Wonderful though electricity was in its early days as a miraculous source of light and power, installations did seem to have a habit of catching fire rather too often. In 1896, a young Swiss professor, François Borel, who was researching ways of improving cables, filed a patent for an all-mineral-insulated fire-resistant cable. But it was not until the 1930s that a French company found ways to manufacture the cable in commercial quantities. At the same time, buoyed by the publicity of the Louvre permitting its use for the museum’s first-ever artificial lighting system, mineral-insulated cable became the choice for applications where fire safety was critical. In 1936, mineral-insulated cable manufacturing technology was transferred to the UK.

Critical circuits

With the advent of high-rise building, fire protection of electrical life safety conductors became extremely important. These critical circuits in high-rise buildings, hospitals, institutions and places of public assembly are required to be protected from fire. They supply power for two essential fire protection functions: facilitating safe egress for occupants, and fire fighting. Circuits that facilitate safe egress for occupants include feeders for pressurization fans for stairwells, smoke extraction fans, the fire alarm system and circuits supplying essential systems in hospitals. Circuits that are required to stay operational for fire fighting include emergency generator, fire pump, and firefighters’ elevator— and again, of course, the fire alarm system.

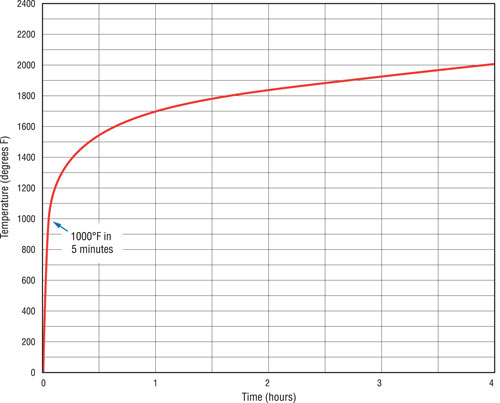

Figure 1. Temperatures reached when exposed to typical commercial building fire

However, while mineral insulated (MI) cable was used for fire protection of life safety systems for ships, tunnels, and buildings that were highly engineered or of an historic or prestigious nature, it was not the first choice for high-rise buildings. Instead, life safety systems were mostly met by traditional construction methods of either encasing cabling in concrete or building gypsum board enclosures or shaftways (or occasionally employing a “wrap” system, i.e., putting a thermal barrier between the conductors and the fire).Masonry walls were specified in 1931 for the shaftways of the Empire State Building — assumed to be the first modern high-rise — that housed elevators, stairwells and mechanical utilities. Gypsum tiles were chosen for the Merchandise Mart in Chicago in the same year. In the 1960s, as the demand for lighter and more elastic shaft wall systems grew, gypsum panel wall systems started to be more widely used.

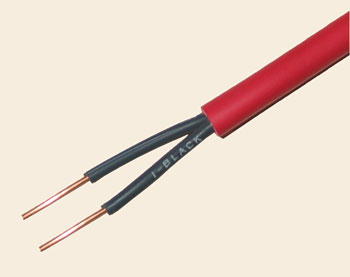

In late 1999, fire-rated polymer insulated cables became available. This presented a sea change in the status quo as improved technology significantly expanded the options for meeting fire code requirements. Specially designed polymer insulation changes into hard insulating ash under fire conditions, thus allowing electrical conductors to remain isolated from one another. With the advent of this new technology, a new breed of cable — fire-rated polymer insulated power and fire alarm cable — and a new alternative to construction methods was created.

The fire-rated cable market has expanded at a rapid rate since the introduction of polymeric fire resistant cables. This is not because of an increase in construction, but because of increased choices of product and manufacturer for specifiers, and awareness of the advantages of fire-rated cables over construction methods of fire protecting cables.

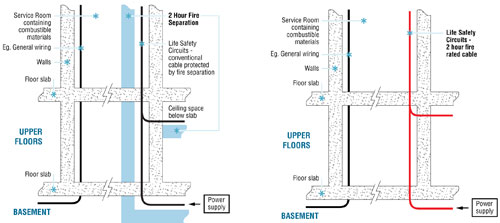

Figure 2. Two-hour fire separation using vertical shaftway and horizontal run construction methods, left; and fire-rated cable, right.

As more manufacturers became involved in production, today’s fire-rated cables come in a variety of styles that appear and install like conventional conduit cables, armored cables and fire alarm cables. Usually competitively priced, these cables are expanding the use of fire-rated cables as a replacement for construction methods.

