Arc-fault circuit interrupters (AFCIs) have just become required for installation in residences under the 2002National Electrical Code(NEC). Not surprisingly, questions have been raised regarding their application and even the need for them. There have been marketing pitches, technical opinions and, quite frankly, intentional misinformation floating around various industry channels. The intent of this article is to bring out the truth about what AFCIs are and what they are not.

This is Part I of a two-part article produced to directly address some of the questions and the misinformation about AFCIs. Part I focuses on the technology, the AFCI product standard and what the NEC is written to accept. Part II will focus on questions related to application and installation in accordance with the NEC.

Background

Contrary to popular belief, AFCIs are not “new.” They are certainly in their infancy relative to many products, but they are not new. Square D began research in this area in the late 1980s and early 1990s; at about the same time the Consumer Product Safety Commission identified a concern with residential fires of electrical origin. A large number of these fires were identified to be in the branch-circuit wiring system.

The need for AFCIs became more apparent as the Electronic Industries Association (EIA) initiated a project and ultimately code proposals to the 1993 NEC to change the instantaneous trip levels of 15 and 20 A circuit breakers. EIA had studied the issue of arcing fires and determined that some level of additional protection from effects of arcing faults would be beneficial. EIA attempted to improve protection by requiring that the instantaneous trip level of a circuit breaker be reduced to the 85 A level. However, it became clear that lowering the instantaneous levels below the minimums already in the market would result in nuisance operation of the circuit breaker due to inrush currents.

The CPSC study and the EIA efforts led to the first proposals to require AFCIs during the revision cycle to create the 1999 NEC.

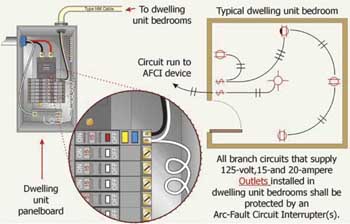

Figure 1. 210.12, Arc-fault Circuit-Interrupter Protection

NEC Code-making Panel 2 (CMP-2) was presented with numerous proposals ranging from protection of basically all 15- and 20-A circuits in dwelling units to protection of living and sleeping areas. After listening to many presentations, reviewing large amounts of data, conducting extensive discussions and giving consideration to the issues, CMP-2 concluded that AFCI protection should be required for branch circuits that supply receptacle outlets in bedrooms. The panel placed an effective date of January 1, 2002, for the requirement to become effective. CMP-2 members unanimously passed this action. Subsequently, the requirement was retained in the 2002 NEC with enhancements.

The Need for Arc-Fault Protection

Just as we only need a smoke alarm or a circuit breaker when a problem occurs, we also only need AFCI protection when a problem occurs—then we really need it. A fuse or circuit breaker cannot detect hazardous arcing current that is below its time-current opening characteristic. Arcing faults are frequently below the characteristic. The data on fire origin shows the need for this protection.

A recent report by the National Association of State Fire Marshals states:

According to the National Fire Protection Association and the National Fire Incident Reporting Sys- tem data, during the five-year period from 1994- 1998, there were an average of 73,500 total electrical fires annually, which were responsible for 591 Deaths, 2,247 injuries, and property damage totaling $1,047,900,000. The electrical problems that lead to these fires went undetected by conventional circuit breakers. Of these 73,500 electrical fires, 60,900 or 82% were caused by arcing and not by overloads or short circuits. 1

It may not be realistic to expect AFCIs to detect 82 percent of the conditions that cause fires from electricity and the cited report does not expect that. However, the conclusion indicates the high percentage of cases in which at least one authoritative source finds arcs to be a fire cause worthy of attacking. The AFCI does just that and does it effectively.

AFCIs address a real cause of home fires. Below is a list of reported incidents in which AFCIs detected arcing conditions that could have developed into fire causes.

- An appliance plug damaged by impact repeatedly caused tripping of the AFCI until the problem was discovered. When the appliance cord was replaced, no further tripping of the AFCI occurred.

- A room air conditioner that had developed a defect tripped the AFCI. The performance of the AFCI was questioned until the offending appliance was discovered and disconnected. The AFCI continues in service with no further tripping.

- An AFCI installed in a new building tripped repeatedly until damage caused by a nail through insulation was discovered and corrected.

- An AFCI installed as a retrofit in an older building tripped as soon as it was turned on. The installing electrician found the problem with extensive evidence of arcing in an old lighting fixture.

- Another damaged lamp with line-to-ground arcing was found when an AFCI was installed in an existing circuit. The AFCI tripped when the circuit was first energized after the installation.

- An AFCI tripped when retrofitted into an existing circuit. Examination of the circuit disclosed that wire insulation had burnt back exposing bare conductors near their connection to a receptacle. The exposed wires had been arcing through the charred insulation. It appeared that heat from a loose connection at the receptacle had caused the wires to burn back.

