In this article, we’ll explore a major shift taking place in electrical inspections: moving away from reactive troubleshooting and toward intelligent, AI-powered strategies that emphasize foresight, accuracy, and workplace safety.

Furthermore, the article provides some practical examples of how AI is already making a measurable impact, like predictive maintenance that reduces downtime, thermal imaging cameras, and automated reporting tools that let technicians spend more productive time in the field. Tasks that once required hours of paperwork and log reviews are now completed in minutes, giving crews more time to focus on solving real issues [1-3].

We’ll also introduce emerging technologies, such as autonomous drones and AI models capable of interpreting complex Single Line Diagrams (SLDs). These aren’t futuristic concepts; they’re already transforming inspections today.

Yet this shift isn’t just technical; it’s strategic. As history reminds us, with cautionary examples like Nokia [4] (see Figure 1), success depends not only on innovation but also on timely adoption.

The goal of this article is to illustrate how embracing AI-driven inspection technologies early can help electrical professionals enhance safety, efficiency, and shape future industry standards.

As technological advancements accelerate across industries, electrical inspections have reached a critical turning point. Traditional methods—such as flashlights, manual checks, and paper logs—are no longer sufficient. Today’s electrical infrastructure is too interconnected, too critical, and often too aged to rely solely on these outdated practices. AI is quickly becoming essential, not just a new trend, but a practical tool to bridge the gap between aging equipment and rising safety expectations [5], combining human expertise with machine-powered insights.

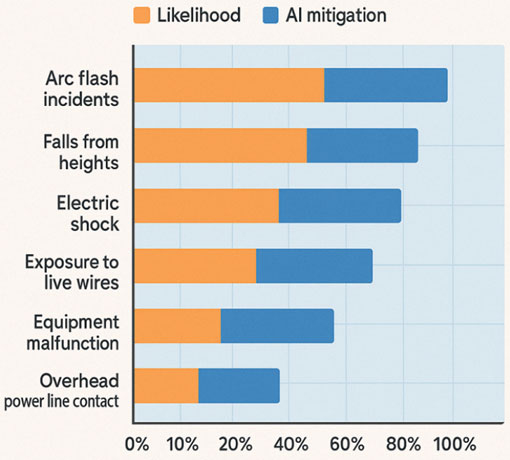

Figure 2 illustrates a comparative chart highlighting AI’s potential to mitigate six common job site hazards. For instance, predictive thermal imaging systems and real-time arc flash calculators powered by AI can reduce electric shock and arc flash incidents by as much as 80–90% [6]. Even hazards traditionally considered non-electrical, such as falls from heights, can be significantly reduced using AI-assisted route planning, robotic inspections, and proactive hazard alerts. These improvements represent more than just convenience; they mark a clear and measurable shift toward technology-driven risk prevention.

Experts now describe this moment as a strategic inflection point—AI adoption in electrical inspections isn’t just theoretical; it’s a practical, necessary evolution in response to increasing demands on electrical safety. The sections that follow explore the real-world pressures driving this transition.

Aging Electrical Assets

Across North America and Europe, large parts of the electrical grid are decades beyond their intended lifespan—many components are now over 40 to 50 years old. Studies clearly link asset age to a high risk of failures. AI-driven predictive analytics can significantly reduce downtime, typically by 40–60%, by spotting early warning signs of equipment deterioration long before traditional methods [7-10].

Combined with growing energy demands, increased climate stresses, and delayed maintenance, the need for proactive detection becomes urgent. Generative AI models are already being implemented on critical systems to predict failures, optimize maintenance schedules, and cut down on both emergency response costs and overall risk.

- Skill Gaps and Retiring Experts

As experienced electrical professionals retire, they often take valuable hands-on knowledge with them—skills built from years of intuitive troubleshooting, like hearing, smelling, or sensing a problem before instruments detect it. Meanwhile, a younger generation entering the workforce may have strong digital skills but lacks the same practical, field-based experience.

