The expansion of ground-fault circuit-interrupter (GFCI) protection in the 2020 National Electrical Code® (NEC®) is a step toward increasing electrical safety regarding electric shock protection. To fully grasp this update to the code, one must understand the requirements and functionality of this technology for installation and inspection purposes. Where did it come from? How to have a code-compliant installation? We will cover all these questions, but an explanation behind the technology behind GFCI must come first.

WHAT IS A GFCI?

The ground-fault circuit-interrupter, according to NEC-2020 Article 100:

A device intended for the protection of personnel that functions to de-energize a circuit or portion thereof within an established period of time when a ground-fault current exceeds the values established for a Class A device.

Informational Note: Class A ground-fault circuit interrupters trip when the ground-fault current is 6 mA or higher and do not trip when the ground-fault current is less than 4 mA. For further information, see UL 943, Standard for Ground-Fault Circuit Interrupters.1

There are a few different key points to uncover in the Article 100 definition. First, a GFCI is a device intended for the protection of personnel. How does it protect personnel? The technology is designed to de-energize a circuit within a set threshold of time when a ground-fault current reaches a particular magnitude. What is a ground-fault? According to the NEC-2020:

An unintentional, electrically conductive connection between an ungrounded conductor of an electrical circuit and the normally non–current-carrying conductors, metallic enclosures, metallic raceways, metallic equipment, or earth.

We can understand now that GFCI is a device protecting personnel by de-energizing a circuit after an unintentional, electrically conductive connection provides current to ground at a set amount for a particular duration of time. This path of unintentional current could be through the human body, thus the necessity of GFCI protection to prevent electrocution. The informational note from the GFCI definition also states that it de-energizes the circuit with a ground fault current at 6mA or higher and will keep the circuit active for a ground-fault current less than 4mA. Ground-fault circuit-interrupters are governed by harmonized product standards from Underwriters Laboratories, Inc. (UL 943) and the Canadian Standards Association (CSA C22.2 No.144.1).

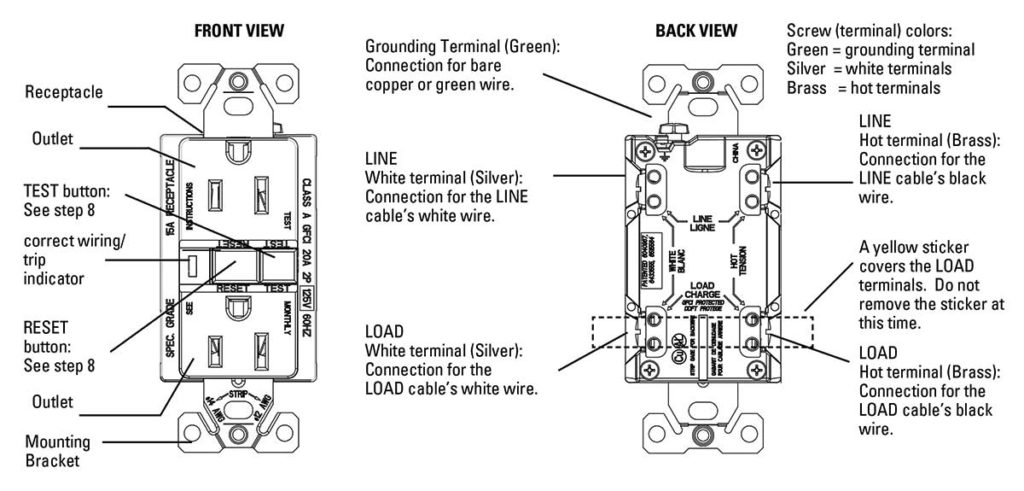

Figure 1. GFCI Receptacle Features

THE NEC ON GFCI

Ground-fault circuit-interrupters are covered in Article 210 of the NEC covering branch circuits. In 210.8, Ground-Fault Circuit-Interrupter Protection for Personnel, the Code provides the locations where GFCIs are required to protect the branch circuit. In parts 210.8(A) through (F), the NEC covers the mandated protections in dwelling units, areas other than dwelling units, crawl space lighting outlets, specific appliances, equipment requiring servicing, and outdoor outlets. According to the new NEC-2020 for 210.8(A), Dwelling Units:

“All 125-volt through 250-volt receptacles installed in the locations specified in 210.8(A)(1) through (12) and supplied by single-phase branch circuits rated 150 volts or less to ground shall have ground-fault circuit-interrupter protection for personnel.”

