Arc Fault Current Interrupter (AFCI) protection was first required in dwellings, starting with the 1999 version of the National Electric Code (NEC)[1]. This was after the United States Fire Administration (USFA) found that “fires in residential electrical distribution systems are an important contributor” to the number of fire-related deaths in the US [2]. This study led the U.S. Consumer Product Safety Commission (CPSC) to investigate further, which led to Underwriters Laboratories (UL) becoming involved and concluding that AFCI technology looked very encouraging in solving this problem [2]. The Electrical Safety Foundation states that “each year in the U.S., arcing faults are responsible for more than 28,000 home fires, killing and injuring hundreds of people” [3].

When AFCI protection was added to the NEC, the requirement was simply for receptacles in bedrooms [4]. This requirement has evolved, and in the 2023 version, AFCI protection is now required in many areas of a home, and the NEC provides six different installation options. But do these options truly give installers reasonable ways of providing protection? Looking at the six options:

- one option is the most widely used.

– AFCI breakers [NEC 210.12(A)(1)]

- two options that should be sunset:

– the use of branch/feeder-type AFCI breakers since current AFCI breakers are combination type [NEC 210.12(A)(2)]

– the use of” supplemental” AFCI breakers since these never made it to the market [NEC 210.12(A)(3)]

- three options that are unrealistic:

– the use of “system combination-type” AFCI breakers/outlets since there is no definition of “system combination-type” [NEC 210.12(A)(4)]

– using a standard breaker with an AFCI OBC outlet if the home run is type MC/AC with metal boxes [NEC 210.12(A)(5)]

– burying the home run in concrete [NEC 210.12(A)(6)]

Two questions immediately jump out after looking at this list: “Why is 210.12(A)(4) unrealistic?” and “Where is the option of using a standard breaker with an AFCI outlet as the first receptacle in the branch circuit, with Type NM wiring and plastic boxes?”

Let’s consider NEC 210.12(A)(4). There are four conditions on this option, with the last one specifying that the combination of circuit breaker and OBC AFCI be identified as meeting the requirements of a “system combination-type AFCI”[1]. This condition would be realistic and provide protection against arcing if there was a definition of “system combination-type.” Currently, there is no UL or NEC standard for this term. NEC 210.12(A) does have an Informational Note directing people to UL1699A for OBC AFCI devices. But UL1699A has never been published as a Standard – today it is an outline of an investigation into OBC AFCI devices. In the past, information has been presented to the NEC Code Making Panel indicating a “system combination-type” product is available. This item was a kit consisting of an AFCI breaker along with an AFCI receptacle. This does not appear to be readily available in the market and does not meet either the letter or the spirit of 210.12(A)(4); nor does it meet the original intent of the Code Making Panel to offer options to installers and consumers.

The second question is addressed in Public Input #2794, submitted to the NEC. In the past, when this option was proposed, concerns were raised that this configuration wouldn’t protect the home run from parallel arc faults. That if a parallel arc fault were to occur in the home run, the only device that could interrupt power is the circuit breaker which wasn’t designed to detect arcs. While circuit breakers may not have been designed to detect arcs, it doesn’t mean they can’t provide the same protection for portions of the branch circuit, especially if certain conditions are placed on the installation option. Keep in mind that circuit breakers are designed to detect and interrupt overcurrent – it doesn’t matter whether this overcurrent is caused by an overloaded circuit or a parallel arc.

To aid the NEC in evaluating this proposal, UL performed a research experiment and published the results in two reports Effectiveness of Circuit Breakers in Mitigating Parallel Arcing Faults in the Home Run [5], and Evaluation of Run Length and Available Current on Breaker Ability to Mitigate Parallel Arcing Faults [6]. This research had the overall objective of acquiring experimental data to ascertain if standard circuit breakers can respond to parallel arc faults and under what conditions, including fault current availability at the service equipment and the length of the home run.