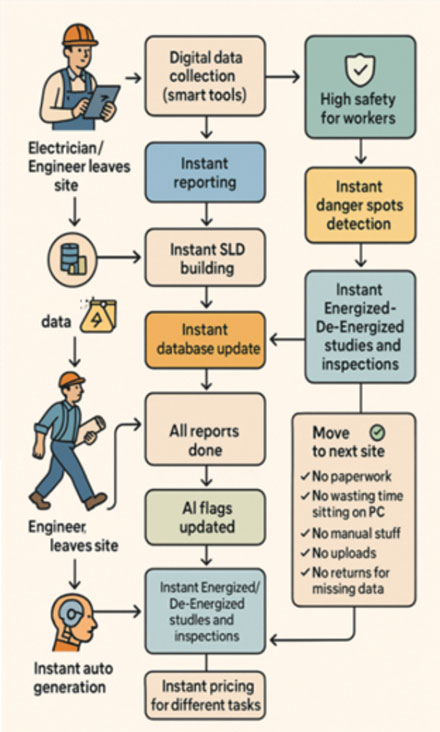

As shown in Figure 3, AI tools are not meant to replace either group—they support both. Intelligent systems capture experienced inspectors’ intuitive decision-making and knowledge, embedding these insights into digital platforms that guide newer technicians in real time.

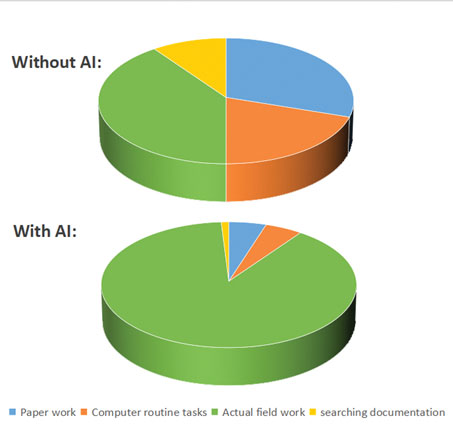

Figure 4 highlights how AI reduces time wasted on repetitive administrative tasks, freeing electricians and engineers to focus on challenging field tasks. Figure 5—a Dilbert comic—humorously reflects fears about automation. But the real message isn’t replacement—it’s smarter allocation of work.

AI handles repetitive, low-value tasks like paperwork and data entry, enabling technicians to excel in the field where their expertise matters most.

- Systems Are Becoming Too Complex

From EV (Electric Vehicle ) charging networks and smart grids to IoT-connected equipment, today’s electrical infrastructure has surpassed the capability of traditional inspection methods. With growing complexity, manual processes can’t keep pace. Figure 5.

AI-enabled inspection systems, on the other hand, scale effectively, analyzing thousands of simultaneous data streams to instantly detect anomalies and recommend corrective action. These capabilities are especially valuable in distributed energy systems, where integrating multiple data types (thermal, electrical, environmental) leads to quicker fault identification, precise diagnostics, and better overall system optimization.

- Regulatory and Insurance Pressure

Regulatory and insurance demands are shifting rapidly from reactive investigations to proactive compliance, and increasingly require clear, verifiable evidence. AI-enhanced inspection tools provide accurate, traceable records that satisfy insurers and regulatory bodies alike.

Field studies show that timely AI-driven fault detection and detailed logs can reduce insurance claims by 20–30%. This change aligns with a broader industry move toward “Responsible AI,” emphasizing transparency, accountability, and built-in safety from the outset [12].

- The Data Is Already There

Most modern electrical facilities already collect vast amounts of operational data, from thermal imaging cameras, circuit-breaker monitors, to networked sensors. The issue isn’t gathering data, but extracting useful insights from it.

The real power of AI is its ability to turn this flood of data into actionable intelligence. Today’s AI models can automatically process infrared images, identify faults, and even generate inspection reports. By turning passive logs into live diagnostics, AI reveals opportunities previously locked away in isolated data.

