In an effort to ensure that information is being provided to others within the electrical industry globally, I would like let you see some of the activities that Energy Safe Victoria (ESV) has undertaken for the electrical industry in the past few months, along with our normal operational activity.

1. We have made an ad for the television segments that has been screening recently. It is designed to reduce the do it yourself and unlicensed segment of the industry.

2. Warning of using the ELV halogen downlights; we have had issues with house fires caused by these lights. AS/NZS 3000:2007 is about to be released and the requirements in this document will address the issue, however is this occurring in your area?

Message for the Electricity Industry

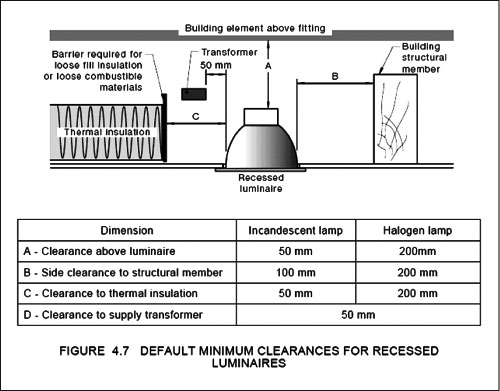

Compared to the current Wiring Rules, AS/NZS 3000 covers the issue of downlight installation much more explicitly—and includes a diagram and a table showing the default minimum clearances for recessed luminaires or downlights. They are reproduced here, together with the draft standard.

AS/NZS 3000 will be in force from early 2008 and will apply to all new buildings, retrofits and new installations of recessed lamps.

Apart from working to the new standards straight away, registered electrical contractors and licensed electricians should remain vigilant and provide appropriate advice if they observe wrongly installed and dangerous downlights when called to work at customers’ premises.

The new standard – 4.5.2.3 Recessed luminaires – says: “Recessed luminaires and their auxiliary equipment shall be installed in a manner designed to minimise temperature rise and prevent the risk of fire.

“The temperature rise at the rear of a recessed luminaire shall be limited to prevent damage to adjacent materials.

“This requirement shall be satisfied by one of the following methods:

(a) The use of a luminaire specifically designed and certified by the manufacturer to permit—

(i) contact with combustible materials; or

(ii) enclosure or covering by thermal insulation material, as appropriate to the location of the luminaire.

(b) Installation of the luminaire within a suitable fire resistant enclosure.

(c) Provision of required clearances from combustible and thermal insulating material as specified by the manufacturer of the luminaire.

(d) Provision of the default clearances from combustible and thermal insulating material as specified in Figure 4.7.

“Where manufacturer’s installation instructions that specify required clearances are not available, the luminaire shall be installed in accordance with (b) or (d).

“NOTE: In the case of a suitably designed luminaire, the installation instructions may specify that no clearance is required.

“Recessed luminaires and their auxiliary equipment shall be installed in such a manner that necessary cooling air movement through or around the luminaire is not impaired by thermal insulation or other material.

“Where thermal insulation is of a type that is not fixed in position (e.g., loose fill), a barrier or guard constructed of fire resistant material shall be provided and secured in position to maintain the necessary clearance (see figure 4.7).

“Where thermal insulation may reasonably be expected to be installed in the space containing a recessed luminaire, the luminaire shall be installed in such a manner as to provide for the subsequent installation of thermal insulation.

“Recessed luminaires shall be installed in accordance with (a) or (b), or provided with equivalent protective measures, where there is a likelihood of extraneous combustible material (e.g., leaves or vermin debris, etc.) collecting on or around the luminaire.”

Advice for Property Owners

As the State’s electricity, gas and pipeline safety and technical regulator, ESV shares the concern of fire authorities and other safety agencies at the number of fires caused by downlights in properties.

Property owners can be assured that downlights, when correctly installed, do not pose a problem. Similarly, insulation material in the roof does not pose a problem.

But, if downlights are installed incorrectly—for example they are placed close to structural timber or covered by insulation or ceiling debris—they are dangerous and pose a substantial fire risk.

Property owners are advised to take note of the following:

- Never allow electrical equipment such as downlights to be installed close to insulation material or structural components of the property.

- Regularly inspect downlights and transformers to ensure there is a non-flammable/mechanical barrier installed around them to prevent insulation or other material covering them.

- Clearance of material around downlights and transformers must be equivalent to at least a handspan in width.

- When downlights are installed, insist on the use of the best quality fittings and guards.

- Following any work in the roof space ensure that all the downlights and transformers are clear of insulation or other material.

- If in doubt, contact your local registered electrical contractor or contact ESV directly on 1800 800 158.

- To ensure there is no danger from downlights, arrange an ESV electrical Home Safety Inspection. Find out more on this website or by calling 1800 800 158.

- For any electrical work around the home, always engage a registered electrical contractor for all electrical work, and insist on a certificate of electrical safety when the work is complete.

- Ensure there are safety switches installed on both the power and lighting circuits in properties.

New Wiring Rules covering the installation of downlights will be introduced across Australia in the next few months. The Rules will specify the minimum clearances which must be observed around downlights both for incandescent and halogen lighting products.

Find Us on Socials