Many questions are being raised about the requirements for bonding metal gas piping systems. More specifically, when corrugated stainless steel tubing (CSST) is installed for the gas piping in a building, bonding methods and bonding jumper sizes that are more restrictive than required by theNational Electrical Code® are causing some of the confusion and concern. This issue is not a small problem and has generated a significant amount of interest by various groups. This article takes a look at what the NEC requires regarding bonding of metal gas piping systems. It also explores recent revisions to NFPA 54 the National Fuel Gas Code and some of the challenges inspection authorities, electrical contractors, and gas piping installers are encountering today on a regular basis.

Photo 1. Metal gas piping using corrugated stainless steel tubing (CSST) distributed through an iron manifold. Photo courtesy of Bill McGovern, city of Plano, Tx.

Purpose

It is important to understand what is intended to be accomplished from a performance standpoint by meeting the metal piping bonding rules in applicable codes. The NEC provides excellent performance language in Section 250.4 that informs users about what is intended to be accomplished by code-compliant grounding and bonding. Section 250.4 is comprised of two subdivisions (A) and (B). Section 250.4(A) deals with performance criteria for electrical systems that are grounded, and Section 250.4(B) addresses those systems that are ungrounded. When dealing with bonding requirements for metal gas piping, one should identify the performance criteria that apply from 250.4. A closer look at 250.4 reveals that there are multiple list items in each subdivision. The two performance rules in 250.4 that apply to bonding metal piping systems are provided in (A)(4) and (B)(3). Both of these rules deal with bonding of electrically conductive materials and other equipment. Within each of these rules one can see that bonding of these electrically conductive materials (metal gas piping in this case) that are likely to become energized is necessary, and that the bonding must be done in a manner that connects them together and to the electrical supply source in a manner that establishes an effective ground-fault current path.

Performance

The performance language in 250.4(A)(1) and 250.4(B)(1) also mention reasons for grounding electrical systems and electrical equipment. The reasons are to limit the voltages imposed by lightning, line surges, or unintentional contact with higher voltage lines, and grounding can stabilize voltage to ground during normal operation. It is important to remember that this performance rule applies to the grounded electrical systems in (A)(1) and grounded equipment in (B)(1). Sections 250.4(A)(2) and (3) deal with grounding and bonding performance rules for electrical equipment as do 250.4(B)(1) and (B)(2). Metal gas piping bonding is not included in these requirements but is included in 250.4(A)(4) and (B)(3).

Specific NEC Bonding Requirements

Electrical bonding is addressed in the NEC in Part V of Article 250. The section dealing with bonding metal gas piping is 250.104(B). This rule applies to various metal piping systems, including gas piping systems that are likely to become energized where installed in or attached to a building or structure. This rule calls for a bonding jumper to be connected between the metal gas piping and the service equipment enclosure, the grounded conductor at the service, the grounding electrode conductor if of sufficient size, or to one or more grounding electrodes of the grounding electrode system. The connection points (points of attachment) of the bonding jumper are required to be accessible. ThisCoderule also clearly indicates the minimum size for the bonding jumper generally has to be sized using Table 250.122 based on the rating of the circuit likely to energize the piping system. These circuits are generally considered as those that supply gas-fired equipment. At a minimum, the size of the bonding jumper should be not less than the size of the equipment grounding conductor of the circuit supplying the equipment. The overcurrent device for the circuit determines the minimum size. One could install larger bonding jumpers and exceed the minimum. This is often specified in the plans for larger construction projects. It is a good approach to verify with the local inspection authority how they approach sizing bonding jumpers for metal gas piping systems, because recent changes in other applicable standards and in the installation instructions provided by manufacturers of certain types of gas piping systems result in the minimum bonding jumper size being larger than what is required by theNEC.

New Gas Piping Material

Metal gas piping systems in buildings are often installed using hard metal piping that is suitable for gas distribution such as steel and wrought iron, copper and brass, or aluminum alloy. Recently a new type of steel tubing joins the list of piping systems for use in gas systems. Corrugated stainless steel tubing (CSST) is recognized by the National Fuel Gas Code (NFPA 54) and it must be listed to meet the performance, installation, and construction criteria in ANSI LC 1/CSA 6.26. Since CSST is a metal gas piping system, it falls under the bonding requirements in Section 250.104(B) of theNEC. An interesting feature of CSST products is that they provide manufacturer’s instructions for installation. Interestingly these instructions in some cases, not all, specify bonding requirements that are more restrictive than theNECrules. This could be where some of the inconsistencies and confusion lie, in addition to the fact that there is at least one CSST manufacturer that does not impose any bonding requirements that are more restrictive than the bonding rules in theNEC. It should be noted that NFPA 54 requires that manufacturer’s instructions must be followed in addition to applicable local gas supplier (often a utility) regulations.