II.THE NEW REALITY: WHAT AI CAN DO TODAY

Industry experts caution that delaying AI adoption can lead to reduced efficiency, preventable equipment failures, and reputational risk. In contrast, early adopters are already seeing safer operations, lower costs, and stronger compliance.

![Figure 6. AI is already being actively used at job sites: Drones, IR scans, Blueprints [13]](https://iaeimagazine.org/wp-content/uploads/2026/01/2025-05-Huf-FIG6.jpg)

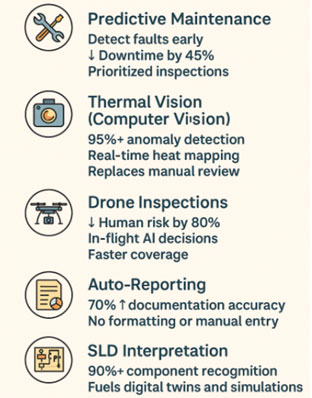

Predictive maintenance systems now combine thermal imaging, vibration analysis, and historical fault data to identify potential failures early, cutting downtime by as much as 45% in real-world installations [14].

AI-enhanced thermography (Figure 7) achieves over 95% accuracy in detecting heat-related problems, enabling immediate, condition-based interventions.

![Figure 7. AI-enhanced thermography detects heat anomalies with over 95% accuracy [15]](https://iaeimagazine.org/wp-content/uploads/2026/01/2025-05-Huf-FIG7-1.jpg)

![Figure 8. AI drones inspection [16]](https://iaeimagazine.org/wp-content/uploads/2026/01/2025-05-Huf-FIG8-1.jpg)

Single Line Diagram (SLD) interpretation models now help teams quickly build digital twins of their electrical systems, recognizing components with over 90% accuracy.

These aren’t prototypes. They are deployed tools — already reshaping inspection workflows and improving outcomes in real-world environments.

These capabilities represent a shift from reactive checks to proactive, intelligent operations. Figure 9 highlights these tools at a glance — a snapshot of how AI is already reshaping the field.

III.HOW IT WORKS: UNDER THE HOOD OF AI-DRIVEN INSPECTIONS

AI-powered inspection systems rely on multiple coordinated technologies designed to help field teams in real time and provide managers with accurate, actionable insights. For instance, AI-based quality inspections in manufacturing have already cut inspection times by up to 80% by automating everything from image capture to defect detection.

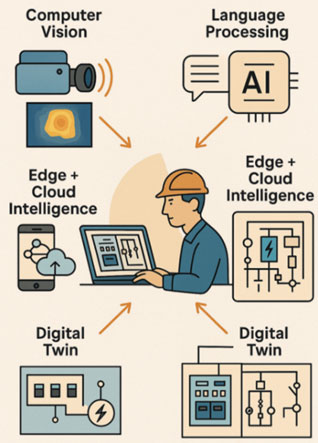

- Computer Vision

Modern inspection tools use advanced image-recognition technologies (like YOLO [18] and OpenCV [19]) to detect heat anomalies, spot missing labels, and classify equipment condition from thermal or standard images. Because these systems work reliably even in low-light or noisy settings, they dramatically speed up inspections and improve detection accuracy. They are now being customized specifically for electrical tasks, such as identifying corroded connections or thermal issues in panelboards.

- Language Processing

Large Language Models (LLMs) convert spoken or written field notes into clear, standardized reports. These AI tools streamline documentation across teams and translate technical observations into reports easily understood by engineers, managers, and non-technical stakeholders alike. Integrated into mobile apps, these tools enable inspectors to generate complete reports by voice while still on-site, significantly improving communication and reducing turnaround times [20].

- Edge + Cloud Intelligence

Today’s AI systems are often hybrid: lightweight AI models run directly on mobile devices and inspection equipment to provide instant results in the field, while more powerful cloud-based engines analyze historical and contextual data for deeper insights. This combination ensures fast, responsive analysis on-site, along with continuous improvement and long-term optimization of inspection practices, allowing teams to adapt quickly as new risks emerge [21].