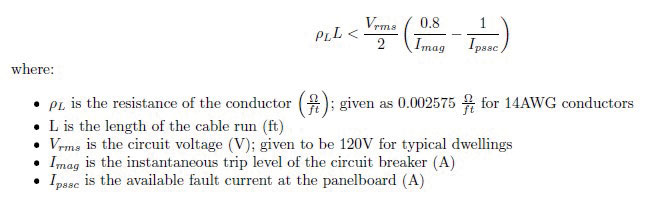

The result of UL’s studies was the conclusion that “circuit breakers could mitigate an arcing fault, provided the following inequality is satisfied”:[6]

Looking at equation (1), we see three variables that need to be determined: the length of the home run (L), the instantaneous trip level of standard circuit breakers (Imag), and the amount of available fault current at the service equipment (Ipssc). UL’s first step was to compute the average instantaneous trip level of circuit breakers currently available on the market[5] by conducting an extensive research study using breakers from four different manufacturers. They looked at whether breakers were new vs. old, placed in different positions in the panel, etc., resulting in a total of 575 experiments. The results showed that for new breakers, the average trip current is 213A, with s = 33.2A. This means that 99% of all breakers will trip at or below 300A[5] (2.6 s above the mean).

It should be noted that another finding from UL’s study was that “older” breakers (ones with more than 30 years of service time) had a much wider distribution in terms of trip levels. UL attributed this to the fact that circa 1990 there was an industry-wide design change to circuit breakers[5]. Due to this, these breakers were removed from the study. And while this is an interesting finding, it doesn’t affect this proposal. This option is for 210.12(A), which lays out regulations for new construction. It is not looking to modify 210.12(E), which governs branch circuit extensions and modifications. But does this mean we need to worry about breakers in 10, 20, or 30 years from now? Probably not. UL didn’t attribute the wide trip distribution to the age of the breakers but to an overall change in design. There has been no evidence that installed breakers respond any differently after 30 years of service.

Taking the above value for Imag, let’s move on to the length of the home run. This variable already has an approved value of 50 feet (for 14AWG cable) in NEC sections 210.12(3)(b) and 210.12(4)(b). We will use this value in our calculations.

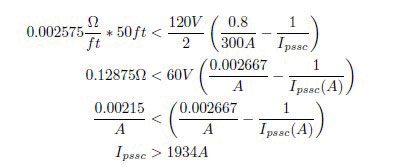

Using the values above (plus 120V for Vrms and 0.002575 Ω/ft for rL), we can solve for the last variable, Ipssc:

This gives us a lower limit for the available fault current in order for the new proposal to provide equivalent AFCI protection to the currently approved options. But in fact, this AFCI OBC proposal limits installations to where there is 3000A of fault current at the service panel. This is 1.5x what is required based on the inequality from UL. Of the three variables in equation (1), Ipssc is the most difficult to determine; therefore, in order to give the AHJ a relatively easy way of verifying the 3000A requirement, the following three conditions are placed on the proposal:

- The transformer directly supplying the service equipment shall have a minimum rating of 25kVA

- The service conductor from the transformer directly supplying the service equipment shall not be installed in ferromagnetic conduit

- The maximum service conductor length from the transformer directly supplying the service equipment shall not exceed 38m (125 ft) with a minimum 3/0 aluminum conductors or 22.9m (75 ft) with a minimum 1/0 aluminum conductors

The substantiation and details on these conditions can be found in the NPFA’s published Report on Proposals under PI#2794. Some may say that these conditions are overly restrictive/conservative, and they are correct! But protecting people and property from arcing, which could lead to home fires, is a serious matter; any new installation option should be conservative when first used.

And remember, as with all currently approved installation options in the Code, if the AHJ cannot verify the above conditions, the installation should not be approved. Another benefit of this proposal is giving the AHJ and homeowners a convenient way to test if AFCI protection is active. They simply need to press the ’Test’ and ’Reset’ buttons on the device without going to the panelboard.