Fire Protection of Life Safety Circuits: Codes and Test

Since life safety is the most important consideration for all projects, fire protection of life safety electrical circuits has long been mandated by code. Over the decades, codes have been updated, mostly in response to lessons learned from investigations into the causes of fires. Municipalities are also taking fire code compliance more seriously. Following up on the August 2007 deaths of two firemen killed while fighting a fire at 130 Liberty Street, the former Deutsche Bank building at the World Trade Center site that was being demolished, New York City has cracked down on fire code violations. In the twelve months preceding June 2008, 225 people have been arrested on charges of failing to appear in court to answer outstanding criminal summonses for fire code violations.

Most states and Canadian provinces adopt a model code, such as the International Building Code (IBC) and the National Building Code (Canada) as the basis for their own code. Code requirements for life safety circuits in the United States are provided by the National Fire Protection Association (NFPA) and theNational Electric Code(NEC). However, thetypeof fire protection for critical life safety circuits is not specified by code.

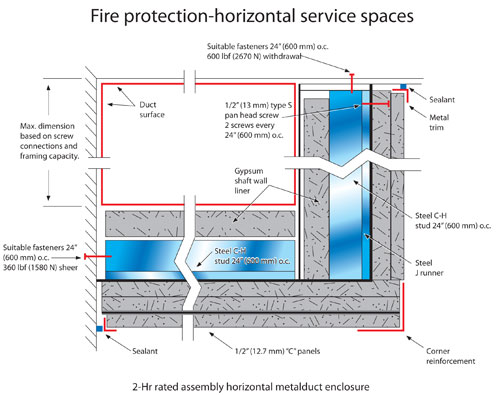

Figure 3. Two-hour rated assembly horizontal metal duct enclosure (fire-tested both sides). While meeting test temperature requirements, this assembly is not tested

Fire testing in North America, on the other hand, involves mounting the cable on a brick wall and exposing it over a 2-hour period to an actual controlled fire where temperature increases to 1850°F, at which point the cables are hit with the full force of a firefighter’s hose. This subjects the cable to the same conditions that all fire-resistant building materials, such as fire doors, are exposed to, but with the added requirement that the cable has to maintain circuit integrity throughout the fire and after the hose stream application; the cable must continue to operate electrically throughout the test (electrical integrity is evidenced visually by a light supplied with power coming through the cable in the furnace) and after the hose stream.

The standards that have to be met vary widely around the world. As a rule, the International Electrotechnical Commission (IEC) and European fire test standards are weak and undiscerning. Their tests have been developed by cable manufacturers and have been described as “tests that are designed to pass cables rather than test them.” They are generally similar to Flame Testing in that the tests involve placing cables over ribbon burners for some interval of time, sometimes with a weak water sprinkler spraying on the cable. Flame temperatures are measured and statements are made that the cable withstands 1381°F (750°C) or 1742°F (950°C) for 30, 60 or 120 minutes. To the uninitiated, the tests look impressive, but they are not difficult to pass, and have little to do with a real fire. In addition, the tests allow different levels of passing grades, so that a cable may pass one grade but fail another, thus requiring the system designer to stipulate what grade of pass is acceptable for a given application —hardly a good idea when dealing with life safety.

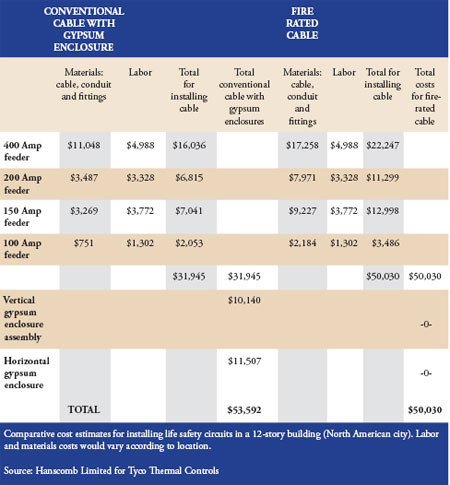

Figure 4. Comparative cost estimates

In contrast, North American tests for electrical cables subject the cables to the same fire conditions as any other fire-rated product, such as door and wall assemblies. The difference being that while door and wall assemblies are judged on how they limit the temperature on the unexposed side, electrical cables are exposed to fire that is expected to develop in a real commercial building; that is, cables are completely exposed and must continue to operate for either one or two hours while the fire is developed through a standard fire exposure time-temperature curve that reaches 1850°F. The results are pass/fail with no grades of pass/fail.

