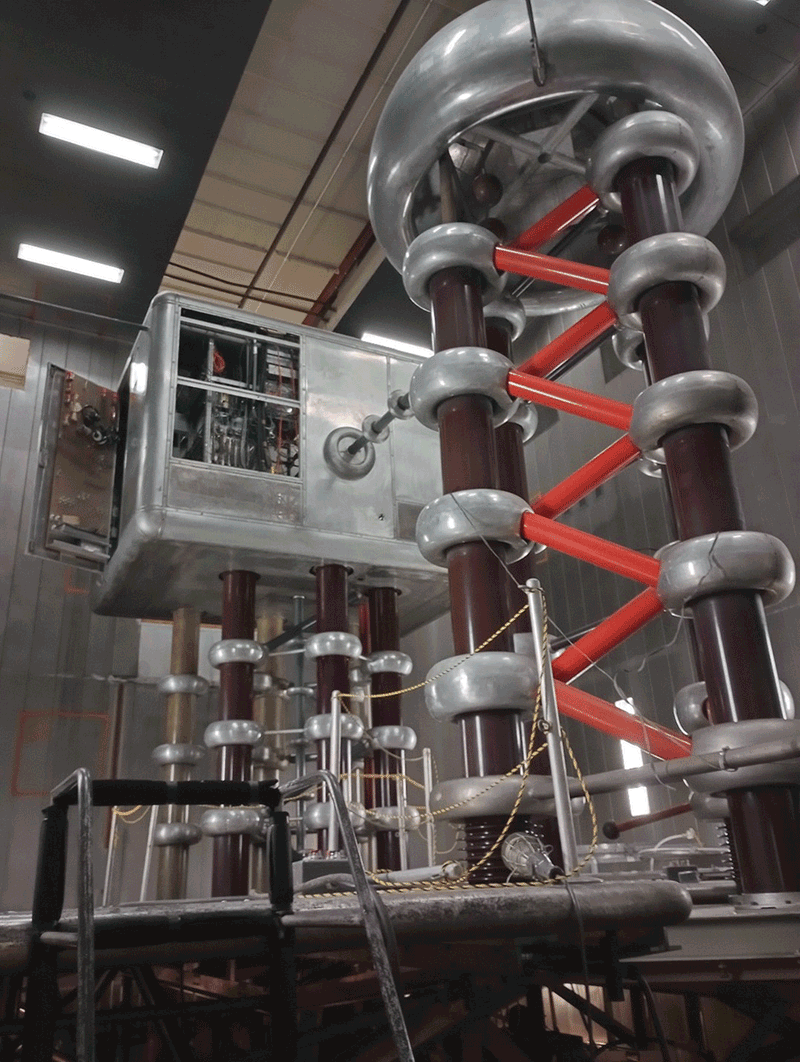

Today’s quickly evolving technology makes it impossible for the NEC to keep up with every possible thing that you may find on an inspection. What do you do when you encounter equipment that you have no idea what it is or how it should be properly installed?

First, ask. Most people love to have you ask about their jobs, and the equipment that they work with, if you present as being really interested. If you come across as being derogatory or judgmental, they will get defensive. What does this equipment do? How long does it operate without shutting down? Even if you don’t understand what they are talking about, it will provide time for you to closely look at the equipment.

