During 2003, many AFCI articles and comments have appeared in IAEI News. This publication activity is associated with the actions taken by code-making panel 2 on the more than 60 proposals received relative to Section 210.12 of the NEC. In particular, CMP-2 has proposed a revision that would require protection by a combination AFCI. This would effectively obsolete the field-proven branch/feeder AFCI and replace it with a combination AFCI that is not even commercially available. The present paper expands on an Eaton Electrical comment in the IAEI News, September/October, AFCI Forum.1 This paper expands on the forum comment and supports the Eaton Electrical viewpoint that the existing code language should not be changed to reference a specific type of AFCI. In particular, the present code language is non-exclusionary and presently permits either type of device.

AFCI Enhanced Protection

AFCIs were added to the NEC because of the dire U.S. electrical fire statistics. A recent National Fire Protection Association (NFPA) report2 shows that the electrical fire statistics are worse than was believed at the time of the original adoption of AFCIs into the Code. The average annual number of fires in one- and two-family dwellings in the U.S. caused by electrical arcing is over 60,000, and result in nearly 500 deaths annually and property damage of almost $1 billion. AFCIs were designed to provide enhanced protection against these electrical arcing faults, and to reduce the number of electrical fires.

Reviewing the UL Standard for AFCIs sheds some light on the protective features of AFCIs. The standard for AFCIs is UL 1699.3 The standard defines five different types of AFCIs. The types are: branch/feeder, combination, outlet circuit, portable and cord.

Branch/feeder AFCIs have been commercially available for over six years. It is important to note that only the branch/feeder and the combination type (if it were commercially available) would meet the NEC requirement of providing protection for the entire branch circuit. The outlet circuit, portable and cord types are specific-use to protect only the downstream connected cords or devices. Since this article relates to the NEC, we will limit further discussion to the branch/feeder and combination types.

There has been confusion over the types of faults that AFCIs detect. To understand the protection that AFCIs provide, a common understanding of the types of faults is important.

Parallel Arcing Fault4

This is an across-the-line fault at which arcing occurs.

In our experience, parallel arcing faults result from an insulation fault between an ungrounded circuit conductor and either (1) a grounded circuit conductor, or (2) ground. The amount of current available in a parallel fault is determined by the available short-circuit current at the point of the fault. Here we note that the fault current levels used for the UL 1699 standard are 75 amps and above. The 75-A level was chosen because a UL report 5 of available short-circuit currents concluded that 100 percent of all residential circuits have at least 75 amps of available fault current at the receptacle location. At these current levels, arcs have high power dissipation, large diameters, and are associated with electrode (copper) melting with ejection of heated electrode material. This results in a large spatial region where ignition is probable.

Series Arcing Fault 4

A series fault at which arcing occurs.

[A series (continuity) fault 4 is a partial or total local failure in the intended continuity of a conductor characterized by either infinite resistance (a completely severed conductor) or by resistance that alternates between infinite resistance and high or normal resistance such as intermittent connection at a loose wiring terminal or splice. Note: A series fault may contribute to an insulation fault.]

With respect to series arcing faults, we note that, since the fault is only in one of the circuit conductors, the load determines the amount of current that is conducted. These low current arcs have low power dissipation and small diameter. Consequently, the spatial region for ignition is small.

High Resistance Series Fault4

A series fault characterized by the presence of abnormally high resistance (high resistance in comparison to the normal resistance of the normal conductor but not high comparison to the infinite resistance of a completely severed conductor) in a wire, at a wire termination, or wire splice, resulting in a reduction of ampacity and an excess of heat dissipation at the fault. Examples are a partially severed stranded conductor with only a small percentage of the strands intact and a corroded wire terminal or splice.

In our experience, these high resistance series faults result from a build-up of copper or aluminum oxide that creates a high resistance “glowing contact.”6 This high-resistance point can become extremely hot with temperatures exceeding 600° F causing insulation failure that can result in a damaging high-power parallel arcing fault or ground fault. Glowing contacts can develop at virtually any electrical connection conducting current. The current in the high resistance fault, like the series arcing fault, is limited to the current being drawn by the load—until the insulation degrades to the point where this type of fault becomes a parallel arcing fault or causes leakage current to ground.

