An electrical plans examiner’s duties include reviewing specifications, drawings, and engineered plans to verify compliance with local, state, and national standards. It’s up to the designer to prove compliance with indoor and outdoor electrical systems, including services, conductors, equipment, components, fixtures, appliances, devices for all types of occupancies without voltage limitations. Electrical plans examiners are also responsible for verification of fault current and load calculations.

I have experienced many different aspects and roles in the industry throughout my career in the electrical industry. One that I find to be an extremely challenging one is an electrical plans examiner. You are in a position to identify specific details that can completely change the outcome of a project. As a plans examiner, it is your duty to enforce compliance through the preliminary stages of construction, which is challenging because you are filtering through issues before they really happen. Out of the many obstacles a plans examiner faces, one challenge is “To calculate, or not to calculate.” I get asked repeatedly, as a plans examiner, how many calculations do you do throughout the day. To be quite honest, so many that sometimes I don’t even realize that I am doing them. I go through each review, trying to play detective more than an engineer, and when I identify a possible problem, I go straight to calculating.

To write a single article on all of the calculations in the National Electrical Code would be impossible. An article wouldn’t have enough space and lack important information. My goal is to focus on some learning experiences and highlight key identifiers to help anyone looking to better identify issues during the design, review, and construction phases.

Answering the Dilemma, “To Calculate, or Not to Calculate”

The best answer that I have is; It depends? I think that becoming a good plans examiner takes experience, patience, and the ability to accept mistakes while learning from them. A lot of my experience has come from my short-comings. While I’m reviewing drawings, I’m looking for abnormal conditions, equipment, scenarios, and engineered calculations with insufficient information. After some time, many plan examiners will gain the ability to look at specific equipment, conductors, and conditions and identify almost immediately if something is incorrect. My investigative senses rise for refurbished occupancies, existing services with large loads added to them, or occupancies having additions done to them.

For this article, I will focus on what I believe are the most important: working clearances, conductor ampacity, and overcurrent protection, grounding conductors, lighting, receptacle, dryer, cooking appliances, and kitchen equipment load calculations. This article will focus on the 2020 edition of the NEC.

The Foundation of Design

Before I can even start the review process, I need to step back and ask myself a few simple questions like what is the occupancy type, and is it new or an existing occupancy? What is the purpose of the work being performed? Are the codes and standards referenced compliant? Before I can even begin to dive into the weeds, I need to have a basic understanding of the scope of work and purpose.

Knowing the type of occupancy, and if it is a new occupancy or an existing one, tells a plans examiner a lot. The occupancy type can dramatically increase or decrease building code requirements as well as electrical requirements. Good examples may be high rise building (75 feet or greater) or health care facilities. This can change specific requirements that the plans examiner should be aware of before the review even starts. Knowing if the occupancy is new or existing changes what details will be needed for a complete review. Obviously, with new occupancies, all of the information will be provided for you. But most of the time on existing occupancies, where large loads are being added, it is necessary to review the existing conditions and calculations to know if the existing conditions can support the new additions. Many times, I have to contact the designer to request additional information or request a revision and request resubmission in order to obtain the information.

The purpose of the work often will make a difference in certain aspects of the review also. For example, if the purpose of the scope of work is to resolve or fix any kind of impairment or make conditions for occupants safer, then generally, there will be more variances on other pending code issues. It’s not uncommon that owners will work on portions of an occupancy rather than the entire building all at once. Plans examiners should be aware of any existing hazardous conditions and ensure that those issues are the priority of the work being performed. You wouldn’t want to allow large renovations to an existing occupancy if they didn’t resolve some of the existing life safety issues.

Knowing the designer’s codes and standards is crucial to perform a proper review, especially if performing calculations. Many changes happen between each cycle, and those changes often include the numerical values in tables, demand factors, adjustment factors, and correction factors. How can one perform a proper review if they are calculating numbers that differ from the appropriate cycle? Not only that, but obviously, the design shall be performed on the correct editions that meet all local, state, and national standards.