The NEC goes on to list the following required branch circuit locations to be protected by GFCI technology: bathrooms, garages, outdoors, crawl spaces, basements, kitchens (countertop receptacles), sinks (within 1.8 m, 6 ft), boathouses, bathtubs, laundry areas, and indoor damp and wet locations. The Code also requires that GFCI protection shall be installed in a readily accessible location. The definition from the NEC-2020 for a readily accessible location is:

“Accessible, Readily (Readily Accessible). Capable of being reached quickly for operation, renewal, or inspections without requiring those to whom ready access is requisite to take actions such as to use tools (other than keys), to climb over or under, to remove obstacles, or to resort to portable ladders, and so forth.”

There are a few updates to the GFCI code requirements from the development of the 2020 edition of the NEC. One key update is GFCI is now required to protect 125-volt to 250-volt receptacles supplied by single-phase branch circuits rated 150 volts or less to ground from the former 125-volt, single-phase, 15- and 20-amp receptacles covered in NEC 2017. This now requires 250V receptacle loads in the areas listed in 210.8(A)(1) through (A)(11) and 210.8(B)(1) through (B)(12), such as appliances like electric clothes dryers, welders, and electric ranges (within 6ft of the sink) will require GFCI protection.

Another key code update to the 2020 NEC pertaining to 210.8 in general:

“For the purposes of this section, when determining the distance from receptacles, the distance shall be measured as the shortest path the supply cord of an appliance connected to the receptacle would follow without piercing a floor, wall, ceiling, or fixed barrier, or the shortest path without passing through a window.”

This language used to include doorways as an exception to the measurement requirements. The NEC 2020 has removed the doorway portion to now include receptacles within the mandated distance to have ground-fault circuit-interrupter protection regardless of whether there is a doorway within the path of the supply cord. This change means that, for example, the receptacle located outside the bathroom whether in a hallway or bedroom, if within 6 ft of the inside edge of the sink, would be required to have GFCI protection.

CODE COMPLIANT INSTALLATION

While 210.8 covers what areas shall be protected by GFCI technology, it does not cover the specifics of how to be compliant. The final judgment lies with the authority having jurisdiction (AHJ). The most common practice to be compliant with the GFCI requirements is to install a UL 943 Listed Class A circuit breaker or receptacle to protect the required outlets and appliances. You can ensure the device is listed as UL 943 Class A by its mandated factory marking. While installing the device, be sure to note the manufacturer recommended connection methods and terminal torque values. The terminal torque values are listed either on the device or in the installation instructions. If the torque value cannot be determined, NEC 110.14(D) has an informational note that guides you to contact the manufacturer or refer to Annex I which provides information from UL 486A-486B for the torque values. A loosely-terminated conductor can increase the risk of a hazard.

There are distinct differences in GFCI protection when installing a circuit breaker or receptacle. A GFCI circuit breaker will provide GFCI protection to the entirety of the branch circuit including the “home run.” With a receptacle application, the installer has the decision to provide GFCI protection to loads in the circuit downstream of the receptacle or to only the individual receptacle. There are also different variations of GFCI receptacles such as hospital-grade and weather-resistant that feature tamper-resistant systems inside of the receptacle.

Proper Installation Method for GFCI Circuit Breaker:

The installation procedure is the same for both single- and two-pole ground fault interrupters except for the additional load power connection required for the two-pole GFCI. Before installing a GFCI, disconnect all power supplying this equipment. Follow electrical safe work practices per NFPA® 70E. (NOTE: This installation procedure is for a two-pole circuit breaker featuring two “hot” legs. A grounded conductor is not needed in this type of installation such as with an air conditioner.)

- Turn off main breaker.

- Move the handle of the GFCI to “OFF.”

- Connect the ground wire (green or bare) of the circuit to be protected to the ground lug or bar in the end use equipment. Torque per ground bar/lug requirements.

