OK all you sports fans out there, it’s football season; and everyone is fired up and running out to buy the latest item of team gear to show their support. But, hey, wait just a minute; your team did real well last season, but maybe it’s time to make a different choice for this season. I know you’re thinking to yourself, What do football and hazardous locations have to do with each other, right? Well, just like with football teams, in a hazardous (classified) area, you also have a choice. The choice in football is which team to support, which one will perform better in volatile situations and atmospheres. When we talk about the hazardous (classified) area, we also have a choice of methodologies to mitigate and prevent volatile situations and atmospheres. The football stadium, however, is not the type of hazardous (classified) location we will be discuss in this article; although, sports fans, a fumble during either process could have the potential to be extremely hazardous in both arenas.

Photo 1. Modern explosionproof equipment

In this article, the reader will take a journey through history for a sobering and sometimes frightening look at the beginnings of the classification of a hazardous (classified) location. We will take a look at the electrical industry’s modern methods of classification to see, and understand, just how far we have progressed. We will then look at the differences between the two commonly used systems for classification of a hazardous (classified) location or area: theNational Electrical Codes(NEC) Division system, and the International Electrotechnical Committees (IEC) Zone system.

History of Hazardous Locations

Modern Methodologies

These modern methodologies provide us with an environment where many different and much needed processes and tasks can be performed. The fear of the consequences and results of flammable/combustible or dust-concentrated atmospheres that always lurked in the minds of owners, operators and employees has all but disappeared. There was a time, however, when it wasn’t always this way. Let’s visit the past to see how industry first attempted to detect and classify an area, and how, at times, it had to suffer through many unfortunate incidents to discover that an area or location was, indeed, a hazardous (classified) location.

The First Hazardous Areas

Historical documents tell us that one of the very first hazardous areas known to exist, in which many men, women and children worked, both in the United States and abroad, was the coal mine. In those early coal mines, a double hazard existed in the way of methane gases and vapors, along with carbonaceous dust or coal dust. Unfortunately, those miners did not have any really safe method of detecting a hazardous area or location prior to placing workers in harm’s way. Nowadays, our material groups, methods of classification, and means of detection would have easily told us that a hazard existed.

Methane and Carbonaceous Dust

Having experienced violent explosions many times, the wary miners knew that the shafts oftentimes would be full of methane gas that would float to the roof of the mines as it is lighter than air, and that it would be present the next day after the miners extracted the coal from the mineshafts. This posed a very serious problem for those miners, so the need for detection and mitigation of the deadly gas was a priority.

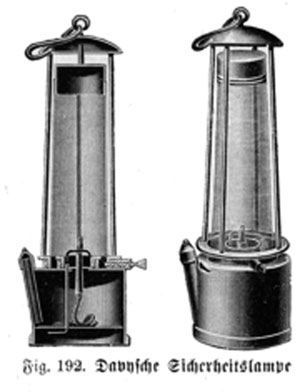

Most explosions were set off by the very primitive miners’ lamps. The miners were quite often afforded insult to their injury by an even more violent secondary explosion caused by the carbonaceous dust that was raised into a massive cloud by the primary methane explosions, which most times traveled right through the mine causing great injury and frequently death to whole crews of miners.

The Fireman

Having lost so many men, yet still needing the precious coal for the many processes that used this commodity, a way had to be found to detect and remove the methane prior to the employment of men and materials to collect the newly harvested coal. It was thought that if the deadly methane could be identified, the secondary explosions of carbonaceous dust could also be eliminated. Enter what the NEC now refers to as the qualified person, which in our early history was called the fireman. This person would crawl along the floor of the mine, wrapped in the most primitive form of PPE—a wet blanket; and equipped with a torch, he would then proceed to ignite the layer of methane at the roof of the mineshafts where it would gather. This was all done in hopes that once all of the methane burned off, the shaft would be deemed safe for harvesting the coal—that was in the rare case that the explosion from the methane didn’t cause a secondary explosion from the concentration of carbonaceous (coal) dust.

The Penitent Man

These early firemen, as they were called, did not have much success in walking away from their early attempts at detection and classification, which gave way to employing the next qualified person known as the penitent man. Since no one would volunteer any longer for the job as a fireman, the early owners of the coal mines went to the local prisons in search of volunteers. Many of the prisons used coal for heat and for many of the day-to-day processes; this being the case, the convicts were offered shorter sentences if they would volunteer for the job of fireman. This action led to the prison volunteers becoming known as the penitent man, derived from the word “penitentiary.”

Photo 5. Fireman facing forward

This term was also due to the resemblance of the protective clothing to that of certain Roman Catholic Orders. This type of detection went on for quite a while; however, after very few, if any, of the prisoners were successful enough to actually have sentences shortened, even the prisoners refused to volunteer for the job.

