The almost two hundred pages and ninety five equations of IEEE Standard 80-2000 provide a well explained procedure for the design of safe and practical grounding systems for electric substations. There are two objectives of a safe grounding system as detailed in Clause 4.1: “To provide means to carry electric currents into the earth under normal and fault conditions without exceeding any operating and equipment limits or adversely affecting continuity of service,” and “To assure that a person in the vicinity of grounded facilities is not exposed to the danger of critical electric shock” under normal and fault conditions. One might ask, “What is dangerous about grounded facilities?” Grounded facilities are only as safe as the quality of the ground. Facilities are only safe when they are effectively grounded. Effectively grounded, as defined by the NESC on page 6, is “Intentionally connected to earth through a ground connection or connections of sufficiently low impedance and having sufficient current-carrying capacity to limit the buildup of voltages to levels below that which may result in undue hazard to persons or to connected equipment.” In other words, the second objective of Standard 80 is to make sure that all metallic non-current-carrying substation parts are effectively grounded.

Hazardous Voltages

The voltages that Standard 80 is concerned with are touch voltage, step voltage, meshvoltage, metal-to-metal touch voltage and transferred voltage. Touch voltage is the potential difference between the earth surface on which a person may stand and the surface of a facility the person is touching. Step voltage is “The difference in surface potential experienced by a person bridging the distance of 1 m with the feet without contacting any grounded object.” Mesh voltage is “The maximum touch voltage within a mesh of a ground grid.” Metal-to-metal touch voltage is “The difference in potential between metallic objects or structures within a substation site that may be bridged by direct hand-to-hand or hand-to-feet contact.” Transferred voltage is “A special case of touch voltage where a voltage is transferred into or out of the substation from or to a remote point external to the substation site.” The people that Standard 80 is trying to protect are the people who work within substations and the general public who may approach a substation. Though we can partially reduce the hazard to workers within a substation by requiring them to wear personal protective equipment like insulated footwear, the hazard to the public, someone outside the fence, can only be reduced by proper design of the grounding system.

