The emergence of energy storage systems (ESSs), due to production from alternative energies such as wind and solar installations, has driven the need for installation requirements within the National Electrical Code (NEC) for the safe installation of these energy storage systems. This information is important to both the installer and the inspector for electrically safe systems to be installed. This helps to ensure that the occupants of structures, as well as the structures themselves, remain safe. We will explore some of the 2017 NEC requirements found within Article 705 for “Interconnected Energy Power Sources” and Article 706 for “Energy Storage Systems.”

Article 706 is primarily the result of the work developed by a 79-member Direct Current (DC) Task Group formed by the NEC Correlating Committee. The DC Task Group combined input from many different sources, working groups, organizations, and companies, including the IEEE Battery Group, the Article 690 Task Group, the National Electrical Manufacturers Association, and equipment manufacturers.

Twelve standards were referenced in the development of Article 706. These standards are included in the informational note located after the Scope at 706.1. The developing DC Task Group also had to consider existing text concerning energy storage in Articles, such as Articles 480, 690, 692, and 694, and how those Articles correlate with this new Article 706.

To begin with, it is important to understand what Article 706 applies to and what it does not apply to. The scope of Article 706 informs Code users that this information applies to all permanently installed energy storage systems. This applies to ESSs operating at more than 50 volts AC or 60 volts DC. These may be stand-alone or interactive with other electric power production sources.

Definitions are important

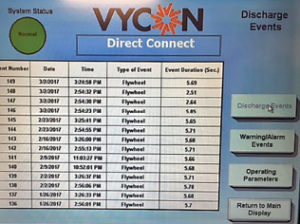

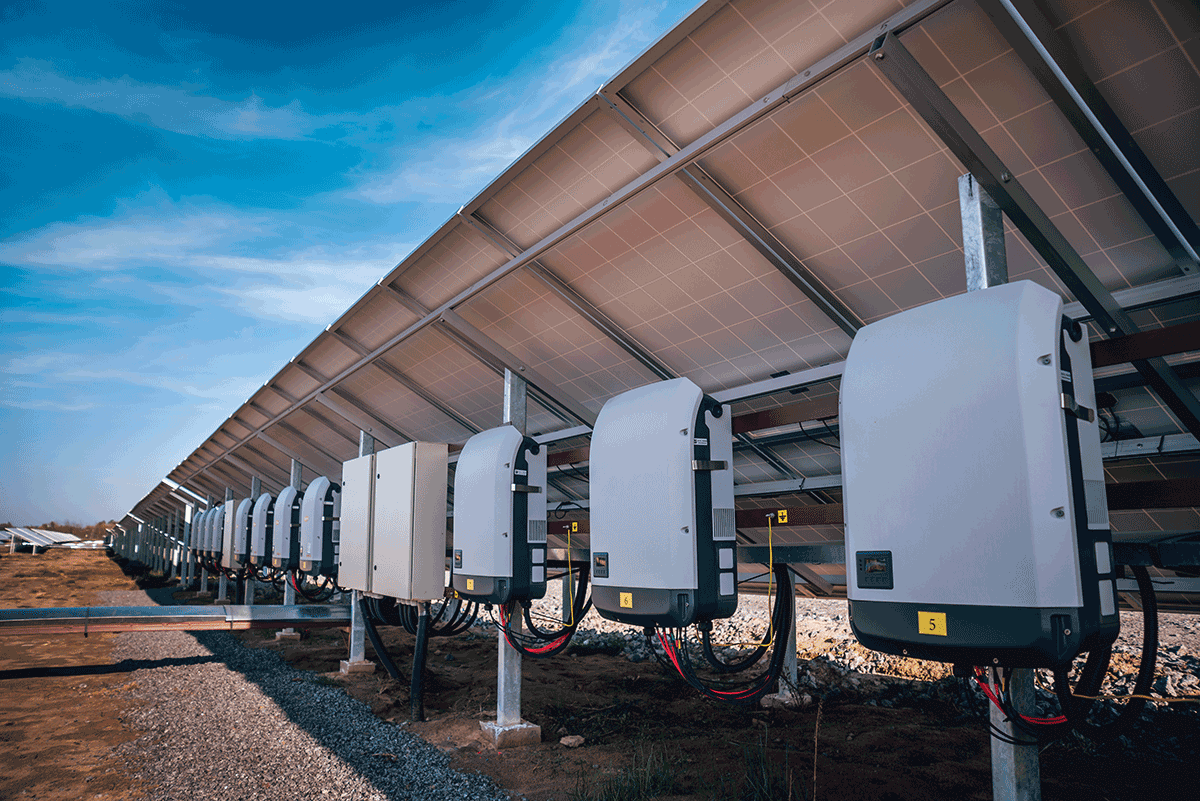

What exactly is an energy storage system? Because this is a new article for the 2017 NEC, it is important to define what will be discussed. An ESS is one or more components assembled together capable of storing energy for use at a future time. It can include (but is not limited to) batteries, capacitors, and kinetic energy devices (e.g., flywheels and compressed air). Several of these systems can have AC or DC output for utilization. They can also include inverters and converters to change stored energy into electrical energy. [See photos 1 and 2.]

