After decades of debate, 10-amp general branch circuit conductors are established in the 2026 NEC—this article explores the technical, historical, and regulatory forces that made this major shift possible.

by Chuck Mello and Peter Graser

The advent of energy-efficient technology and changing government regulations prompted changes to the National Electrical Code (NEC), allowing the general use of 10-amp branch circuits. After almost a decade of activities, 10-ampere branch circuits and associated conductors are now referenced in the 2026 edition of the NEC. Recent changes and additions in Articles 210, 240, 310 and the most widely used cable wiring methods now recognize the option to use this new minimum size of branch circuit. This article will provide the first part of that story.

However, looking historically, 10-amp branch circuits are not “new.” The first NEC 10-ampere branch circuit recognition happened in the late 1970s with changes to motor branch circuit conductors, mainly in section 430.22 in coordination with NFPA 79. This change was primarily driven by competition from European and Asian industrial equipment manufacturers using small motors with smaller conductors. The change was supported by specific testing conducted by Bussmann, now Eaton Bussmann. To be competitive, US-based manufacturers needed provisions that allowed for smaller than the existing minimum 15-ampere branch circuits and related conductors.

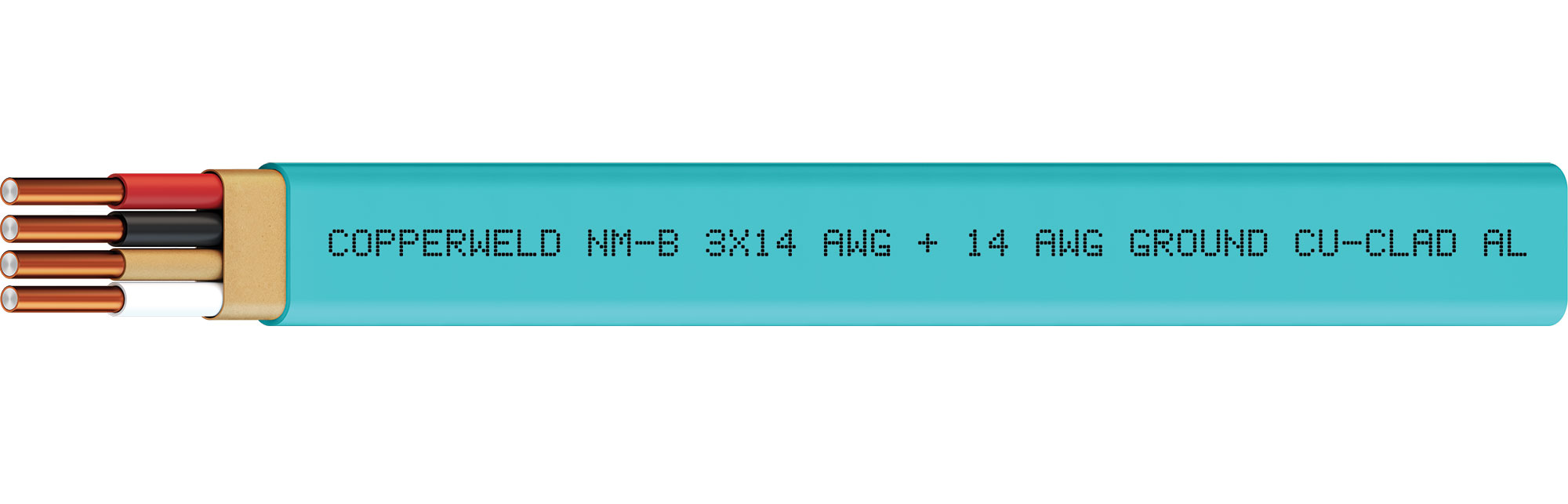

For the general branch circuit conductors found in Article 310, the motivation came from an entirely different place. Conceived in response to federal government directives towards conservation of both energy and critical minerals, 10-ampere general branch circuit conductors aimed to economize the usage of critical minerals important to the nation. After much research and debate, 10-ampere circuit conductors now appear in the 2026 edition of the NEC for permitted uses. Key changes regarding the permitted minimum wire sizes are found in 210.24, 240.4, and 310.5(A) covering branch circuits, overcurrent protection, and general wiring methods. Other changes to minimum conductor sizes were made to four cable wiring methods, as found in articles 330, 334, 336, and 340. These wiring methods are Metallic Sheathed cable (MC), Non-Metallic Sheathed cable (NM), Tray cable (TC), and Underground Feeder cable (UF). Also updated was Table 310.16 for sizing conductors by ampacity to include ampacities for 10 ampere conductors in the 60 °C, 75 °C, and 90 °C temperature columns.