Enter the Ponies

Once the day of the penitent man grew obsolete, ponies wrapped in blankets and hosed down with water and fitted with a special candle strapped to their saddles were used to detect the deadly methane gas as they were sent down the mineshafts at a gallop. Being much faster than either the fireman or the penitent man, the ponies were highly successful and were able to escape with not much more than singed manes and tails. This means of detection and classification, however, was brought to an end as well by laws that prevented cruelty to animals. With the eventual use of mechanical ventilation to dilute the ignitible concentration of methane gases, one of the earliest forms or methods of protection was discovered: adequate ventilation. This method is still employed today in modern coal mines by following the guidelines in NFPA 120, Standard for Coal Preparation Plants, which allows adequate ventilation to reduce the Class 1, Division 1, or Zone 0 area to an unclassified area.

Moving Forward

Now that we have taken a look at one of the very first hazardous locations and at how attempts were made to detect the areas and atmospheres associated and to mitigate them, let’s fast forward to today’s modern methodologies of detection, classification and mitigation. With the ingenuity and hard work of many groups like Underwriters Laboratories (UL), the Canadian Standards Association (CSA), Factory Mutual (FM), the American Petroleum Institute (API), the National Fire Protection Association (NFPA), the Instrumentation Systems and Automation Society (ISA), the International Electrotechnical Commission (IEC), and others, we no longer have to rely on actions or processes like those that were used by the fireman or penitent man in the early coal mines.

Divisions vs. Zones

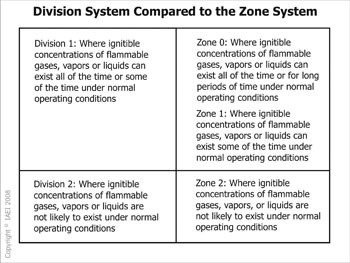

Instead we have current methodologies such as the NEC’s Division system and the IEC’s Zone system. We don’t delve into the class of hazard in this article, as neither time nor space permits. What we will be examining is the second part of the equation — division/zone. What are the real differences between these two methods of classification of a hazardous (classified) location? Let’s start out with the definitions of each method.

Photo 6. Box cathedral in coal mine

In the NEC’s Division system there are two types of divisions, which are Division 1 and Division 2 areas or locations. Division 1 locations are laid out with regard to the hazardous (classified) location. NEC Section 500.5(B)(1) tells us that within a Division 1 location, ignitible concentrations of flammable gases, flammable liquid-produced vapors, and combustible liquid-produced vapors can exist under normal operating conditions. It also goes on to tell us that ignitible concentrations of such gases may also frequently exist because of repair or maintenance operations. This is often due to leakage, or to breakdown and/ or to faulty operation of equipment, or to processes that may release these ignitible concentrations into the atmosphere. Section 500.5(B)(1) then tells us the consequences of the breakdown and/ or faulty operation of this equipment or processes may lead to simultaneous failure of electrical equipment in such a way as to cause the electrical equipment to become a source of ignition.

If we look at atmospheres where dust or fibers and flyings are covered under the NEC Division system, Section 500.5(C)(1) tells us that it is also the same for Division 1 dust areas. These are areas where ignitible concentrations of combustible dust exist, or in which Group E dusts such as aluminum and magnesium may be present in quantities sufficient to be hazardous, as well as in NEC Division 1 fiber and flying locations, where easily ignitible fibers and flyings are handled, manufactured, or used as indicated in NEC Section 500.5(D)(1).

Division 2

Just like in theNECDivision 1 system, the aforementioned scenarios for theNECDivision 2 locations are also the same forNECDivision 2—dust areas where ignitible concentrations of combustible dust could easily exist due to abnormal operations as indicated inNECSection 500.5(C)(2). Combustible dust accumulations are present but are normally insufficient to interfere with the normal operation of electrical equipment or other apparatus, unless they become suspended in the air and the accumulations of dust on, in, or in the vicinity of, are sufficient to interfere with the safe dissipation of heat from electrical equipment. This dust could be ignitible by the abnormal operation of, or failure of electrical equipment.

A Division 2 location dealing with fibers and flyings, would be where easily ignitible fibers and flyings are stored or handled, other than in the process of manufacturing, as indicated in 500.5(D)(2).

Zones

Having taken an in-depth look at the elements of theNECDivision system and at how it defines a hazardous (classified) location or area, let’s move to the IEC Zone system and see how it is breaks down and defines a hazardous (classified) location or area.