There are three types of storage systems described within the definitions found at NEC 706.2. These systems are:

- Energy Storage System, Self-Contained;

- Energy Storage System, Pre-Engineered of

Matched Components; and - Energy Storage System, Other.

A battery is also a defined term in Article 706. A battery is defined as two or more cells connected together electrically in series, in parallel, or a combination of both to provide the required operating voltage and current levels. We will discuss batteries more, and understanding this definition is important to proper application of the Code.

How and where these are used

Energy storage systems can be (and typically are) connected to other energy sources, such as the local utility distribution system. There may be one or more sources connected to an ESS. The connection to other energy sources is required to comply with the requirements of 705.12. Article 705 covers the installation of one or more electric power production sources operating in parallel with a primary source(s) of electricity.

The point of connection is addressed in 705.12 and informs Code users that the output of an interconnected electric power source must be connected as specified in 705.12(A) or (B). In looking at 705.12(A), it can be determined that this applies to the supply side of the connection. The language here explains that an electric power production source is permitted to be connected to the supply side of the service disconnecting means as permitted in 230.82(6). Article 230 contains the requirements for electric services.

Next on the list is 705.12(B), which speaks to the load side of the connection. Information for this side of the connection instructs installers that the output of an interconnected electric power source is permitted to be connected to the load side of the service disconnecting means of the other source(s) at any distribution equipment on the premises. Furthermore, this Code text directs the user of the Code to comply with 705.12(B)(1) through (B)(5) for this purpose.

Disconnection means is an important consideration with these systems. This information is found at 706.8(A). It is crucial that the load disconnecting means serving multiple sources of power disconnects all energy sources when in the off position. This helps to ensure worker safety, as well as the safety of the equipment and the structure.

In the event of an unexpected loss of primary source, an ESS with a utility-interactive inverter needs to comply with the requirements of 705.40, which states that upon the loss of primary source, an electric power production source will be automatically disconnected from all ungrounded conductors of the primary source and will not be reconnected until the primary source is restored. This section also tells Code users that an interactive inverter is permitted to operate as a stand-alone system to supply loads that have been disconnected from electrical production and distribution network sources.

Specific requirements for the point of connection is necessary when installing an energy storage system. The point of connection between an ESS and the electric power production sources must be in accordance with 705.12, which was mentioned earlier.

Locations for energy storage systems

It is important to plan and discuss the location of an energy storage system with the electrical inspection authorities before installation of this equipment. In many cases, this will include the building inspector and the fire marshal. The language found in 706.10 informs the installer or inspector that battery locations must conform to information found within this section.

Appropriate ventilation is important to dissipate harmful off-gassing that can result from the use of batteries. Provisions need to be made for sufficient diffusion and ventilation of any possible gases from the storage device to prevent the accumulation of an explosive mixture. A pre-engineered or self-contained energy storage system is permitted to provide ventilation in accordance with the manufacturer’s recommendations and listing for the system.

Another important consideration when using batteries as an energy storage system is the guarding of live parts. Direction is given that guarding of live parts needs to comply with 110.27 titled “Grounding of Live Parts.” This includes protection against accidental contact or physical damage to the storage system. Warning signs are required for entrances to rooms and other guarded locations where battery systems have been installed. The marking of these warning signs has to comply with the requirements found in 110.21(B), which gives direction for field-applied hazard markings and warning labels.

The required working spaces in and around the energy storage system must also comply with 110.26. Working space is measured from the edge of the ESS modules, battery cabinets, racks, or trays. When dealing with battery racks, there needs to be a minimum clearance of 25 mm (1 in.) between a cell container and any wall or structure on the side not requiring access for maintenance. Energy storage system modules, battery cabinets, racks, or trays are permitted to contact adjacent walls or structures, provided that the battery shelf has a free air space for not less than 90 percent of its length. An informational note adds some clarity in that this additional space is often needed to accommodate energy storage system equipment, hoisting equipment, tray removal, or spill containment.