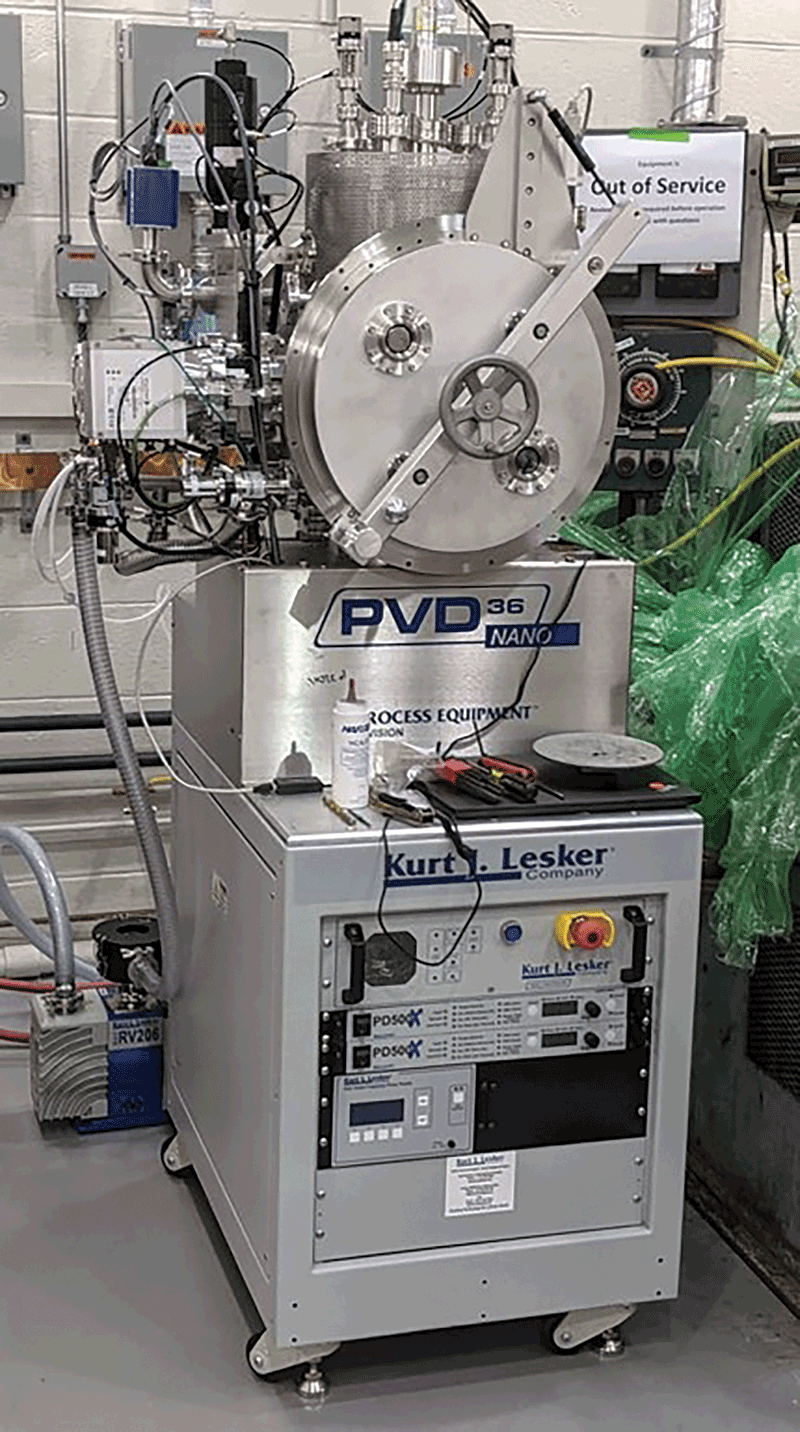

While looking, is there a label? Note who the manufacturer is, voltage and ampacity requirements, and is it NRTL-listed? Not all equipment will have an NRTL listing. Standards committees have as much trouble keeping up with new technology as the NEC. And NRTL-listing is not necessarily mandatory for AHJ approval. Articles 90.7, 110.2, and 110.3 make it clear that an NRTL-listing is a preferred option for AHJ approval, but not the only option.

As the AHJ, you have the authority to require a field evaluation/certification before you accept the equipment if it is not NRTL-listed. Make sure that this is completed by an NRTL that is OSHA-approved to inspect to the most likely standard. An NRTL that evaluates storage containers may not be appropriate to evaluate the batteries and inverter that are in the Battery Energy Storage System. Further information on NRTLs can be found at OSHA’s Nationally Recognized Testing Laboratory (NRTL) Program – Current List of NRTLs | Occupational Safety and Health Administration.

