In many electrical installations today, some protection needs extend beyond the installation requirements of the Code. Static electricity and the buildup of static charges are major concerns in many installations such as data processing centers, semiconductor facilities, and many hazardous (classified) locations. In the information technology (IT) world, minimizing static electricity and circulating currents is a concern for protection of sensitive electronic equipment and events leading to data losses. In hazardous (classified) locations, on the other hand, electrical wiring, including the grounding and bonding circuits, is extremely important for safety of persons and property. Because sources of ignition are a primary concern in explosive atmospheres, it is often necessary to provide a more enhanced protection system of handling static electricity in hazardous locations. Therefore, many engineering designs in these types of electrical installations incorporate a system of protection from static electricity. This article takes a basic look at some of these concerns, some fundamentals of static electricity, and some protection techniques that can be used to provide additional protection from static electricity.

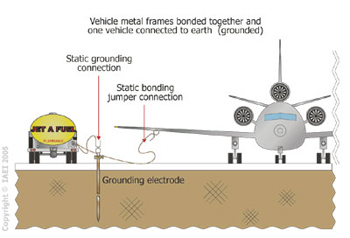

Photo 1. Static grounding and bonding equipment in operation while fuel is being transfered

Humidity and Its Impact

Grounding of equipment is not necessarily a solution to static problems. Each problem requires its own study and solution, though humidity plays an important part in the degree of concern. The higher the humidity the less chance there is of a static discharge occurring. In some industries, increasing humidity in the area of a static discharge has been found effective in dissipating the charge. One example is in the printing industry.

While humidification does increase the surface conductivity of the material, the charge will dissipate only if there is a conductive path to ground. Surface resistivity of many materials can be controlled by the humidity of the surroundings. At a humidity of 65 percent and higher, the

Photo 2. Connection of static bonding and grounding equipment to mobile tank vessel during the loading process

surface of most materials will adsorb enough moisture to ensure a surface conductivity that is sufficient to prevent accumulation of static electricity. When humidity falls below about 30 percent, these same materials could become good insulators, in which case accumulation of charge would increase. It should be emphasized again that humidification is a not a solution for all static electricity problems encountered, because some insulating materials do not adsorb moisture from the air and high humidity will not noticeably decrease their surface resistivity. Examples of such insulating materials are uncontaminated surfaces of some polymeric materials, such as plastic piping, containers, and the surface of most petroleum liquids [NFPA 77 6.4.2.3].

Static Electricity Ignition Source

It should be clearly understood that the primary goal in providing static protection is to eliminate the ignition source of the fire triangle. The degree of additional protection needed is specific to each condition encountered. There are no mandatory electrical code requirements to provide such protection; however hazards do exist and must be considered for safety. Generally, the type of installation, type of explosive or flammable atmosphere (dust or gases) and the natural environment are all contributing factors to the degree or extent of static electricity as an ignition source. For a static electricity discharge to be a source of ignition, the following four conditions must exist simultaneously:

1. An effective means of separating charge must be present.

2. A means of accumulating the separated charges and maintaining a difference of electrical potential must be available.

3. A discharge of the static electricity of adequate energy must occur.

4. The discharge must occur in an ignitible mixture [NFPA 77 – 4.3.1].

Sparks from ungrounded charged conductors, including the human body, are responsible for most fires and explosions ignited by static electricity. Sparks are typically intense capacitive discharges that occur in the gap between two charged conducting bodies, usually metal. The ability of a discharge spark to produce ignition or explosion is directly related to its energy, which will be some fraction of the total energy stored in the conductive object.

Beyond the NEC

The NEC refers, through a fine print note, to the Recommended Practice on Static Electricity, NFPA 77-2000. It is important to emphasize that these methods of protection for static electricity and static ignition sources must overlay the requirements of the Code and are never intended to substitute for those requirements.

