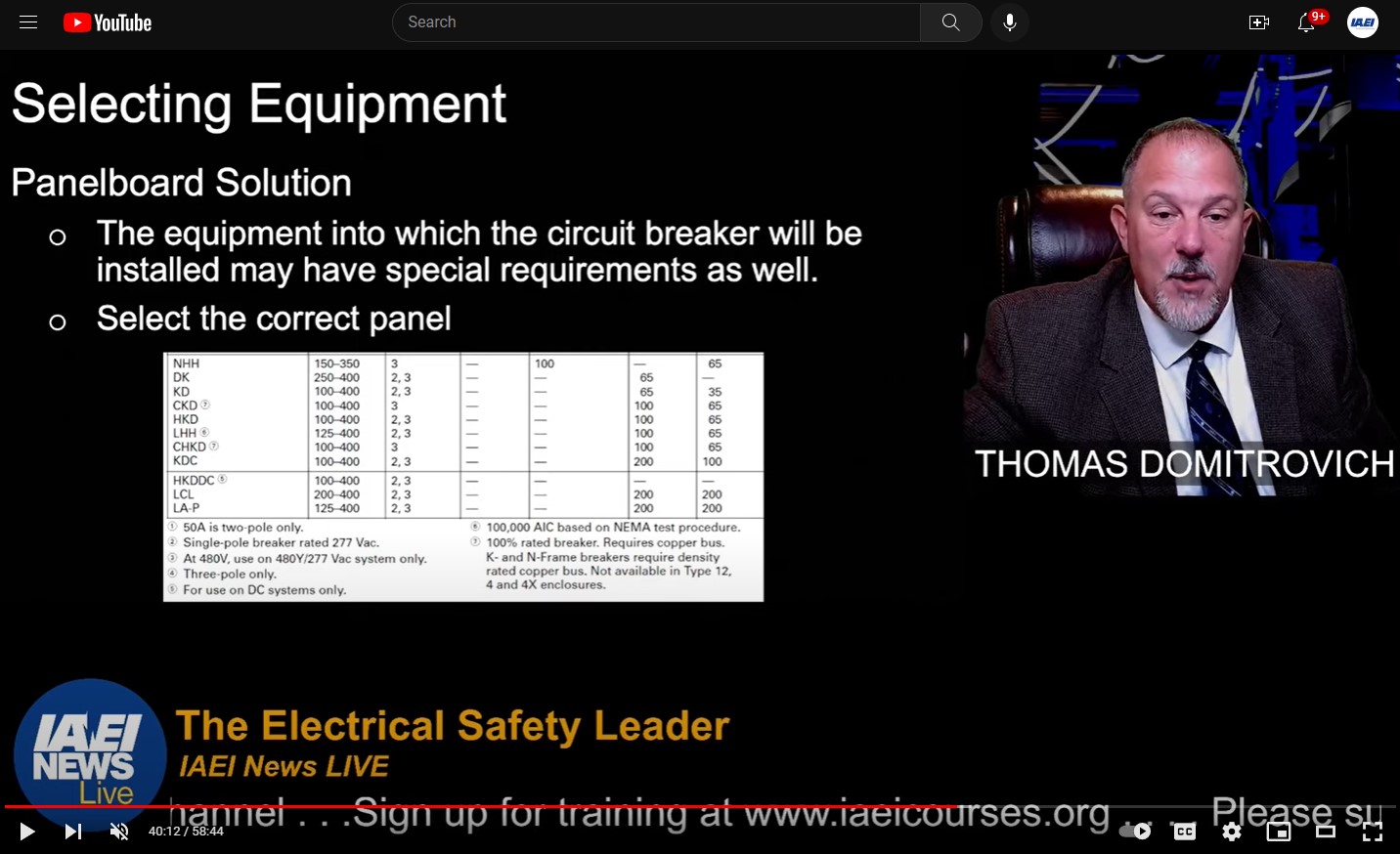

There are several requirements in theNational Electrical Code® (NEC®) that call for the total selective coordination of various systems. However, this can result in increasing the downstream arc flash hazard should energized (hot) work be required. Code-making Panel 10 (CMP-10) accepted a proposal for the 2011 NEC in an attempt to address this concern.

2011 NEC

The new section added to Article 240 requires the use of zone selective interlocking (ZSI), differential relaying, energy-reducing maintenance switching or an approved equivalent means where a circuit breaker without an instantaneous trip function is used.