All of today’s branch/feeder AFCIs combine the thermal and magnetic protection of a standard circuit breaker with arc-fault detection circuitry to sense high-power parallel arcing faults. As pointed out in the AFCI Forum comment,1 the commercially available branch/feeder AFCIs also contain earth leakage protection that provides protection against ground faults. As a consequence, commercially available branch/feeder AFCIs provide complete protection to the commonly used branch-circuit installation wire (NM-B plus ground), protection against all arcing faults between two conductors (parallel faults) in 2-wire cords and protection via ground fault against all arcs-to-ground of 30 mA and above at any point in the circuit. Significant protection is also provided against glowing connections7 via ground fault and parallel arc detection.

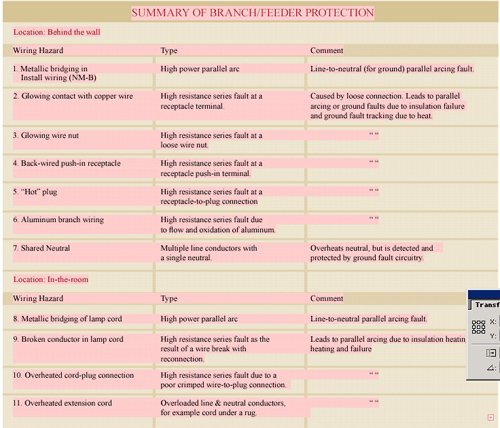

Table 1. Summary of branch/feeder protection

Table 1 summarizes the protective features of the branch/feeder AFCI relative to eleven recognized home wiring fault hazards. Seven of these are “behind-the-wall” faults and four are “in-the-room” faults. Seven of them start as high resistance series faults while two start as parallel faults. Two are related to current overload. With respect to parallel faults, the same UL study that was used as the basis of the 75-ampere threshold, and direct experience, shows it unlikely that a standard circuit breaker would respond to many of these situations.5 All of these hazards are mitigated by the currently available branch/feeder AFCIs.

From a standard’s standpoint, the difference between the branch/feeder and combination types is that the latter must pass low current arc detection tests: namely to detect arcs down to 5-amperes in 2-wire cords. Thus the combination AFCI must clear low current arcs within the times specified in Table 56.1 of UL 1699.

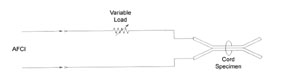

Figure 1. Circuit diagram for carbonized path arc clearing time test

In a 20-amp circuit, for example, a 30-amp arc (150% rating) must be detected and interrupted within 0.11 seconds (13 arcing half cycles) and a 5-amp arc within 1 second (120 arcing half cycles). But in our experience, when a copper conductor breaks in a 120-volt circuit, low-current arcs of these durations are highly unlikely. This is to be expected because, from Paschen’s curve,8 the minimum breakdown voltage for flat parallel copper electrodes in air exceeds 300 volts. The circuit voltage is too low for arc re-ignition at the AC current zero. Thus the UL Standard (UL 1699) contains long duration low-current arcing tests, but these are performed using either a parallel cut across conditioned SPT-2 conductors (see figure 1), or with the separation of a copper rod from an opposing carbon-graphite rod during current conduction. Here sustained arcing is possible because high temperature carbon emits electrons and this emission facilitates arc reignition in 120-volt circuits.

These UL 1699 conditions certainly result in long-duration low-current arcing, but the conditions are rarely encountered in residential circuits.

Experience with Branch/feeder AFCIs

Branch/feeder AFCIs have been UL listed for four manufacturers, Siemens, GE, Square D, and Cutler-Hammer, for several years. Not only are they listed; they have been commercially available since 1997 with more than 5 million installed. In total these devices have been operating in residences for approximately 20 billion hours and can no longer be regarded as “new products.”

As AFCIs became a requirement in a given area, there was a learning curve associated with wiring practices. Some of the early troubles encountered by electricians were related to the fact that most were unaware that all commercially available branch/feeder AFCIs have an earth leakage element as part of the enhanced protective functions. This ground-fault element (most are set at approximately 30 mA) provides rapid response to insulation damage in the commonly used branch-circuit installation wire (NM-B plus ground) where a break in the neutral or hot conductor will result in current flow to the bare ground wire. As with the installation of ground-fault devices, the neutrals of AFCI-protected circuits must be kept isolated from the neutrals of other circuits and from ground wires. Following this installation learning curve, unwanted tripping has not been a problem.

