In most areas of the country, building construction is booming, and there is a huge need for and use of temporary construction power. As electrical inspectors and installers in the field, we either inspect, install, or otherwise work with these types of installations frequently, if not daily. That being the case, it can be easy to become too comfortable with electrical equipment that is commonplace and all around us. We may often be a little complacent regarding temporary electrical power. Installations with compromised Code requirements would never be allowed, but often are accepted in temporary service installations for expediency, because “That’s the way we’ve always done it,” or because others aren’t addressing the issue, or even because of the attitude that is prevalent in many minds in the construction trades — It’s only temporary! Keep your shirt on! Or as our Aussie friends say, No worries!

Temporary services can create challenges for installers and inspectors. This article focuses on temporary services, temporary service equipment short-circuit current ratings, common Code violations that may be found in temporary service installations, and the need for comprehensive inspections every time a service is installed, whether temporary or permanent.

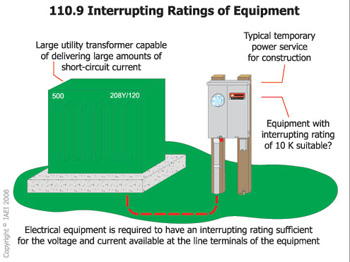

Figure 1. Service equipment installed close to a transformer with large kVA capacities require suitable equipment short-circuit interrupting ratings.

Common Code violations indicate that there is somewhat of a lax attitude toward temporary power services. Hazards exist every day on construction sites. Let’s not add to the problem! Some perils are obvious, such as the possibility of a fall from an upper level of a high-rise building. Others may be just as real, but not as apparent. One such item is short-circuit protection and ratings of temporary electrical service equipment. The classic example is a temporary service rated 200 amperes or less, that is supplied from a 500 kVA or larger transformer and located immediately next to the service equipment, with a very short length of service conductor (see figure 1).

Photo 2. Temporary service

In this case, a ground fault in the electrical service equipment could result in high levels of fault current flowing into equipment that most often does not have a sufficient interrupting rating, possibly causing an explosion and/or damaging life and property. This type of installation would not comply with NEC 110.9 and 110.10, yet is commonplace. Many types of accidents occur on construction sites. A ground fault could easily occur when a temporary service is struck and knocked down by construction equipment. Overhead conductors may be snagged by a truck or forklift mast, etc., even if all Code minimum clearances were complied with. But not to worry; after all, it’s only temporary, right?

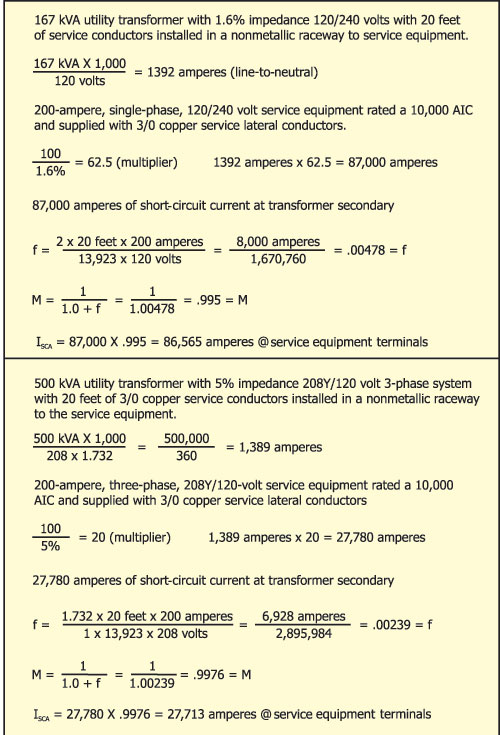

This is an issue, however, that many jurisdictions have not addressed. Again, it appears that there is an attitude of complacency. Is that a good reason not to require at least the minimum level of code-compliance? Some may ask, Where’s the ‘body count’? Remember that not every Code rule exists because of a death or injury, though that does get people’s attention, at least for a while. The rule may be totally appropriate, and necessary to a safe installation. Another concern is that requiring electrical equipment for temporary services to have adequate interrupting ratings would result in an uproar from the construction community, because of the additional cost for equipment with higher fault-current ratings. The minimum requirements of the Code apply whether the service is temporary or not. Appropriately rated equipment can be added, and the job can be done without a huge expense, though you are practically guaranteed to hear, We’ve never had to do that before! That’s true in many cases. But electrical systems and installations have improved greatly over the years for safety and usability, as has the NEC; and as an industry, we are learning all the time, or should be, as our trade is constantly changing. It should be noted that the calculations found in figure 2 are based on an infinite current supply from the serving utility.