Definitions

Static Electric Discharge. A release of static electricity in the form of a spark, corona discharge, brush discharge, or propagating brush discharge that might be capable of causing ignition under appropriate circumstances [NFPA 77 3.1.16].

Static Electricity. An electric charge that is significant only for the effects of its electrical field component and that manifests no significant magnetic field component [NFPA 77 3.1.17].

Static Electricity Basics

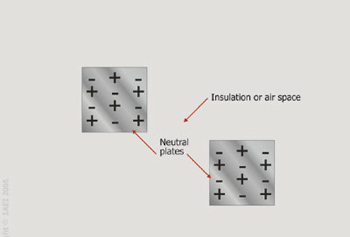

Figure 1. Two metal plates (conductors) each with like charges

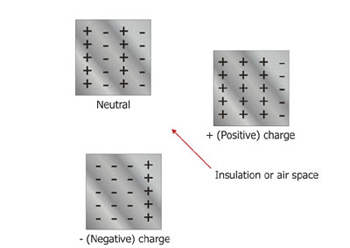

All matter, whether liquid or solid, is made up of various arrangements of atoms. Atoms are made up of positively charged protons and neutrons with no charge, which together form the nucleus or core of the atom; negatively charged electrons surround the nucleus. Atoms are considered to be electrically neutral in their normal state; basically this means that there are equal amounts of positive and negative charge present. Atoms can become what is referred to as “”charged”” when excess, or a deficiency, of electrons exist relative to the neutral state (see figures 1 and 2).

Figure 2. Two metal plates (conductors) with unlike charges

In electrically conductive materials, such as metals of the ferrous and nonferrous types, electrons move freely. In materials made up of insulating material such as plastic, glass, motor oil, etc., electrons are bonded more tightly to the nucleus of the atom and are not free to move. Some examples of electrically conductive materials are wire, metallic enclosures, bus bars, etc, while insulating materials include such items as glass, petroleum-based products, paper, rubber, etc.

In insulating materials in the form of fluids, an electron can separate from one atom and move freely or attach to another atom to form a negative ion. The atom losing the electron then becomes a positive ion. Ions are charged atoms and molecules.

Figure 3. A person holding up a static charge

Elimination or separation of the charge generally cannot be prevented absolutely, because the origin of the charge lies at the interface of materials. When materials are placed in contact, some electrons move from one material to the other until a balance (equilibrium condition) in energy is reached. This charge separation is most noticeable in liquids that are in contact with solid surfaces and in solids in contact with other solids. The flow of clean gas over a solid surface produces negligible charging [NFPA 77- 4.1.8]. This is the primary reason for the gasoline dispensing hazard warnings at motor fuel dispensers. It is important to observe and adhere to all warnings and directions relative to the transfer of gasoline to a motor vehicle or portable container. Always place portable gasoline containers on the ground when filling them, otherwise the charging currents allow static charges to build without a path to dissipate. The possibilities of ignition or explosion of gasoline vapors during these types of operations is increased when all appropriate safety procedures are not followed. Elimination of differences of potential (voltage) between objects reduces these hazards.

Static Discharge and Separation

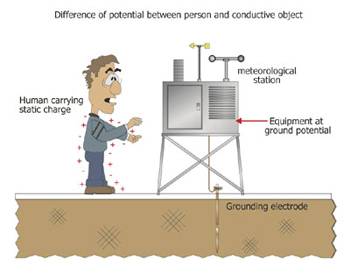

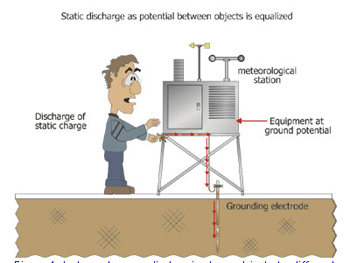

Figure 4. A charged person discharging to an object at a different potential. In this case, it is a grounded object

A capacitor is described basically as two conductors that are separated by an insulating material. In static electric phenomena, the charge is generally separated by a resistive barrier, such as an air gap or form of insulation between the conductors or by the insulating property of the materials being handled or processed. In many applications, particularly those where the materials being processed are nonconductive (charged insulators), measuring potential differences is challenging to say the least.