The North American fire test, American National Standards Institute/Underwriters Laboratories ANSI/UL 2196/Underwriters Laboratories Canada (ULC S 139)Standard Method of Fire Test for Evaluation of Integrity of Electrical Cablesis gaining acceptance as the discerning electrical cable test around the world (the nearest contender, the Australian test, is equivalent in discernment, but is weak in terms of gradations of pass/fail). Cables are fire-rated (as are “wrap systems”) and listed by UL asElectrical Circuit Protective Systems (UL Category FHIT or Category FHJRC in Canada). These guides provide precise detail of how cables must be installed in order to achieve their rating. Details include types of support, spacing of supports, materials allowed and so forth.

Codes are increasingly calling for 2-hour fire-rating.NEC695.6(B) Fire Pumps and NFPA 72 Fire Alarm standard andNEC760 cite a minimum fire rating of two hours (2 h) for fire alarms. The reason is partially for evacuation of people from buildings, although this can generally be accomplished in a shorter timeframe, but more particularly for firefighting — for preserving power to allow firefighters a minimum of two hours of reliable power to aid in getting the fire under control.

Figure 5. Typical mineral insulated (MI) cable

There is a steady trend towards a 2-hour requirement for cable survival in a fire, and not just in North America. It makes sense that a fire is going to last more than one hour and that the firefighting systems should be maintained for two hours minimum. Standards that stipulate different levels of fire survivability for circuits of varying importance seem to lower the bar and allow less effective fire protection. In North America there is no need to accept less than the best for critical circuits — fire-rated cables that withstand one hour of the test without exception withstand two hours.

Fire Protection Using Construction Methods

1. Conduits encased in concrete

Encasing conventional wiring in concrete is a traditional method for addressing fire protection. Two inches of concrete has historically been considered adequate for one-hour fire resistance; approximately four inches are required to protect conductors for two hours.

Encasing conduits in concrete is very cost effective if proper coverage can be achieved throughout the entire circuit. However, while it is perfectlyfeasibleto encase conduits up to 2-in. diameter in a slab floor of a building (2-in. concrete times two, plus 2-in. conduit implies a 6-in. thick slab), it is hard toguaranteeuniform 2-in. coverage, and larger conduits are difficult because of the thickness of the slab. If 4-in. concrete is required to achieve a 2-hour rating, the slab can be very large indeed, e.g., 4-in. conduit with 4-in. concrete on either side implies a 12-in. slab! In addition, the lack of fire rating of junction and pull boxes compromises the system.Moreover, this method, as with other construction methods, isnota listed system for fire protection of electrical conductors.

Note: Encasing conduit in concrete is also very difficult after the fact when retrofit work has to be done.

2. Gypsum board enclosures

Characteristics. Gypsum, a mineral, has outstanding fire-resistant properties. When exposed to high temperatures, chemically combined water in the gypsum is gradually released, providing protection until all of its combined water is completely driven off. Its fire resistance plus the fact that gypsum panels were far less expensive than MI fire-rated cable (the only other viable non-concrete alternative for years) made gypsum board enclosures a traditional and obvious choice for the fire protection of life safety electrical circuits.

Other advantages include:weight—a 2-hour fire-rated gypsum wall weighs only nine pounds per square foot; andthinness—a 2-hour fire-rated wall is only 3-½ inches thick. They also install more quickly and economically than “wet” shaft walls, such as masonry. Gypsum panel shaft walls are completed early in the construction process and finished later, along with other interior partitions. Moreover, gypsum panel systems have undergone extensive independent testing as fire barriers—gypsum boards of different core formulation are fire-rated from one to four hours. By adding layers of gypsum panels to each side of the studs, the fire resistance of virtually any wall can be increased.

In addition, when used for fire protection of electrical cables, gypsum panels are commonly perceived as inexpensive; or even “free” in the sense that gypsum board used for fire-rated enclosures is usually absorbed within the overall gypsum board budget line item rather than listed as a separate line under the electrical estimate.

Challenges of specifying gypsum panel enclosures

Since the introduction of polymer fire-rated cables as another alternative, many in the building industry are reassessing the apparent obvious advantages of gypsum board enclosures.