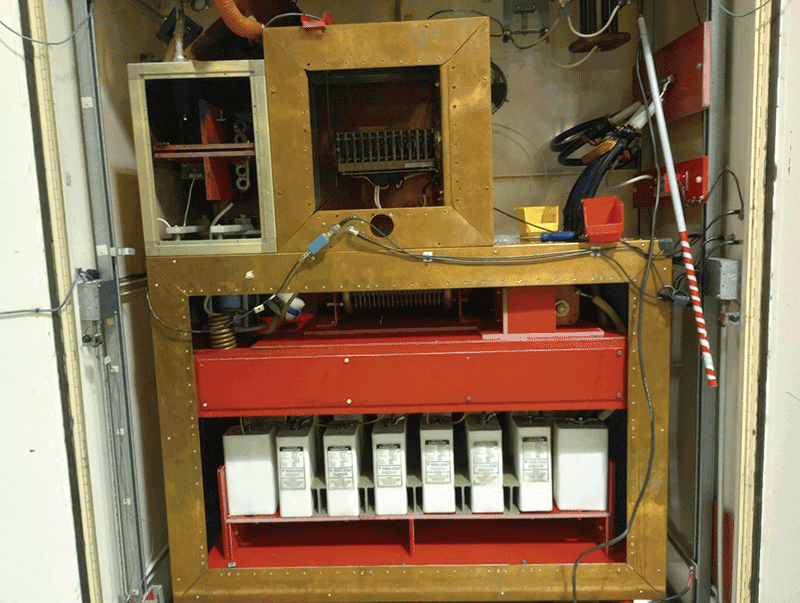

If you, as the AHJ, decide to approve the equipment yourself, reviewing the UL Standard that seems most appropriate for the equipment will provide assistance with what you should look for. Many of the UL Standards are available in a read-only version on www.ul.com. The equipment is required to have a label that lists voltage, ampacity, and frequency. Equipment rated for 50 hertz, or non-US voltages will generally not work properly on US systems. A frequency converter can help with the hertz mismatch. A buck/boost transformer may be required to correct the voltage. If you have equipment from overseas, they will occasionally add a transformer at the factory to make it US-ready. Check the configuration, as zigzag transformers are sometimes used. Art. 450.5 states that “zigzag transformers shall not be connected on the load side of any system grounding connection”. Most of our building systems are solidly grounded systems. Equipment with a zigzag transformer would require an isolation transformer first to create an ungrounded system for a code-legal installation. From a practical standpoint, a zigzag transformer will not operate as expected unless installed on an ungrounded system.

Is there a wiring diagram or specs provided by the manufacturer? Always assume that equipment can run continuously unless you have proof otherwise, calculating ampacity at 125% of nameplate. Is there any internal overcurrent protection that would operate in the event of equipment malfunction? If not, your branch circuit fuses or breakers would now be expected to protect the internal parts of the equipment, not just your branch circuit wiring. The 15-amp breaker in the panel cannot be expected to prevent the circuit boards in the equipment from going up in flames.

Is there an installation or owner’s manual? Hopefully, it is in English. If not, be very careful in obtaining a translation. Going from Mandarin to English in a romance novel is not the same as translating technical specifications. Did they properly convert from meters to feet? Or only change the units and not the number? Are they giving ampacity requirements based on 400 volts or our US 480 volts?

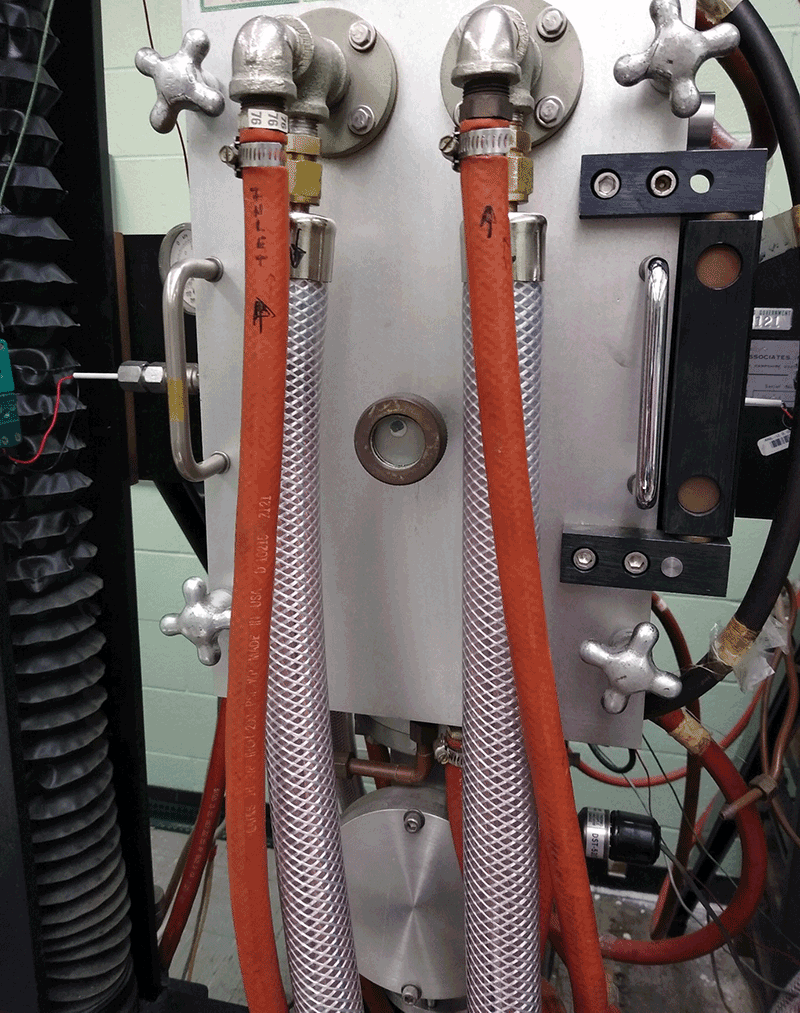

Is the equipment acceptable for the location it is being installed in? Is it outdoors, indoors, wet or damp location? What is the ambient temperature in which it will be operating? Is it a dusty, possible Class 2 hazardous location? Are there tanks of fuel and gases in the area that may require Class 1 consideration? Is the area subject to frequent flooding or tidal considerations? Lightning? If you have the installation manual, it may not give you this information. Is the enclosure sealed and gasketed? Does it have open vents that would allow bugs and other critters to enter? Is there anything that would give you a reason to question if this equipment can be located in this area?