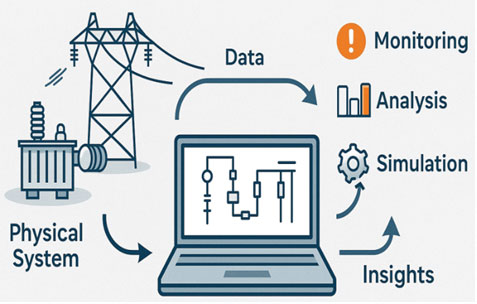

- Digital Twins

Digital twins are virtual replicas of physical systems, like having a live-updating blueprint of your substation. Built using AI and digitized Single Line Diagrams (SLDs), they let teams monitor, simulate, and plan maintenance remotely.

As shown in Figure 10, data from the field feeds into a digital model that supports real-time monitoring, fault prediction, and simulation of failure scenarios — all before crews are even dispatched. In many facilities, this has reduced the need for frequent in-person inspections and helped electricians better prepare for complex tasks.

Think of it as Google Maps, but for your electrical grid — showing what’s working, what’s failing, and what to fix next [22].

Figure 11 illustrates how these technologies form a responsive and connected inspection ecosystem. Validated by both field deployments and independent studies, their impact is already visible, with measurable reductions in inspection delays, manual error, and operational risk. This shift isn’t just a technical upgrade; it’s a foundational transformation of how inspections are executed, managed, and scaled.

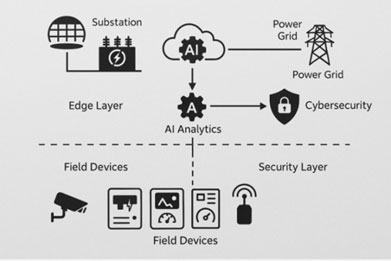

- SMARTER SYSTEMS, SHARPER RISKS: WHY AI-READINESS MUST INCLUDE CYBER-READINESS

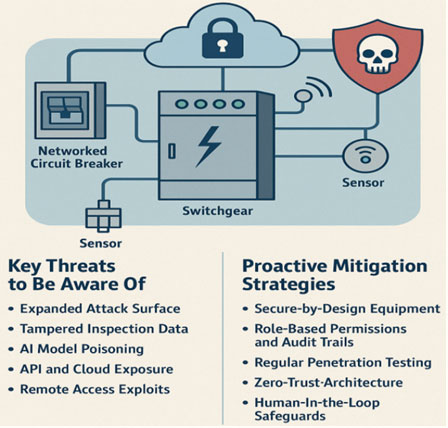

The electrical industry isn’t just changing the way inspections are done—it’s changing the nature of the systems themselves. Circuit breakers now have IP addresses. Switchgear can be remotely accessed. Sensors constantly send diagnostic data to cloud-based platforms, while AI analyzes thermal images and interprets SLDs instantly.

Autonomous drones routinely inspect transmission towers ahead of crews. These advancements greatly improve safety and efficiency, but they also introduce new, less obvious risks.

Each “smart” device expands the potential attack surface. Without equally strong cybersecurity measures, the benefits of AI could be overshadowed by vulnerabilities. Every sensor, tablet, thermal camera, or other connected device can become an entry point for cyberattacks if not properly secured.

- The Hidden Costs of Falling Behind

Simply upgrading hardware is no longer enough. Implementing AI without addressing cybersecurity can introduce greater risks than sticking to traditional methods. Cyber threats in AI-driven environments aren’t just operational—they’re strategic, persistent, and often invisible to conventional security methods. Key vulnerabilities include methods like expanded Attack Surface. With over 65% of industrial cyber breaches originate from unsecured devices—including mobile inspection tablets, thermal cameras, and IoT sensors.

