Electrical inspectors as well as building inspectors have important roles in assuring safety for persons and property. It is essential for safety that jurisdictions establish and maintain an effective code enforcement program. Inspections of installed work provide an opportunity for potential shock hazards, electrocution, fire and other hazards to be identified and corrected before the occurrence of such sad and unnecessary events. When one gets right down to it, the inspector has a huge responsibility and is an essential element of the overall electrical safety system. Inspection for electrical safety is a noble profession that requires diligence, dedication, and, most importantly, commitment to reasonable application of the codes and standards in the interest of protection of property and the public.

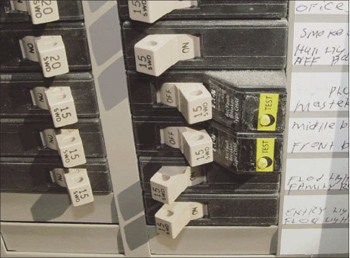

Photo 1

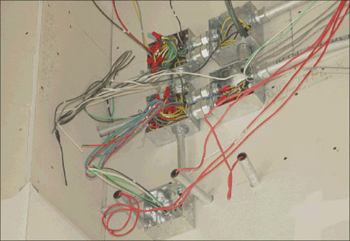

Photo 2

Some other benefits of code enforcement and building inspections that are not usually mentioned are the positive affects on the insurance rates and the reduced amount of fires and injuries. Usually the numbers tell the bigger part of the story. Areas with a lot of fires and injuries that are related to electrical installations or building construction are generally those that are deficient in a meaningful code enforcement program. Those that do not fully understand the hazards of electrical safety sometimes have difficulty understanding the importance of the inspector’s responsibilities in electrical and building safety and conformance assessment in general. The message of proactive electrical safety and its importance is one that must be conveyed more visibly, and not just in reactionary fashion. Electrical inspections are an important part of filling this need.

Without getting sidetracked into a whole different discussion about those issues mentioned above, this article is one of a series of articles that takes a closer look at the essential role of the electrical inspector and how important it is for the electrical inspector to know how to identify those hot spots in the field. It is generally well understood that the purpose of the NEC is “”the practical safeguarding of persons and property from hazards arising from the use of electricity”” without exception, as clearly indicated in Section 90.1. This concept should always be kept in mind when application and enforcement of the rules contained in the Code. Well, that’s about enough time spent on the basics and the purpose. However, one must never downplay the importance of developing a true understanding of how the electrical Code came to be and why it is necessary for electrical safety. Electrical inspectors know and understand this and also how this is a primary driving force in the high levels of dedication and commitment to electrical safety they carry with them on the job every day.

The Code is the minimum

Another concept that should be well understood is that the Code is the minimum set of safety rules and requirements. It contains provisions that are essential for safety. That means one must do at least that much in the interest of electrical and building safety. When the minimum requirements of the Code are met, and proper maintenance is provided as needed, it generally results in installations that are essentially free from hazards but that might not necessarily be adequate for future expansion of electrical use [see 90.1(B)].

It is generally understood and a fairly common practice for local jurisdictions to amend or modify the minimum international and national standards with local requirements as deemed necessary. When jurisdictions adopt the NEC, they should do so with the understanding that based on consensus and substantiation, the rules contained in the NEC are the minimum that must be applied and followed. Local amendments or modifications to the minimum national and international standard(s) are usually more restrictive and for specific reasons of conditions that are unique to that region or area. Examples of common local amendments that are necessary are those dealing with harsh soil conditions and the negative effects the soil has on electrical

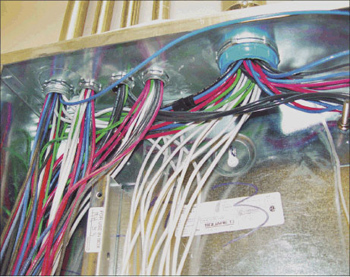

Photo 3

equipment in contact with the earth. This is common in various geographical areas. Another might be the more intense heat or levels of ultra-violet rays that sunlight has on electrical equipment. There are various other reasons that local amendments to the Code are necessary. Jurisdictions adopting the NEC into law should exercise careful discretion when considering modifying (through local amendments or Code rules) the minimum electrical safety standards. The Code is the minimum, so we must do at least that much. In most situations that is generally the best approach.

The value of electrical inspection checklists

IAEI was recently approached about putting together an article that provides the reader with a top ten list of important items to check for when inspecting electrical installations. In other words develop an electrical inspection checklist. This idea is a good one, but it is difficult to create a written form that would provide all necessary and meaningful information for installers and inspectors and then limit it to a list of only ten items! However, an article that draws attention to the hot spots of electrical installations appeared to be interesting and might provide useful information for the readers.

Photo 4

First, let’s not discount the use of checklists in the inspection process. This type of approach has many benefits and positive results. Three benefits are consistency and uniformity in the application of the rules as well as effective training tools for the inspector and installer. Checklists are great starting points for inspectors, but it should be clearly understood that checklists are generally always non-inclusive and each job is going to have a certain amount of uniqueness to it, which might require diversion from any basic checklist. The best approach is to use the checklists as guides and treat each installation with a certain amount of individual attention, always remembering that the NEC is the umbrella for any checklist. This means do not rely on the checklist(s) alone; rely on the Code.