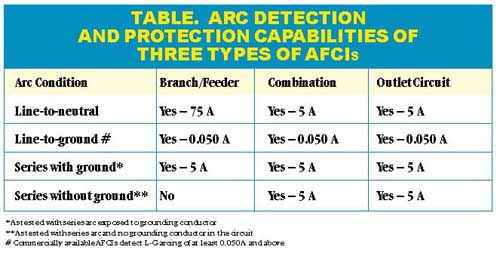

Table 1. Table 1 briefly compares the capabilities of the three types plus the outlet branch circuit AFCI.

As you might guess from that list, the greatest number of fires from electrical causes is in homes ten years old and older where changes have been made to electrical circuits by various owners and where insulation is deteriorating with age, use and misuse. However, fires from electrical arcs are recorded for residences of all ages. Besides, all homes become older homes. If the protection is not present before they age, they will remain unprotected as they age.

NEC 210.12 Requirement

NEC 210.12 defines an AFCI as “a device intended to provide protection from the effects of arc faults by recognizing characteristics unique to arcing and by functioning to de-energize the circuit when an arc fault is detected.” The AFCI has two basic functions, which are recognizing arc characteristics and de-energizing the circuit when it recognizes them. There is no protection unless the source of voltage is disconnected from the hazard, once the hazard is detected.

The requirement of 210.12(B) states, “All branch circuits that supply 125-volt, single-phase, 15- and 20-ampere outlets installed in dwelling unit bedrooms shall be protected by an arc-fault circuit interrupter listed to provide protection of the entire branch circuit.”

This requirement in the 2002 NEC reads the same as that in 1999, except for two points. First, “outlets” read “receptacle outlets” in 1999. The change indicates that CMP-2 intended that all fixed wiring be protected. The protection extends also to extension and appliance cords. Second, the word “entire” is added, again indicating the intention to protect the fixed wiring of the entire branch circuit.

The only devices covered by the UL 1699 Standard for Arc-fault Circuit Interrupters that also satisfy these NEC requirements are the branch/feeder and combination AFCIs, when they are installed at the source of the branch. The branch/feeder AFCI is the circuit-breaker type that has been the topic of discussion since the AFCI was first proposed for the 1999 NEC. Branch/feeder AFCIs are listed by at least four manufacturers and are readily available. A combination AFCI has not yet appeared commercially, but at least two manufacturers have mentioned development of them.

AFCI Types

There are six devices covered in UL 1699, three of which are defined there as follows:

Branch/feeder AFCI — A device intended to be installed at the origin of a branch circuit or feeder, such as at a panelboard. It is intended to provide protection of the branch-circuit wiring, feeder wiring, or both, against unwanted effects of arcing. This device also provides limited protection to branch-circuit extension wiring. It may be a circuit-breaker type device or a device in its own enclosure mounted at or near a panelboard.

Outlet circuit AFCI — A device intended to be installed at a branch-circuit outlet, such as at an outlet box. It is intended to provide protection of cord sets and power-supply cords connected to it (when provided with receptacle outlets) against the unwanted effects of arcing. This device may provide feed-through protection of the cord sets and power-supply cords connected to downstream receptacles.

Combination AFCI — An AFCI which complies with the requirements for both branch/feeder and outlet circuit AFCIs. It is intended to protect downstream branch-circuit wiring and cord sets and power-supply cords.

Definitions of the cord or portable AFCIs or the leakage-current detector-interrupter are not provided here because they are for specialized applications and are not intended for general protection of branch circuits.

Table 1 briefly compares the capabilities of the three types plus the outlet branch circuit AFCI.

This table, together with the definitions, is intended to help clarify the differences between these three types. So far, only the branch/feeder AFCI has been offered commercially, to the knowledge of the authors. It is the commonly available AFCI in circuit-breaker form. The outlet circuit AFCI is intended for protection of extension and appliance cords. It could also be produced in “feed through” form to protect fixed wiring on its load side. Located at a receptacle outlet, it would not protect the entire branch and would not satisfy the NEC 210.12 requirement.

The combination AFCI is intended to combine the performance of the other two in a single device. Its location is not specified in the definition; however, it can be configured in a form, such as in a circuit breaker, to be located such that it will protect the entire branch circuit, including fixed wiring plus extension and appliance cords in accordance with the UL 1699 Standard.

Branch/feeder AFCI Performance

One of the major reasons for development of AFCI technology is that a number of fires are caused by arcing short circuits in fixed wiring that are not detected by an overcurrent protective device before the fire starts. An overcurrent protective device (a circuit breaker or fuse) has an intentional time delay to allow for elevated current such as would be experienced when operating a microwave oven or starting a vacuum cleaner motor. In other words, when starting a vacuum cleaner, the elevated current is essential and is contained within the conductors. When the current is an arc, it is causing damage continuously. The AFCI distinguishes between the hazardous arc and normal current flow.