- Tampered Inspection Data. Subtle manipulations, such as falsifying heat readings or altering sensor data, can mislead maintenance teams and delay critical repairs.

- AI Model Poisoning. Introducing malicious data during AI training or real-time analysis can undermine the reliability of inspection systems, causing either dangerous false alarms or missed hazards.

- API and Cloud Vulnerabilities. Many inspection systems rely on third-party cloud services and APIs for diagnostics or reporting. Without strong encryption and access control, these services can become gateways for cyber intrusions.

- Remote Access Exploits. Attackers have already demonstrated the capability to take control of drones and field sensors, interrupt automation, or inject false data into key operations.

These cybersecurity threats (Figure 12) aren’t hypothetical—they’ve already affected industries worldwide. As organizations increase their reliance on AI, cybersecurity can no longer be viewed as an optional support function. It must become a core part of any safety-focused electrical inspection strategy [23].

- BUILDING A DEFENSIBLE AI INSPECTION SYSTEM

The solution isn’t to slow down AI adoption, but to strengthen it. A secure-by-default approach ensures that AI tools deliver their benefits without introducing new risks. Practical strategies for building robust, defensible AI inspection systems include:

Secure-by-Design Infrastructure

Use platforms that embed encryption, user authentication, and strong access controls as core features, not optional extras.

- Role-Based Permissions & Audit Trails

Clearly define who can access specific systems and keep detailed logs of user activity. Traceability helps maintain accountability and quickly identifies problems.

- Regular Penetration Testing

Just as circuit breakers are regularly tested for reliability, AI systems should undergo routine cybersecurity stress tests to uncover vulnerabilities before attackers do.

- Zero-Trust Network Architecture

No device, user, or action should be trusted automatically. Each interaction must be continuously verified and secured.

- Human-in-the-Loop Oversight

While AI speeds up decisions, the final responsibility must stay with trained professionals. Human experts must validate critical AI recommendations and retain the ability to override decisions when necessary.

- Cybersecurity Is the New PPE

Just as electricians rely on gloves, grounding, and safety gear on the job site, cybersecurity is the digital safety equipment protecting your AI inspection tools. Running AI systems without these protections is like working on live equipment without safety gear.

As inspections become smarter and more interconnected, they must also become more resilient. The advantages of AI-driven inspection are significant—but so is the responsibility to deploy these systems securely, transparently, and with long-term safety as a priority.

VI.HOW TO PREPARE: ADVICE TO MANAGERS, PLANNERS, AND LEADERS

When you’re ready to bring AI into your electrical inspections, use this clear, actionable plan to guide your journey from pilot project to full adoption. Print this page, check off tasks as you complete them, and share your wins along the way!

- Overview: AI Implementation Strategy

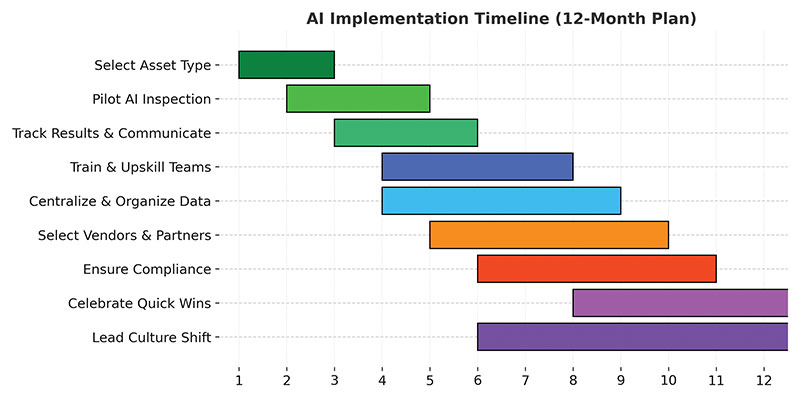

Figure 13 above shows a chart highlighting the six foundational actions every organization should take to get started with AI, emphasizing practical benefits like quick wins, skill support, and organized data. Furthermore, refer to Figure 14 for a proposed 12-month plan.

