For a short period of only eight years nearly a ½ century ago clustered along the edges of a handful of fast-growing American metropolitan areas, Copper Clad Aluminum saw its only use in the USA as a residential building wire. By 1980, it then completely disappeared from the US building wire market.

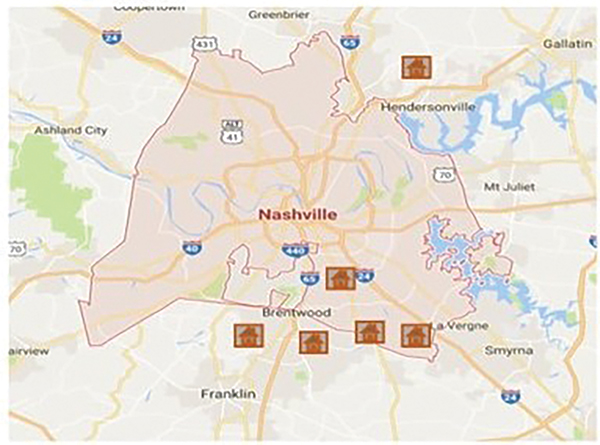

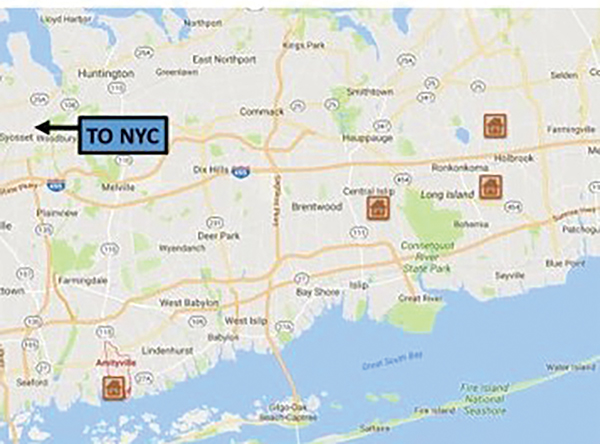

Due to the historically low cost of copper from 1980–2005, CCA could not compete against solid copper as a conductor material. Therefore, only a handful of inspectors and contractors have any experience at all with Cu-Clad NM-B and THHN, the most common conductors for residential branch circuit wiring. This situation being the case, for the purpose of this study, it was decided to undertake locating municipalities and residences where Cu-Clad BCBW (branch circuit building) wire is being used. As mentioned in Part One of this article, (September-October 2016), some hundred thousand residences nationwide are wired with Cu-Clad. In addition to a few dozen others, two particular metro areas of the country saw prolific use from 1972–1980: Metro Nashville, Tennessee and Long Island, New York (Metro NYC). This article will focus on these two metro areas.

Nashville and Long Island are climatically different from one another, and thus statistically interesting. Nashville summers are hot and humid, with averages just short of 90°, and frequently peaking over 100°. Winters are mild and wet but can be surprisingly frigid at times, sometimes seeing periods of week-long stretches with temperatures in the single digits. Long Island can also be hot in the summer but is better known for its wet and harsh winters. The January average temperature is below freezing. Being coastal, nor’easters, hurricanes and flooding are not uncommon in the late summer and autumn. The air on Long Island also tends to contain higher than average levels of salt, being coastal, which can contribute to accelerated corrosion of industrial metals such as aluminum and copper.

To have Cu-Clad BCBW in service within these two different climates for five decades can provide real-world insight into its performance.

Nashville, TN

With the assistance of IAEI inspector and Master Electrician Steve Mallory, we identified several neighborhoods as having homes wired with Cu-Clad BCBW. The age of the residences and circuit installations ranges from 38 – 44 years. Most of the locations employ, in part, some original “push in” electrical devices. All of them utilize devices and connectors designed for copper-only, as is permitted by UL. Certain locations underwent remodeling projects and/or expansions where more modern electrical devices were either reconnected with the Cu-Clad BCBW or pig-tailed to copper NM-B or THHN.

