEC we see today.

Within Chapter 3 of the 2020 NEC, you will see articles covering items that were also covered in the 1937 NEC, such as general requirements for wiring methods, nonmetallic-sheathed cable, rigid metal conduit, electrical metallic tubing, and surface metal raceways.

When it comes to wiring methods and protection from a general installation standpoint, there are many code requirements within Article 300 that cover residential, commercial, and industrial installations. For example, code requirements listed within the 2020 NEC Article 300 that are considered to be more commonly used are:

300.4 – This section covers protection against physical damage for conductors, raceways, and cables. Within this section, you will find common code requirements around holes being bored where the closest edge to the wood member edge is not less than 1 ¼” or you must protect it with a 1/16” thick steel plate. You will also find the bushing/grommet requirement for nonmetallic-sheathed cables ran through metal studs.

300.5 and Table 300.5 – Minimum cover requirements, cables, and conductors under buildings, backfill requirements, earth movement…the list goes on in section 300.5 for what is required for underground installations. Table 300.5 provides the minimum cover requirements, or burial depths, of conduits based upon the type of wiring method and location being installed.

300.7 – Provides requirements for sealing raceways that are exposed to different temperatures (to help prevent condensation buildup) and installation fittings in raceways that are subject to thermal expansion.

300.14 – Requires six inches of free conductor to be left at each outlet, junction, and switch point. Side note: an injection of irony here is that the six inches of free conductor have been a requirement in the NEC since the 1937 edition in section 3011. Yet, think of how many older homes were built after 1937, where you have changed out devices and found there is nowhere near the required six inches of free conductor—further proving how critical it is to both perform a proper installation and have them inspected accordingly.

Some changes within the NEC happen based on no longer having a need for certain requirements. For example, past requirements for asbestos-covered conductors became obsolete when asbestos was deemed as an unsafe material and could no longer be used in new installations.

However, without question, the backbone for driving change within the NEC is public input that is submitted through the NFPA standards development process. This is an open, consensus-based process where anyone in the world, with the exception of NFPA employees, is given the opportunity to have their voice heard twice over: once during the initial public input stage and again during the public comment stage.

During the NEC cycle change from the 2017 code to the 2020 code, Article 300 alone saw over 100 public inputs at the first stage and over 30 public comments during the second stage. Based on valuable input from the public, some of the notable changes to Article 300 of the 2020 NEC cycle are:

300.4(G) – Removed the exception that previously contained language around threaded hubs and bosses and made that verbiage part of the context of 300.4(G). Added a fourth option for use as an insulated fitting with raceways containing 4 AWG or larger conductors, specified as a listed metal fitting that has smoothly rounded edges. Changed formatting of the section to have the four options listed in a numbered format versus paragraph format. The title of 300.4(G) was changed from “Insulated Fittings” to “Fittings” to also recognize listed fittings that may not be insulated.

300.7(A) – More clarity was brought to this section, which covers sealing of raceways exposed to different temperatures, which has been part of the NEC since 1937. The type of sealant that must be used is better clarified by adding language that states, “Sealants shall be identified for use with cable insulation, conductor insulation, a bare conductor, a shield, or other components.”

300.15(F) – Within the 2017 NEC, fittings covered by 310.15(F) were required to be accessible after installation. A revision to this section in the 2020 NEC added the verbiage, “unless listed for concealed installation,” to the last sentence giving latitude for the use of fittings that are listed for concealed installation.

300.25 – A new section was added that addresses electrical wiring methods within exit enclosures (stair towers). When a stairway is required to be separated from the building by fire-rated walls or other means, such as within NFPA 101® Life Safety Code®, only wiring that serves equipment within the stairway is permitted.

300.45 – This section, which covers signs for equipment over 1000 volts, was modified by replacing the term “warning” with “danger,” which was already a requirement to have written in the text of the sign. Additionally, 300.45 was changed to clearly state the requirements of Section 110.21(B) must also be met with danger signs, ensuring the sign will be durable for the environment.

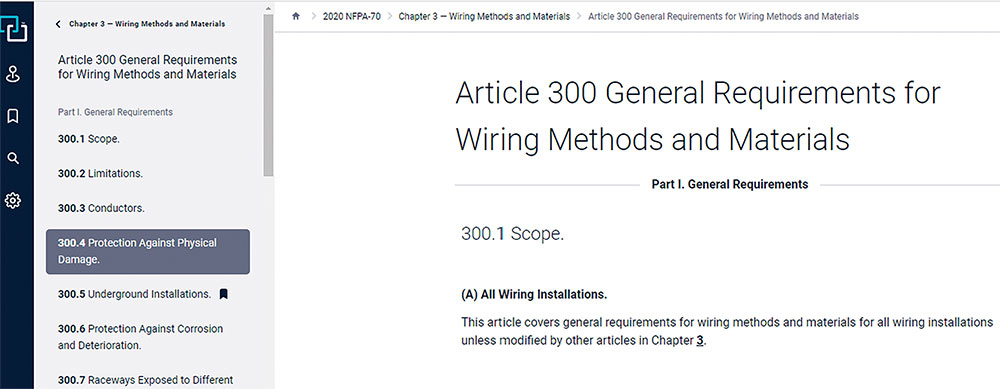

The NEC has been delivering safety around electrical installations since 1897, not just through the strong foundational requirements established in early versions but also by the changes that have continued to be made in each cycle through the present-day NEC. The inclusive and transparent NFPA Standards Development Process that oversees the NEC is an absolute necessity for a document like this to stand the test of time, while continuing to keep people and property safe. While changes in materials, technologies, and public input have altered the way that Article 300 appears through the years, the creation of NFPA LiNK™ has also changed how we look at the NEC by making it more usable, interactive, and at our fingertips whenever we need it. Although change through the years is inevitable, many of the thoughts and requirements laid forth by early NEC committees still remain usable and timeless. A true testament that the content and development process of the NEC continues to cement its place as the world’s foremost, incomparable solution for safe electrical installations.

The National Electrical Code® (NEC®) is now available in NFPA LiNK™, the association’s information delivery platform with all NFPA codes and standards, supplementary content, and visual aids for building, electrical, and life safety professionals and practitioners. Learn more at nfpa.org/LiNK.

Find Us on Socials