Getting Started

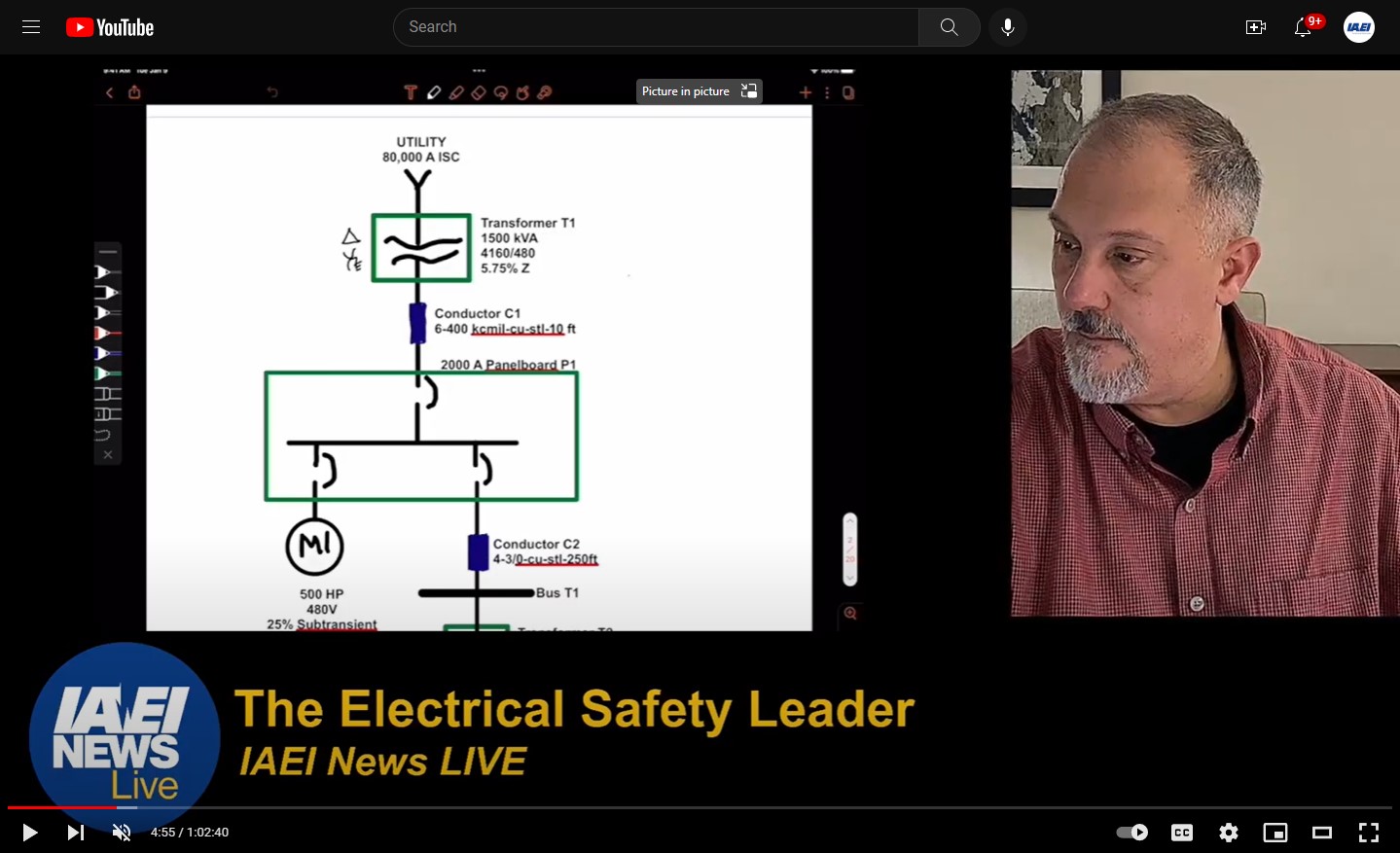

During a review, I always try to focus on the electrical service first. I always like to think of a service as the root of a tree, and if there are problems with the root of the tree, it will affect the rest of the tree. Just like the structure of a building, the foundation is the most important, and electrical services are the foundation for electrical infrastructures. Examiner should focus on the service size and rating, the grounding and bonding, service load calculations, and current limiting and fault calculations.

