Whether one is involved in designing, installing, or maintaining an electrical system, protection must be of primary concern. This includes not only safeguarding equipment and facilities from damage or improper operation, but it also includes the safety of personnel who may be exposed to the hazards inherent with any electrical installation.

Relative to safety of personnel, consideration for some form of ground-fault protection must be made to prevent current flow through the body due to line-to-ground faults. This is not to be confused with ground-fault protection for equipment, which has a totally different level of protection and a totally different intent. Because of the effects of current flow through the human body, ground-fault protection for personnel typically addresses current in the 4 to 6 milliampere range. Ground-fault protection for equipment addresses electrical apparatus damage due to line-to-ground faults and looks at current several orders of magnitude higher.

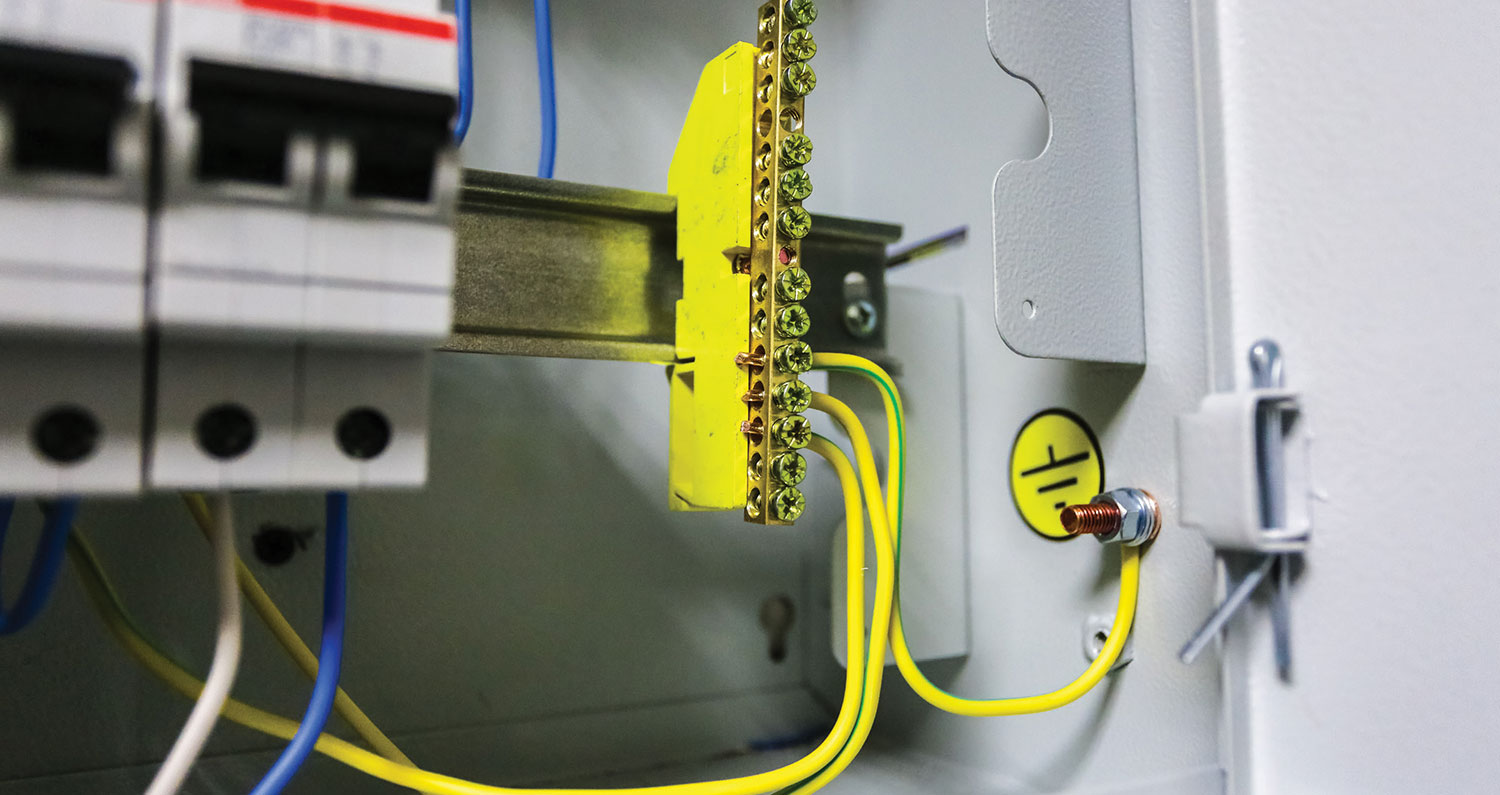

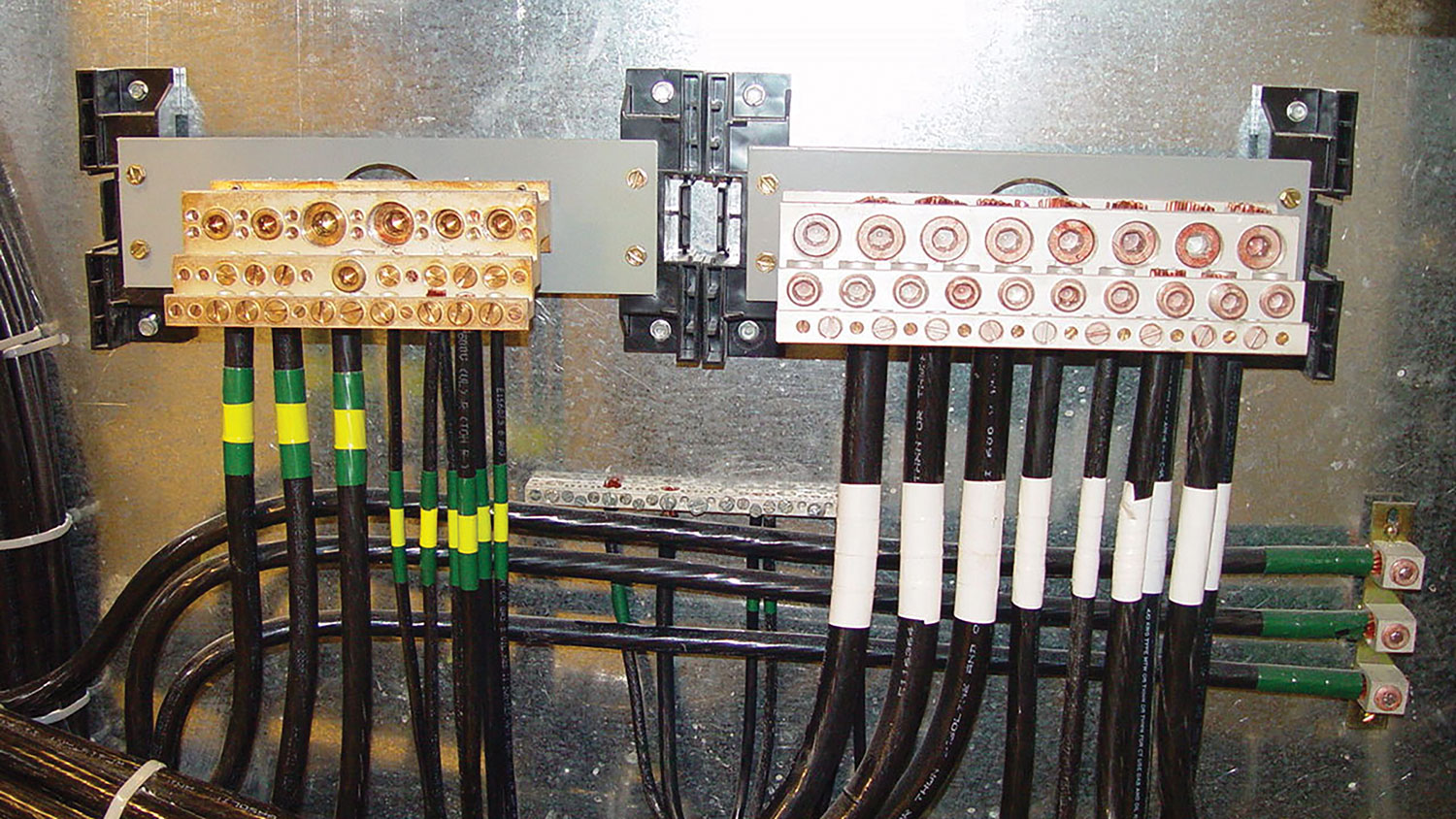

An assured equipment grounding conductor program (AEGCP) is a method of protection for personnel against ground-fault current flow through the body. The basic concept of the AEGCP is that conductive surfaces which may become energized due to line-to-ground faults and with which personnel may come in contact be properly grounded. Thus if properly grounded and a line-to-ground fault occurs, the low impedance path would allow resulting current flow to be large enough to be detected and removed by the circuit protective device. This would then de-energize the conductive surface subject to contact by personnel, removing the shock hazard.