- Connect the white (neutral) load wire of the circuit to be protected to the wire connector of the GFCI marked “Load Neutral.” Torque the lug screw per torque requirements listed on the side of breaker. Neutral connection is optional for 208 V and 240 V systems.

- Connect the “hot” (black or red) wire(s) of the circuit to be protected to the wire connector(s) of the GFCI marked “Load Power.” Torque lug screw per torque requirements listed on the side of breaker.

Proper Installation Method for GFCI Receptacle for Individual Load Protection:

(Follow electrical safe work practices per NFPA® 70E.)

- Turn off main breaker.

- Connect the LINE cable wires to the LINE terminals:

- The white wire connects to the White terminal (Silver)

- The black wire connects to the Hot terminal (Brass)

- Connect the grounding wire (only if there is a grounding wire):

- For a box with no grounding terminal: Connect the LINE cable’s bare copper (or green) wire directly to the grounding terminal on the GFCI receptacle.

- For a box with a grounding terminal: Connect a 6-inch bare copper (or green) 12 or 14 AWG wire to the grounding terminal on the GFCI. Also connect a similar wire to the grounding terminal on the box. Connect the ends of these wires to the LINE cable’s bare copper (or green) wire using a wire connector. If these wires are already in place, check the connections.

- Complete the installation:

- Fold the wires into the box, keeping the grounding wire away from the White and Hot terminals. Screw the receptacle to the box and attach the faceplate.

Proper Installation Method for GFCI Receptacle for Downstream Branch Circuit Protection:

(Follow electrical safe work practices per NFPA® 70E.)

- Turn off main breaker.

- Connect the LINE cable wires to the LINE terminals:

- The white wire connects to the White terminal (Silver)

- The black wire connects to the Hot terminal (Brass)

- Connect the LOAD wires to the LOAD terminals:

- The LOAD white wire to the LOAD White terminal.

- The LOAD black wire connects to the LOAD Hot terminal.

- Complete the installation:

- Fold the wires into the box. Screw the receptacle to the box and attach the faceplate.

GFCI INSTALLATION INSPECTION

As previously stated, the most common practice on compliance with the GFCI code requirements is to install a UL 943 Listed Class A circuit breaker or receptacle to protect the required outlets and appliances.

In order to be listed under UL 943, the device must have a “Supervisory Test” to enable the ability of manually testing the tripping mechanism. On both circuit breakers and receptacles, the Supervisory Test is adhered to by providing a push button often labeled “TEST.”

The device must have an audible or visual indication that the test is performed. Receptacles commonly have an LED located on the face visually indicating the tripping mechanism. Circuit breakers will trip the handle to provide visual indication. Both receptacles and circuit breakers have added options for an audible indication of tripping mechanisms for applications where both audible and visual indication is necessary.

On receptacles that are downstream to their GFCI protection, a GFCI-testing tool can be used to simulate a ground-fault which should trip the protecting device. These GFCI protecting devices may also have LEDs to provide further visual indication of a trip or an “End of Life” scenario. “End of Life” is a feature that self-tests the device to ensure that GFCI protection is being provided to the branch circuit. If the GFCI protection has expired or malfunctioned, the End of Life LED will indicate this status. Refer to the manufacturer product documentation to learn more about the device’s Supervisory and End of Life tests.

It is recommended that both the installer and inspector of GFCI installations perform the Supervisory Test as well as noting the status of the visual indication LEDs to verify proper installation. UL 943 also requires the product to have the Supervisory Test procedure completed on a monthly schedule which would be the owner’s regular maintenance responsibility.

SUMMARY

Ground-fault circuit-interrupter protection has been providing a safer environment for installers, inspectors, and consumers since introduced in the NEC for dwelling units nearly fifty years ago. Having a grasp on where GFCI is required in the code and the best practices for installation enables electrical industry professionals to take full advantage of the technology and its many applications. The latest expansion of GFCI in the NEC-2020 only looks to further advance safety of the industry and the public from electrical hazards.

- NFPA 70®, National Electrical Code®, 2020 edition. Copyright© 2019, National Fire Protection Association. For a full copy of NFPA 70®, please go to www.nfpa.org.

Find Us on Socials