As discussions of a standard began in 1994, a rough but scientific experiment was conducted to determine the time and current within which an arc will ignite tissue paper. It was found that arcs above 5 amperes were likely to cause fire ignition if they persisted for a second and those below 5 amperes were much less likely to cause fire. Since then, other experiments have been conducted that suggest that fire can be ignited with lower current levels, but none have been definitive.

The branch/feeder AFCI was the first type to be developed. The intention was to protect branch-circuit wiring primarily and to also provide protection for extension and appliance wiring to the extent it could. The 5-ampere level was found to be difficult to achieve in line-to-neutral arcing at the time AFCIs were first developed, since it is essential to also avoid nuisance operation for the broad range of signals in electrical circuits. In any general-use branch circuit, a variety of dimmers, computers, motors, entertainment appliances and other equipment that produce arcs as part of normal operation may be installed or connected. The 5-ampere detection requirement was set for series arcs that include arcing to grounded conductors.

The 75-ampere level was taken from a survey conducted by UL for the EIA that reported that the lowest short circuit level available at a receptacle within the United States is 75 amperes. This means that a line-to-neutral fault in a branch circuit will have 75 amperes or more available. Correspondingly, AFCI testing verifies that the AFCI will detect an arc in a circuit with 75 amperes available. Therefore, the 75-ampere detection level will identify and de-energize arcing short circuits that are known fire causes.

During the tests, actual current flowing is somewhat less than 75 amperes. The test circuit has 75 amperes available before the arc is introduced. The arc current will be lower because of the impedance of the arc itself. The AFCI must detect the arc current.

Questions have arisen about the ability of the branch/feeder to detect series arcs. The UL 1699 Standard requires that the branch/feeder detect arcs in circuits that deliver 75 amperes and higher fault current. It does not distinguish between series and parallel. These are short-circuit conditions—and are the conditions that drove the industry to develop arc detection. We know that fires occur from these higher energy arcs. This means that true series arcs with no arcing to a grounding conductor, which are at load current values well below 75 amperes, are not detected.

Outlet Circuit AFCI Performance

In considering a device located at the receptacle, it was clear as the standard was being written that the primary function of such a device would be protection of extension and appliance wiring. Detection of series arcs at the lower current level of a single appliance would be important. The device was envisioned to be electrically closer to the appliance and not necessarily in the circuit with the variety of products and conditions on a general branch circuit. Therefore, for the envisioned outlet circuit (OC) AFCI, a 5-ampere detection level was required in the standard for line-to-neutral, line-to-ground and series arcs.

Combined Performance

There is a place for each of these devices. As we look at the need addressed by NEC 210.12(A), a branch/feeder AFCI is necessary to protect the entire circuit. Protection would be enhanced if an outlet circuit AFCI were added for extension and appliance wiring.

The ideal device is the combination AFCI located at the source of the branch. The combination AFCI combines the performance of the branch/feeder with that of the outlet circuit in a single unit. With the technology available, why not require combination performance to provide the best available protection for the entire branch?

Causes of Tripping of the Branch/Circuit AFCI

The circuit-breaker branch/feeder AFCI incorporates functions of both an overcurrent protective device and an arc-detection device. It is designed to trip under the following conditions.

Overcurrent.For any current above its current rating it will trip according to its circuit breaker time-current characteristic.

Hazardous arcing.For arcing at current levels of about 75 amperes and above, the AFCI will trip. Commercially available AFCIs will actually operate at some level below 75 amperes. The AFCI will operate faster than a fuse or circuit breaker under short-circuit overcurrent conditions up to about 125 amperes.

Arcing ground faults.The standard requires tripping on faults of 5 amperes and greater. Commercial units will actually detect ground faults of 50 milliamperes and greater. Tripping will be instantaneous, with no intentional delay.

Neutral grounding.If the neutral conductor (grounded-circuit conductor) of an AFCI protected circuit touches grounded metal, the AFCI will trip if the impedance to ground is very low impedance.

Abnormal environments.Some abnormal events may also cause tripping, such as high voltage surges from lightning or utility line surges, voltage or frequency fluctuations from poorly regulated backup generators, or mechanical shock.

More To Come

Part II of this article addresses such questions as which circuits must be protected under the NEC and how to check and troubleshoot installed AFCIs. Look for these questions in the next edition of this magazine.

1. “AFCI Inquiry and Report” by the Consumer Product Safety Task Force of the National Association of State Fire Marshals, August 1, 2002.

Find Us on Socials