Likewise, guidance and allowances are given for pre-engineered and self-contained energy storage systems. Language found in the last paragraph at 706.10(C) advises that pre-engineered and self-contained energy storage systems are permitted to have working space between components within the system in accordance with the manufacturer’s recommendations and listing of the system.

Lastly, it is important that entrance and egress considerations and planning be discussed and well thought out for rooms enclosing an ESS. Information can be found at 706.10(D) for personnel door(s) intended for entrance to and egress from rooms designated as energy storage systems rooms. These doors are required to open in the direction of egress and must be equipped with listed panic hardware. Section 706.10(E) mandates that illumination has to be provided for working spaces associated with energy storage systems and their equipment and components. The luminaires providing this required illumination cannot be controlled by automatic means only. Specific location requirements for these luminaires cannot expose maintenance personnel to energized system components or create a hazard to the system or system components upon failure of the luminaire.

Plaque and directories for an ESS

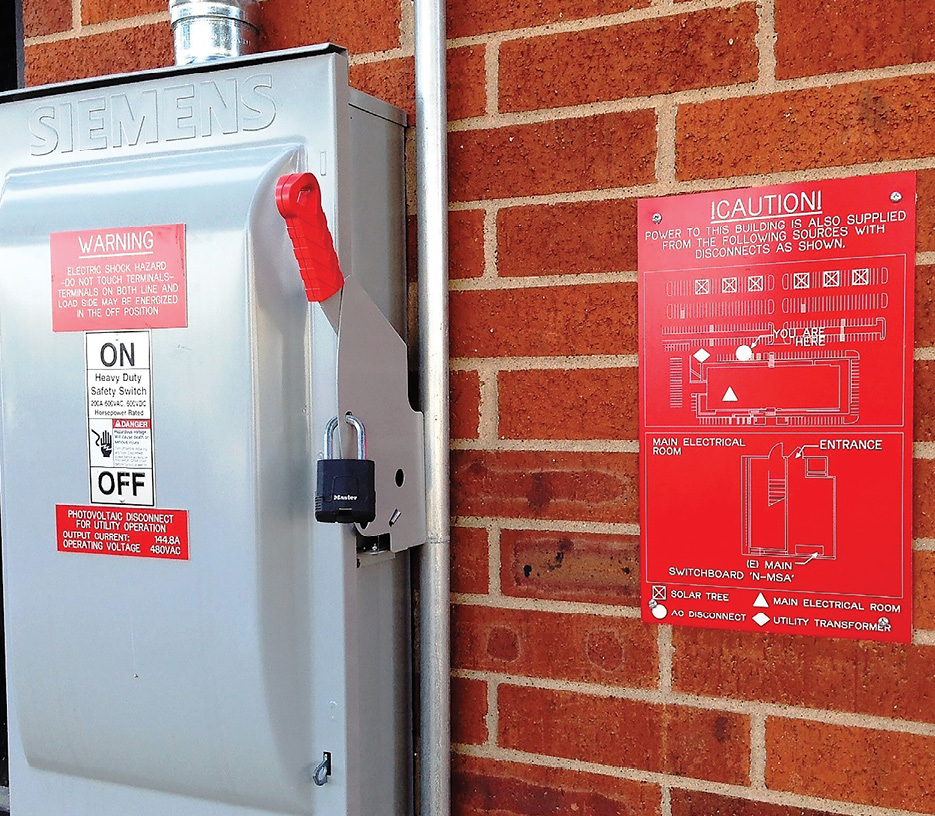

It is important for individuals working on energy storage systems to be able to locate an electric power source directory for the system. Alternative energy systems interconnected to the primary source of electricity might injure workers that do not get the sources disconnected properly before conducting repairs or maintenance. Many times, the original installer or original contractor will not be available to work on this system.

A well prepared and specific directory will ensure that the end-user can find and disconnect components of the system in case of repair or maintenance needs. The directory should be a permanent plaque or directory denoting all-electric power sources on the premises. This directory should be installed at each service equipment location and at locations of all-electric power production sources capable of being interconnected. The markings or labels also need to be in accordance with 110.21(B). [See photo 3.]

Overcurrent protection

As with other aspects of an electrical system, proper overcurrent protection for energy storage system circuits and equipment is an important aspect of a safe and properly functioning ESS. Circuit conductors need to be protected in accordance with the requirements of Article 240. Protection devices for these energy storage system circuits are to comply with the requirements of 706.21(B) through (F) with the circuits protected at the source from overcurrent.