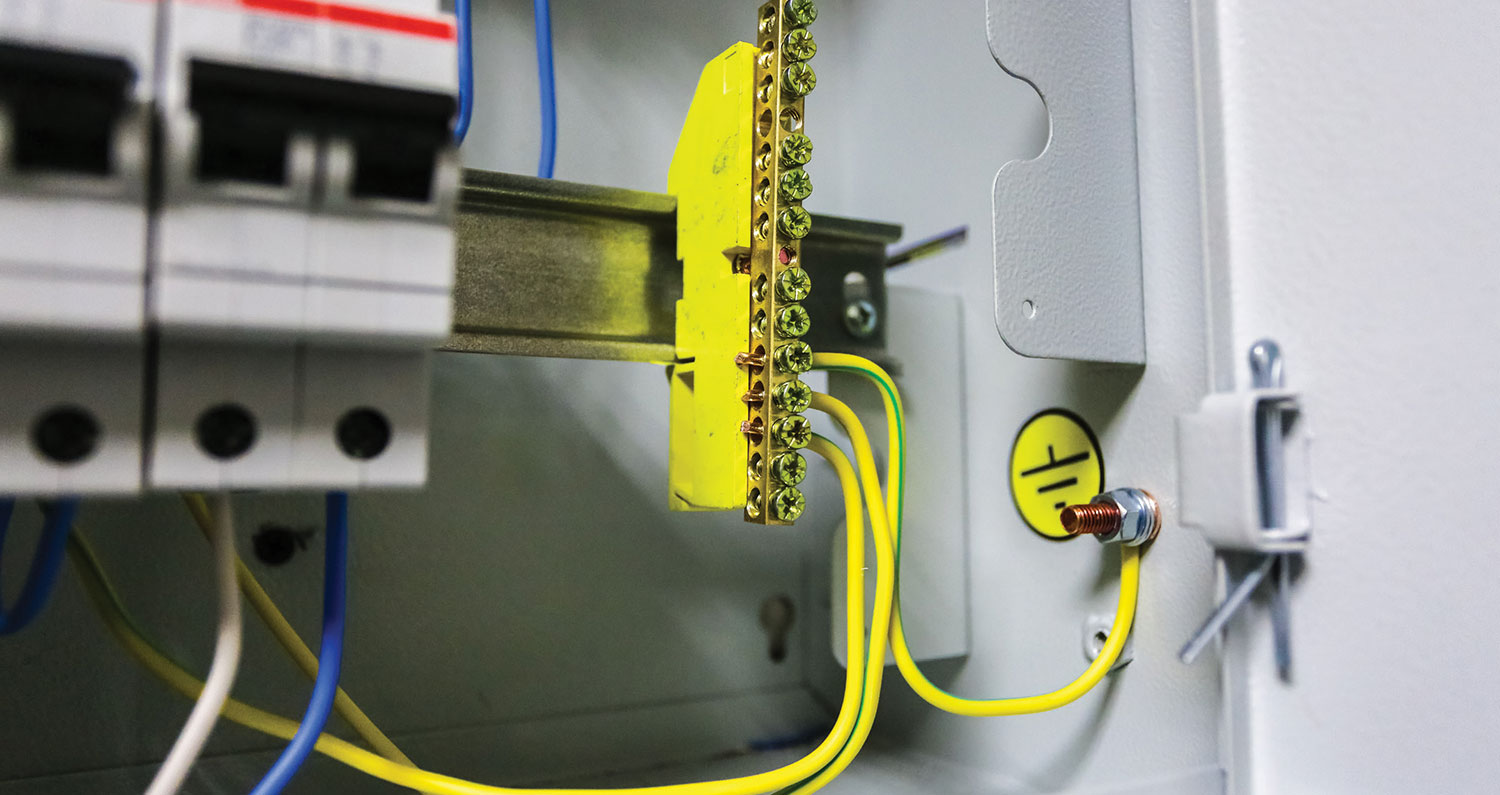

Photo 3. Bonding connections are required to be accessible. Photo courtesy of Bill McGovern, city of Plano, Tx.

Just to clarify theNECrules regarding installation instructions, Section 110.3 of theNECapplies to equipment and 110.3(B) more specifically imposes the requirement that listed electrical equipment be installed and used in accordance with any instructions included in the listing or labeling. This requirement applies to electrical equipment, not the metal gas piping, which has its own installation requirements.