One is probably most familiar with the common static charge built up by walking or scuffing the feet on carpet fibers. People are conductors of electricity and thus are capable of holding a static charge. Release of such static charges is also a familiar experience for most individuals. Children often are amused and entertained when this phenomenon is first realized. Electrical static charging results from rubbing materials together and is known as triboelectric charging. It is the result of exposing surface electrons to a broad variety of energies in an adjacent material, so that charge separation (discharge) is likely to take place. The breakup of liquids by splashing and misting, or even flow in some instances, results in a similar charge release. It is only necessary to transfer about one electron for each 500,000 atoms to produce a condition that can lead to a static electric discharge. Surface contaminants at very low concentrations can play a significant role in charge separation at the interface of materials.

Electrically conductive materials can become charged when they are in the vicinity of another highly charged surface. Electrons in the conductive material are either drawn toward or forced away from the region of closest approach to the charged surface, depending on the nature of the charge on that surface. Like charges will repel and unlike charges will attract. If electrically conductive material that is charged is connected to ground or bonded to another object, additional electrons can pass to or from ground or the object. If contact is then broken and the conductive material and charged surface are separated, the charge on the isolated conductive object changes. The net charge that is transferred is referred to as an induced charge.

The basic objective when dealing with concerns and hazards of static electricity and stray voltages is to try to eliminate, or at least minimize, any differences of potential between electrically conductive objects and other objects and the ground. Potential difference, that is, the voltage, between any two points is the work per unit charge that would have to be done to move the charges from one point to the other. Work must be accomplished to separate charges, and there is a tendency for the charges to return to a neutral (uncharged) condition. Separation of electric charge might not, in itself, be a potential fire or explosion hazard. There must be a discharge or sudden recombination of separated charges to create arcing to pose an ignition hazard. One of the best methods of providing protection from static electric discharge is constructing an electrically conductive or semi-conductive path that will allow the controlled recombination of charges and dissipation of charges (usually to earth). Two terms used most often when providing protection from static electricity and lightning are grounding or one of its derivatives, and bonding or one of its derivatives.

Photo 3. Static protection equipment (manual type) used for establishing bonding connection between a fuel additive storage tank and mobile vessels or portable containers during the transfer process

Definitions of Grounding and Bonding

From NFPA 70

Grounded.Connected to earth or to some conducting body that serves in place of the earth [NFPA 70 Article 100].

Bonding (Bonded).The permanent joining of metallic parts to form an electrically conductive path that ensures electrical continuity and the capacity to conduct safely any current likely to be imposed [NFPA 70 Article 100].

From NFPA 77

Grounding.The process of bonding one or more conductive objects to the ground, so that all objects are at zero (0) electrical potential; also referred to as “earthing” [NFPA 77 – 3.1.10]. Keep in mind that the term earthing is not currently a defined term.

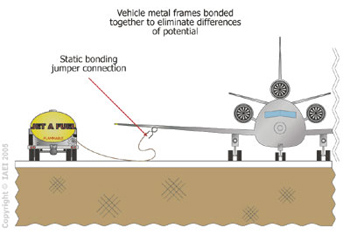

Bonding.The process of connecting two or more conductive objects together by means of a conductor so that they are at the same electrical potential, but not necessarily at the same potential as the earth [NFPA 77 – 3.1.2].