- Interactive Checklist & Key Guidance

Phase 1: Getting Started (0–3 months)

Start Small, Prove Fast

√ Select one asset type (e.g., switchgear, transformer).

√ Pilot AI inspection tools (60–90 days).

√ Track results (fault detection, downtime, accuracy).

√ Clearly communicate pilot successes.

Phase 2: Building Capability (3–6 months)

Upskill Your Teams:

√ Train teams to interpret AI alerts.

√ Maintain human oversight for key decisions.

√ Clarify verification and approval roles.

Organize Your Data:

√ Centralize data (thermal images, logs, records).

√ Ensure data is clean, secure, and searchable.

√ Establish easy data-entry standards.

Phase 3: Choosing Partners and Tools (3–9 months)

Partner with the Right People:

√ Select experienced electrical & AI providers.

√ Verify familiarity (CSA, NFPA, ISO standards).

Ensure Compliance:

√ Ensure tools align with industry regulations.

√ Confirm ethical and transparent AI use.

Phase 4: Reinforcing Adoption (6–12 months)

Celebrate Quick Wins:

√ Highlight measurable early successes.

√ Update stakeholders regularly.

Lead the Culture Shift:

√ Position AI as supportive, not disruptive.

√ Actively involve teams; listen to feedback.

√ Recognize team successes openly.

Note that: A full-scale AI inspection rollout across a department or facility in 12 months is realistic—if you start with a focused pilot, prepare your data early, train your people well, and build internal champions. It’s not about going fast—it’s about going smart.

VII.WHAT THE FUTURE HOLDS: A GLIMPSE AHEAD AT THE INTELLIGENT ELECTRICAL FRONTIER

Electrical inspections are now entering a new era—one characterized by close integration between experienced professionals and smart, responsive technology. Traditional practices involving manual inspections, paper documentation, and delayed decision-making are quickly giving way to real-time monitoring, automatic alerts, and predictive maintenance strategies.

These changes aren’t on the distant horizon—they’re happening now. Industries such as utilities and manufacturing have already begun actively implementing these AI-powered tools, with field results showing significant improvements. Early adopters report inspection cost savings of up to 30%, alongside notable reductions in downtime and documentation errors.

As inspection systems become increasingly automated and intelligent, the real advantage will no longer be simply having access to advanced tools, but rather, the capability and readiness of organizations to effectively deploy and manage them.

VIII.EMERGING CAPABILITIES RESHAPING INSPECTION PRACTICE:

- Augmented Reality (AR) in the Field

Smart glasses and AR headsets will soon overlay thermal images, voltage ratings, inspection procedures, and safety protocols directly onto the technician’s field of view, reducing dependence on tablets and paper documentation and significantly improving accuracy and speed in the field.

- Adaptive AI Models

Future inspection systems will increasingly become self-learning, adjusting to local conditions and historical inspection patterns. Rather than relying on fixed thresholds, these systems will continuously improve their accuracy by adapting dynamically to changing equipment conditions, environment shifts, and technician feedback.

- Autonomous Aerial Inspections

AI-powered drones will independently handle flight planning, identify anomalies during inspection flights, and directly upload inspection data, eliminating rigid pre-programmed paths and greatly reducing human exposure to hazardous environments.

- Enterprise System Integration

AI-driven inspection tools will integrate seamlessly with existing maintenance management systems (like SAP [24] or Maximo [25]). Automatic fault detection will instantly trigger work orders, schedule repairs, and close inspection loops, removing paperwork and reducing the lag between fault detection and maintenance response.

Together, these emerging technologies will create a continuous operational loop—from field-level data collection and analysis, straight through to real-time decisions in the control room.

Organizations that prepare now, by structuring their data, training their teams, and securing digital systems, will lead the transition. The focus is no longer simply about testing new technology; it’s about developing reliable, integrated systems that teams can confidently trust and use every day.

