Question

A minimum 8 AWG copper bonding conductor is utilized to bond the hot and cold copper water piping rising from the ground to serve a hydromassage bathtub along with other metal components installed under the hydromassage bathtub. Why does the Code require installers to run a bonding conductor to the location of a double insulated circulating pump motor when this bond wire is not required to be connected to anything?

Answer

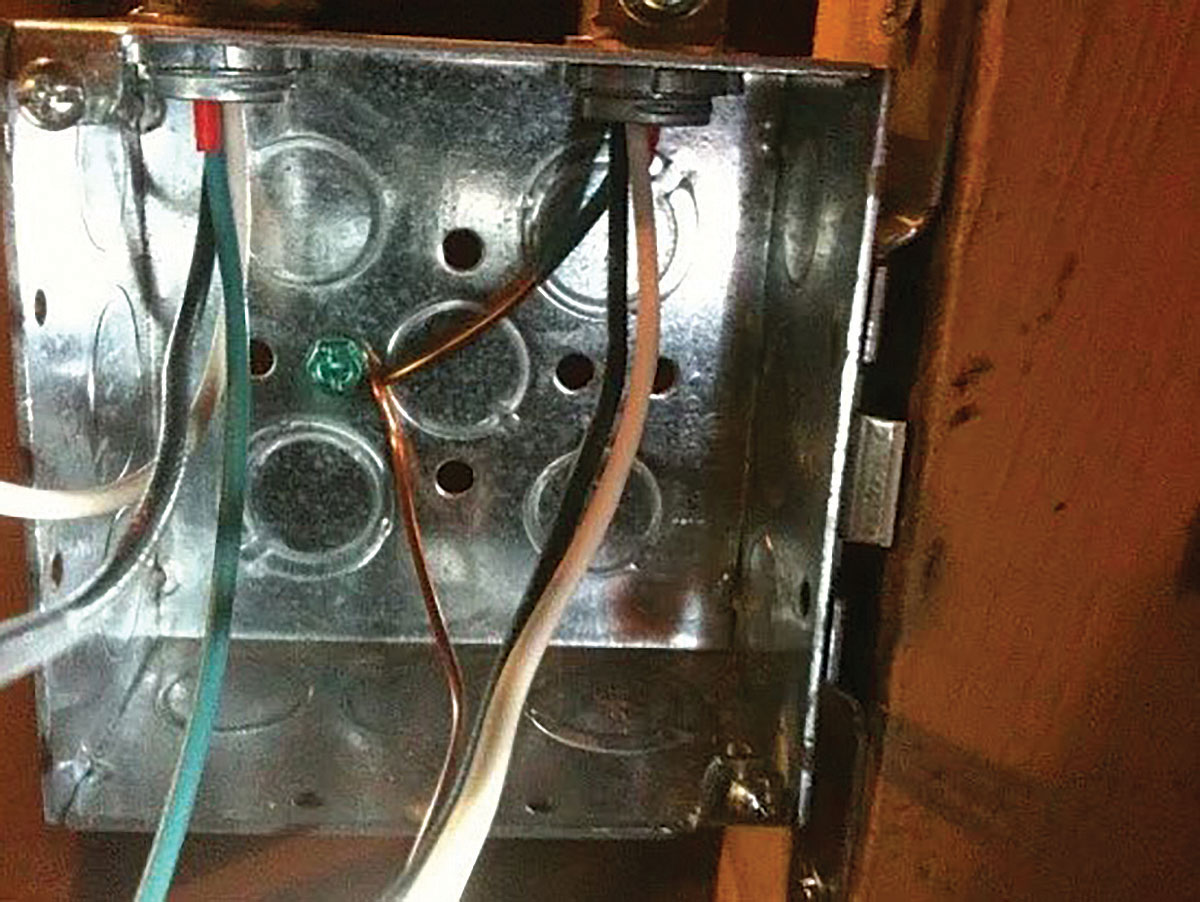

Photo 1. 8 AWG solid copper bonding jumper installed from copper water lines to hydromassage pump motor

All metal piping associated with a hydromassage bathtub and all grounded metal parts in contact with the circulating water is required be bonded together using an 8 AWG solid copper bonding jumper. This bonding jumper is required to be connected to the terminal on the hydromassage bathtub circulating pump motor. Furthermore, this bonding jumper should not be connected to a double insulated circulating pump motor (680.74). A change was implemented in the 2011 NEC at 680.74 to require an 8 AWG or larger solid copper bonding jumper long enough to terminate on a replacement non-double insulated pump motor. This bonding jumper is to terminate to the equipment grounding conductor of the branch circuit of the motor when a double insulated circulating pump motor is used. This added language here at 680.74 is similar to the wording found at 680.26(B)(6)(a) for a double insulated circulating pump motor and possible replacement at a permanently installed swimming pool. This bonding jumper for a double insulated circulating pump motor is required to be in place in the event that the double insulated motor is replaced at a future date with a non-double insulated motor, which would require the bonding jumper for bonding to associated metal components. Inspectors and installers alike will have to decide what to do with the other end of this 8 AWG or larger solid copper bonding jumper if a double insulated circulating pump motor is employed and no metal piping and no grounded metal parts are present. — Keith Lofland, IAEI Director of Education

Find Us on Socials