Application of the Terms

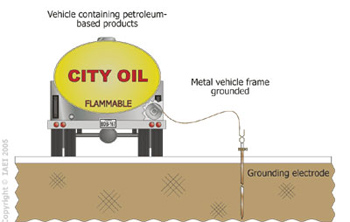

So for all practical purposes, when the term grounding is used, it should be thought of as including a connection or path to the earth to put electrically conductive materials at the same potential as the earth. When the term bonding is used, it should be thought of as connecting electrically conductive materials together to eliminate differences of potential between them and form one conductive mass. Note that bonding generally includes a path to the earth, but the earth is not referred to in the definition. See figures 5, 6, and 7 that graphically demonstrate the differences between the two concepts and also show the two working together to provide desired protection. It can be concluded that bonding conductive parts together minimizes potential differences between them, even when the resulting system is not grounded. Grounding (earthing), on the other hand, equalizes potential differences between the objects and the earth. The relationship between bonding and grounding is shown in the figures 5, 6, and 7.

Figure 5. A vehicle connected to the earth (grounded)

Controlling Static Electricity Ignition Hazards

Ignition hazards from static electricity can be controlled by the following methods:

1. Removing the ignitible mixture from the area where static electricity could cause an ignition-capable discharge

2. Reducing charge generation, charge accumulation, or both by means of process or product modifications

3. Neutralizing the charges

Grounding isolated conductors and air ionization are primary methods of neutralizing charges.