First off, I look at the service size and rating, location, and ensure that it meets some of the Code’s basic requirements. It’s important to the service size and rating in order to prove that the service can properly supply the intended loads. You want to ensure that the service conductor sizes, overcurrent protection devices, and ratings are all compliant with the code. I’m looking at the location of the utility source, service disconnect, and any other enclosures or boxes related to the service. Every plans examiner should be focusing on the feeder and branch circuit load calculations and ensure that they do not exceed the service rating. All of the service equipment should meet the working clearances, space, depth, and height requirements noted in Article 110.26(A) through (F) of the National Electrical Code.

Branch-Circuit, Feeder, and Service-Load Calculations

Section 220.1, Branch-Circuit, Feeder, and Service Load Calculations, in the National Electrical Code provides the scope for Article 220 and specifies that the article provides the requirements for calculating branch-circuit, feeder, and service loads. The article is broken down into five separate parts. Part I provides general requirements. Part II provides calculations specifically for branch-circuit loads, Part III and V focus on feeder and service loads, and Part IV provides calculations for farm loads. I’ll be focusing this article on Parts I through III. Keep in mind, as specified in Section 220.3, that not all load calculations are found in Article 220. Specific equipment and articles have additional load calculations for branch-circuit, feeder, and service calculations. A good example would be Article 430, Motors, Motor Circuits, and Controllers. Section 430.26 specifies the feeder demand factors for motors.

I almost like to look at Article 220 in a bird’s eye view, load calculations for dwelling units, and then all other occupancies. It’s important to pay attention to the type of occupancy and know when you can apply demand factors and when not to. Why is it important? Because we need to know if the loads will be continuous or non-continuous. For example, when referring to lighting load demand factors, there is a difference between a dwelling, a multi-family dwelling, and commercial occupancy. The National Electric Code allows demand factors at times where the entire load will not likely be energized for three or more hours.

Another thing to keep in mind is the difference between the type of conductors. Feeder and service conductors allow for demand factors since not all loads will be energized at the same time. Branch circuits typically don’t.

It is important to note that, as stated in Section 220.5, specific nominal voltages shall be used. When calculating ampere ratings, it is permissible to round up or down to the nearest fraction. Rounding up for any calculations resulting in 0.5 or greater, and rounding down if less than 0.5.

Lighting Loads

Lighting loads are separated into two basic categories dwelling and non-dwelling units. All occupancies calculations for lighting loads are based on the outside dimension of the dwelling, building, or area involved, see Section 220.11. The dwelling unit minimum load calculation shall not be less than 3-volt amperes per square foot per Section 220.14(J). For non-dwelling units, Section 220.12(A) that you shall calculate the outside dimensions based on the value given in Table 220.12 for minimum lighting loads.

For service and feeder calculations, the Code allows for us to apply demand factors in accordance with Table 220.42 for general lighting. Obviously, with more occupancies supplied by the same service or feeder, more of an allowance can be applied. Keep in mind, the code recognizes the opportunity that with more occupancies, there is less of a chance that all of the lighting will be energized at the same time. Note that demand factors cannot be applied when all of the lighting is being used simultaneously; see informational note under Table 240.42.

Receptacle Outlets

With the exception of Sections 220.14(J) and (K), receptacles shall be calculated at 180 volt-amperes per device regardless of if they are single or duplex receptacles. Any single piece of equipment that has four or more receptacles installed shall be calculated at 90 volt-amperes per receptacle.

Non-dwelling occupancies have applicable demand factors that can be applied to receptacles, as you will find in Section 220.44. It states that demand factors for receptacles shall be permitted to be made subject to the demand factors given in Table 220.44. This allowance recognizes that many outlets throughout commercial occupancies will not have stationary loads connected and are typically used for cleaning purposes or quick portable loads.