- CONCLUSIONS

Artificial intelligence in electrical inspections is no longer just experimental—it’s quickly becoming standard operational practice.

The real opportunity now isn’t just digitizing traditional inspections. It’s rethinking how expertise, safety, and practical action come together on the job site. AI helps extend the insights of skilled technicians, reduce human errors, and accelerate responses to faults, all while preserving and amplifying the essential judgment and experience of your teams.

Successful organizations won’t necessarily have the most technology—they’ll be the ones who integrate it intentionally, aligning tools with training, ethical responsibility with practical execution, and innovation with trust.

This shift demands clear leadership, and in industries where safety is critical, strong leadership is mandatory. Companies that act early will set industry standards that others will follow.

Those who delay risk falling behind in a rapidly evolving environment.

Leadership in this new era won’t only be measured by reduced downtime or cost savings. It will also be defined by who builds safer, smarter, more resilient inspection systems—and who equips their teams with the confidence and clarity to use them fully.

AI isn’t replacing your crew—it’s giving them better tools. The goal isn’t automation for automation’s sake; it’s to let your teams focus on what they do best: keeping electrical systems safe, reliable, and operational.

The roadmap is clear. The technology is ready. The future of electrical inspections isn’t coming—it’s already here.

References:

[1] “The Exponential Growth of AI: Surpassing Moore’s Law and Rewriting Computing Boundaries,” DecentralandDuke, Medium, Mar. 2025. Available: https://decentralandduke.medium.com/the-exponential-growth-of-ai-surpassing-moores-law-and-rewriting-computing-boundaries-4bc107ecb7cb

[2] “AI and Compute,” OpenAI, May 2018. Available: https://openai.com/index/ai-and-compute/

[3] K. F. Pilz et al., “Trends in AI Supercomputers,” arXiv, Apr. 2025. Available: https://arxiv.org/abs/2504.16026

[4] “Nokia: The Rise and Fall of a Mobile Giant,” BBC News, Sep. 2013. Available: https://www.bbc.com/news/technology-23947212BBC

[5] J. Fiegler-Rudol, K. Lau, A. Mroczek, and J. Kasperczyk, “Exploring Human–AI Dynamics in Enhancing Workplace Health and Safety: A Narrative Review,” Int. J. Environ. Res. Public Health, vol. 22, no. 2, p. 199, Jan. 2025. Available: https://www.mdpi.com/1660-4601/22/2/199

[6] S. Chen, K. C. Paul, and T. Zhao, “Enhancing Arc Fault Detection Performance through Data Augmentation with Artificial Intelligence Technology: An Approach to Time Series Dataset Enlargement,” in Proc. 2024 IEEE Energy Conversion Congress and Exposition (ECCE), Oct. 2024, pp. 1866–1872.

[7] “Europe’s Main Barrier to Decarbonising Its Power Supply by 2045 Is Its Aging Grid Infrastructure, 40% of Which Is Over 40 Years Old,” PV Tech, Sep. 2023. Available: https://www.pv-tech.org/more-lines-more-digitalisation-more-climate-resilience-grids-must-be-priority-for-europes-net-zero-plans/

[8] “Inside the World’s Largest Interconnected Grid,” DG+, Sep. 2024. Available: https://www.dgplusdesign.com/insights/inside-the-worlds-largest-interconnected-gridDG Plus Design

[9] “Nexans Climate Day 2022 – Press Kit,” Nexans, Sep. 2022. Available: https://www.nexans.com/app/uploads/2024/03/2022-09-26-press-kit-Nexans-Climate-Day-2022.pdfNexans

[10] “Aging Infrastructure,” Itron. Available: https://na.itron.com/problems-we-solve/aging-infrastructureItron+1Pro Aviation Tips+1