Resistance in the Path to Ground

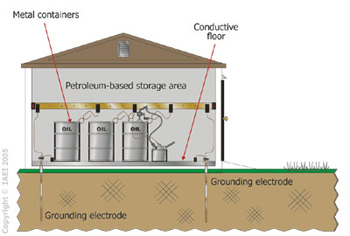

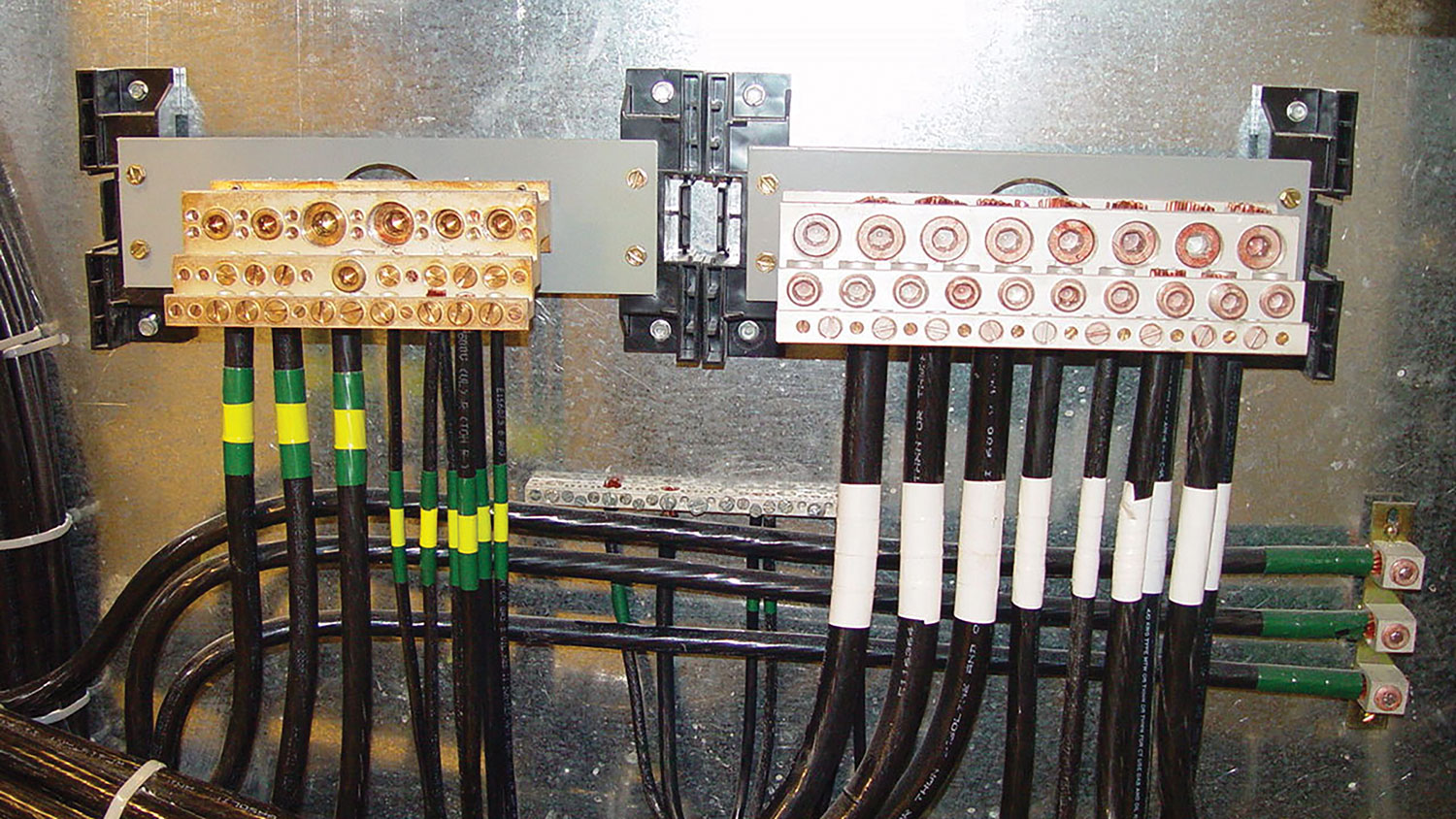

Figure 8. Drum containers with oil-based products in a storage room with a static grounding and bonding system employed at that location

