The 2026 edition of the National Electrical Code® (NEC®) brings significant updates that reflect the rapid advancement of technology and the growing complexity of electrical systems across the industry. From global structural changes that affect multiple chapters, such as reorganizing medium-voltage requirements and consolidating limited-energy system articles, to entirely new topics like Electric Self-Propelled Vehicle Power Transfer Systems (ESVSEs), this cycle demonstrates a commitment to clarity, consistency, and modern application. The Independent Alliance of the Electrical Industry (IAEI), long recognized as the trusted leader in electrical safety and education, will release an in-depth book and presentation that provides comprehensive insight into these and many other changes. Whether you’re a designer, installer, inspector, or educator, understanding the latest code updates is critical to ensuring compliance and protecting lives and property. As always, IAEI remains the premier resource for the most accurate, relevant, and actionable information in the industry.

Important Note: At the time of this writing, the second draft meetings have been completed, and the following is based on the adoption of the second draft. The NFPA Annual Conference in June of 2025 will hear votes from the floor and then appeals can be made to the NFPA Standards Council. The NFPA Standards Council is scheduled to issue the 2026 NEC in August 2025 with a proposed publication date of September 2025.

Global Changes in the 2026 NEC

Every code cycle introduces refinements and updates, but some changes have a broader impact that stretches across multiple articles and chapters. These wide-reaching modifications—referred to as global changes—reflect deeper structural evolutions within the NEC. The 2026 edition continues this trend by improving clarity, reducing redundancy, and aligning terminology and structure for modern electrical applications, especially in high-voltage and limited-energy systems.

New and Restructured Articles

Several new articles have been introduced, many of which stem from reorganized content in previous editions. Notably, Articles 265 through 270 now house requirements for systems over 1000 volts ac and 1500 volts dc, representing a complete reallocation and update of the content that previously existed in Article 235, which has been deleted. This realignment also includes Article 270, focused specifically on grounding and bonding for these high-voltage systems. The following are the new articles for medium voltage:

- 206 Non-Power-Limited Remote-Control and Signaling Circuits [From 300.26]

- 265 Branch Circuits Over 1000 Volts [From Part II of deleted Article 235]

- 266 Feeders Over 1000 Volts ac, 1500 Volts dc Nominal [From Part III of deleted Article 235]

- 267 Outside BC & Feeders Over 1000 Volts ac, 1500 Volts dc Nominal [From Part IV of deleted Article 235 and Article 395]

- 268 Services Over 1000 Volts ac, 1500 Volts dc, Nominal [From Part V of deleted Article 235]

- 270 Grounding and Bonding of Systems Over 1000 Volts ac, 1500 Volts dc, Nominal. [From Part X of Article 250]

- 624 Electric Self-Propelled Vehicle Power Transfer Systems (ESVSEs)

