Most inspectors don’t have or have not read the UL Standards related to PV systems, because the standards are expensive and do not relate directly to the job of ensuring that listed PV modules and inverters are installed in a manner that meets the requirements of the National Electrical Code (NEC–NFPA 70). However, the requirements in the standards affect what the instruction manuals must say and those instructions guide the PV installer because NEC Section 110.3(B) requires that the instructions and labels on listed products must be followed. On May 8th of 2012, Underwriters Laboratories (UL) released a revised version of UL Standard 1703, the “Standard for Safety for Flat Plate Photovoltaic Modules and Panels.” This UL standard is also an American National Standard Institute (ANSI) approved as ANSI/UL 1703-2012.

Most inspectors don’t have or have not read the UL Standards related to PV systems, because the standards are expensive and do not relate directly to the job of ensuring that listed PV modules and inverters are installed in a manner that meets the requirements of the National Electrical Code (NEC–NFPA 70). However, the requirements in the standards affect what the instruction manuals must say and those instructions guide the PV installer because NEC Section 110.3(B) requires that the instructions and labels on listed products must be followed. On May 8th of 2012, Underwriters Laboratories (UL) released a revised version of UL Standard 1703, the “Standard for Safety for Flat Plate Photovoltaic Modules and Panels.” This UL standard is also an American National Standard Institute (ANSI) approved as ANSI/UL 1703-2012.

The Standards Development Process

For each of the major standards that UL publishes, a Standards Technical Panel (STP) is established and the STP actually controls the content of the standard through a rigorous process known as the Collaborative Standards Development System (CSDS). The STP membership consists of a balanced selection of representatives from all areas of interest that are involved in the product that the standard addresses. The STP for UL 1703 has more than 50 members from PV module and material manufacturers, PV installers and systems designers, electrical inspectors and plan reviewers (including IAEI members), users, NFPA Code-Making Panel members, IBEW, laboratories, government agencies, universities, and a general interest area.

ll parts of the standard are continually reviewed, analyzed with respect to Code changes and new equipment developments and discussed. Anyone may make proposals for changing the standard. The proposals are circulated, revised, re-circulated and voted on by the STP members. Negative votes must be accompanied by suggested changes and all negative votes must be addressed. UL, as a member of the STP, has only one vote just like all other members.

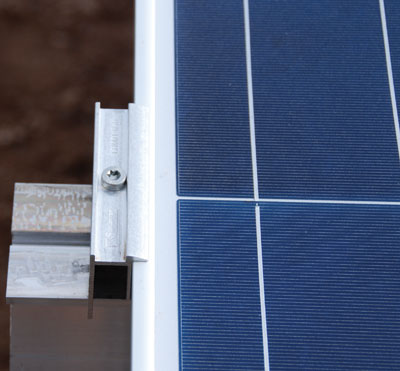

Photo 1. Top of frame module mounting. Listing is valid only if the method is in the instruction manual.

The STP meets about once a year, but may be convened more frequently as the need arises.

Safe Installations

When equipment is manufactured according to the requirements in the standard and is evaluated by one of the National Recognized Testing Laboratories (NRTL), it can be then certified as complying with the standard and the product is put on a list showing that certification. This is the Certification/Listing process. In the NEC, PV modules, charge controllers, inverters, combiners and ac PV modules are required to be listed. Currently, the US Occupational Safety and Health Administration (OSHA) has recognized four of the numerous NRTLs as capable of certifying and listing PV equipment. They are UL, TUV Rheinland NA, Intertek (ETL), and CSA International.

Certified/listed equipment, when installed according to the requirements established by the NEC will generally result in a hazard free electrical installation.

What’s New for Inspectors and Plan Reviewers?

AHJs around the country have been aware for some time that consistency in the PV module instructions manuals has been lacking. These inconsistencies stem from a lack of preciseness in UL 1703 in the areas of module mounting, module grounding, and the way the rated short-circuit current and module open circuit voltage are to be used in the application of NEC requirements to the module installation. Module manufacturers have widely varying instruction manuals in terms of content and detail. They issue tech notes that address mounting and grounding the modules, but it is unclear whether or not these tech notes have been reviewed by the certifying/listing NRTL for compliance with the standard.

Photo 2. Improper module grounding has failed.