A Typical Grounding System

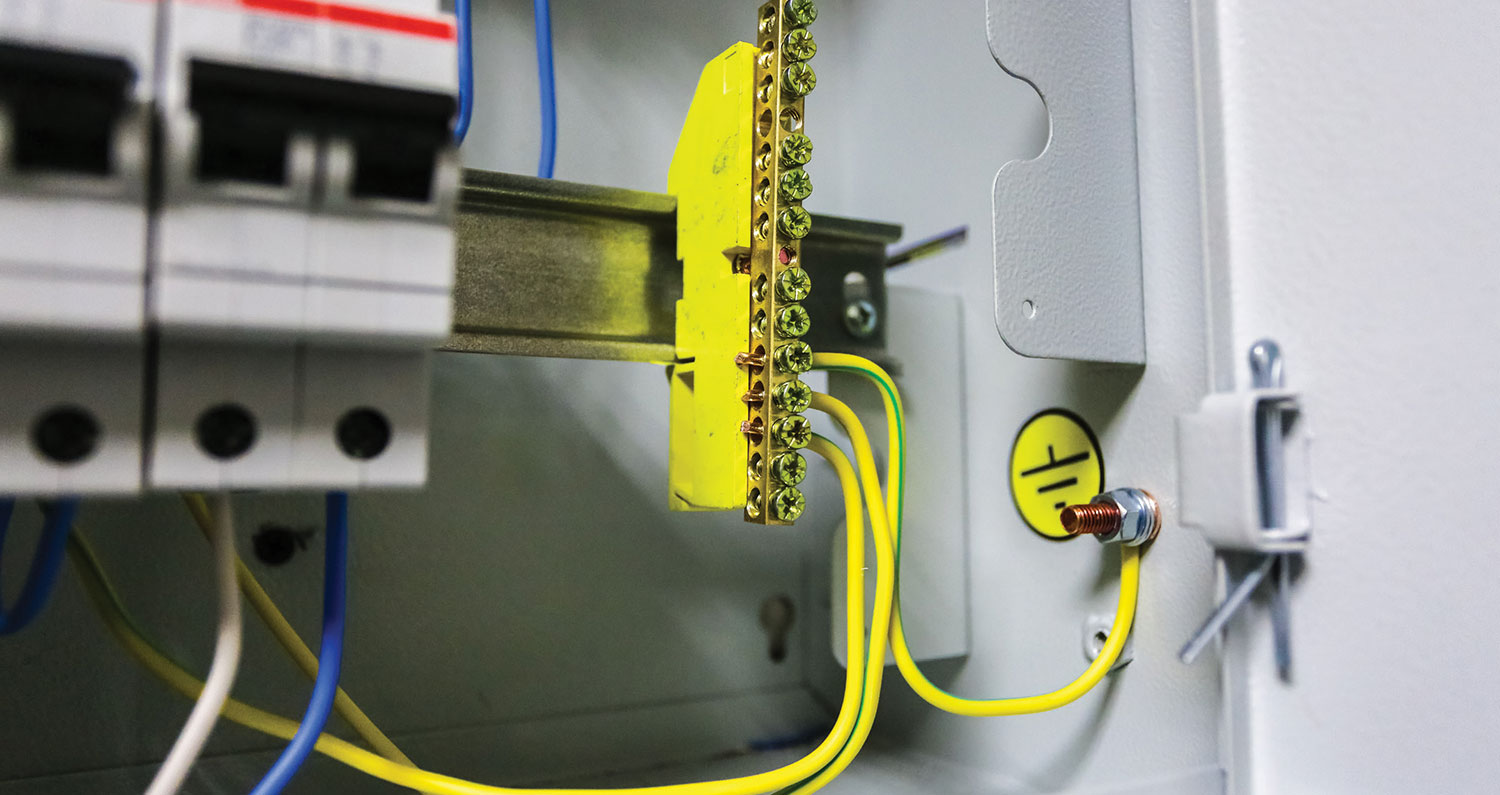

Figure 1

A typical substation grounding system designed for installation in low resistance soil per Standard 80 might look something like the following: a network of 4/0 AWG bare copper conductors buried 12 to 18 inches below grade in a grid pattern spaced 10 to 20 feet apart and extending outside the perimeter fence. [Figure 1]

At crossings, the conductors would be securely bonded. Ground rods would be securely bonded to the grid at corners and at junction points along the perimeter. All aboveground metallic facilities including structures, transformers, breakers, and fencing would be securely bonded to the grid with grounding conductors. Additional ground rods would be securely bonded to the grid at major facilities and surge arrester locations.

The Design Process

The process of design as described in Standard 80 is one of acquiring data on the proposed substation and site characteristics, developing a preliminary design, calculating the various hazardous voltages at many locations within and outside the substation to determine the relative safety of the design, modifying the design as necessary, and recalculating the hazardous voltages to insure the design meets the objectives. The process may have to be worked through many times before the objectives are achieved.

Input Data

A large part of the design process is the accumulation of data for input into the equations. The layout of the facilities to be installed in the substation must be complete. The available fault-current magnitudes must be known. In order to determine the maximum fault durations, the protection scheme must be complete. The effect of future changes must be considered. For example, making changes to an existing grounding system to accommodate increases in available fault current can be very expensive. The soil resistance characteristics must be measured at the site of the proposed substation.

Soil Resistance

Soil resistance is often the most difficult information to obtain. The electrical resistance of soil varies with soil temperature, soil moisture content, current magnitude, and soil type. Since soil type often varies with depth and location, the soil resistance profile at a proposed substation site may be quite complex. It is rare to find uniform soil resistance over the entire area and at various depths. The discussion of soil characteristics starts in Clause12 of Standard 80. “To determine the actual soil resistivity, tests such as those described in IEEE Standard 81-1983 should be performed” (Clause 12.4).

IEEE Standard 81-1983

IEEE Standard 81 is the IEEE Guide for Measuring Earth Resistivity, Ground Impedance, and Earth Surface Potentials of a Ground System. The most accurate method for measuring soil resistance is what they call the Wenner four-point method. This method is discussed in detail in section 7, page 12 of Standard 81. The four point method consists of driving four short ground rods into the soil, placed in a straight line, separated by a distance (a). The rods are only driven into the ground to a depth (b) = a /10. The test instrument induces a current (I) into the soil between the two outer rods and then measures the voltage (V) on the two inner rods. The resistance is equal to the voltage divided by the current (V/I). The instrument does the calculation. The instrument reading then has to be multiplied by 2pa to get the average resistance.

Photo 2

The resistance we measure with a rod separation of 2 meters is the average resistivity of the soil to the depth of 2 meters. The resistance we measure with a rod separation of 4 meters is the average resistivity of the soil to the depth of 4 meters. If the 2-meter resistance and the 4-meter resistance are different, then the soil type, moisture content, and/or temperature of the top two meters of soil is different from the bottom two meters of soil. One instrument, which can be used to measure the soil resistance, is shown in photo 2.

The soil resistance measurement instruments cost from $1800 to $4500 and it is not uncommon for two people to spend three days taking measurements at a 100 m by 100 m site. The goal is to develop a three dimensional analysis of soil resistance. Many measurements should be taken on the site including measurements at various depths. The number of measurements necessary to obtain an adequate resistance profile for a site is dependent upon the variability of the soil. It is common to find several layers with dramatic differences in resistance below the surface. Changes in lateral resistance are usually more gradual. The number of measurements should be increased in areas of great change in resistance and in areas of high resistance. Interpretation of the soil resistivity measurements and the development of a soil model are the most difficult part of soil data procurement. In Part 3, I will talk about soil model development and continue with the design process.

Find Us on Socials