Figure 2. Calculations based on an infinite current supply from the serving utility

The Code does not place any less importance on proper short-circuit protection and adequate ampere interrupting capacity of overcurrent protective devices and equipment ratings for temporary services as compared to permanent service installations. The question is, do we?

It is important to remember that chapters 1 through 4 of the NEC apply to temporary services. Section 590.2(A) states that “Except as specifically modified in this article, all other requirements of this Code for permanent wiring shall apply to temporary wiring installations.”

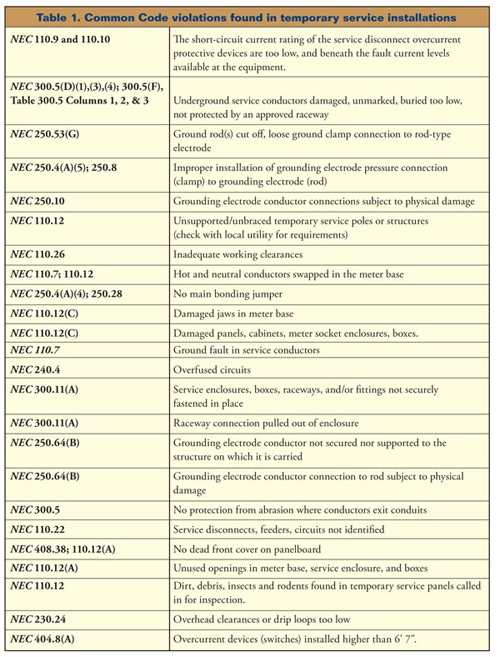

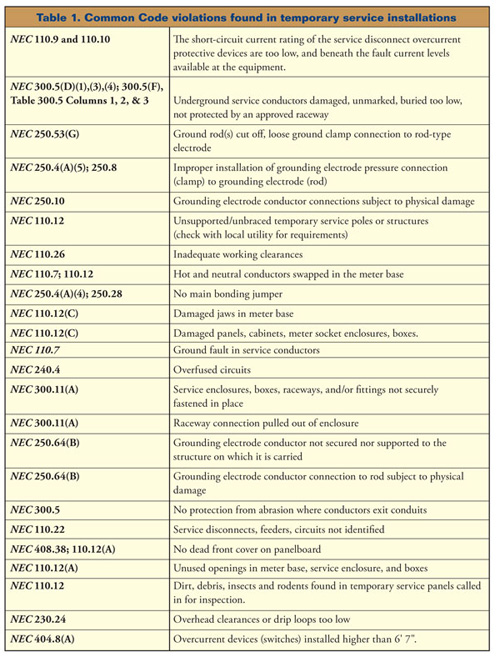

Table 1. Common code violations found in temporary service installations

Because of the heavy workload that many jurisdictions have, it’s often easy to feel rushed or get in a hurry when inspecting temporary services. The thought may prevail, It’s only temporary, it’s not a big deal. Such assumptions are risky, and can be dangerous. The need to inspect carefully each temporary service every time it is placed on a jobsite cannot be overlooked, even if you have previously inspected it, perhaps many times before. Even if the installation looks safe, there could be hidden hazards that may not be apparent. Also, things can happen to the equipment between the time it was first inspected and when it is used again on the next jobsite.

Table 1, continued

In some jurisdictions, electric utilities may provide — and their line crews may also install — temporary services. In such cases, it is possible that no electrical inspection is performed or required, or the persons inspecting may be professionals in their field but not trained electrical inspectors that understand the hazards and know what to look for to assure a safe installation that is code-compliant. The question is, are these types of installations truly safe?