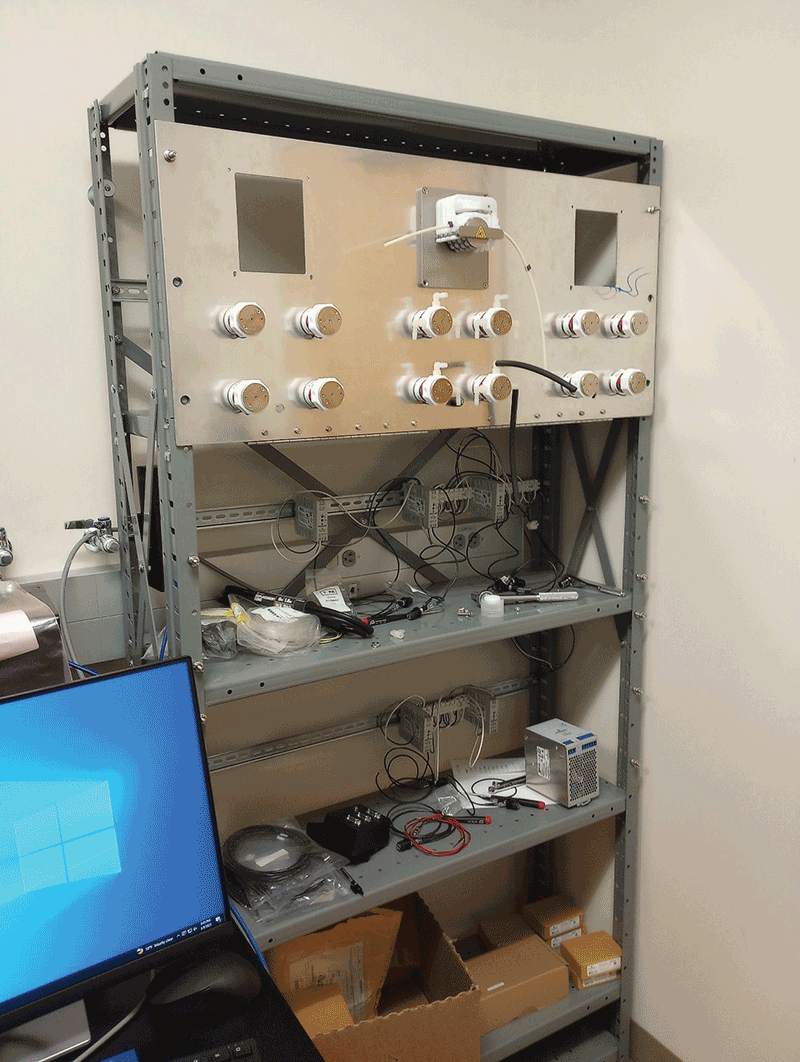

You will encounter the occasional item that was built in someone’s garage. The first inclination is to tell them “NO.” But then you are going to hear how the equipment they need isn’t made anywhere in the world, there is no testing standard that covers it, and their process will fail without it. You alone will be solely responsible for their failure in life if you don’t approve this installation. You can either be firm and not let them use it, cut the end off the cord, red tag it, or any other means to prevent its use. Or require a field evaluation. Or approve it yourself as the AHJ. I strongly caution against the last option. Your reputation, your livelihood, is at stake. If you approve it, and someone gets hurt, the building burns down, or other catastrophes, you will end up in court. You most likely will be sued. You may be found liable. These all depend on who you are working for, their liability, and your contract language. I am not a lawyer, but you may want to consult one to see if this is the path you should take.

For some of us, because of our clientele, saying no isn’t an option. If you are stuck in that position, statement (9) in Article 110.3(A) sums up what you need to consider: any “factors that contribute to the practical safeguarding of persons using or likely to come in contact with the equipment.” Ultimately, the NEC isn’t a design guide; it is a safety manual. Is there any possibility that someone could get hurt by this equipment? If so, is there anything that can be done to protect people and property? Anything operating below 50 V and 5 mA is considered safe by many governmental institutions. Adding guarding to prevent inadvertent contact with energized electrical components or hot or moving parts will be required. Are all electrical parts and pieces rated for the maximum voltage and ampacity that they may be exposed to? Are the internal components listed or recognized by an NRTL? Make sure that everything is documented. Take lots of pictures, and send an email to follow up on ALL personal conversations. Keep ALL your documentation. In today’s paperless society, this is even easier. Scan everything, put it in a digital folder, and save it on a flash drive. Then, back up the flash drive.

Finally, enjoy the stories you get to tell everyone about that really crazy gizmo that you got to look at and might be what saves the world. Just don’t show off pictures that have been deemed a security risk by the FBI or CIA. That will get you in trouble.

Find Us on Socials