Modules are generally tested, labeled, and listed with four mounting holes that are to be used for bolting the modules to the mounting surface. However, many installers use mounting racks that use clips that fasten the modules to the racks by clamping the top of the module to the rack with these clips which generally are not located near the four mounting holes. See photo 1. A few module manufacturers have instruction manuals that specify that top clips may be applied at certain locations on the modules, but most do not have these instructions.

Grounding issues abound for plan reviewers and inspectors and many module grounding systems are failing around the country. See photo 2. Typically a module has four labeled grounding holes that have been tested to meet UL 1703 requirements for safe connection to earth through the equipment-grounding system. Again module instruction manuals and tech notes vary greatly in the level of detail associated with using the labeled grounding holes to ground the PV modules. A few manufacturers supply hardware that has gone through the UL 1703 testing and evaluation process with the modules. Some manufacturers specify locally procured hardware like star washers and nuts and bolts to ground modules. See photo 3. Others provide very sparse instructions on grounding. And the content of tech notes ranges from very good to very poor with respect to grounding.

Photo 3. Correct hardware?

Since the inception of UL 1703, the standard has required that each PV module instruction manual have statements requiring that the short-circuit current (Isc) and the open-circuit voltage (Voc) be multiplied by 125% before any NEC requirements were applied. The 125% on Isc was to address normal and expected high levels of irradiance up to 1250 watts per square meter that can occur in many areas of the country for three hours or more. The 125% factor applied to the rated Voc was to address the fact the module voltage decreases as temperature increases, and this factor accounts for modules exposed to temperatures as low as -40°C (-40°F). In 1996, during deliberations for the 1999 NEC, all parties including the PV Industry, UL, AHJs, and the Code-Making Panels at NFPA agreed that these 125 factors should be removed from UL 1703 and placed in the Code.

They were placed in the 1999 NEC in 690.7 (Voc) and 690.8 (Isc), but until this revision of UL 1703, they have remained in the standard. Of course, looking at NEC 110.3(B) that requires the instructions with the listed product to be followed that duplicated the requirements of NEC Sections 690.7 and 690.8 created a very poor situation for the AHJs and the installers. Do we duplicate those 125% factors, which have been required in both the instructions and in the Code?

Current Revisions to UL 1703 Have Clarified Several Areas

In general, it is evident that previous editions of UL 1703 have not provided sufficiently detailed requirements to the NRTLs to allow them or require them to properly evaluate the instruction manuals for the PV module in terms of NEC-compliance, mounting, grounding, and the specifications related to the electrical parameters.

Photo 4. Module fire rating valid for this mounting?

The May 8, 2012 revision of UL 1703 has addressed several of these longstanding issues.

1. The NRTL must verify the contents of the manual and NEC-compliance.

These revisions now include a requirement that the certifying/listing organization verify that the contents of the instruction manual and any tech notes comply with the standard and do not violate any NEC requirements. Here are a few of the relevant revisions extracted from UL 1703:

48.1 “A module or panel shall be supplied with installation instructions describing the methods of electrical and mechanical installation. The instructions shall include the following in addition to any other information required by this standard:

c) “A list containing the date of the first edition of these instructions and the dates of any and all subsequent revisions, amendments, and tech notes related to these instructions.”

48.1.1 “The electrical installation instructions shall include a detailed description of the wiring method to be used in accordance with the National Electrical Code, ANSI/NFPA 70.”

48.7 “The contents of the instruction manual and subsequent revisions to the instruction manual shall be verified for compliance with this standard by inspection.”

2. The 125% factors have been removed from the module instruction manual.

48.5 “To allow for increased output of a module or panel resulting from certain conditions of use, the installation instructions for a module or panel shall include the following statement or the equivalent: “Under normal conditions, a photovoltaic module is likely to experience conditions that produce more current and/or voltage than reported at standard test conditions. The requirements of the National Electrical Code (NEC) in Article 690 shall be followed to address these increased outputs.”

3. A module not mounted in accordance with the instructions in the manual will no longer retain its UL 1703 listing. This emphasizes the NEC requirement in 110.3(B).

48.1(B) 2) “The module is considered to be in compliance with UL 1703 only when the module is mounted in the manner specified by the mounting instructions below.”

4. A module not mounted per the mounting instructions will invalidate the fire rating on the module. See photo 4.

48.1(B) 1) “The fire rating of this module is valid only when mounted in the manner specified in the mechanical mounting instructions.”

5. A module not grounded according to the grounding instructions in the manual and not in accordance with the labeled grounding points on the module will invalidate the listing on the module. See photos 5 and 6.