[11] “Dilbert Official Website,” Dilbert.com. Available: https://dilbert.com/

[12] M. Shaik, “Intelligent Automation for Insurance Claims Processing,” Int. J. Innovative Res. Manage. Eng. Technol., vol. 7, no. 4, pp. 1–9, Jul.–Aug. 2019. Available: https://www.ijirmps.org/papers/2019/4/231793.pdf

[13] “What is Air Thermography,” MapperX, Sep. 9, 2024. Available: https://mapperx.com/en/what-is-air-thermography/

[14] Fluke Corporation, “Applying Infrared Thermography to Predictive Maintenance,” Everett, WA, USA, 2010. Available: https://www.testequity.com/UserFiles/documents/pdfs/fluke/IR-thermography-predictive-maintenance.pdf

[15] Z. Tang and X. Jian, “Thermal Fault Diagnosis of Complex Electrical Equipment Based on Infrared Image Recognition,” Sci. Rep., vol. 14, p. 5547, 2024. Available: https://www.nature.com/articles/s41598-024-56142-x

[16] “What is AI-Based Thermal Imaging for Quality Control?” DAC.digital. Available: https://dac.digital/deep-tech/our-solutions/quality-control-solutions/thermal-imaging-for-quality-control-solutions/

[17] J. Hliboki, “Automated Regulatory Reporting Explained: Benefits and Best Practices,” 8020 Consulting, Apr. 1, 2025. Available: https://8020consulting.com/blog/automated-regulatory-reporting-benefits-and-best-practices

[18] J. Redmon, S. Divvala, R. Girshick, and A. Farhadi, “You Only Look Once: Unified, Real-Time Object Detection,” arXiv, Jun. 2015. Available: https://arxiv.org/abs/1506.02640

[19] K. Pulli, A. Baksheev, K. Kornyakov, and V. Eruhimov, “Real-Time Computer Vision with OpenCV,” Commun. ACM, vol. 55, no. 6, pp. 61–69, Jun. 2012.

[20] H. Pu, X. Yang, J. Li, R. Guo, and H. Li, “AutoRepo: A General Framework for Multi-Modal LLM-Based Automated Construction Reporting,” arXiv, Oct. 2023. Available: https://arxiv.org/abs/2310.07944

[21] Y. Himeur, A. Alsalemi, F. Bensaali, and A. Amira, “The Emergence of Hybrid Edge-Cloud Computing for Energy Efficiency in Buildings,” Aug. 2021. Available: https://www.researchgate.net/publication/353666691_The_Emergence_of_Hybrid_Edge-Cloud_Computing_for_Energy_Efficiency_in_Buildings

[22] X. He, Q. Ai, R. C. Qiu, and D. Zhang, “Preliminary Exploration on Digital Twin for Power Systems: Challenges, Framework, and Applications,” arXiv, Sep. 2019. Available: https://arxiv.org/abs/1909.06977

[23] M. Gupta, C. Akiri, K. Aryal, E. Parker, and L. Praharaj, “From ChatGPT to ThreatGPT: Impact of Generative AI in Cybersecurity and Privacy,” IEEE Access, vol. 11, pp. 12345–12360, 2023.

[24] “SAP S/4HANA: Next-Generation ERP for Digital Business,” SAP, Feb. 2015. Available: https://www.sap.com/products/erp/s4hana.html

[25] “IBM Maximo Application Suite: Asset Management Reimagined,” IBM, Jul. 2021. Available: https://www.ibm.com/products/maximo.

Dr. Huthaifa N. Abderahman has received a Ph.D. in Electrical and Computer Engineering from the University of Ottawa (2016), B.S.E.E. and M.S.E.E. degrees from the Hijjawi Faculty of Engineering Technology, Yarmouk University (2008 and 2011). Currently he works in the capacity of a Systems Engineer and Head of R&D at KROON Electric, Ottawa, ON. His main areas of research interest are Power systems safety, AI systems, data mining, and system optimization. Dr. Abderahman is a registered Professional Engineer in Ontario / Canada.

Find Us on Socials