If temporary construction power installations are within your responsibility, please consider the following suggestions: Good working relationships are important, but it’s wise not to make assumptions that because you know the contractor and/or may have inspected this particular piece of equipment before, that the equipment is still safe and meets at least the minimum Code standards. There may be hidden concerns or damage that you or they have no idea exists. Damage to electrical equipment can easily occur, for example, where the temporary power pole is removed by a backhoe that pulled it out of the earth. In the process, the service grounded (neutral) conductor was pulled on very hard, which destroyed the neutral and ground bar in the service equipment. In other cases, the service ungrounded conductors were completely pulled out of their terminations in the service equipment or meter base, or made very loose.

Another example is supply-side grounded and ungrounded conductors being connected to the wrong terminals of service equipment, which if energized will give off enough fireworks to remind you of the 4th of July! Many temporary service installations are installed by non-electrical personnel that often don’t realize what is needed or required for electrical safety. All they know is that “the boss said to put the pole in” and, by golly, that’s what they’re doing. And, usually, all the builder or owner is concerned about with his service is, How quick can you get this thing approved, and get me my power? Sound like the real world to you? It is common in field construction trades to have varying skill levels and awareness of electrical safety. Many non-electrical construction trades people really don’t have a good idea of what is electrically safe or not, and what items — especially subtle errors — may place their safety and others around them at risk.

OK, at this point you may be saying, Hey, give me a break! If there were conductors pulled out of lugs, I’d catch that in a heartbeat. Yes, you probably would catch the obvious stuff, but what about those more subtle things that can be deadly if ignored or bypassed because you have a huge inspection schedule, a limited amount of time, and you promised contractors that you’d be at their jobsites soon but you’re already running late? Most of us have “been there, and done that.” We enjoy being out in the field, being a part of what’s going on, and helping people. However, when it comes to safety, and signing our name to an inspection approval or citation, we need to take the time even when we don’t think we have it. Every installation is important, even if it’s a temporary one.

I have personally experienced situations where a construction laborer moved the ground rod from one temporary service that was approved and energized by the utility, to another lot location in the subdivision for a new temporary service. Hey, the power is on, it must be okay! The man didn’t do it maliciously, he simply had no idea of the importance of grounding, or how a lack of it could affect his own safety! Installers have the responsibility to comply with NEC 110.7, Insulation Integrity, and assure that their electrical installation is free from short circuits and ground faults. Installers also must continue to be encouraged to look over their work and check it as needed before calling it in for inspection. As electrical inspectors, we visibly inspect the installation, drawing on our experience, training, and Code knowledge for compliance with adopted codes and standards. Quality electrical inspections are a vital part of safety for persons and property arising from the use of electricity.

One proposal for NEC-2008 intends to improve safety on construction sites. Proposal #13-11 creates new Section 445.20, which will require GFCI protection for all 125 and 125/250-volt, single-phase, 15-, 20-, and 30-ampere receptacle outlets that are part of portable electric generators. It may surprise you that this has not been previously required in the Code, but it’s true.

Table 1 provides some common Code violations often found on temporary services. This is intended to be a useful guideline, but not an all inclusive checklist. Others items may apply to specific installations or geographical areas.

Installing a temporary service on a jobsite means that many more inspections will follow on the same site. As subsequent inspections are made, changes to the temporary service installation that had previously been approved may develop because of damage or abuse. Finding support posts knocked over, grounding electrode conductors cut in half or damaged, or other types of physical damage is not uncommon. The electrical permit holder has responsibility for the safety of the temporary service installation. However, as we become aware of unsafe situations regarding the temporary service electrical equipment, we need to alert the permit holder as soon as possible.

In summary, we have focused on temporary services, their equipment short-circuit current ratings, common Code violations found in temporary service installations, and the need for comprehensive inspections every time a temporary service is installed.

There is an apparent need in the field to be more aware of electrical safety for temporary electrical service installations. In general, the only difference between a temporary electrical service and a permanent one is the length of time that it exists. Making sure that service equipment has the proper ratings for the short-circuit current available at the equipment, and that every temporary service installation is thoroughly inspected will go a long way toward electrical safety.

Find Us on Socials