Workmanship is important

There is a general requirement applicable to all electrical installations: Electrical equipment (see definition of equipment) is to be installed in a neat and workmanlike manner in accordance with Section 110.12. If a job is worth doing, it is worth doing right. Generally speaking, good electrical

Photo 5

work usually looks good as well and the comfort level of inspectors is generally raised by the quality and appearance of the work. It’s not hard for electrical inspectors to tell if the electrical installer has experience and meets the objectives anticipated in the workmanlike manner rule. But it is also important that the inspector not get too comfortable because the work looks good from outside appearances. An installation can appear neat and workmanlike on the surface, but contain serious problems on the inside. This is an important consideration and can affect the approach of the installer and the electrical inspector.

A look at electrical inspection hot spots

With a more general approach, a list of ten electrical inspection hot spots is easily established. When applying the general requirements of the NEC, a few of the many hot spots come to mind (see table 1).

Table 1. Ten general hot spots for electrical inspection

Listing and Installation Instructions

Equipment Ratings and Use

Electrical Terminations and Connections

Working Space for Electrical Equipment

Circuit Identification Requirements

Location and Number of Services and Service Equipment Rating

Grounding and Bonding Circuits

Application of Overcurrent Protection Requirements

General Wiring Installation Requirements

Conductor and Cable Current-Carrying Capacities

Photo 6

The first important item is the approval process and how the inspector utilizes listing and use of listed products as a basis for approvals. So this should be a general item that has broad application and purpose to electrical installations and systems. It is a fairly simple requirement that is a primary contributor to electrical safety. Verify that the equipment or material is listed (see photo 1). Equipment that is listed has been evaluated for electrical safety and generally includes installation instructions for the installer to provide direction on its use and the limits of its use. It is a common violation in the field, yet it is a Code rule that should be so reasonable and easy to enforce and easy to comply with. It is still amazing to witness how many folks don’t follow installation instructions. Section 110.3(B) is fairly clear and, without exception, is the first hot spot in this list of ten.

There are three other critical inspection hot spots in electrical installations to which the rules in chapter one of the Code apply. They are equipment interrupting ratings covered in Section 110.9; electrical terminations and connections covered in Section 110.14; and adequate working space and dedicated space for electrical equipment covered in 110.26.

Equipment ratings and use

Equipment must have sufficient electrical ratings for the voltage, current, phase and system, etc., and must be applied in systems while not exceeding those limits [see NEC 110.9]. Look at the labels required to be provided on the equipment (see photo 2). There is a plethora of

Photo 7

information to be understood from just the equipment labels. I think many inspectors would agree that there is an enormous amount of information to be included on the labels and it seems to require smaller and smaller print to get it all on the labels. Magnifying glasses and angle mirrors are common tools for inspectors these days to assist with these challenges. Installers should have a good understanding of the markings on equipment as well. Manufacturers of electrical equipment are more than happy to provide additional guidance and information as needed, but the questions need to be asked. It’s tough to learn at the end of a red tag or inspector’s notice of violation in the field.

Electrical terminations and connections

Electrical circuits are only as good as their weakest link. Common points for electrical failures are connections and terminations at equipment and devices such as switches and receptacles; so, electrical connections and terminals are definite hot spots in the inspection process (see photo 3). Follow the weakest link theory when installing or inspecting electrical terminals and connections. Be sure that the terminal or connection device is suitable for the use and properly

Photo 8

installed. This includes compatibility between conductor materials and the device, proper torque, and ratings, etc. Improper connections and terminations are primary causes of electrical failures and fires.

Working spaces for electrical equipment

The minimum working spaces required in chapter one for electrical equipment are necessary for ready and safe operation of such equipment (see photo 4). When installing electrical equipment that requires the minimum working and dedicated space, installers should approach the situation as though they might have to service the equipment or work on it in the future. Enough working space to meet the minimum distances provided in Article 110 of the Code is essential for safety and a definite electrical inspection hot spot. See 110.26 and 110.32, 110.33, and 110.34 for the minimum distances required for equipment based on applied voltages.

Circuit and disconnecting means identification

Photo 9

Identification of circuits and disconnecting means as to the load served is an essential part of the inspection and should be approached from the viewpoint of the occupant’s safety. The primary beneficiary of a well thought out circuit directory on a switchboard, panelboard, motor control center, etc., is the occupant or user long after the final inspection and occupancy building is taken. So the basic disconnecting means and circuit identification requirements provided in Section 110.22 are also inspection hot spots. Installers and inspectors sometimes get a bit too casual with circuit identification requirements. Changes in the 2005 NEC have placed more specific emphasis and requirements to address this issue [see the revisions to Section 408.4].