There are several significant issues that come to the forefront when assessing gypsum board enclosures. One is the complexity of designing and constructing fire-resistant walls and shafts that are effective in producing the fire rating required as a fire barrier.

A second is the performance of gypsum enclosures given the fact that while they have been tested for their resistance to fire,they have never been tested or listed for their protection of electrical conductors. A third concerns the construction/inspection issues of gypsum enclosures.

Designing gypsum board enclosures. Familiarity and knowledge of fire ratings of different gypsum panel types is critical as panel types vary in fire resistance. Since wall and shaftway systems involve a number of products, knowledge of assembly details is also critical in meeting performance criteria. Such details include: size of framing members; number of fasteners; type of joint compound and finish; and fire-stopping materials to address penetrations that breach the panel wall.

It cannot be stressed enough that the integrity of a gypsum enclosure must be evaluated as an assembled system. The selection of individual products with appropriate fire ratings will not compensate for deficiencies in the size of studs or number of fasteners, for example. In addition, it is essential that the assembly built in the field is representative of the one tested. Given these concerns, it is not at all surprising to learn that many industry experts consider fire-resistant assembly design and construction to be among the most complicated issues facing today’s architects and specifiers.

In order to explore where and why gypsum board enclosures are used for protection of critical electrical conductors, and to elicit in-the-field experiences of using them, one cable manufacturer surveyed contractors, design/build firms, architects and engineers across the country. It found that fire-rated vertical shaftways were commonly used in high-rise buildings for protecting life safety cables and that gypsum walls were used for separating “normal supply” electrical cables from emergency and life safety cables. “Common practice” and “not being aware of alternatives” were the most common reasons for specifying gypsum enclosures.

Answers relating to the experiences of using construction methods were varied and can be summarized:

2-hour fire-rated enclosures (are):

- Difficult to make

- Workmanship-dependent

- Subject to subsequent deterioration

- Not listed for electrical cable protection

- May not be dedicated, as called for by code

- Contribute to difficulties in on-site trades coordination

- Take up valuable space

- Not as cost-effective as they are perceived to be

Performance of gypsum enclosures:

Fire protection code issues

A closer look at code and testing requirements raises the question ofwhatis being tested. Although gypsum assemblies are tested, the testing does not determine if an electrical conductor behind a gypsum wall would survive. The test only stipulates a maximum temperature at the back (or inside) of the wall, which, it turns out, exceeds many cables’ capability.

For example, UL/ULC wall and partition system test criteria states:

“…Surface temperatures on the unexposed side of the test specimen are measured at a minimum of nine locations…” “… Average temperature of the unexposed surface is not permitted to increase more than 250°F above ambient nor is any individual thermocouple permitted to rise more than 325°F above ambient….”

If ambient temperature is assumed to be 70°F, the average temperature of the unexposed surface should be 325°F with a maximum temperature of 395°F. According to results of a fire test conducted by Warnock Hershey International, an independent fire-testing laboratory, unprotected conventional wiring failed in less than three minutes when the temperature reached 450°F.

Figure 6. Typical RHW polymer insulated cable construction

Conventional wiring is simply not designed to withstand temperature levels of 450°F. Most conventional wiring is rated 194°F (90°C); and in some cases a temperature as low as 248°F (120°C) can cause failure in PVC. Other insulations are better than that, but they could well fail under the type of temperatures found in testing gypsum enclosures.

Construction/inspection issues.As pointed out earlier, gypsum shaft assemblies are highly complex and difficult to make properly. They are not listed for electrical cable protection. They are very trade sensitive and are subject to subsequent damage. They also take up space and create construction coordinating problems.

Construction detail issues that can impact enclosure performance include:

• Substitution of a different gypsum panel than the one specified

• Whether panels are applied horizontally or vertically, joints should be staggered so that a joint will not occur on both sides of the same stud; on multilayered walls, each gypsum layer should be offset from the layer beneath

• Framing — type and spacing that does not correspond to enclosure assembly tests

• Fasteners — type and spacing that does not correspond to enclosure assembly tests

• Penetrations — deficiencies in noting size, type and number of breaches in the wall (e.g., from conduit or pipe) and addressing them with fire-stopping materials

• How and where a partition intersects with a floor or ceiling assembly that does not correspond to design in enclosure assembly tests

• Location of conductors, which must be inside a shaft created by gypsum or on the opposite side of a wall, rather than within the wall cavity space

• Electrical conductors cross expansion joints, which must be fire-stopped and are subject to expansion and contraction