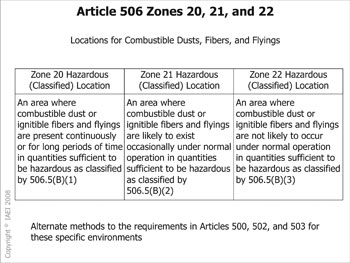

Table 1. Article 506, Zones 20, 21, and 22

In the IEC Zone system, the areas are made up of six distinct types of Zones, which are Zone 0, Zone 1, and Zone 2 for gases and vapors, and Zone 20, 21, and 22 for ignitible concentrations of dust or ignitible fibers and flyings. Let’s now take a close look at IEC Zone 0 locations and at how they are defined with regard to the hazardous (classified) location.NECSection 505.5(B)(1) tell us that within a Zone 0 location, ignitible concentrations of flammable gases or vapors are present continuously, or are present for long periods of time.NECSection 505.5(B)(2) then tell us that in a Zone 1 location, ignitible concentrations of flammable gases or vapors are likely to exist under normal operating conditions, or may exist frequently because of repair or maintenance operations, or in which equipment is operated or processes are carried on, of such nature that equipment breakdown or faulty operations could result in the release of ignitible concentrations of flammable gases or vapors and also could cause simultaneous failure of electrical equipment in a mode to cause the electrical equipment to be a source of ignition, and the Zone 1 location is adjacent to the Zone 0 location from which ignitible concentrations of flammable gases or vapors could be communicated, unless such communication is prevented by adequate positive-pressure ventilation from a source of clean air and effective safeguards against ventilation failure are provided.

Zone 2

NECSection 505.5(B)(3) tells us that within a Zone 2 location, ignitible concentrations of flammable gases or vapors are not likely to occur in normal operation and, if they do occur, will exist only for a short period of time. This section goes on to say, “or in which volatile flammable liquids, flammable gases, or flammable vapors are handled, processed, or used, but in which the liquids, vapors, or gases are normally confined within closed containers or closed systems from which they can escape, only as a result of accidental rupture or the breakdown of the containers or systems, or as a result of the abnormal operation of the equipment with which the liquids or gases are handled, processed or used; or in which ignitible concentrations of flammable gases or vapors normally are prevented by positive mechanical ventilation but which may become hazardous as a result of failure or abnormal operation of the ventilation equipment.” With that in mind and with the Zone 2 location adjacent to the Zone I location from which ignitible concentrations of flammable gases or vapors could be communicated, unless such communication is prevented by adequate positive-pressure ventilation from a source of clean air and effective safeguards against ventilation failure are provided, the results could be catastrophic.

Zones 20, 21, & 22.

Dust or Fibers and Flyings

Now that we have looked at the Zone system for flammable gases and vapors, let’s take a look at how the Zone system defines dust and fibers and flyings.NECSection 506.5(B)(1) tells us that within a Zone 20 location, ignitible concentrations of dust or fibers and flyings are present continuously, or that ignitible concentrations of dust or fibers and flyings are present for long periods of time. Within a Zone 21 location, as indicated inNECSection 506(B)(2), we are told that ignitible concentrations of combustible dust or ignitible fibers or flyings are likely to exist under normal operating conditions; or may exist frequently because of repair or maintenance operations; or in which equipment is operated or processes are carried on, of such nature that equipment breakdown or faulty operations could result in the release of ignitible concentrations of combustible dust or ignitible fibers or flyings and also cause simultaneous failure of electrical equipment in a mode to cause the electrical equipment to be a source of ignition; and if the Zone 21 location is adjacent to the Zone 20 location, ignitible concentrations of combustible dust or ignitible fibers or flyings could be communicated, unless such communication is prevented by adequate positive pressure ventilation from a source of clean air and effective safeguards against ventilation failure are provided.

In a Zone 22 location, as indicated byNECSection 506(B)(3), ignitible concentrations of combustible dust, fibers, or flyings are not likely to occur in normal operation and, if they do occur, will exist only for a short period; or in which combustible dusts, fibers, or flyings are handled, processed or used but in which the dust or fibers or flyings are normally confined within closed containers of closed systems from which they can escape only as a result of the abnormal operation of the equipment with which the dusts, or fibers, or flyings are handled, processed, or used; and the Zone 22 location is adjacent to the Zone 2I location from which ignitible concentrations of dusts, fibers, or flyings could be communicated, unless such communication is prevented by adequate positive-pressure ventilation from a source of clean air and effective safeguards against ventilation failure are provided.

Conclusion

We have just taken an in-depth look at the history of hazardous (classified) locations and their classification methods. Using these two modern systems as examples, and looking at how each classifies an area or location, the reader can see that while there are slight differences there are many more similarities, and that both methods are actually a lot alike in many respects. While both systems are quite adept at identifying an area, whether the area contains gases or vapors, dust, or fibers and flyings, it is still advisable to seek out the properly trained and experienced design team of professionals and qualified persons interacting with the owner to ensure that the proper degree of hazard has been identified, that proper equipment and wiring methods are used, and that the proper method of protection and protection techniques are implemented. By enlisting these design professionals, we can all ensure that our workplaces and the people that work in and around them can continue to remain safe, to thrive, and to produce the necessary goods and services that we all need and enjoy.

Hey, how about that other choice; you know, which football team will you support this season? What method will they choose to avoid a hazardous atmosphere?

Find Us on Socials