Protection of persons, equipment, and property

Chapter two of the Code is titled “”Wiring and Protection”” and contains hundreds of minimum

Photo 10

requirements. Let’s look at a few of its critical electrical inspection hot spots. The rules for ground-fault circuit interrupters and arc-fault circuit interrupters are located in Article 210. These two forms of protection directly correlate with 90.1 of the Code. The minimum requirements for GFCI and AFCI protection are in the interest of protection persons and property (see photos 5 and 6). These are inspection hot spots and the inspector should verify that they are installed in locations that require this type of protection [see NEC 210.8 and 210.12].

Location and rating of service equipment

Requirements for electrical services are provided in Article 230 of chapter two. The number of services to a building or structure and the location of the service disconnecting means are two key hot spots relating to the electrical service (see photo 7). There are many more critical requirements for electrical services, such as equipment rating, size of service conductors, location of the service, overcurrent protection, and so on.

Grounding and bonding

Grounding of the electrical services and systems supplying the premises is another primary inspection hot spot. The rules for grounding and bonding are provided in Article 250 of chapter two. It is important that one develop an understanding of the performance criteria and purpose of grounding and bonding. This is clearly provided in NEC 250.4. Effective bonding is directly related to the proper operation of overcurrent protective devices. Grounding is essential and plays a slightly different role in minimizing shock hazards and providing a means to keep conductive equipment and enclosures at earth potential, which serves to minimize shock hazards. An additional benefit of grounding is dissipation of lighting or other overvoltage conditions that might be imposed on the electrical system. Grounding and bonding circuits work cooperatively to provide essential safety and functionality of overcurrent protection during ground-fault and short-circuit events.

Overcurrent protection

Compliance with the rules in Article 240 is another hot spot for the installer and electrical inspector. Protection of electrical equipment and conductors is accomplished by proper application of overcurrent protection (see photo 8). Verification of overcurrent protection types, sizes, and locations is essential for electrical safety. Standard ratings of overcurrent protective devices are provided in Section 240.6. It is important to verify that overcurrent protective devices are applied in circuits within their short-circuit current interrupting ratings in accordance with Section 110.9.

General electrical wiring rules

Photo 11

Article 300 of chapter three in the Code includes requirements for wiring methods for electrical installations. Essentially these general provisions provide information about how to install electrical circuits, wiring methods, and equipment. Some hot spot electrical inspection essentials in Article 300 include, but are not limited to, installation and grouping of conductors of the same circuit, wiring method burial depths, protection of cables installed in walls, length of conductors in boxes, and number of conductors in boxes and raceways (see photo 9). Be on the lookout for crowding in junction boxes and enclosures, too many wires in raceways, and conductor protection from abrasion where necessary. These are definite hot spots that can lead to excessive heat and failure in time. It is important to verify that whatever wiring method is used for an installation is permitted for that particular use. Each wiring method article generally provides the restrictions on its use under the uses not permitted section (.12) of the respective article.

Conductor and cable current-carrying capacities

Verification of properly sized conductors is another electrical inspection hot spot. Conductors must be capable of carrying the connected load. The rules for wire sizes are provided in Article 310 in chapter three. Several factors impact the ampacity of conductors and cables in electrical installations: calculated loads; temperature compatibility with connected equipment, especially at terminations as previously discussed; coordination with the overcurrent protection, and compliance with product listings are some essential factors in determination of conductor ampacities.

How the conductors are installed also might require additional consideration. For example, installing conductors in higher ambient temperatures, installing multiple current-carrying conductors or cables together in a manner that they are able to dissipate heat generated by current loading. Watch for the grouping (bundling) of cables and excessive numbers of current-carrying conductors in raceways (see photos 10 and 11). These are definite inspection hot spots that installers and inspectors should be watchful for. Apply the appropriate correction factors and be sure that the conductor is adequate for the load and is properly protected after the correction factors are applied.

There are many more installations that are also inspection hot spots such as luminaire (lighting fixture) installations, motors and air-conditioning equipment installations and special equipment and occupancy installations as provided in chapters five and six of the Code. As previously covered in this article, this list of electrical inspection hot spots is not all-inclusive. It is, however, a fairly good starting point that provides some insight into the responsibilities and approach of the electrical inspector in verifying that installations are safe and meet the minimum requirements of the Code. Obviously, all of the Code rules are for justified reason, and we have not visited all rules that might apply to every electrical installation. Each installation warrants its own unique challenges and is the determining factor in which Code rules are applicable.

Electrical inspection is an essential element for electrical safety for persons and property. Hopefully this article has provided a small glimpse of some common areas of concern for inspectors as they diligently carry out their daily work. Inspection is a big responsibility, but it is only a part of the responsibility for safe electrical installations. The primary responsibility for compliance with the Code rests with the installer and owner. The role and responsibility of inspectors is to verify compliance with requirements applicable to those installations and systems. It is equally important that installers of electrical conductors and equipment have a clear and urgent sense of awareness of the electrical installation hot spots that must be given attention in the interest of electrical safety. Electrical safety is a responsibility shared by many. As always, the authority having jurisdiction has the final approving authority and responsibility. Where there is any question about minimum requirements of the NEC, or any local Code requirements, always consult the authority having jurisdiction in that particular area.

Find Us on Socials