Specifically, for office buildings, Section 220.14(K) specifies that receptacles loads shall be calculated to be the larger of either the calculated load from 220.14(I) or at 1 volt-ampere per square foot.

Dwelling Specific Calculations

A dwelling unit is a unit, or multiple units, that provide the complete and independent living facilities that include permanent provisions for living, sleeping, cooking, and sanitization. In each dwelling unit, there are required branch circuits and circuit loads. As we see in Section 220.52 (A) and (B), each small-appliance and laundry circuits shall be calculated at 1500 volt-amperes each. In accordance with Section 210.11(C)(1) and (2), each dwelling is required at minimum (2) small-appliance circuits and (1) laundry circuit.

When looking at fastened in place appliances, with the exception of cooking equipment, clothes dryers, heating, and air conditioning equipment, as long as there are (4) or more fastened in place appliances, you are able to add up the wattage and apply a 75% demand factor to all in accordance with Section 220.53. They exclude certain fastened in place appliances like ranges because they have their own calculations.

When considering electric clothes dryers, you shall always calculate each dryer at 5000 watts (volt-amperes) or the nameplate rating, whichever is larger, per Section 220.54. That means that the basis of your calculation can never be less than 5000 watts per dryer. The good news is that the code recognizes that not all dryers will be used at the same time, especially in a multi-family dwelling, and allows for demand factors given in Table 220.54. Obviously, the more dryers, the more allowance for demand factors.

Like dryers, it’s common to have many household electric ranges, wall-mounted ovens, counter-mounted cooking units, and other cooking appliances in multi-family dwellings. The Code also recognizes that not only will it be rare that all equipment in every dwelling will be used simultaneously, but even individual units will not be used at their full potential. What are the chances that someone is going to use all of the burners on their stove on high and turn the oven up to 500 degrees? Probably unlikely. For this reason, the code implements allowances on household cooking equipment in accordance with Section 220.55. Table 220.55 is one of the more confusing tables in Article 220. Over the past couple of editions, code panels have worked to simplify this table, and one of the biggest changes is a complete identifiable separation of columns for demand factors and maximum demand. Like with ranges, the more household cooking equipment, the more allowance of demand factors. Please pay close attention to notes (1) through (5) associated with Table 220.55; they specify specific calculations for ranges that exceed 12 KW but not over 27 KW, averaging multiple ranges over 12 KW that are different sizes, branch circuit loads, and even ranges used in instructional programs.

Other Specific Loads

Some specific loads apply to non-dwelling occupancies throughout all parts in Article 220. Storefront signs or neon lighting shall be calculated at 1200 volt-amperes per dedicated branch circuit in accordance with Section 220.14(F). Show windows shall be calculated in either of the following ways, the unit load per outlet as required by other sections or at 200 volt-amperes per linear 300 mm (1 ft) of the show window.

Kitchen equipment located in non-dwellings also has an allowance for demand factors as specified in Section 220.56. The code recognizes that not all of the equipment will be used at the full load at all times, especially simultaneously. Kitchen equipment is recognized as electric cooking equipment, dishwasher booster heaters, water heaters, and other equipment located in kitchens. They shall not apply to space-heating, ventilating, or air conditioning equipment located in kitchens. Keep in mind, though, after all demand factors have been applied, the calculated load shall not be less than the sum of the two largest equipment loads.

It’s also important to understand Section 220.60, noncoincident loads. The Code tells us that where it is unlikely, and I always like to reiterate the phrase “unlikely” that two or more loads will be used simultaneously, we only need to account for the largest load. For example, if the space-heating equipment is a larger load than the air-conditioning unit, then the designer needs only account for that load. As a plans examiner, you need to be aware of when the loads shall be calculated and when they don’t need to be.

Feeder and service neutral loads shall be calculated as the maximum net calculated unbalanced load between the neutral and any one of the ungrounded conductors, in accordance with Section 220.61(A). There are some permitted reductions, as we see in Section 220.61(B). A service or feeder supplying household electric ranges, wall-mounted ovens, counter-mounted cooking units, and electric dryers can have a demand factor of 70% applied to the neutral calculated load.

