Although arc flashes have been a danger since electricity was harnessed for use, arc flashes were not addressed as specific hazards by the electric power industry until recently. This is changing.

Arc flashes are unseen dangers that can occur without any direct contact between a worker’s body and an energized wire or piece of equipment. They’re often accidentally initiated by workers that are unaware that they are in a potentially life-threatening situation.

What Happens in an Arc Flash?

Arc flashes produce extremely high temperatures, up to 35,000 degrees Fahrenheit, roughly four times hotter than the surface of the sun. Heat causes the expansion of air molecules, producing a strong blast of pressurized air.

Materials in the blast zone vaporize, expanding in volume and being propelled forcefully over great distances. While arc flashes don’t always produce arc blasts, they often occur together in the same way that thunder follows lightning.

The amount of energy released during an arc flash depends on the system voltage, the current magnitude of the arc fault, and the fault’s duration. Arc flashes in an enclosed space, like an electrical power control panel, magnify the blast, and the energy explodes through the opening in the enclosure, right toward the worker. This video of an arc flash simulation tells the story: https://www.youtube.com/watch?v=6hpE5LYj-CY.

Arc Flash Damage to the Human Body and Mind

The heat generated by an arc flash causes severe or fatal burns, even if the victim is up to ten feet away. Droplets of molten metal are propelled at very high speeds, covering the worker and potentially being inhaled as vapor. Shrapnel created in the explosion travels at speeds exceeding 700 miles per hour and can penetrate a worker’s body. The bright light of the arc flash can damage or destroy eyesight.

An arc flash blast is strong enough to lift a worker off their feet, rip them from a ladder, and throw them across a room, potentially causing severe or fatal injury upon landing. This enormous wave of pressure can collapse lungs and fracture ribs. The sound wave, measuring as high as 140 decibels within two feet of the arc, results in hearing loss.

Clothing ignites, causing worse burns than those suffered on exposed skin. Young, healthy workers stand a better chance of surviving an arc flash and blast than older workers, according to the American Burn Association.

Those who do survive often live the rest of their lives with disfiguring burn scars and post-traumatic stress disorder (PTSD). Even if physically capable of returning to work, many can’t cope with the crippling anxiety and overwhelming fear that it could happen again.

Costs of Arc Flash Injuries

An estimated five to ten arc flashes/blasts occur daily in the United States. Over 2,000 arc flash victims are treated every year for burns, nerve damage, hearing loss, and heart attacks. Arc flash victims frequently lose six to eight months of work time. In the most severe cases, these injuries end careers and cost lives. Medical expenses for survivors are estimated to average over a million dollars, with litigation and case settlement costs soaring into the tens of millions.

Recognizing Arc Flash Hazards

Before you can take action to protect your workers and your company from these catastrophic incidents, you have to discover where arc flash hazards are present in your workplace by conducting arc flash hazard (AFH) assessments.

How to Conduct an AFH Assessment

- Identify which equipment requires assessment. Prioritize your efforts by the risk each piece of equipment poses to your workers.

- Collect data required for the AFH assessment. Make certain you’re wearing the required arc-rated clothing and other arc flash personal protective equipment (PPE) when you collect the following data:

- Equipment data needed to analyze potential short circuits, such as the voltage, size (mVA/kVA), impedance, X/R ratio, etc.

- Data on protective devices built into your electrical system, to determine the arc duration, such as the presence of breakers/trip units, existing relay settings, time-current curves, amp ratings, and total clearing times.

- Data for the arc flash study, such as the type of equipment, what type of enclosure, if any (cabinet, box, terminal, etc.), conductor gaps, type of grounding present, number of phases, and the estimated working distance for the equipment.

- Compile a list of all electrical power system equipment that shows not only the existing connections but also any possible alternative connections that could occur under all possible operating conditions.

- Prepare or update a one-line diagram of the entire system.

- Perform the short circuit study to calculate the available 3-phase fault current of each piece of equipment, as well as a calculation of the current of every possible contributing branch/load.

- Determine the expected arc fault current by calculating the arc current and all branch currents that are contributing to the arc current.

- Estimate the arc fault duration from protective devices and any contributing arc current from branches that will also pass through each protective device, magnifying the arc fault.

- Estimate the incident energy of each piece of equipment at each working distance.

- Identify the arc flash boundary for each piece of equipment.

- Document the AFH assessment in written reports, annotate the one-line diagrams and place the appropriate AFH labels on each piece of equipment. Annotate any assumptions you made during the assessment. It is this documentation that provides evidence of OSHA and NFPA compliance.