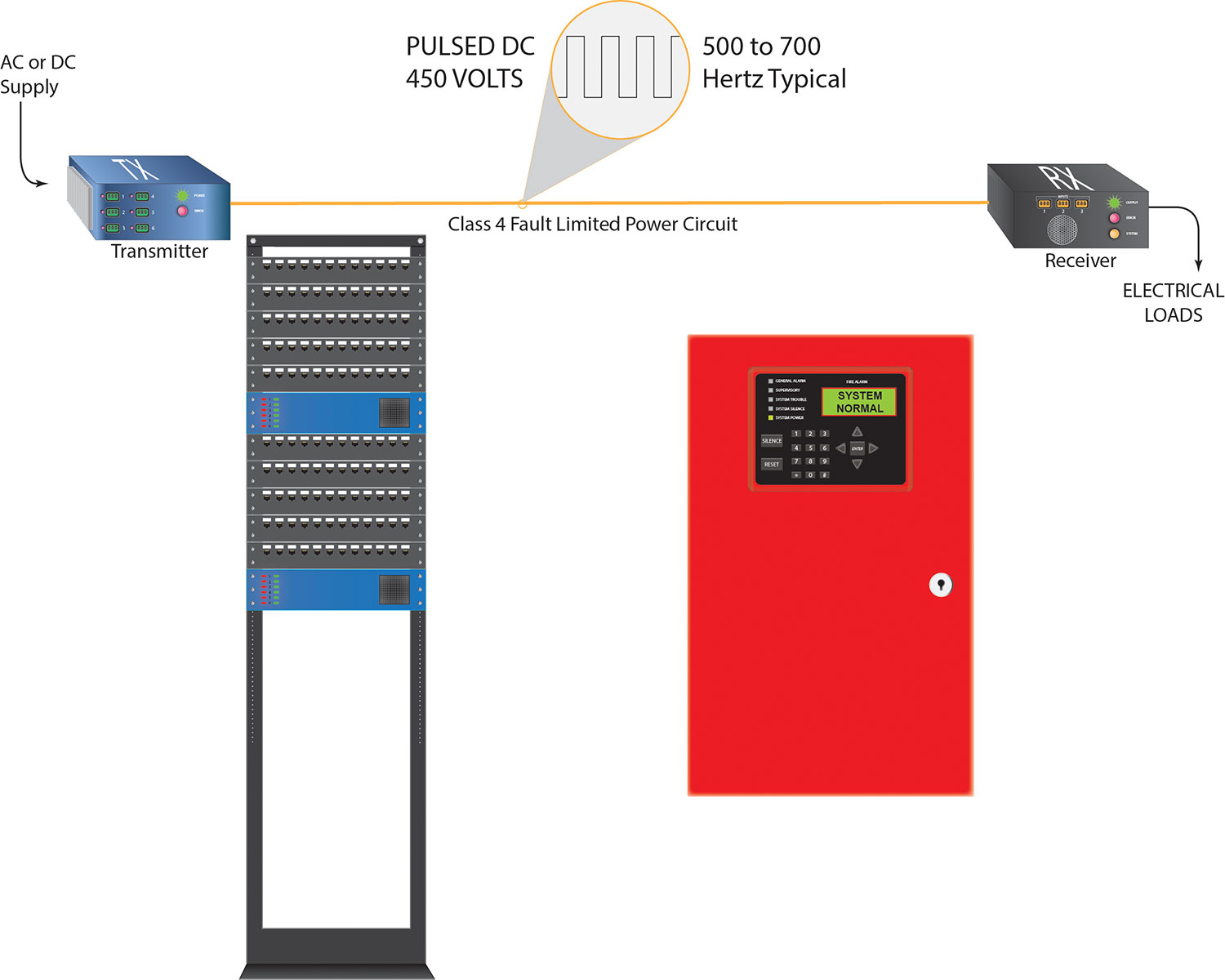

In parallel, the NEC has introduced a comprehensive set of articles (720–750) dedicated to limited-energy systems, consolidating requirements and resolving long-standing overlaps between Chapter 7 and the now-reduced Chapter 8 (Communications).

These new articles provide clearer guidance for technologies like power-limited circuits, fault-managed power, and optical fiber systems. This is key as these systems become more prevalent in modern infrastructure. These new articles consist of the following:

- 720 General Requirements for Limited-Energy Systems Wiring Methods & Materials

- 721 Powers Sources for Limited-Energy Systems

- 722 Limited-Energy Cables for Power-Limited circuits, Fault-Managed-Power Circuits, Optical fiber Circuits, and Communications Circuits

- 723 Raceways, Cable Routing Assemblies and Cable Trays for Limited-Energy Systems

- 742 Overvoltage Protection of Limited-Energy Systems

- 750 Grounding and Bonding of Limited-Energy Systems

Relocated and Deleted Articles

To support better organization, several articles have been relocated to more appropriate sections based on topic alignment. For example:

- Article 220 has been renumbered as Article 120 , Branch-Circuits, Feeder and Service Load Calculations, to better reflect its role in branch-circuit, feeder, and service load calculations.

- Article 728 (Fire-Resistive Cable Systems) has moved to Article 772.

- Article 750 (Energy Management Systems) has moved to Article 130.