• If splices are made, an access panel has to be provided in the enclosure

• Not dedicating the gypsum enclosure to life safety circuits

Figure 7. Typical metal-clad polymer

One of the many lessons learned in the tragic high-rise fire in Philadelphia in 1991, which resulted from major failures in nearly all fire protection systems, was the importance of having truly independent emergency electrical systems. Primary and secondary electrical risers had been installed in a common enclosure, which led to their almost simultaneous failure when fire penetrated voids in the wall above the ceiling of an electrical closet.NEC700-12(d) of the then-currentNational Electrical Code, 1990 recognized separate feeders as a means of supplying emergency power, but those services to be “widely separated electrically and physically…to minimize the possibility of simultaneous interruption of supply.”NEC-2008 requires dedicated enclosures for life safety circuits.

It is this requirement for separation between normal and emergency feeders that encourages the use of gypsum enclosures; yet the same effective separation can be achieved by using a fire-rated cable, fully rated for two hours, while avoiding all the issues surrounding drywall enclosures.

In our litigious society, there is also the inevitable question of who is liable in the event of a fire that is traced to a faulty enclosure? Is it the architect, engineer, contractor or, possibly, the manufacturer?

Economics of Gypsum Panel Enclosures Versus Fire-Rated Cables

Despite the challenges of specifying and constructing gypsum board enclosures and the critical questions regarding their performance, a key question should be: Where do gypsum board enclosures stand in terms of economics?

With the present availability of polymer fire-rated cable, the question of economics is clearly a significant issue. Are gypsum panel enclosures really less expensive than polymer fire-rated cable?

Hanscomb Limited, the producer ofYardsticks for Costing, estimated costs for constructing life safety circuits in a typical 12-story high-rise building in a North American city. Two methods were analyzed: one, using a conventional cable within a gypsum panel enclosure; the other, using fire-rated cable.

Pricing for installing 2-hour vertical and horizontal shaft wall assemblies was obtained from three contractors and averaged. Pricing of conventional cable and polymer fire-rated cable was also obtained from contractors and averaged.

The circuits included a 400-A, 500-kcmil emergency feeder which runs horizontally from the generator to the electrical room in the basement. The others, 200-A, 150-A, and 100-A, run horizontally and vertically.

(Obviously, kcmil is a 1000 cmils. A circular mil is the area of a circle with a diameter of one thousandth (0.001) of an inch. All wire sizes larger than 4/0 AWG (American Wire Gauge) are given as kcmil sizes. Kcmil wire size is the equivalent cross sectional area in thousands of circular mils.)

While the fire-rated 500-kcmil cable cost approximately 85 percent more than conventional cable, its cost was reduced to 56 percent more than equivalent conventional cable after including conduit and fittings. As might be expected, fire-rated cable is more expensive than conventional cable; but the cost of the enclosure has to be taken into account when using conventional cable.

Figure 8. Typical critical integrity (CI) fire-alarm cable for twisted pair communication wiring

The costs of installing a 2-hour vertical gypsum enclosure with liner panel(1.5-ft x 4-ft, three-sided) and a 2-hour fire-rated horizontal enclosure with liner panel (1.5-ft x 4-ft) were $10,140 and $11,507 respectively.

The bottom line shows that the cost of using several sizes of conventional wiring plus one horizontal run and one vertical shaft is more ($53,592) than using fire-rated cable ($50,030).

Costs will vary depending upon how many conductors are protected, their size and the length of the enclosures — and, of course, local labor costs. A one-hour enclosure is much simpler and less expensive to make, but in order to ensure that a reasonable protection is provided for critical circuits, it is prudent to require a2-hour construction enclosure even where codes do not mandate it. What the calculations indicate is that using gypsum enclosures for meeting fire-protection codes is notautomaticallycost-effective and that estimating costs of alternatively using of fire-rated cable is worthwhile.

Costs, however, are not the only issue in specifying fire-rated life safety circuits. With the trends towards increased survivability of critical circuits and availability of fire-rated cables — plus the growing vigilance regarding fire protection code compliance on the part of authorities — using only 2-hour rated electrical cable systems is the wisest course. Using fire-rated cables also precludes any concerns about construction deficiencies — an issue that continually challengesconscientious electrical inspectors.