Electrochemical energy storage systems

Part III of Article 706 applies to energy storage systems that comprise sealed and non-sealed cells, batteries, or system modules that comprise multiple sealed cells or batteries that are not components within a listed product. An informational note at the introduction of Article 706 Part III states that an energy storage component, such as batteries, that is integrated into a larger piece of listed equipment, such as an uninterruptible power supply (UPS), is an example of components within a listed product.

For dwelling units, an ESS cannot exceed 100 volts between conductors or to ground. An exception dictates that where live parts are not accessible during routine ESS maintenance, voltage exceeding 100 volts is permitted at the dwelling unit energy storage system. This information can be found at 706.30(A).

When addressing the disconnection of series battery circuits subject to field servicing, where the circuits exceed 240 volts nominal between conductors or to ground, provisions must be made to disconnect the series-connected strings into segments not exceeding 240 volts nominal for maintenance by qualified persons. Non-load break-bolted or plug-in disconnects are permitted.

Another aspect to an ESS is the storage system maintenance disconnecting means. An energy storage system exceeding 100 volts between conductors or to ground must have a disconnecting means, accessible only to qualified persons, that disconnects ungrounded and grounded circuit conductor(s) in the electrical storage system for maintenance. It is important to point out that this disconnecting means cannot disconnect the grounded circuit conductor(s) for the balance of any other electrical system. Somewhat different that what is found above for disconnection of series battery circuits, a non-load break-rated switch is permitted to be used as a disconnecting means.

When installing or inspecting storage systems of more than 100 volts, the battery circuits for an energy storage system that exceed 100 volts between the conductors or to ground is permitted to operate with ungrounded conductors. For this condition, the installation must be provided with a ground-fault detector and indicator installed to monitor for the presence of ground faults within the storage system.

It is typical to inspect or install battery systems utilizing flexible cables to allow for interconnection between the various batteries. Flexible cables, as identified in Article 400, in sizes 2/0 AWG and larger, are permitted within the battery enclosure from battery terminals to a nearby junction box where they should be connected to an approved wiring method. Remember who does the approving within the NEC? Approval is granted by the authority having jurisdiction (AHJ). Flexible battery cables are also permitted between batteries and cells within the battery enclosure. These cables are required to be listed and identified as moisture resistant. When installing flexible fine-stranded cables, remember that these cables are only permitted to be used with terminals, lugs, devices, or connectors in accordance with 110.14.

Where top terminal batteries are installed on tiered racks or on shelves of battery cabinets, working space in accordance with the storage equipment manufacturer’s instructions has to be provided between the highest point on a storage system component and the row, shelf, or ceiling above that point. An informational note at 706.34(B) directs the user of the Code to IEEE 1187 entitled “Recommended Practice for Installation Design and Installation of Valve-Regulated Lead-Acid Batteries for Stationary Applications.” This document provides guidance for top clearance of valve-regulated lead-acid (VRLA) batteries, which are the most commonly used battery in cabinets. It is also made clear in 706.34(C) that gas piping is not permitted in dedicated battery rooms. Mixture of a volatile gas in a corrosive location is a recipe for trouble.

Flow battery energy storage systems

Flow battery energy storage system requirements can be found in Part IV of Article 706. In general, all electrical connections to and from this system and system components are required to be in accordance with the applicable provisions of Article 692, titled “Fuel Cell Systems.” [See photo 4.]

The flow battery energy storage system and system components must also meet the provisions of Parts I and II of Article 706. Unless otherwise directed by Article 706, flow battery energy storage systems have to comply with the applicable provisions of Article 692.

Other energy storage technologies

Information for other energy storage technologies can be found in Article 706 Part V. This information applies to ESSs using other technologies intended to store energy, and when there is a demand for electrical power to use the stored energy to generate the necessary power. All electrical connections to and from this system and the system components must comply with the applicable provisions of the NEC. Unless otherwise directed by Article 706, these “other” energy storage technologies would need to comply with the applicable provisions of Article 705 Part III.

Energy storage systems have been a part of our built environment for several years. As with any newer technology, sometimes the NEC is in a position of playing catch up in order to provide information toward safely installing these systems. Many alternative energy systems tied to ESS are designed and intended to operate for several years. With that being the case, it is equally important that systems used to collect, hold, and distribute this energy receive the attention necessary from the installer and the inspector to ensure years of proper operation.

Together as installers and inspectors, our goal should be to continue to march toward an electrically safe environment. Keeping your family, as well as other families, electrically safe is an accomplishment and something of which to be proud. Remember, electrical industry installers and inspectors are often the first line of defense in preventing electrical accidents or deaths. They are the “First Preventer” in the long line of fire and safety organizations.

Find Us on Socials