The following articles are no longer found in the NEC. The contents have been relocated to other areas of the document:

- 235 Branch Circuits, Feeders, and Services Over 1000 volts ac, 1500 Volts dc, nominal

- 770 Optical Fiber Cables

- 805 Communications Circuits

Clarified Terminology and Definitions

A notable terminology update includes the replacement of “Branch-Circuit Overcurrent Protective Devices” with the simplified term “Overcurrent Protective Device (OCPD).” This change supports consistent use of language across the NEC while maintaining the functional meaning of the device.

Parallel section numbering

In addition, parallel section numbering has been reinforced. For instance:

- Listing requirements now consistently appear in section .2 of applicable articles.

- Requirements for reconditioned equipment are found in section .3.

This structured numbering aligns with Section 2.2.1 of the NEC Style Manual, enhancing usability and code navigation.

Limited-Energy System Realignment

One of the most impactful global changes is the redefinition of limited-energy system requirements. Code Making Panel 1 has removed the independence of Chapter 8, integrating its content into Chapter 7. The restructured Chapter 7 (Articles 720–760) now houses all primary installation requirements for limited-energy systems, including communications—a major step toward a unified approach. The 2029 NEC edition is expected to complete this transition with further clean-up and final placement of all related provisions.

Medium Voltage Coordination

Medium voltage requirements—defined consistently throughout the 2026 NEC as systems over 1000 volts ac, 1500 volts dc, nominal—have also been harmonized. A Correlating Committee Task Group has ensured that language across all relevant articles is aligned. New or revised articles such as 245, 305, and 495 ensure clear guidance on conductors, overcurrent protection, and equipment for medium-voltage systems. The future of the term “Medium Voltage” itself is under review, with the intent of further clarifying its application and scope in future editions.

New medium voltage articles include the following:

- 245 Overcurrent Protection for Systems Rated Over 1000 Volts ac, 1500 Volts dc, Nominal

- 265 Branch Circuits Over 1000 Volts ac, 1500 Volts dc, Nominal

- 266 Feeders Over 1000 Volts ac, 1500 Volts dc, Nominal

- 267 Outside Branch Circuits and Feeders Over 1000 Volts ac, 1500 Volts dc, Nominal

- 268 Services Over 1000 Volts ac, 1500 Volts dc, Nominal

- 270 Grounding and Bonding of Systems Over 1000 Volts ac, 1500 Volts dc, Nominal

- 305 General Requirements for Wiring Methods and Materials for Systems Rated Over 1000 Volts ac, 1500 Volts dc, Nominal

- 315 Medium Voltage Conductors, Cable, Cable Joints, and Cable Terminations

- 495 Equipment Over 1000 Volts ac, 1500 Volts dc, Nominal

Section 110.16

The 2023 NEC brings forth pivotal amendments aimed at enhancing electrical safety, particularly concerning arc-flash hazard marking. These revisions, detailed in the updated Section 110.16, mark a significant departure from previous standards, emphasizing clarity, compliance, and alignment with industry best practices.

Removal of General Hazard Awareness Requirement

One of the most notable updates is the removal of the general hazard awareness requirement previously mandated under 110.16(A). This adjustment streamlines the focus on specific arc-flash hazards, ensuring that marking requirements are direct and actionable.

Expansion of Arc-Flash Hazard Marking

Under the new regulations, the scope of arc-flash hazard marking has been expanded significantly. Whereas previously limited to service equipment or feeder-supplied equipment of 1200A and above, the revised NEC now mandates arc-flash hazard labels on a broader range of equipment. This includes switchboards, switchgear, enclosed panelboards, industrial control panels, meter socket enclosures, and motor control centers likely to require examination, adjustment, servicing, or maintenance while energized.

Alignment with NFPA 70E for Enhanced Safety Practices

A pivotal aspect of these changes is their alignment with NFPA 70E-2024, Standard for Electrical Safety in the Workplace. This alignment ensures that the newly mandated arc-flash hazard labels adhere to safe work practices outlined in NFPA 70E. It emphasizes the inclusion of critical information such as nominal system voltage, arc flash boundary, incident energy levels, minimum required personal protective equipment, and the date of assessment application.