Both multi- and single-family residences were built with Cu-Clad BCBW. It should be noted that due to the tumultuous economics of the 1970s, Cu-Clad BCBW was widely used in apartment complexes built during this period. Double digit interest rates for home loans discouraged single-family home construction, making renting the only viable option for many. This situation demanded the building of apartments. Multi-family residential construction in many cities outpaced other construction sectors during the Cu-Clad era. Commonly, it is known that multifamily residences, such as apartments and condominiums, have lower incidents of electrical fires than single family. It is thought that apartments and condos receive more consistent electrical maintenance than single family, contributing to their better record. Another point of view is that multifamily, especially apartments, should perform worse regarding electrical fires. Profit-driven management companies forgo necessary electrical repairs and renovation for as long as possible in an attempt to maintain margin. The fact that the data points decidedly in one direction, despite the economic incentive for apartment managers to skimp, could provide a reason for a deeper investigation.

The single-family residences wired with Cu-Clad BCBW tended to be larger residences built for wealthier buyers who could afford to not use banks to purchase their homes. Nevertheless, entire neighborhoods of working-class bungalows wired with Cu-Clad were also identified.

Long Island, NY

With the assistance of Thomas J. D’Agostino, P.E., and a certified ASHI Home Inspector, the several communities were identified as having homes wired with Cu-Clad BCBW. The majority of the residences inspected were single family units and condominiums. In the case of the Snug Harbor development located in Amityville, a 167-unit condominium complex built from 1973–1975, the inspected units are located along a salt water creek with direct access to South Oyster Bay, a high saline environment. Many of the units sit steps away from the community dock where residents can rent boat slips.

Three Ways to Identify Cu-Clad BCBW within the Branch Circuit

Now that neighborhoods with Cu-Clad BCBW have been located, more details as to the condition of the installations will be forthcoming in this article. Before this, however, how can an inspector identify it within a branch circuit? The most complete and readily accessible reference material on the subject of Cu-Clad BCBW identification is found in InspectApedia.com, a free on-line encyclopedia of building and environmental inspection, testing, diagnosis, and repair. The editor of InspectApedia is Daniel Friedman of Poughkeepsie, NY. The mission of the service is to keep professional home inspectors informed and to provide a dynamic user-driven format for issues important to the readership. Electrical safety is an essential component of the mission. In the InspectApedia article “Copper-Clad Aluminum Wire Safety and History,” Freidman and D’Agostino deal with the issue of CCA identification, among others. The article notes that identification of CCA can be tricky due to the copper-clad hide. According to Friedman, “Externally, if we eschew noticing printed labels and marking that may be present on copper-clad aluminum wire, and if we simply look at the wire itself, stripped of insulation, the wire looks like copper. However, if we can take a closer look at a relatively square-cut end of the wire, we should see an aluminum core surrounded by a copper skin. Without disassembly and possibly even careful cutting of the end of the wire, this detail may not be easily visible since typical wire nippers compress the end of the wire when making a cut.”

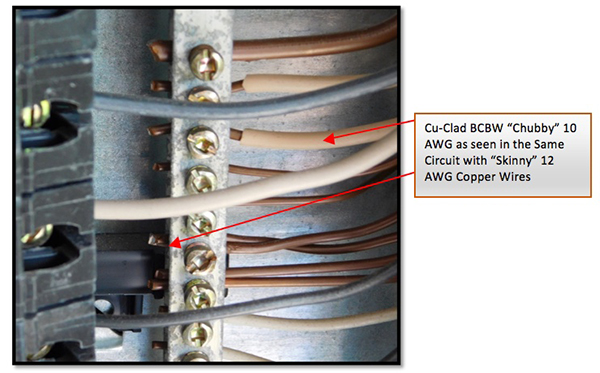

Look for Chubby Wire:

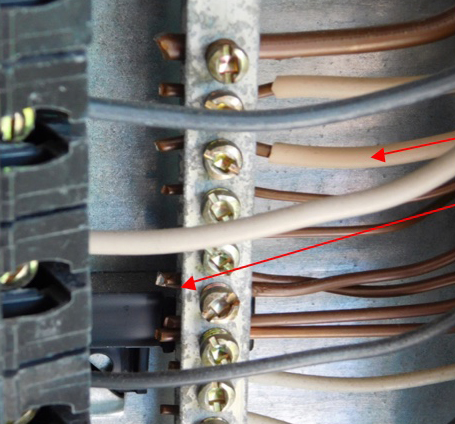

Another clue to identifying Cu-Clad BCBW in a circuit is to look for “chubby” wires. As per the NEC, Cu-Clad BCBW must be sized as if it were solid aluminum, making it appear “fat” or “chubby” in the circuit. Table 310.15(B) is the NEC reference for allowable ampacities for Cu-Clad wire diameters.