Additionally, these small conductors may be used with raceway-type wiring methods, also found in Chapter 3. Two sizes of 10-ampere conductors were added: 16 AWG copper and 14 AWG copper-clad aluminum (CCA). Single-metal aluminum conductors, however, will remain unchanged, as there was no input for reducing this minimum size either through Public Input (PI) or code panel action. The smallest size of aluminum will remain at 12 AWG at an ampacity rating of 15 amperes.

As established by Code Making Panel 2 (CMP2), the principal application for 10-ampere conductors is for dedicated lighting circuits, as article 210.23(A)(2) prohibits their use for general power uses, including receptacles, fixed appliances (except as permitted for individual branch circuits), garage door openers, and laundry equipment. Exhaust fans, such as those found in bathroom or laundry room applications, however, are permitted to be served by 10-ampere circuits on the same circuit as the lighting.

Modern lighting, especially LED lighting, uses significantly less energy than in the past. With the greater efficiency now mandated by law and adopted by energy codes, the old requirement for a minimum 14 AWG copper wire rated at 15 amperes is overkill for the typical lighting loads of today. The times and the economics were ripe for innovation.

The Origin Story

Expanding the allowance for 10-ampere conductors in the NEC began in early 2017, with input developed for the 2020 NEC edition. For that cycle, a series of technically substantiated public inputs (PIs) were submitted on behalf of Copperweld Bimetallics to add 14 AWG copper-clad aluminum to Article 310. Chuck Mello and Peter Graser, the authors of this article, were the principal authors of these proposed changes. The PIs sought to bring electrical circuits in sync with the changes brought about by the Energy and Security Act of 2007, which aimed at enhancing U.S. energy efficiency and self-sufficiency. As part of that legislation, lighting circuit efficiency was enhanced to meet a minimum of 45 lumens per watt, which essentially drove the lighting industry away from the traditional incandescent bulbs used in residential, commercial, industrial, and governmental buildings, and towards full LED adoption. The act essentially made lighting circuits extremely efficient and reduced the loading in practical application to a point where 10 ampere capacity was more than sufficient for the expected load demand for those types of circuits. It should be noted that the BRIGHT Act of 2022 (the Bulb Replacement Improving Government with High-efficiency Technology Act) requires even greater efficiency still. The BRIGHT Act will require general service lamps (GSLs) in government buildings to achieve 120 lumens per watt by 2030 – 3X the efficiency of the current requirement!

Ultimately, the proposed 10-ampere conductors did not make it into the 2020 NEC; however, many of those involved with codes saw the benefit of 10-ampere conductors. Hindsight shows a fortuitous result from that cycle that encouraged the continued development of the idea. Code Making Panel 6 (CMP6) resolved the entire set of PIs and ultimately rejected the ensuing Public Comments (PCs), too. The panel’s committee statements alluded to a need for further research and credible data, despite the technical substantiation that had been provided with the proposals. In a twist, in the committee meeting for the Second Revision, CMP6 took independent action to allow 14 AWG CCA conductors to be used as remote control and signaling conductors (PCS conductors) in both TC and MC cables. This allowance was based upon the strength of the technical substantiation provided with the PIs and PCs, despite never having asked for such an application by the submitted PIs.

Because the ampacity rating proposals for 14 AWG CCA had all been rejected by CMP6, a question then arose after the Second Draft about how to protect limited power circuits being served by 14 AWG CCA PCS conductors. This caused Mr. Mello and Mr. Graser to file amending motions for that cycle’s technical session to make the membership aware of the situation. Ultimately, the motions failed on the floor of the technical session, so the problem still existed.

On appeal to the Standards Council, the case was brought that 14 AWG CCA needed to be included at the very least in Table 310.16 so that PCS circuits wired with 14 AWG CCA would be properly protected by over-current protection devices (OCPDs). Rather than granting the appeal, and after reviewing the entire record to date, the Standards Council decided that a Bimetallics Task Group (BTG) be formed and populated with balanced interests to study the issue. It also granted principal and alternate membership seats on CMP6 to the American Bimetallic Association (the ABA), so that CMP-6 had representation for all three of the accepted wiring materials—copper, aluminum, and copper-clad aluminum.

