Is an electrical inspection in your area viewed as a public safety activity that is respected without compromise? Are the inspection services offered in your area properly funded, or are they under scrutiny for budget cutting? Do the inspectors in your area meet a rigorous set of qualifications and continuing education requirements? Is an inspection viewed as necessary to ensure the benefits of public safety, or merely an “activity required by law”?

Depending on your answers, it may be that some in your area suffer from blue sky syndrome. This malady is generally found in mayors, city council members, state officials and others that say, “Why do I need to have electrical inspections? I look out the windows and don’t see any fires … just blue sky.”

This article is the second of a three-part series on electrical safety, the National Electrical Code (NEC®) and the inspection community. In this part, we will explore the issue of whether or not electrical inspections suffer at the expense of political issues facing the construction industry. Part three will discuss how qualified inspectors, continuing education and the performance of solid inspections add value to installers, users and the local jurisdiction as a whole.

Victimized by success?

Inspectors may be suffering from the success of electrical safety. By continually advancing electrical safety through updating of the NEC and state and local codes, and by having electrical inspections performed in a professional manner by qualified inspectors, the industry has been successful at reducing the incidence of major electrical fires and electrocutions. It is through these blinders of success that the view of electrical inspections has changed.

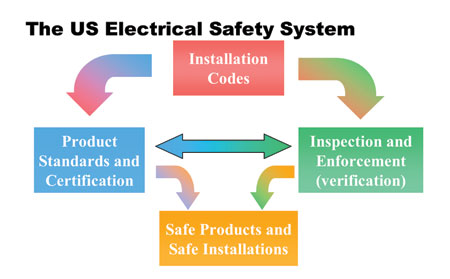

Figure 1. Electrical inspection makes up one of the three critical components of electrical safety.

Electrical safety benefits from astute electrical inspection mechanisms. In fact, as this author has pointed out for well over a decade, electrical inspection makes up one of the three critical components of electrical safety, the others being an installation code and product standards.

As shown in figure 1, to achieve safe electrical installations, there needs to be a solid and up-to-date installation code, effective product standards that work seamlessly with the code, certification to those standards, and finally, inspection and enforcement. The last element generally falls upon state and local governments to provide. Inspection and enforcement cost money, but it also provides important dividends. It is the methodology that ensures that an installation actually complies with the code and that the proper products are being used in the appropriate manner.

If fires were occurring on a daily basis, elected officials would be lined up at the door of the inspector asking why this is happening. But because the efforts in electrical safety, including inspections, have been very successful, officials quickly see inspections as a possible place to cut funding. After all, if the sky is blue, why spend money on the inspection department? The answer is simple: The inspection process has helped achieve a higher level of electrical safety. Reducing the quantity or quality of inspections will only reverse today’s established electrical safety success. It may be years before the drastic impact from such a reversal becomes evident, but it will occur.

The budgeting process

Electrical inspection departments seem to quickly suffer at the expense of the budgeting process. In the author’s discussions with inspectors around the country, an interesting trend appears to be emerging. Inspection fees charged to installers and end users will more than pay for a high-quality electrical inspection department that is appropriately staffed, and well-trained and

-equipped. However, in the vast majority of cases, the department is provided with minimal funds and a significant share of inspection fees are siphoned off into the governmental “general fund.” In other words, the inspections that were intended to achieve a public safety objective are rapidly being turned into a means to simply generate revenue for the municipality.

Part of what has allowed this to happen is that the industry is not well-equipped to describe the standards for an electrical inspection to those within municipalities that would benefit from that knowledge, i.e., elected officials. Inspections are performed differently across the country and the time and effort for each individual inspection varies greatly. Unfortunately, the expedient answer in many cases is to just deploy fewer inspectors and have them do faster, less-thorough inspections. This is where the electrical inspection community can learn a great lesson from the fire service community, which has defined its process very well in various standards. The response time, the number of personnel and the qualifications of personnel are all outlined in its national standards. This allows local fire service entities to clearly explain not only what they need, but also why they need it.

Areas to address

There are several areas that the electrical industry must address to help local inspectors combat the perception or misunderstanding that electrical inspections are simply a revenue-generating exercise, or worse, unimportant.

First, there need to be more consistent qualifications for electrical inspectors. Certainly, all inspection disciplines have their unique needs. However, electrical installations can be very complicated and there is a need to have electrical inspectors that are well-trained in all aspects of electrical installations. The International Association of Electrical Inspectors (IAEI) Certified Electrical Inspector program is a good start to this effort.

Second, there needs to be a more consistent process for electrical inspections. Today, everybody sort of “does their own thing” and as a result, inspections are inconsistent from one jurisdiction to the next. This often leads to misunderstandings between the inspectors and the installers that tend to increase tensions at the political level. It is recognized that many electrical installations are unique and as such, have unique inspection requirements. However, developing a standardized process by which to approach all inspections, no matter the jurisdiction, would be beneficial to the inspection community overall.

Third, actual time and motion studies of inspections are a must. It is difficult to understand how the final inspection of a 2,000-square-foot home can take 10 minutes in one jurisdiction and 90 minutes in another. There needs to be better understanding of what is being inspected and how it is being inspected in order to define time requirements for various types of inspections. This will become beneficial at the local level because it will provide a stronger basis to explain why additional resources are needed as construction grows. If one person can truly only properly inspect eight homes a day, then there shouldn’t be an expectation for one person to inspect 30 homes a day and do the same high-quality job.

Moving forward

There is no doubt among the electrical inspection community that the importance of electrical inspections is taken for granted; the question is how to convey this to elected officials. Each and every day, the typical electrical inspector finds safety-related installation issues that need to be corrected. If it were not for the inspector, those items would go unchecked and could result in tragedy later. Better mechanisms must be developed to explain the inspection process and the essential resources to the elected officials.

The hard-earned successes of the inspection community are critical to the electrical safety of our society and must be sustained. Certainly, this success cannot become a means to argue that inspections no longer play a critical role for jurisdictions. To maintain this success, and to avoid tragedy, the inspection community, and the electrical industry as a whole, needs to seriously think about advancing the process of inspections and begin the standardization process. With that, both will be better equipped to explain the entire story to the elected officials, retain the integrity of the inspection process, and sustain high standards of public safety.

Find Us on Socials