Further, Freidman and D’Agostino state, “For example, the wire gauge or diameter sizes of copper-clad aluminum wire will follow the same physical sizes as for solid core aluminum wiring. A 15-amp electrical circuit would have been wired with #12 aluminum wire, #12 copper-clad aluminum wire, or with #14 solid copper wire. We summarize these wire sizes for aluminum and copper and copper-clad wire at size of wire required for common household branch-circuit wiring, and also at SE cable sizes vs. amps including wire sizes from #14 AWG through 4/0 AWG.” This concept is reinforced in the InspectApedia article “Size of Wire Required”:

- The electrical circuit must be properly protected by the right fuse or circuit breaker.

- For a 15-amp circuit use #14 copper wire (or #12 copper-clad aluminum wire). The fuse or circuit breaker feeding this circuit is rated for 15 amps.

- For a 20-amp circuit use #12 copper wire (or #10 copper-clad aluminum wire). The fuse or circuit breaker feeding this circuit is rated for 20 amps.

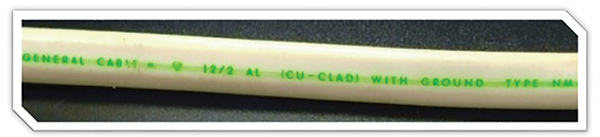

Jacket Markings:

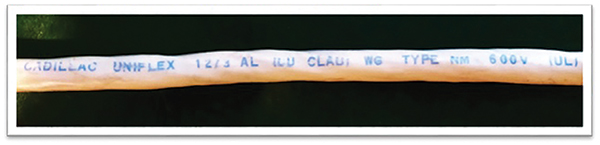

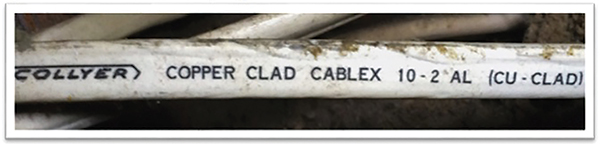

The final clue for identifying Cu-Clad BCBW in a circuit is to check the markings on the insulation jacket. From 1971–1977 there were several manufacturers of Cu-Clad NM-B and THHN: General Cable, Triangle Wire, American Insulated Wire (AIW), Collyer Insulated Wire, ETTCO Cable, Cadillac Uniflex among others. Above are examples of what you might see in the field today. These samples were harvested from active circuit installations in Nashville and Long Island. Due to the historically low cost of copper from 1980 through 2005, none of these wire manufacturers offer Cu-Clad BCBW today, and most have been absorbed by larger wire and cable companies.

Starting in 2017, some IAEI inspectors could begin to notice new Cu-Clad conductors installed in residential branch circuits. After extensive real-world field testing in overseas markets starting in 2008, the only American manufacturer of Copper Clad wire (whose patented manufacturing process is the only one in the world capable of cladding 8000 series aluminum) will reintroduce Cu-Clad NM-B and THHN into the US market. Only conductors containing 8000 series aluminum (solid or bimetal), or solid copper, can be used within residential branch circuits per current NEC requirements. For an inspector to verify that a Cu-Clad building wire is safe, not only should it carry a UL listing on the jacket, but also, it should maintain an UL Component Recognition (RU) for the Copper Clad bimetallic wire itself. The UL Component Recognition DVVU2 gives assurance to the user that the bimetal itself is legitimate, properly bonded and safe. Having both a UL listing and a UL Component Recognition (RU) assures the installer that the conductor not only meets code, but also, upholds the stringent manufacturing standards mandated by ASTM B566 for Copper Cladded Wire. The jacket markings will appear as follows: MANUFACTURER’S NAME outside of the UL legend, followed by PRODUCT SIZE * Cu-CLAD AL * PRODUCT TYPE * 600 VOLT * UL Mark. To avert confusion, the RU mark underwriting the quality of the bimetallic conductor wire is not required to be displayed on the product packaging of the finished conductor, nor is it a requirement to be displayed on the jacket. Advertising fliers inside the packaging with the RU mark are permitted. Verification of the RU can be accessed via the UL website by searching the manufacturer’s name. The color of the outer jacket for Cu-Clad NM type product will be geared to the ampacity of the circuit for which it is intended: 15 Amp Circuit: White; 20 Amp Circuit: Yellow; 30 Amp Circuit: Orange. The entire jacket could be colored, or you might see a black jacket with a wide, easily-identifiable colored stripe (the stripe color relates to the circuit type) .

Find Us on Socials