Implications for Electrical Safety

The implementation of these revisions marks a significant advancement in electrical safety practices. By requiring more comprehensive and visible arc-flash hazard labels on a wider range of electrical equipment, the NEC 2026 enhances awareness and mitigates risks associated with electrical hazards. This proactive approach not only aligns with industry standards but also underscores the commitment to safeguarding personnel working in energized environments.

In conclusion, the changes introduced in NEC 2026 Section 110.16 represent a pivotal step forward in electrical safety regulation. By focusing on clarity, compliance, and alignment with NFPA 70E standards, these amendments are poised to elevate safety standards across various sectors, ensuring a safer working environment for electrical professionals.

Introduction of HF and HF+ Ground-Fault Circuit Interrupters: Addressing High-Frequency Leakage Currents

Another key advancement in the 2026 NEC is the introduction of informational note No. 2 in Section 210.8, which formally recognizes Ground-Fault Circuit Interrupters (GFCIs) marked “HF” or “HF+.” These devices are specifically engineered for environments where high-frequency leakage currents are present—most commonly in equipment that employs electronic power conversion technologies, such as variable speed drives and inverters.

Understanding the Need for HF/HF+ GFCIs

Traditional Class A GFCIs are designed to detect leakage currents between 4–6 milliamperes at standard line frequencies (50–60 Hz). However, modern appliances—especially those with variable-speed compressors or digital motor controllers—can introduce higher-frequency leakage currents onto the grounding conductor. These currents, although not necessarily hazardous to humans, can result in nuisance tripping of standard GFCIs, disrupting power to critical equipment.

Research has shown that the human body is less susceptible to high-frequency currents, as these tend to remain near the skin’s surface rather than penetrating into deeper tissues. This allows for a higher tolerance to leakage currents at frequencies above 60 Hz without compromising safety.

To address this, UL 943 now includes provisions for Class A-HF GFCIs, which are evaluated to allow greater leakage current levels at higher frequencies while maintaining essential personnel protection. The NEC 2026 recognizes this category by requiring that if GFCI protection is used for certain appliances, such as refrigerators and HVAC systems, it must be identified as high-frequency (HF) starting January 1, 2029 [per Section 422.5(C)].

Regulatory Alignment and Industry Impact

This shift is part of a broader effort to harmonize performance expectations between product safety standards and the NEC. Similar to how circuit breakers listed under UL 489 may also bear additional use-case markings such as SWD (switching duty) or HID (high-intensity discharge), GFCIs can now be dual-labeled as HF or HF+ while still conforming to the baseline requirements of UL 943.

These changes are not just a technical clarification—they represent a practical solution to real-world compatibility issues between evolving appliance technologies and protective devices. By embracing HF-marked GFCIs, the NEC 2026 ensures that safety devices remain effective and reliable in a modern electrical landscape increasingly dominated by high-frequency components.

Expansion and Definition of Special Purpose GFCIs in NEC 2026

The 2026 NEC significantly advances the integration and clarity of Special Purpose Ground-Fault Circuit Interrupters (SPGFCIs), building on their original introduction in NEC 2017 under Article 590 for temporary installations. These devices offer a critical solution for applications where traditional Class A GFCIs may be incompatible due to tripping caused by high-frequency leakage currents or operational characteristics of specific equipment types.

New Options for HVAC Applications

One of the most notable changes appears in Section 210.8(F), where Code-Making Panel 2 introduces SPGFCIs as an alternative method for meeting ground-fault protection requirements for outdoor outlets that supply HVAC equipment. As the temporary exception for omitting GFCI protection for listed HVAC equipment sunsets on September 1, 2026, NEC 2026 now provides four compliant options for meeting these protection requirements:

- A standard Class A GFCI device

- A Class A GFCI device marked HF or HF+

- A Class C SPGFCI

- A Class C SPGFCI marked HF or HF+

Importantly, when a Class C SPGFCI is used for HVAC applications, the disconnecting means must be clearly labeled with the warning:

“Warning: Class C SPGFCI Protection

Provided for HVAC Unit.”

