The National Electrical Manufacturers Association has just what you need to answer your circuitbreaker application and preventive maintenance questions. NEMA publishes two standards that provide a wealth of information to help users and specifiers select and maintain circuit breakers.

NEMA Standards Publications AB 3-1996 and AB 4-1996 can answer application questions and preventive maintenance questions for molded case circuit breakers. Proper use of these standards can help prevent fire and shock hazards, down-time due to systems failures, and other operations mishaps.

The two NEMA standards serve a different purpose than the standards used to certify circuit breakers. Molded case circuit breaker manufacturers in the US certify their products to the safety and performance requirements defined in the Underwriters Laboratories Inc. UL 489 standard. When circuit breakers meet or exceed these requirements UL permits their listing Mark to be placed on the circuit breaker. Electrical inspectors that enforce electrical codes look for this listing Mark when approving electrical installations.

While knowledge of the construction and performance requirements is important to manufacturers, information regarding the application, field testing, and maintenance of circuit breakers is more important to specifying engineers, installers, and maintenance personnel. That information is found in these two NEMA standards.

If you specify molded case breakers:

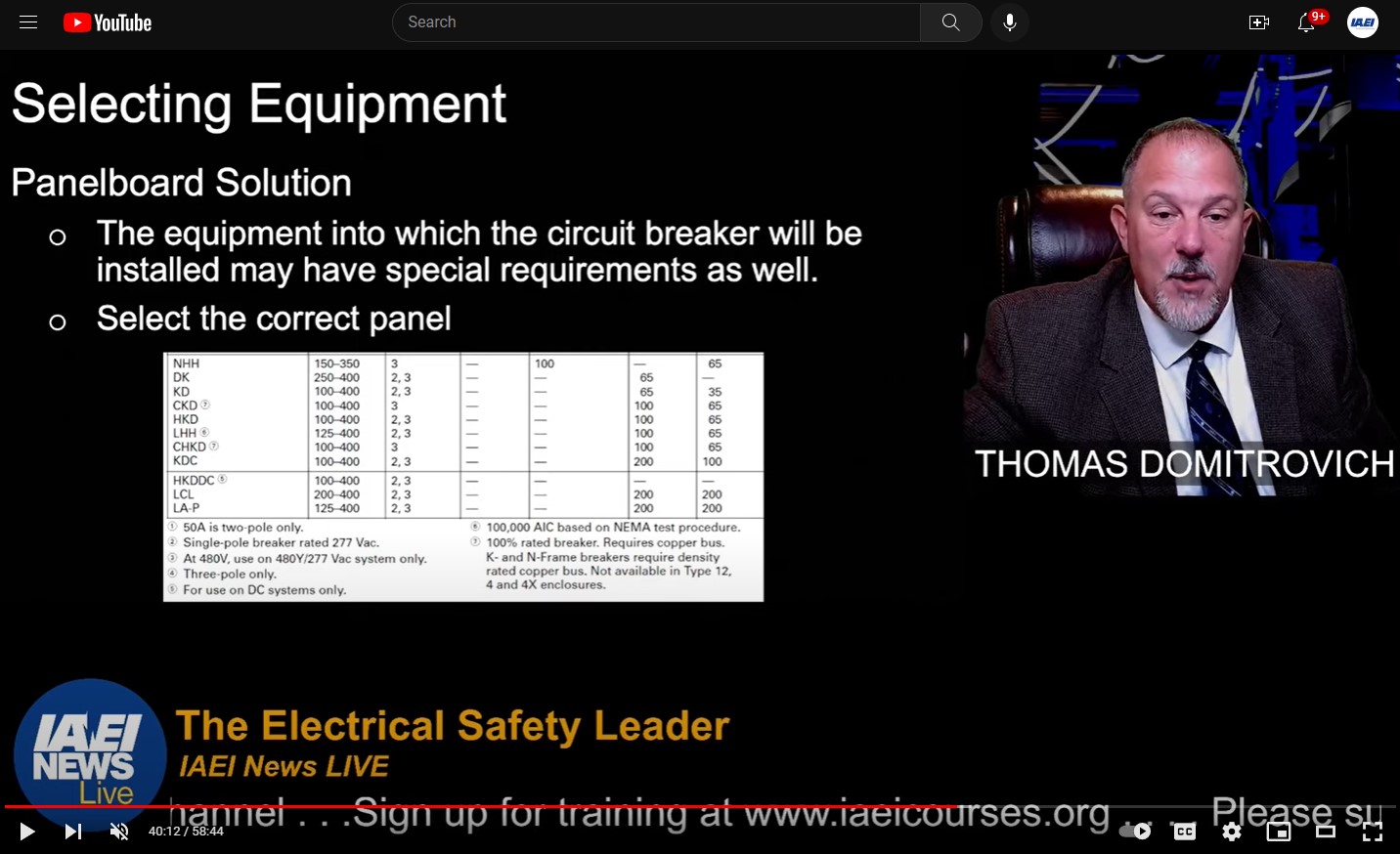

The NEMA AB3-1996 standards publication, Molded Case Circuit Breakers and Their Application, describes the types of circuit breakers available and many of their specific applications. It also lists circuit breaker accessories and ratings, and provides guidance on the selection of circuit breakers. Finally it defines much of the terminology associated with circuit breaker products. In addition to molded case circuit breakers, NEMA AB3 covers molded case switches and their accessories.

Section 5 of NEMA AB3 is especially useful for those who select circuit breakers. This section covers the following topics:

- electrical system parameters environmental conditions (extreme temperatures, humidity, corrosive atmospheres)

- vibration

- shock

- harmonics

- feeder and branch circuit breakers

- load considerations

- temperature ratings of conductors and conductor ampacity

Section 5 also includes a detailed explanation on the following:

- time-current curves

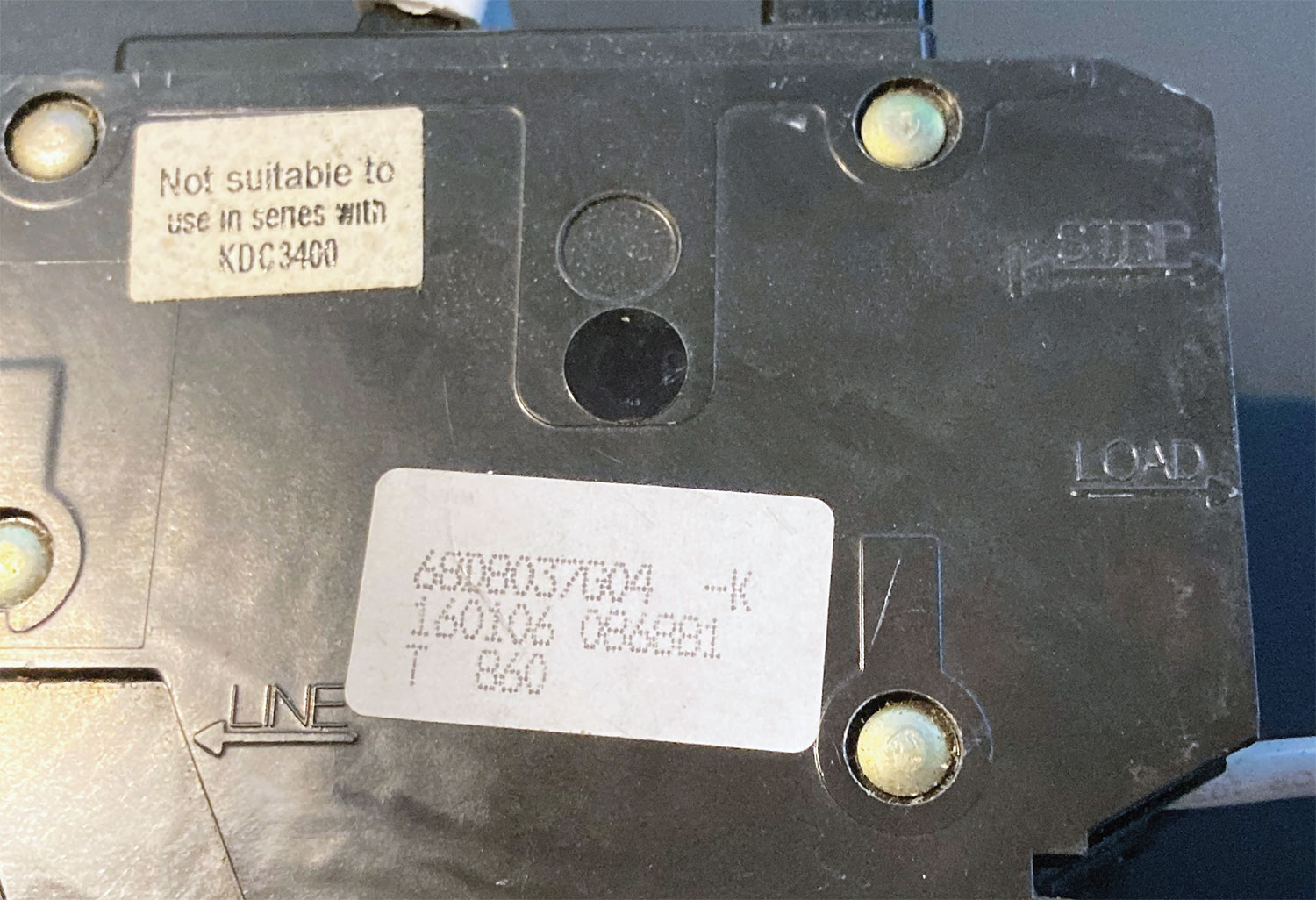

- series-combination ratings

- capacitor switching considerations

- motor loads

- ground-fault protection

- circuit breakers used in DC voltage systems

Finally, Section 5 provides a basic overview of the UL standards requirements for the Listing of circuit breakers.

If you inspect or maintain molded case breakers:

The NEMA AB4 standards publication, Guidelines for Inspection and Preventive Maintenance of Molded Case Circuit Breakers used in Commercial and Industrial Applications, provides guidance for maintenance and field testing of circuit breakers and explains how to evaluate the condition of a circuit breaker. NEMA AB4 provides basic procedures that may be used to inspect and maintain molded case circuit breakers rated up to and including 1000 volts, 50/60 Hz ac or ac/dc. The test methods described in NEMA AB4 may be used to verify certain characteristics of circuit breakers originally built and tested to the requirements of the UL 489 and NEMA AB1 standards. However, it is not intended, nor is it adequate, to verify proper electrical performance of a molded case circuit breaker which has been disassembled, modified, rebuilt, refurbished, or handled in any manner not intended or authorized by the original manufacturer.

These test methods are intended for field use only and are non-destructive. They cannot be used to verify all performance capabilities of a molded case circuit breaker, since verification of certain capabilities requires destructive testing.

Some industrial users have indicated that they are required to conduct periodic operational tests of their circuit breakers. The non-destructive tests outlined in Section 5 of NEMA AB4 may be used to verify certain operational characteristics of molded case circuit breakers including:

- mechanical operation

- insulation resistance

- individual-pole resistance

- inverse-time overcurrent tripping

- instantaneous overcurrent tripping

- rated hold-in current

Section 6 describes tests for the proper use of devices such as shunt trip and undervoltage trip releases, electrical operators that allow opening and closing the circuit breaker from a remote location, auxiliary switches that operate when the circuit breaker opens or closes, and alarm switches that operate when the circuit breaker trips automatically.

The NEMA AB3 and NEMA AB4 standards publications are valuable tools for the safe and efficient operation of molded case circuit breakers. They are indispensable to contractors, specifiers, plant engineers, and maintenance personnel. Keep these NEMA standards in mind the next time you have an application or maintenance question concerning molded case circuit breakers. For a copy of AB3 or AB4 call NEMA at 703/841-3201 or IHS at 800/854-7179.

Find Us on Socials