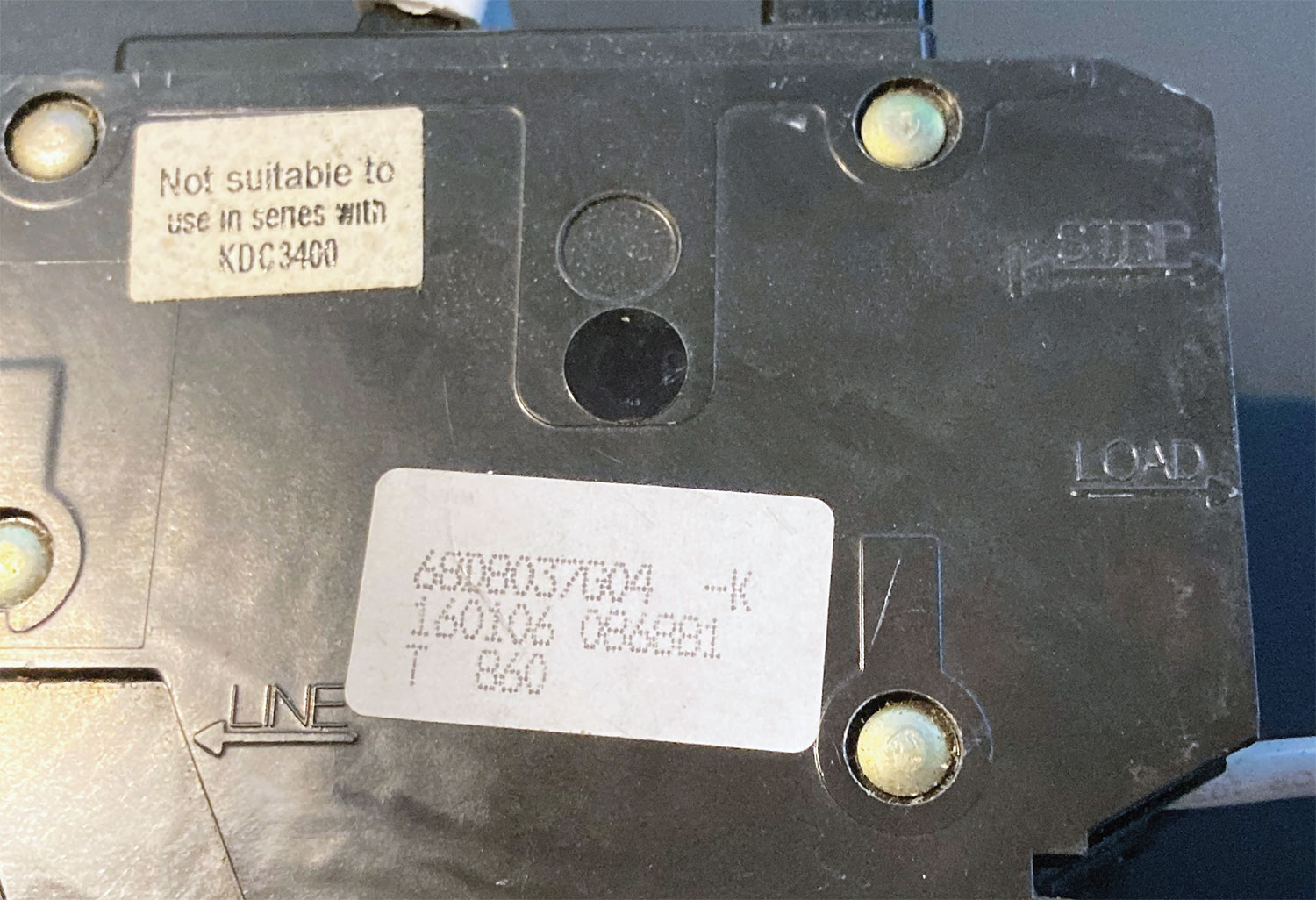

Photo 1. MCCB with LSIG Trip Unit

The Code text reads as follows:

240.87 Noninstantaneous Trip.

Where a circuit breaker is used without an instantaneous trip, documentation shall be available to those authorized to design, install, operate, or inspect the installation as to the location of the circuit breaker(s).

Where a circuit breaker is utilized without an instantaneous trip, one of the following or approved equivalent means shall be provided:

(1) Zone-selective interlocking

(2) Differential relaying

(3) Energy-reducing maintenance switching with local status indicator

Photo 2. LSI Trip Unit

Informational Note: An energy-reducing maintenance switch allows a worker to set a circuit breaker trip unit to “no intentional delay” to reduce the clearing time while the worker is working within an arc-flash boundary as defined in NFPA 70E-2009, Standard for Electrical Safety in the Workplace, and then to set the trip unit back to a normal setting after the potentially hazardous work is complete.

What does it mean?

In its statement on comment 10-41, CMP-10 clarified that the new requirement pertains to the absence of an instantaneous trip function, not the absence of an instantaneous trip setting. This means that a circuit breaker with the adjustable instantaneous trip function set to OFF would not require one of the means specific in 240.87.

Electronic trip units without an instantaneous trip function are typically designated “LS” or “LSG,” where the “L” stands for long time, the “S” stands for short time and the “G” stands for ground-fault. Circuit breakers with LS or LSG trip functions would require the documentation and one of the means specified in 240.87.

Electronic trip units with an instantaneous trip function are typically designated “LI,” “LSI” or “LSIG,” where the “I” stands for instantaneous. Circuit breakers with LI, LSI or LSIG trip functions would not require the documentation and one of the means specified in 240.87, even if the “I” setting switch has an OFF position.

Most manufacturers now offer an instantaneous OFF position on their LSI or LSIG trip units, thus allowing the installer to set the trip unit for LS or LSG functionality in the field.

This section does not apply to thermal-magnetic circuit breakers as they all have an instantaneous trip function.

Other Issues

Photo 3. LVPCB with LSIG Trip Unit

The panel statement on comment 10-41 seems to indicate that the concern of CMP-10 regarded the field adjustable instantaneous trip function on a circuit breaker. This is important to distinguish as an electronic trip molded or insulated case circuit breaker listed to UL 489 or certified to CSA C22.2 No. 5 may have two or more instantaneous trip functions. Low voltage power circuit breakers listed to UL 1066 may have three or more instantaneous trip functions.

Also, if the arc flash hazard is to be effectively reduced, it is important that the instantaneous trip function be set below the prospective arcing fault current, a point that neither the proposal nor the panel action addressed.

Are there other ways to reduce the arc flash hazard?

There are other ways that can be employed to reduce the arc flash hazard, such as reducing the fault current, using faster acting overcurrent protective devices or by using a virtual main with ZSI.

Find Us on Socials