This expanded set of options gives electrical professionals the flexibility needed to select a solution that balances safety and functional compatibility, particularly for HVAC equipment sensitive to standard GFCI behavior.

Defined Classes of SPGFCIs

To provide greater clarity, NEC 2026 introduces formal definitions for SPGFCIs, categorizing them into Class C, Class D, and Class E devices, each intended for specific voltage levels and grounding conditions:

- Class C SPGFCIs: Intended for circuits with no conductor over 300 volts AC to ground, where reliable grounding or double insulation is provided. These devices trip between 15 mA and 20 mA and are suited for equipment that generates higher leakage currents.

- Class D SPGFCIs: Designed for circuits with conductors over 300 volts to ground and specially sized grounding systems that limit body exposure to no more than 150 volts during a fault.

- Class E SPGFCIs: Applicable to circuits over 300 volts to ground with conventional grounding or double insulation, offering rapid response to prevent ventricular fibrillation thresholds.

The definition of the traditional GFCI has also been revised to specifically identify it as a Class A GFCI, helping eliminate confusion and reinforcing the applicability of each GFCI type based on the installation’s characteristics.

Informational Note and UL Standards

The Code now references UL 943C, the Outline of Investigation for SPGFCIs, to guide manufacturers and inspectors on performance expectations, including devices marked “HF” or “HF+” that tolerate high-frequency leakage currents without unnecessary tripping. These are especially valuable in systems employing power conversion electronics.

Special Purpose GFCIs and Electric Vehicles

Another important development is the incorporation of SPGFCIs into Article 625, which governs electric vehicle infrastructure. Section 625.54, if it stands the test of the NFPA Annual meeting NITMAM process, will mandate SPGFCI protection for EV charging equipment where the line-to-ground voltage exceeds 150 volts. This requirement ensures continued personnel protection while accounting for the unique operational profiles of electric vehicle supply equipment (EVSE), which often incorporates advanced power electronics.

Effective January 1, 2029, the following protection measures will apply:

- Receptacles or outlets rated ≤150V to ground: Must use standard Class A GFCI protection.

- Receptacles or outlets rated >150V to ground: Must be protected by SPGFCIs with trip thresholds not exceeding 20 mA.

Exceptions are provided for DC charging outlets and bidirectional EV charging systems, which have distinct operating and safety profiles.

Service Disconnect Location Clarified in NEC 2026

The requirement for an emergency disconnect at one- and two-family dwelling units was first introduced during the 2020 NEC cycle. Since then, Code-Making Panel 4 has received continued public input requesting improved clarity regarding location requirements and acceptable options for the service disconnect. The 2026 NEC edition responds to those concerns with streamlined, clearer language in Section 230.70, focusing on efficiency and safety in emergency situations.

Simplified Outdoor Location Requirement

The 2026 revision mandates that the service disconnecting means for one- and two-family dwellings must now be located in a readily accessible outdoor location, either:

- On the dwelling unit, or

- Within sight of the dwelling unit, as defined in Section 110.29.

This represents a more prescriptive and enforceable standard than prior versions of the Code, which allowed the disconnect to be inside the structure at the point of conductor entry. The revised approach supports first responder safety, facilitates faster access during emergencies, and aligns with the overall emphasis on outdoor emergency disconnects initiated in recent code cycles.

Important Exception for Remote Services

The 2026 NEC includes a key exception to account for dwellings served from a remote service location, such as when a meter or service equipment is located at the property line or along a roadway, distant from the structure. In these cases, the service disconnect is permitted to be located remotely, as long as an emergency disconnect is installed in accordance with Section 225.41. This aligns service and feeder disconnect expectations and preserves occupant and responder safety in less conventional layouts.

To support the exception, Section 225.41 lays out clear requirements for emergency disconnects used with feeders to dwelling units. These devices must be:

- Located on or within sight of the dwelling, outdoors and readily accessible

- Grouped if more than one is provided

- Installed within equipment rated for the available fault current

- Clearly marked as EMERGENCY DISCONNECT with standardized label requirements: Red background with white text

- Minimum ½-inch-high lettering

- Located on the outside front of the disconnect enclosure

An additional identification provision ensures other energy source disconnects (e.g., solar, generator, battery systems) are properly noted when not co-located with the emergency disconnect.