48.1(B) 3) “A module with exposed conductive parts is considered to be in compliance with UL 1703 only when it is electrically grounded in accordance with the instructions presented below and the requirements of the National Electrical Code.”

Photo 5. Right grounding point; wrong hardware and method.

Those grounding instructions include the following:

48.1.1 a) “The grounding method to be used, and where a specific grounding device is supplied or suggested, the following statements:

1) “Where common grounding hardware (nuts, bolts, star washers, spilt-ring lock washers, flat washers and the like) is used to attach a listed grounding/bonding device, the attachment must be made in conformance with the grounding device manufacturer’s instructions.

2) “PV module manufacturers recommending such a method must either 1) thoroughly detail the attachment means in the module installation instructions or 2) refer the installer to readily available manufacturer’s instructions for the grounding/bonding device.

3) “Common hardware items such as nuts, bolts, star washers, lock washers and the like have not been evaluated for electrical conductivity or for use as grounding devices and should be used only for maintaining mechanical connections and holding electrical grounding devices in the proper position for electrical conductivity. Such devices, where supplied with the module and evaluated through the requirements in UL 1703, may be used for grounding connections in accordance with the instructions provided with the module.”

6. A PV laminate without a frame is not considered a listed module until it has been mounted with hardware that has been evaluated with the laminate under this standard or has been subject to a field evaluation by an NRTL.

4) “Any module without a frame (laminate) shall not be considered to comply with the requirements of UL 1703 unless the module is mounted with hardware that has been tested and evaluated with the module under this standard or by a field inspection certifying that the installed module complies with the requirements of UL 1703.”

7. The value of module series overcurrent device marked on the back of the module now has to be at least 1.56 times the Isc in order to comply with NEC 690.8.

47.10 “A module or panel shall be marked relative to the maximum electrical rating of an acceptable overcurrent protective device (for protection against backfeed). The statement on the module or panel shall include the following: ‘Maximum series overcurrent protective device, where required.’ ”

47.10.1 “The ampere rating of the maximum series overcurrent device shall be not less than 1.56 times the rated short-circuit current of the module and the rating shall be rounded up to the next higher available overcurrent device rating. The available ratings are 1–10 amps in one-amp increments, 1.5, 2.5, 3.5, 12 amps, 15 amps, and 20 amps. The rounded up rating of the series overcurrent protective device shall be used in the reverse current tests of 28.1.”

Photo 6. Modules being grounded correctly

These revisions to UL 1703 should clarify the intent and requirements for installing PV modules in a PV system that is compliant with the requirements of the National Electrical Code. The revisions are dated 8 May 2012 and it may take a few months for the module manufacturers, the rack manufacturers and the grounding device manufacturers to work together to get the necessary testing done and to revise the instruction manuals.

Noncompliance with the requirements of UL 1703 or the requirements of the NEC will result in a system that cannot be legally installed in jurisdictions where the NEC is legislated into law. This includes the entire United States.

More Changes Coming

By the time you read this article, the UL 1703 STP will have approved more changes in the standard related to module grounding and module grounding devices. These changes and related changes in UL 2703 (PV Racking), UL 487 (Grounding Devices) and other standards will enhance PV module grounding, reduce the labor requirements, and also reduce the costs associated with grounding.

The PV installer and the inspector will be reasonably assured that a listed module can be installed according to the instructions provided with that module using the Code requirements to achieve a safe and durable electrical system.

For More Information

If this article has raised questions, do not hesitate to contact the author by phone or e-mail. E-mail: jwiles@nmsu.edu Phone: 575-646-6105

See the web site below for a schedule of presentations on PV and the Code. Call the author if you would like to schedule a presentation.

The Southwest Technology Development Institute web site maintains a PV Systems Inspector/Installer Checklist and all copies of the previous “Perspectives on PV” articles for easy downloading. A color copy of the latest version (1.93) of the 150-page, Photovoltaic Power Systems and the 2005 National Electrical Code: Suggested Practices, written by the author, may be downloaded from this web site: <ahref=”http: www.nmsu.edu=”” ~tdi=”” photovoltaics=”” codes-stds=”” codes-stds.htm”=””>http://www.nmsu.edu/~tdi/Photovoltaics/Codes-Stds/Codes-Stds.htm

This work was supported by the United States Department of Energy under Contract DE-FC 36-05-G015149

Find Us on Socials