Experience with Combination AFCIs

Combination AFCIs have been UL listed by three companies, Pass & Seymour Legrand, HETKO and Square D. The Pass & Seymour Legrand device was listed in 1999,9 the HETKO device was listed in the first quarter of 2003, and the Square D AFCI was listed in August/September of 2003. None are commercially available. It must be noted that the detection of low current arcs by combination AFCIs necessitates technology that is capable of distinguishing, on a continuous basis, between damaging arcs and the safe arcs and transient waveforms associated with everyday circuits. Thus there are safe arcs associated with motor brushes (for example, vacuum cleaners), with switches (for example, light controls, hairdryers, etc.), with bi-metal temperature controls of household appliances (for example, irons). Further, there are chopped waveforms associated, for example, with electronic power supplies (computers, lamp ballasts, etc.).

Combination AFCIs, if mandated exclusively, will be installed in millions of homes; each with appliances and circuit loads of varying age and characteristics. Further, these AFCIs will be installed for the life of the home and will have to handle the switching events and electronic waveforms of the future. In Eaton Electrical’s opinion, combination AFCIs must be commercially available, and installed in tens of thousands of homes, before their ability to discriminate between low current damaging arcs on the one hand, and normal arcs plus chopped wave forms on the other hand, can be judged a success. In our experience, the public will not tolerate unwanted, nuisance tripping with the associated power-interruption inconvenience and, in particular, the implication of fire hazards.

Code Proposals — Cause for Alarm

Of particular concern are (1) proposal 2-146 that CMP-2 has “”accepted in principle”” and the associated panel proposal 2-134A. These proposals would change the wording of 210.12(B) to require protection by “a listed arc-fault circuit interrupter, combination type, installed to provide protection of the entire branch circuit.” There is cause for alarm because the change would effectively obsolete the field-proven branch/feeder AFCI and replace it with a combination device that is not even commercially available. Here it is noted that the present Code language is inclusive in that it mandates “an arc-fault circuit interrupter listed to provide protection of the entire branch circuit.” This language permits either the currently available branch/feeder AFCIs or combination AFCIs.

Conclusion

Eaton Electrical advises that the code language should not be changed to reference a specific type of AFCI. The code panel could certainly revisit this subject in future code cycles when combination AFCIs have become commercially available, and if practical field experience indicates superior fire protection capabilities without unwanted tripping. However, in the interests of continued fire safety and consumer choice, the present code language should be retained.

References

1 Comment on the July/August 2003 article, “Truth about AFCIs, Part 3,” IAEI News, page 78, September/October 2003.

2 “Structure Fires in One- and Two-Family Dwellings in which the Form of Heat of Ignition was the Heat from Electrical Arcing Including Unclassified or Unknown-Type Arcing or Overload by Area of Origin” – Nancy Schwartz and Marty Ahrens, National Fire Protection Association – May 2002.

3 UL 1699Standard for Safety for Arc-Fault Circuit Interrupters, First Edition, February 26, 1999

4Technology for Detecting and Monitoring Conditions that Could Cause Electrical Wiring System Fires. UL Report for CPSC, contract #CPSC-C-94-1112, September 1995.

5 “An Evaluation of Circuit Breaker Trip Levels,” fact-finding report prepared by Underwriters Laboratories for the Electronics Industry Association under UL Project 92ME51901, October 25, 1993.

6 “Glowing Contact Areas in Loose Copper Wire Connections,” J. Sletback, R. Kristensen, H. Sundklakk, Norwegian Institute of Technology; and G. Navik, M. Runde, Norwegian Electric Power Research Institute; Proceedings of the Thirty-Seventh IEEE Holm Conference on Electrical Contacts, 1991. And various Japanese reports on the causes of electrical fires summarized and translated by Yasuaki Hagimoto (NRIPS Japan) visiting VTT in February-March 1996.

7 UL Special Services Investigation for Cutler-Hammer entitled “Branch/Feeder Arc-Fault Circuit Interrupter Incorporating Equipment Ground-fault Protection,” File E45310, May 31, 2001.

8Electrical Contacts. Principle and Application. Published by Marcell Dekker, Inc., Edited by P. G. Slade, 1999.

8 Proposal 2-108 submitted in 1999 by Pass & Seymour Legrand for the 2002 NEC (NFPA 70, May 2001 ROP, page 130).

Find Us on Socials