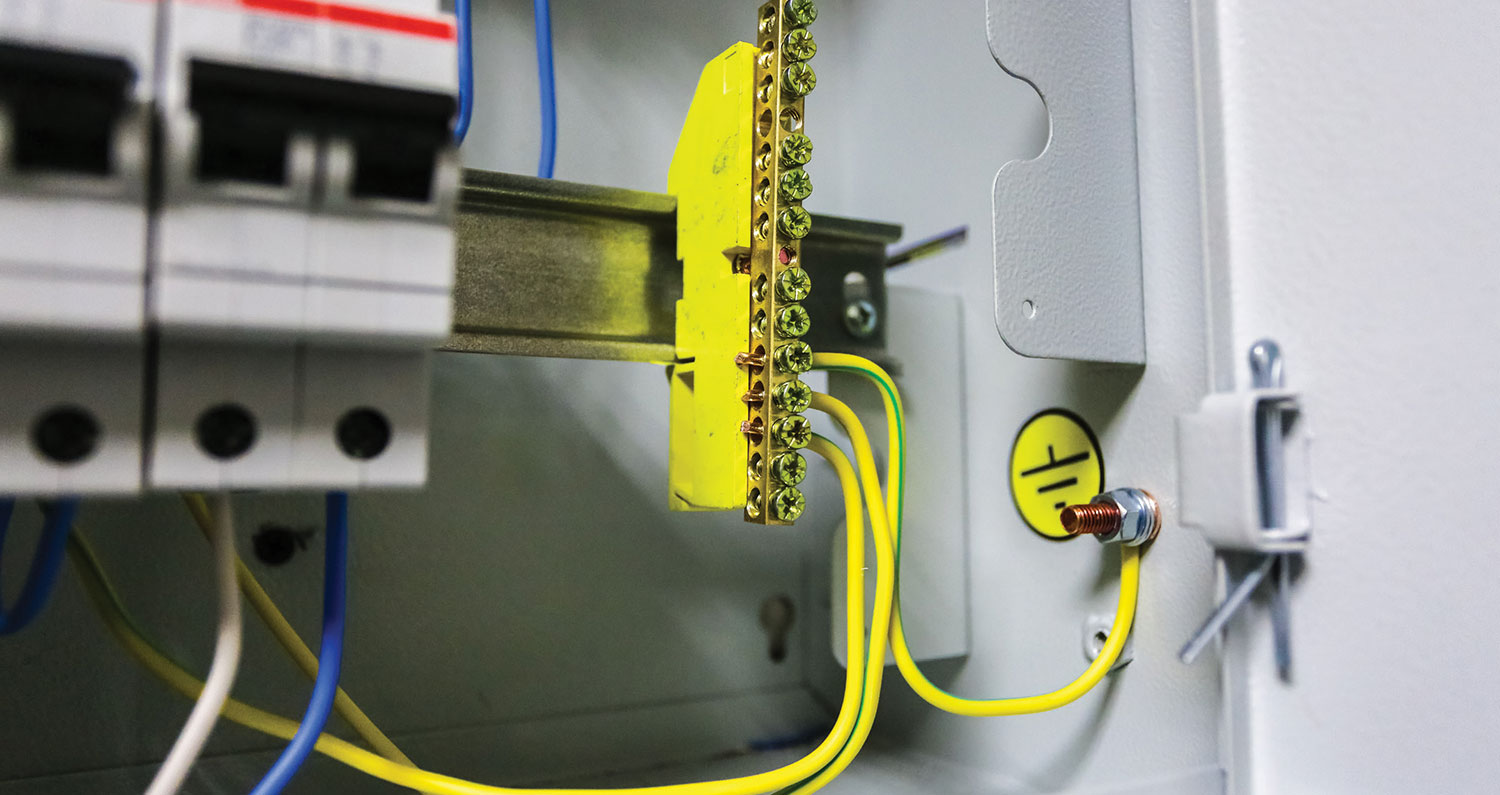

To prevent accumulation of static electricity in conductive equipment, the total resistance of the path to earth (grounding path) should be minimal to dissipate charges that are otherwise likely to be present. The basic goal here is to create a path of dissipation that will not be subject to the negative effects of pressure piling of electrons. A resistance of 1 megohm (106 ohms) or less is generally considered adequate. Where the bonding/grounding system is all metal, resistance in continuous ground paths will typically be less than 10 ohms. Such systems generally include multiple component systems. Greater resistance usually indicates the metal path is not continuous, usually because of loose connections or the effects of corrosion. A grounding system that is acceptable for power circuits or lightning protection is more than adequate for a static electricity grounding system.

The NEC provides rules for sizing grounding and bonding conductors. Tables 250.66 and 250.122 are provided for this purpose. Sizing grounding and bonding conductors for static protection differs because their primary purpose is different. Where electrical conductors of the wire-type are used for static protection, the minimum size of the bonding or grounding wire is dictated by mechanical strength, not by its current-carrying capacity. Stranded or braided wires should be used for bonding wires that will be connected and disconnected frequently [NFPA 77

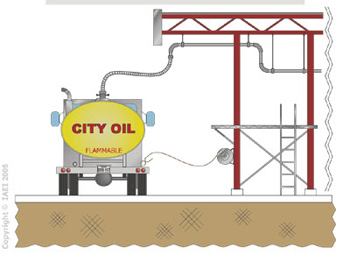

Figure 9. A typical petroleum-based product transfer from a bulk storage facility

6.4.1.3]. Grounding conductors can be insulated (e.g., a jacketed or plastic-coated cable) or uninsulated (i.e., bare conductors). Uninsulated electrical conductors (wires) are recommended, because it is easier to detect defects in them.

Liquids Flowing through Pipes

Charge separation occurs when liquids flow through pipes, hoses, and filters; when splashing occurs during transfer operations; or when liquids are stirred or agitated. The greater the interface areas between liquid and surfaces and the higher the flow velocity, the greater the rate of charging. Charges become mixed with the liquid and are carried to receiving vessels where they can accumulate. The charge is often characterized by its bulk charge density and its flow as a streaming current to the vessel. Examples of this situation are where fuel is transferred from a larger mobile or stationary vessel to a smaller vessel, or where gasoline is dispensed from a dispenser to a passenger vehicle.