Arc Flash Labeling

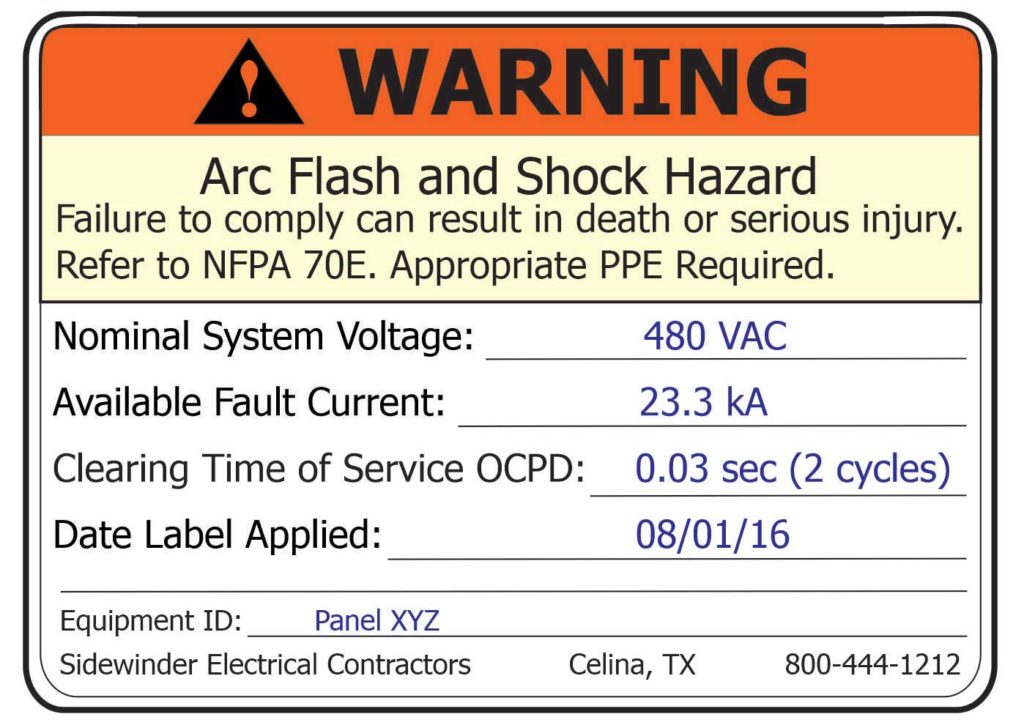

Working in the dangerous electrical power industry requires workers to be attentive to their environment and observe safe work practices at all times. After an AFH assessment has been conducted, equipment that was evaluated should be clearly labeled so that workers can easily tell if they’re in a situation or environment that is more dangerous than the norm.

NFPA 70E references ANSI Z535.4 to specify the requirements for AFH labels. The label must show the nature of the danger, the specific danger zone, and the type of PPE required. Placement of these labels must be clearly visible. The above-pictured label is not NFPA-70E compliant because it lacks the specific information required by the standard. The calculation methods and data that support the label information must be included in the AFH assessment documentation.

Mitigating Arc Flash Risk and Damage

De-energizing electrical power equipment before working on it is the very best way to prevent arc flash. Following that, the best means of reducing the number of arc flash incidents is to eliminate arc flash causes.

Follow proper work procedures and observe all safety practices. Keep machinery in good working order and free of dust, corrosion, and moisture. Keep your mind focused on the job at hand each time you’re working around electrical power. Wherever possible, use safer, insulated tools. Avoid applying excessive force to tools, which can slip and cause a spark.

Reduce the level of the arc energy that can be released in case an arc fault occurs. Ensure that all relays and breakers are operating properly. If these devices fail at any point, the arc energy that is released in an arc fault will be much higher than expected. If your AFH assessment didn’t predict this, your AFH labels won’t be correct, and you won’t be wearing the necessary level of PPE.

Ensure that PPE protects against the specific hazard present, based on the AFH assessment. Although PPE can offer varying degrees of protection, it’s no substitute for following safe work practices and using plain common sense. Keep your PPE clean and in good working condition. Repair or replace damaged PPE promptly.

OSHA and NFPA-70E safety standards specify the type of PPE required for protection against arc flashes. Even so, arc flash PPE allows for curable, second-degree burns. Arc flash PPE includes arc-rated clothing, which is not the same as flame-resistant clothing. Refer to NFPA-70E, Section 130.5(C) for methods of arc flash PPE selection and Section 130.7(C) for the specifics of arc flash PPE required to protect various body parts.

Arc flashes and arc flash blasts have devastating physical and emotional consequences for workers. In addition, they’re very damaging to your company’s bottom line. Ensuring that equipment is de-energized before working on it, avoiding the causes of arc flashes, reducing the level of arc energy available, following safe work procedures, and using the proper level of PPE, protects workers. By emphasizing arc flash safety in your company’s safety program, you let your workers know that they are your most valued asset.

References

- “Don’t Let Arc Flash Cost You,” EHS Daily Advisor, August 19, 2015. https://ehsdailyadvisor.blr.com/2015/08/dont-let-arc-flash-cost/

- “Arc Flash: Fast, Lethal, and Preventable,” EHS Daily Advisor, June 23, 2009. https://ehsdailyadvisor.blr.com/2009/06/arc-flash-fast-lethal-and-preventable/

- “The Perils—and Prevention—of Arc Flash,” EHS Daily Advisor, October 16, 2008. https://ehsdailyadvisor.blr.com/2008/10/the-perils-and-prevention-of-arc-flash/

- “Take Steps to Prevent Arc Flash,” EHS Daily Advisor, August 20, 2015. https://ehsdailyadvisor.blr.com/2015/08/take-steps-prevent-arc-flash/

- “Safe Work Practices to Prevent Arc Flash Incidents,” EHS Daily Advisor, May 6, 2014. https://ehsdailyadvisor.blr.com/2014/05/safe-work-practices-to-prevent-arc-flash-incidents/

- “Preventing Arc Flash Tragedies,” EHS Daily Advisor, June 24, 2009. https://ehsdailyadvisor.blr.com/2009/06/preventing-arc-flash-tragedies/

- Practical Solutions Guide to Arc Flash Hazards, Second Edition, by Conrad St. Pierre, et al. Copyright © 2015 by EasyPower, LLC ISBN 978-0-9971026-0-4

Find Us on Socials