If an AEGCP is used, it must meet several conditions. Section 305-6 of the 1999 NEC addresses the issue.

305-6. Ground-Fault Protection for Personnel.Ground-fault protection for personnel for all temporary wiring installations shall be provided to comply with (a) and (b). This section shall apply only to temporary wiring installations used to supply temporary power to equipment used by personnel during construction, remodeling, maintenance, repair, or demolition of buildings, structures, equipment, or similar activities.

(a) Receptacle Outlets.All 125-volt, single-phase, 15-, 20-, and 30-ampere receptacle outlets that are not part of the permanent wiring of the building or structure and that are in use by personnel shall have ground-fault circuit interrupter protection for personnel. If a receptacle(s) is installed or exists as part of the permanent wiring of the building or structure and is used for temporary electric power, ground-fault circuit-interrupter protection for personnel shall be provided. For the purposes of this section, cord sets or devices incorporating listed ground-fault circuit interrupter protection for personnel identified for portable use shall be permitted.

Exception No. 1: Receptacles on a 2-wire, single-phase portable or vehicle-mounted generator rated not more than 5 kW, where the circuit conductors of the generator are insulated from the generator frame and all other grounded surfaces, shall be permitted without ground-fault protection for personnel.

Exception No. 2: In industrial establishments only, where conditions of maintenance and supervision ensure that only qualified personnel are involved, an assured equipment grounding conductor program as specified in Section 305-6(b)(2) shall be permitted to be utilized for all receptacle outlets.

(b) Use of Other Outlets.Receptacles other than 125-volt, single-phase, 15-, 20-, and 30-ampere receptacles shall have protection in accordance with (1) or, the assured equipment grounding conductor program in accordance with (2).

(1) Ground-fault circuit interrupter protection for personnel.

(2) A written assured equipment grounding conductor program continuously enforced at the site by one or more designated persons to ensure that equipment grounding conductors for all cord sets, receptacles that are not a part of the permanent wiring of the building or structure, and equipment connected by cord and plug are installed and maintained in accordance with the applicable requirements of Sections 210-7(c), 250-114, 250-138, and 305-4(d).

(a) The following tests shall be performed on all cord sets, receptacles that are not part of the permanent wiring of the building or structure, and cord- and plug-connected equipment required to be grounded.

(1) All equipment grounding conductors shall be tested for continuity and shall be electrically continuous.

(2) Each receptacle and attachment plug shall be tested for correct attachment of the equipment grounding conductor. The equipment grounding conductor shall be connected to its proper terminal.

(3) All required tests shall be performed

(a) Before each use on site,

(b) When there is evidence of damage,

(c) Before equipment is returned to service following any repairs,

(d) At intervals not exceeding 3 months.

(b) The tests required in (2)(a) shall be recorded and made available to the authority having jurisdiction.1

Very similar wording on this issue can be found in Subpart K of the OSHA Construction Standard, specifically

29CFR1926.404

(b)(1)Ground-fault protection –

(b)(1)(i)General. The employer shall use either ground-fault circuit interrupters as specified in paragraph (b)(1)(ii) of this section or an assured equipment grounding conductor program as specified in paragraph (b)(1)(iii) of this section to protect employees on construction sites. These requirements are in addition to any other requirements for equipment grounding conductors.

..1926.404(b)(1)(ii)

(b)(1)(ii)Ground-fault circuit interrupters. All 120-volt, single-phase 15- and 20-ampere receptacle outlets on construction sites, which are not a part of the permanent wiring of the building or structure and which are in use by employees, shall have approved ground-fault circuit interrupters for personnel protection. Receptacles on a two-wire, single-phase portable or vehicle-mounted generator rated not more than 5kW, where the circuit conductors of the generator are insulated from the generator frame and all other grounded surfaces, need not be protected with ground-fault circuit interrupters.

(b)(1)(iii)Assured equipment grounding conductor program. The employer shall establish and implement an assured equipment grounding conductor program on construction sites covering all cord sets, receptacles which are not a part of the building or structure, and equipment connected by cord and plug which are available for use or used by employees. This program shall comply with the following minimum requirements:

(b)(1)(iii)(A)A written description of the program, including the specific procedures adopted by the employer, shall be available at the jobsite for inspection and copying by the Assistant Secretary and any affected employee.

(b)(1)(iii)(B)The employer shall designate one or more competent persons (as defined in 1926.32(f)) to implement the program.

(b)(1)(iii)(C)Each cord set, attachment cap, plug and receptacle of cord sets, and any equipment connected by cord and plug, except cord sets and receptacles which are fixed and not exposed to damage, shall be visually inspected before each day’s use for external defects, such as deformed or missing pins or insulation damage, and for indications of possible internal damage. Equipment found damaged or defective shall not be used until repaired.