Pulling all of this together, along with the conditions, we see the following public input being submitted to the NEC:

A listed outlet branch-circuit-type AFCI installed on the branch circuit at the first outlet in combination with a listed branch-circuit overcurrent protective device installed at the service equipment if all of the following conditions are met:

(a) The branch-circuit wiring shall be unspliced and untapped from the branch-circuit overcurrent device to the outlet branch-circuit AFCI.

(b) The maximum length of the branch-circuit wiring from the branch-circuit overcurrent device to the first outlet shall not exceed 15.2 m (50 ft) for a 14 AWG copper conductor or 21.3 m (70 ft) for a 12 AWG copper conductor.

(c) The first outlet box shall be marked to indicate that it is the first outlet of the branch circuit.

(d) The transformer directly supplying the service equipment shall have a minimum rating of 25 kVA.

(e) The service conductor from the transformer directly supplying the service equipment shall not be installed in ferro-magnetic conduit.

(f) The maximum service conductor length from the transformer directly supplying the service equipment shall not exceed 38 m (125 ft) with minimum 3/0 aluminum conductors or 22.9 m (75 ft) with a minimum 1/0 aluminum conductors.

(g) The branch-circuit overcurrent protective device shall be a listed single pole thermal-magnetic circuit breaker and shall be located in the service equipment.

(h) The branch-circuit overcurrent protective device shall not be a circuit breaker identified as high magnetic trip.

Informational Note: Some manufacturers mark their high magnetic trip circuit breakers as “H” or “HM” and can be found in their product literature.

There is another concern, not about this proposal, but one that this option could help alleviate. As stated above, the use of an AFCI breaker is the most used of the available installation options and is causing problems for some homeowners. Modern appliance manufacturers need to meet Energy Star requirements and some of these new designs are causing unwanted tripping of AFCIs. A concern within the safety community is that homeowners will not want to deal with these nuisance trips, remove the AFCI breaker, and replace it with a standard breaker.

If this were to happen, they would be removing the protection they need. And remember, when it comes to circuit breakers, often homeowners can only replace their AFCI breakers with standard breakers from the same company. If there happens to be an incompatibility between that specific brand of breaker and their specific brand of appliance, they don’t have a lot of options. If this proposal was added to the NEC, and homeowners experience incompatibilities with nuisance tripping, they can try AFCI outlets from different manufacturers in an attempt to solve the problem.

Summary

The bottom line is that right now, installers have limited reasonable options available to them to provide homeowners with AFCI protection. By adding this AFCI OBC option, with all the accompanying requirements, installers will have additional options in providing equivalent protection against arcs and potential home fires – which is a good thing.

References

[1] NFPA 70. National Electric Code. National Fire Protection Association, 2023.

[2] Siemens Industry. History of the AFCI. url: https://assets.new.siemens.com/siemens/assets/api/uuid:6d713093-b2ee-41e3-a015-ad35d853f1ab/sie-wp-afcihistory.pdf

[3] electrical safety foundation. url: https://www.esfi.org/home-electrical-fires/#:\~:text=Electrical\%20distribution\%20systems\%20are\%20the\%20third\%20leading\%20cause,and\%20causing\%20over\%20\%24700\%20million\%20in\%20property\%20damage.d

[4] NFPA 70. National Electric Code National Fire Protectoin Association, 1999.

[5] PhD Paul W. Brazis Jf. and PhD Fan He. Effectiveness of Circuit Breakers in Mitigating Parallel Arcing Faults in the Home Run. Tech. rep. 2011.

[6] PhD Paul W. Brazis Jf. and PE David A. Dini. Evaluation of Run Length and Available Current on Breaker Ability to Mitigate Parallel Arcing Faults. Part I: Effect of Panelboard Current for 50 Foot Run Lengths. Tech. rep. 2012.

Find Us on Socials