A More Practical, Safer Approach

These updates reflect NEC’s continued effort to balance practical installation considerations with life safety priorities. By tightening the language and addressing edge cases—like distant service points—the 2026 Code provides clearer guidance to installers, inspectors, and first responders alike.

Grounding, Bonding, and Safety in Electric Self Propelled vehicle power transfer systems (ESVSEs)

With the introduction of Article 624 for Electric Self-Propelled Vehicle Power Transfer Systems (ESVSEs), the 2026 NEC makes a major step forward in bridging the gap between conventional EV infrastructure and the expanding landscape of electrified non-road vehicles. However, along with this recognition comes the critical challenge of ensuring these systems are safely integrated into the power distribution system wiring, especially in environments with increased risk, such as marinas, farms, or airfields.

Shock protection

One of the key safety considerations in Article 624 is the requirement for proper grounding and bonding of ESVSE installations. Since these systems often operate in environments with high exposure to moisture, soil contact, or metal structures, the potential for fault current presents an elevated risk of electric shock. The requirements found in this article help reduce the likelihood of coming in contact with energized parts. When paired with the requirements of Article 555 for example for Marinas, ESVSEs used with electric boats in marina applications may need to comply not only with Article 624, but also with Article 555 (Marinas and Boatyards) and Article 682 (Natural and Artificially Made Bodies of Water), both of which introduce stringent grounding and leakage current limits.

Overcurrent and Disconnecting Means

Another area Article 624 addresses is overcurrent protection and disconnecting means:

- Circuits supplying ESVSEs must include overcurrent protection in accordance with 210.20 and 240.4.

- A disconnecting means must be readily accessible and capable of de-energizing the equipment quickly during maintenance or emergency scenarios.

This aligns ESVSE installations more closely with established EVSE practices found in Article 625 while preserving the flexibility required for diverse use cases—from dockside charging of electric watercraft to mobile battery storage systems used in field operations.

Looking Ahead: Bidirectional Power and Grid Integration

As ESVSEs evolve, so does the potential for bidirectional energy flow. Like electric vehicles, ESVs equipped with export equipment can provide stored energy back to premises or even the utility grid, creating both opportunities and concerns:

- Coordination with Article 705 (Interconnected Electric Power Production Sources) will be essential as bidirectional transfer becomes more commonplace.

- Proper labeling and signage must be provided to alert personnel to the presence of dual sources of energy (ESVSE and utility)

- GFCI devices must be able to accommodate reverse power flow.

The 2026 NEC’s inclusion of these systems reflects a growing understanding that electric mobility isn’t limited to road vehicles. From powering events with mobile battery trailers to running irrigation pumps via solar-charged tractors, ESVSEs offer flexibility—but only if installed with safety and code compliance in mind.

Closing remarks

As the electrical industry continues to evolve, staying informed about changes to the National Electrical Code is more critical than ever. The 2026 edition introduces substantial updates—from restructured medium-voltage content and limited-energy systems realignment to the addition of new articles addressing cutting-edge technologies like electric self-propelled vehicles. These changes reflect the NEC’s ongoing mission to enhance clarity, support innovation, and—most importantly—improve safety.

The IAEI remains committed to providing the most thorough and authoritative resources in the field. With the release of our comprehensive 2026 NEC book and presentation, electrical professionals will be equipped with the tools and knowledge needed to apply the latest code with confidence. Safety starts with education, and the IAEI continues to lead the way.

The 2026 NEC® Is Here—Are You Ready?

Want to dive deeper into the latest updates to the NEC®? Get ready for our upcoming Analysis of Changes, NEC-2026—your go-to resource for understanding how these critical changes affect electricians, inspectors, and designers. This edition features a fresh, updated look alongside practical insights that break down key revisions with real-world examples, expert analysis, and knowledge-testing questions to ensure you’re fully prepared for the new requirements. Stay ahead of the curve—pre-order today at iaei.org or call Michelle at (800) 786-4234.

Find Us on Socials