..1926.404(b)(1)(iii)(D)

(b)(1)(iii)(D)The following tests shall be performed on all cord sets, receptacles which are not a part of the permanent wiring of the building or structure, and cord- and plug-connected equipment required to be grounded:

(b)(1)(iii)(D)(1)All equipment grounding conductors shall be tested for continuity and shall be electrically continuous.

(b)(1)(iii)(D)(2)Each receptacle and attachment cap or plug shall be tested for correct attachment of the equipment grounding conductor. The equipment grounding conductor shall be connected to its proper terminal.

(b)(1)(iii)(E)All required tests shall be performed:

(b)(1)(iii)(E)(1)Before first use;

(b)(1)(iii)(E)(2)Before equipment is returned to service following any repairs;

(b)(1)(iii)(E)(3)Before equipment is used after any incident which can be reasonably suspected to have caused damage (for example, when a cord set is run over); and

(b)(1)(iii)(E)(4)At intervals not to exceed 3 months, except that cord sets and receptacles which are fixed and not exposed to damage shall be tested at intervals not exceeding 6 months.

..1926.404(b)(1)(iii)(F)

(b)(1)(iii)(F)The employer shall not make available or permit the use by employees of any equipment which has not met the requirements of this paragraph (b)(1)(iii) of this section.

(b)(1)(iii)(G)Tests performed as required in this paragraph shall be recorded. This test record shall identify each receptacle, cord set, and cord- and plug-connected equipment that passed the test and shall indicate the last date it was tested or the interval for which it was tested. This record shall be kept by means of logs, color coding, or other effective means and shall be maintained until replaced by a more current record. The record shall be made available on the jobsite for inspection by the Assistant Secretary and any affected employee.2

While the AEGCP is permitted, it is only valid if all requirements are continuously met which requires correct administration and strict enforcement. Because of concerns largely with the lack of enforcement, an effort to remove the AEGCP was made during the revision cycle for the 1999 Code. This effort was based on experiences that indicated personnel were not properly protected because of improper enforcement, primarily on construction sites. During those discussions, arguments were made that lack of enforcement was not the correct reason to remove this option and that other means of protection would also be ineffective if not properly enforced. The result was that Section 305-6 was modified but the AEGCP remained as an option.

During the current revision cycle for the 2002 NEC the effort to remove the language permitting the AEGCP is again being made. Proposal 3-138a, referencing Section 305-6(a), Exception No. 2, was submitted by the panel, CMP-3, to delete Exception No. 2 in its entirety. Substantiation for the proposal was that “The sufficient availability of GFCI (Ground-Fault Circuit Interrupter) protection and proven safety record eliminates the need for this exception.” Arguments are again being made to allow AEGCP to remain in the language for those who want to use it, and who will enforce and administer its requirements correctly. The outcome for the 2002 NEC will be determined by the action of the panel during this code cycle.

Finally, it is very important to point out that a false sense of security can be created through the use of ground-fault protection for personnel, regardless of the method used. A clear understanding of the method used and the protection it affords personnel must exist. Simply because the AEGCP is used, or a device is connected to a GFCI device does not mean personnel are protected from all possible shock situations. Since the AEGCP relies on current flow high enough to be detected and removed by the circuit protective device, it does not contribute to safety of personnel in a series contact situation. Its effectiveness is also reduced in high impedance or partial ground fault situations. Further, neither the AEGCP nor the GFCI devices provide safety to personnel in line-to-line or line-to-neutral contact situations. As with other protective methods and equipment in the electrical discipline, there are specific designs for specific hazards. These must be clearly understood and the correct protection employed for the hazards present.

References

1 NFPA 70-1999,National Electrical Code, (Quincy, MA, National Fire Protection Association, 1998) p. 70-116.

2 Subpart K, OSHA Construction Standard, 29CFR 1926.404.

3 NFPA 70E-2000, “Standard for Electrical Safety Requirements for Employee Workplaces,” (Quincy, MA, National Fire Protection Association)

4 NFPA 70B-1994, “Recommended Practice for Electrical Equipment Maintenance,” (Quincy, MA, National Fire Protection Association)

5 “Soares Book on Grounding,” 7th Edition, (Richardson, TX, International Association of Electrical Inspectors)

6 Roberts, Earl W.,Overcurrents and Undercurrents, All About GFCIs,(Mystic, CT, Reptec)

Find Us on Socials