In fuel bulk storage facilities, where the amount of product being transferred is great, concerns for appropriate levels of protection from static electricity are amplified. Static bonding and grounding systems and equipment are manufactured specifically for providing this type of protection. These systems are often interlocked with pumping operations to not allow fuel or oil flow in the piping systems until they have been connected. Other types of protection involve only a mechanical connection between the bulk storage tank and smaller vessel without an electrical interlocking system (see photos 1 and 2). These types of operations are also often observed at an airport where aircraft is being fueled by mobile vehicles.

Grounding Storage Tanks for Nonconductive Liquids

Storage tanks for nonconductive liquids should be grounded properly. Storage tanks on foundations constructed on the earth are considered inherently grounded, regardless of the type of foundation (e.g., concrete, sand, or asphalt). For tanks on elevated foundations or supports, the resistance to ground could be as high as 100 ohms and still be considered adequately grounded for purposes of dissipation of static electric charges, but the resistance should be verified in these cases for assurances that an adequate path to ground is achieved. Addition of grounding rods and similar grounding systems will not reduce the hazard associated with static electric charges apparent in the liquid [NFPA 77 7.5.2.2].

Basic Static Concerns with Combustible Dust

Combustible dust is defined as any finely divided solid material 420 µm or smaller in diameter (i.e., material that will pass through a U.S. No. 40 standard sieve) that can present a fire or deflagration hazard. For a static electric discharge to ignite a combustible dust, the four conditions listed in paragraph four need to be met.

A sufficient amount of dust suspended in air needs to be present in order for an ignition to achieve sustained combustion. This minimum amount is called the minimum exposable concentration (MEC). It is the smallest concentration, expressed in mass per unit volume, for a given particle size that will support a deflagration when uniformly suspended in air.

For historical reasons, the ability of a solid to transmit electric charges is characterized by its volume resistivity. For liquids, this ability is characterized by its conductivity.

Powders are divided into the following three groups:

(a) Low-resistivity powders having volume resistivities in bulk up to 108 ohm-m. Examples include metals, coal dust, and carbon black.

(b) Medium-resistivity powders having volume resistivities between 108 and 1010 ohm-m. Examples include many organic powders and agricultural products.

(c) High-resistivity powders having volume resistivities above 1010 ohm-m. Examples include organic powders, synthetic polymers, and quartz [NFPA 77 8.4.2.1].

Powders with lower resistivity are prone to effects of static charges and can become charged during flow. The charge rapidly dissipates when the powder is conveyed into a storage device or container that is grounded. However, if conveyed into a nonconductive container, the accumulated charge can result in a spark as the charge in the dust and power attempts to equalize potential differences during this process.

Minimizing charging effects and differences of potential are critical for safety from fire and explosions related to these types of operations. The Code addresses bonding of metal duct systems only by a reference from a fine print note [see Section 250.104(B) FPN]. Although it is clear that this type of bonding is not a requirement of the NEC in accordance with 90.5(C), it may well be a requirement contained in other NFPA standards applicable to particular installations or special occupancies. Even if this type of protection is only a recommended practice, experience has shown that these are the best and most common practices and are usually implemented.

Summary

This article was not intended to be totally inclusive of all concerns and methods of protection for static electricity, but only to raise a level of awareness about the hazards and where information can be obtained to assist in implementing appropriate protection systems. The NEC provides a reference through a fine print note (FPN) to Recommended Practice on Static Electricity, NFPA 77-2000. The American Petroleum Institute (API) also has produced a document titled Protection Against Ignitions Arising Out of Static Lightning and Stray Currents API RP 2003-1998. There is also excellent information in the IEEE Green Book Section 3.2 and 3.3 about static electricity and protective measures that can be taken.

Find Us on Socials