Overcurrent Protection and Conductor Ampacity

Throughout the review process, plans examiners should be focused on the overcurrent protection and conductor sizes for all services, feeders, and branch circuits. I’m looking at the conductors and verifying if the conductors are based on the minimum required sizes in accordance with Section 310.16 or if the designer has upsized them for voltage drop. Typically, I’m looking for upsized conductors to verify the appropriate equipment grounding conductor also. If the ungrounded conductors are upsized, then Section 250.122(b) applies, and the designer must upsize the equipment grounding conductor proportionally per Chapter 9, Table 8. It’s important to verify at this point if any adjustment factors come into play when designers have more than three current-carrying conductors in the raceway, earth, or cable. If so, you will need to calculate the adjustment factors in accordance with Table 310.15(C)(1). Also, keep an eye on any noted ambient temperatures that are not based on 40 degrees Celsius. You may need to apply correction factors if the conductors are not per Section 310.15(B)(2).

At the same time, one should be focusing on the overcurrent device itself. Remember, the conductors shall be protected against overcurrent with the appropriately sized overcurrent device. We find the standard overcurrent devices in Section 240.6. While calculating conductor ampacities and ensuring that the designers have the appropriate overcurrent device, keep in mind when it is necessary to go up to the next higher standard fuse size and when you must go down to the next standard size. Section 240.4(B) provides the guidelines of when the designer can move to the next higher size by outlining three different conditions, that the conductors being protected are not a part of a branch circuit feeding multiple general use outlets, it doesn’t correspond with a standard fuse or circuit breaker without overload trip adjustments, and it does not exceed 800 amps. If the calculated ampacity doesn’t meet all three conditions, you will need to move up to the next higher standard fuse or circuit breaker size. Another thing to keep in mind is Section 240.4(D) small conductors. Make sure that the designer is compliant in this section for all conductors sizes up to 10 AWG copper or aluminum.

Effective Ground-Fault Current Path

Next plans examiners should start to determine code compliance for the effective ground current path. I typically start to review this in the initial electrical service stage and maintain my eyes on it throughout the review. I’m specifically looking for ungrounded conductors that are upsized from their minimum required ampacities, typically for voltage drop reasons. It’s easy to verify the appropriate bonding and grounding conductor sizes from the tables if everything is based on the minimum standards, but when it is not, plans examiners should begin the calculations. It’s crucial to verify proper grounding conductor sizes and types, locations, and electrodes. While reviewing the drawings, I’m looking closely at the main bonding jumper connection, the grounded conductor, supply-side bonding jumpers, system bonding jumpers, equipment grounding conductors, and all of the associated grounding electrode conductors.

It’s important to ensure that all of the available grounding electrodes are going to be utilized and that they have the appropriately sized grounding electrode conductors. Keep an eye out for grounding details, too; it is not uncommon to find simple mistakes that not many people notice. When verifying compliance for the grounding electrode at the service, each building or structure supplied by feeders or branch circuits, or a separately derived system, you are required to use Sections 250.66(A) through (C). For grounded conductors, main bonding jumpers, system bonding jumpers, and supply side bonding jumpers use Sections 250.102(A) through 250.122(C)(2). And of course, for equipment grounding conductors, use Sections 250.122(A) through 250.122(G).

Summary

Being a plans examiner is an extremely challenging position in the electrical industry due to the in-depth knowledge of the National Electrical Code, calculations, and by being the filter that helps to resolve issues before they are created in the field. You act as the first line of defense against non-compliant installations. As a plans examiner, I understand that I cannot catch everything, but my goal is to filter as much as possible during the process and to help the inspectors and contractors as much as possible in the field. Remember, when you make a mistake, and you most certainly will try to take the experience and learn from it. It is impossible to know everything, and code and standards are constantly changing, stay involved with the codes and never stop learning!

Find Us on Socials