Their advantages include:

• Come with a built-in fire-rating

• Not workmanship-dependent

• Not subject to subsequent deterioration

• Listed by UL for the specific purpose

• Listed in UL and ULC Fire Resistance Directories

• Easy to install using standard procedures

• Ease coordination difficulties on site

• Take up little space

• Easier to inspect

Fire-Rated Fire Alarm and Fire Cables

The test to qualify a cable as 2-hour fire-rated cable is the ANSI/UL 2196 (ULC S139 in Canada). This protocol utilizes the ASTM E-119 time-temperature curve, and requires that cables remain operational after exposure to temperatures up to 1850°F (1010°C) for two hours followed by the full force of a firefighter’s hose stream.

Mineral insulated (MI) power cable, a 2-hour fire-rated cable listed by Underwriters Laboratories (UL) and Underwriters Laboratories of Canada (ULC) since 1980, is inherently fire-resistant due to its totally inorganic construction. Widely viewed as a superior system, cables are constructed entirely of inorganic materials. For all practical purposes it is fire-proof, non-ageing, mechanically strong of small diameter, and pliable to handle.

Figure 9. Polymer insulated ground wire

Manufactured from copper and magnesium oxide, it features zero smoke, zero flame spread and zero fuel contribution. The construction is inherently tough, yet allows the cable to be bent and molded to fit into tight spaces and can withstand mechanical abrasion without additional mechanical protection. In addition, the inorganic construction of an unjacketed MI cable allows for an environmentally clean electrical cable that does not burn, produce smoke, or contribute fuel when exposed to fire conditions.

RHW polymer insulated power cable, a 2-hour fire-rated cable listed by Underwriters Laboratories (UL) and Underwriters Laboratories of Canada (ULC), this flexible cable is typically installed in conduit like any conventional power cable. The silicone insulation is a special type thatceramifies, that is, it provides electrical protection under fire conditions by turning into a hard ash that preserves the electrical insulation value between conductors. The outer jacket is a cross-linked polyolefin (XLPO) that gives superior abrasion protection and has a low coefficient of friction for easy pulling into conduits. Both insulation and jacket are made from low-smoke, zero-halogen material.

Metal-clad (MC) polymer insulated power cable, manufactured to UL 1569, this copper-armored MC cable achieves a 2-hour fire resistance rating without conduit protection required by other polymer cables. The cable construction is unusual for an MC cable in that the sheath is copper and meets the code requirements as an equipment grounding conductor in both theNational Electrical Codeand theCanadian Electrical Code(this type is new in Canada, and has recently been included in CSA product standards).

Polymer insulated twisted pair fire alarm cable.

Fire-alarm polymeric cable for twisted pair communication wiring meets the survivability requirements of NFPA 72. It is listed as a 2-hour fire-rated electrical circuit protective system when installed in ½-in. minimum electrical metallic tubing (EMT) or rigid metal conduit (RMC) and is ideal for retrofit applications in existing conduit.

This wire is available in shielded and unshielded twisted pair configurations, 18 AWG through 12 AWG. The conductors for both shielded and unshielded cables are insulated with silicone rubber and twisted together to form a single pair. In the shielded design, the pair is wrapped with a conductive tape shield and bare copper drain wire. In both designs, the assembly is covered with a low-smoke, zero-halogen polyolefin jacket.

The cable is tested with a utilization voltage nominated by the manufacturer. A cable that can be used in 120-V circuits should have a utilization voltage of 72 V to ground (details of each manufacturer’s product capability are described in the UL listing).

Ground cable.Typical polymer insulated ground wire used with fire-rated cables. Electrical circuit protective system cable listings are not interchangeable; the components of one system may not be used on another, and only listed materials are appropriate. Thus a ground wire should be specified in the system listing.

Conclusion

Driven by incidents of high-rise fires and failures of critical life safety circuits, the subject of fire protection in general has come a long way, not only with regard to fire protection of electrical life safety circuits, but also to other building systems, for example, fire alarm systems, sprinklers, smoke management technologies, fire separations, flame spread of construction materials, etc. Credit for this goes to improved cable technological development, hand in hand with codes and standards evolution.

Whether designed for commercial buildings, health facilities or airports, the systems specified by architects and engineers are increasingly complex when it comes to fire protection. It is the (and it is their) serious responsibility on the part of professionals to make sure all of the systems are designed and synchronized to function when needed. With the availability of new fire-rated products, plus a discriminating understanding of fire-rated construction methods, building professionals should be equipped to specify the safest systems.

Find Us on Socials