The Bimetallics Task Group

In “the Covid year” of 2020, the initial meeting of the BTG was held virtually on January 21st. The subsequent 13 meetings were held virtually due to the diverse locations of the members of the group and COVID-19 travel restrictions, with the final BTG meeting taking place on August 30th. Thirteen stakeholders were selected by the Correlating Committee (CC) to participate in the activity. The CC appointed a chair, and the meetings were conducted using Robert’s Rules of Order to promote efficient and fair proceedings. The BTG’s mandate had been set by the Standards Council through its decisions D#19-2 and D#19-23, which were “to review the proposed changes to the 2020 edition of the NEC that relate to copper-clad aluminum conductors and recommend changes through a tentative interim amendment and/or provide public inputs for the next revision cycle.”

Top of mind of the BTG was to determine whether 14 AWG CCA should remain in the NEC as a PCS conductor, without clear over-current protection guidance. After some debate, the idea of employing Tentative Interim Amendments (TIAs) to remove 14 AWG CCA from Articles 330 and 336 was taken off the table.

In their place, the BTG began a comprehensive scientific research program to benchmark 14 AWG CCA’s performance and uncover any safety concerns for use with a variety of common circuit components. The first step was to develop a list of concerns and questions from every member of the task group. These were then addressed through research and testing.

The BTG agreed to employ a third-party laboratory for the testing and set about developing an extensive research test plan. Considering that the wire ampacities had been determined in the technical substantiation submitted, the scope focused on the heating of electrical connections. These included common copper-rated circuit components such as twist-on splice connectors, wiring devices, and circuit breakers, which had been a concern of CMP6 as evidenced by the committee statements. The testing plan took a system-level approach rather than testing only discrete components but used applicable UL standards for guidance. The testing plan had many iterations until the majority of the BTG agreed to the scope and process that was developed.

The scope also included circuit breaker trip times as well as analyzing the mechanical strength of 14 AWG CCA as it related to typical bending stresses associated with box fill. As testing data was obtained from the testing facility, it was distributed to each task group member and was discussed in the regularly scheduled task group meetings. Members of the task group also virtually witnessed the testing twice and were provided the opportunity to comment on the testing activity. The completed testing results were issued in two formal reports from the BTG.

As test results emerged, the BTG began to vet the viability of 14 AWG CCA for use as a 10-ampere small branch circuit conductor. Due to the strength of the data, the BTG developed a PI road map with the intention of developing a coordinated set of PIs for the 2023 cycle affecting the necessary code sections to allow for the practical use of 14 AWG CCA as a 10-ampere rated conductor. This resulted in the BTG chair submitting a total of 19 PIs for consideration by four different code-making panels responsible for the affected code sections.

The 2023 NEC Cycle: Postponed Success

In the first revision stage of the 2023 NEC code making process, the idea of 10 ampere conductors was widely accepted by the members of CMP6. CMP-2, CMP-10 and CMP-18 also considered and generally accepted the PIs that were submitted by the BTG. Those PIs under CMP6 purview were technically substantiated by the two benchmark test reports provided by the BTG. The reports demonstrated the performance of 14 AWG CCA to be well above the minimum code safety requirements. Since there was no standard for 14 AWG CCA at the time of testing, these reports used 14 AWG copper at 15 amps as a benchmark for acceptable performance and compared the results of 14 AWG CCA at 10 amps to those benchmarks. Although 16 AWG copper was not the subject of the BTG test plan nor reports, the members of CMP6 saw fit to include 16 AWG copper in the First Revision as a 10-ampere conductor, based upon “the decades of successful use of 16 AWG copper conductors in fixture wire, motor wiring, control wiring, and other current-carrying applications as permitted in the NEC.”

The second revision stage of the NFPA process saw CMP6 reverse its position. Some of the members of CMP6 opposing this addition submitted a series of Public Comments (PCs) attaching test reports that sought to revert the First Revision text back to the 2020 NEC text and thus prevent the 10-ampere conductors from entering the industry. Although highly controversial, CMP6 ultimately decided that more research was necessary to allow 10-ampere conductors to enter Article 310 and the wiring methods.

On appeal, the Standards Council decided to stand with CMP-6’s decision for more research. The Standards Council decision called for the BTG to reconvene for the 2026 cycle, assigning it two tasks. First, to provide—with one or more TIAs—the needed ampacity for 14 AWG CCA conductors for control circuits. Second, to define the scope for a NFPA Fire Protection Research Foundation research project concerning the development of suggested testing methods of branch circuits in thermal insulation. The BTG completed both of the tasks asked of it. However, the only successful TIA pertained to section 300.26 where language was added to address over-current protection requirements for 14 AWG CCA. A second TIA that would have given ampacity values to 14 AWG CCA in Table 310.16 failed to gain the necessary support from CMP-6.

Part II of this article will continue the story with the Fire Protection Research Foundation (FPRF) project results and the additional testing that was completed by third parties based on the FPRF report recommendations.

Find Us on Socials