The Challenges

The National Fuel Gas Code was recently revised to include bonding requirements for metal gas piping that are more restrictive than those in theNEC. The bonding requirements for metal gas piping systems in both NFPA 54 and NFPA 70 have been consistent until this revision. Attempts were made to revise the 2011NECmetal gas piping bonding rules so as to become consistent with NFPA 54-2009. CMP-5 rejected these proposals and indicated that insufficient technical substantiation was provided. Lightning is an unpredictable force. It would be difficult to conclude that by just changing aCoderule, the apparent lightning problems with some CSST products would be resolved. CMP-5 was very careful in their considerations of this proposal. The reason for the significant efforts to change the bonding rules for metal gas piping systems in both NFPA 54 and NFPA 70 are primarily related to problems from lightning events that could cause small rupture holes in the CSST, resulting in leaks and fires in some cases. There has even been property damage from such unfortunate events. This scenario begs two key questions, among others. Should a longstandingNECrule be changed to include requirements for protection against lightning events? This author thinks not. NFPA 780Standard for Installation of Lightning Protection Systemsprovides information about lightning protection for buildings and structures. NFPA 54 provides rules related to installation and performance of gas piping systems and gas equipment.

Standard Scopes

The scopes of NFPA 54 and NFPA 70 are not the same and address different important issues. TheNECrules address fire and shock hazards for persons and property. The bonding requirements for other metal piping systems in theNECprotect the piping system from the electrical system within the building. NFPA 54 covers safety and performance of gas piping systems, including addressing safety concerns. The recent revisions in NFPA 54 Section 7.13 result in new bonding requirements in response to serious issues related to CSST piping system failures and losses from subsequent gas leaks. NFPA 54 includes the new, more restrictive bonding requirements that are an effort to protect specific piping systems that are known to be vulnerable to the effects of lightning. Since the scopes of each standard are different, they must complement each other to achieve effective safety. One area where the documents are similar has to do with following product manufacturer’s installation instructions. Both standards include this requirement, so coordination of the work and enforcement of the rules is necessary to ensure the desired outcome of satisfying both standards.

Impact on Inspectors and Contractors

The impact on inspection agencies, electrical contractors, and gas piping contractors has been increased inconsistency and confusion regarding bonding requirements for metal gas piping systems, specifically those systems that incorporate CSST. Jurisdictions are challenged with the fact that many do not adopt NFPA 54 but do adopt and enforce NFPA 70. This fact coupled with the CSST manufacturer installation instructions that vary between CSST manufacturers and other influencing factors is causing increased anxiety about compliance and liabilities. Some jurisdictions have been convinced that they need to change their local codes or add a new amendment to their current local rules that parallel the CSST manufacturer’s instructions. The problem is not all CSST products require any bonding beyond the minimum required inNEC-2008. Inspectors should know how theNECrequirements have to be applied to installations and systems and they should understand what the rules are intended to accomplish. Metal gas piping systems are required to be bonded where likely to be energized so that any imposing circuit cannot energize the piping system. The bonding required by 250.104(B) also results in the potential of metal gas piping being at or near the potential of ground (the earth). TheNECrules are not intended to provide assured and complete protection against lightning events. As safety standards change, new requirements are incorporated to address substantiated problems with viable solutions. The changes in industry standards have to accompany education and training related to new safety requirements. Contractors and enforcement have responsibilities to learn the requirements and implement them in their work. Enforcers impacted by the bonding requirements in each of the documents should coordinate the installation and work out who inspects, what rules apply, and who does the work. Once this dialog occurs, the approach taken by the code enforcers can be passed on to the contractors.

Summary

Problems have been identified with CSST systems being installed and used for gas systems in buildings. There are current efforts in motion to revise the NEC to deal with apparent lightning protection issues related to CSST piping. Is the NEC rule broken, and do the proposed revisions actually provide the needed solutions? Many in the electrical industry currently have more questions than answers relative to these issues. While one thing is certain, when a jurisdiction adopts a code, that code should be enforced and applied in the field. This article provides a closer look at some current activity relative to proposed changes to bonding requirements for CSST metal gas piping systems. These problems did not exist before CSST entered the market. This should in no way be interpreted that CSST is an inferior product or that there are problems with some varieties of this product, but one has to wonder if this changing of current rules is the answer or if there is a problem with some CSST products. In reflection, the purpose of theNECis the protection of persons and property from the hazards arising from the use of electricity. Lightning protection requirements are clearly beyond the purpose and scope of theNEC. When revising requirements in industry safety standards, consideration must be given to how the scopes of such standards are impacted and whether or not the proposed revisions to the contained requirements are a viable solution to the real problem. These are some of the real challenges that members of NFPA technical committees face when carrying out their responsibilities to produce the best codes possible each revision cycle; a true and often difficult work in progress. The best approach at this time is to verify what the local inspection authority is requiring regarding bonding metal gas piping and meet those requirements, which are now often inconsistent with theNECminimums.

Find Us on Socials